Professional Documents

Culture Documents

Roof purlin design and stress analysis

Uploaded by

_jessecaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roof purlin design and stress analysis

Uploaded by

_jessecaCopyright:

Available Formats

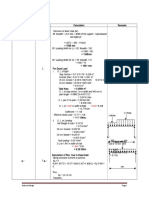

PROJECT :

Selayang Height-Semi D-Type A

Purlin Type :

ROOF

1. simple beam

2. simple beam with sag rod at mid span

3. simple beam with fly bracing

4. simple beam with sag rod + fly bracing

-- stress : full span effective for both x-x and y-y

-- stress : full span for x-x and half span for y-y

-- stress : full span effective for both x-x and y-y

-- stress : full span for x-x and half span for y-y

Purlin configuration :

1. spacing

2. span

3. sag rod position from end support :

4. fly bracing position from end support (each end) :

5. Slope :

1:

10.00

Loadings :

type

1.Dead Loads :

2. Live Loads :

1.20

7.70

0.00

0.00

0.10

theta :

intensity

kN/m2

0.25

0.25

Total :

m

m

m

m

radians

udl (kN/m)

SLS

ULS

0.30

0.42

0.30

0.48

0.60

0.90

deflection : full span

deflection : full span

deflection : span between fly bracing

deflection : span between fly bracing.

x-x direction

eff. span for deflection :

therefore design

span for

deflection :

7.70 m

7.70 m

Force component :

Total force acting on purlin length :

P=

6.93 kN

6.90 kN

0.69 kN

Px =

Py =

Moment Computation :

y

x

theta

x-x direction :

M x-x =

6.64 kNm

x

y-y Direction

1.simple beam

Py

y

M y-y =

2. with sag rod at mid span :

0.66 kNm

M y-y =

0.00 kNm

therefore design M y-y =

0.66 kN/m

Purlin dimensions

~~~~~~~~~~~~ ~~~~~~~

No. Mark :

13

D =

B =

L =

t =

203

71

16

1.6

Px

(please specify from 1 & 2 above)

Try Purlin Type :

mm

mm

mm

mm

Mass =

Ix =

Zx =

Zy =

Y (min. yield stress) =

Py (Design Strength) =

Mx/Zx =

My =

0.66 kNm

Mby =

Ratio=

2.45 kNm

0.27

177.27 N/mm (MPa)

[1.13-0.0019(D/t)(Ys/280)^0.5] Py

297.53 N/mm (MPa)

Factor Of Safety On bending Stress, Po / (Mx/Zx) =

Ratio =

Deflection Check

~~~~~~~~~~~~ ~~~~~~~~~~~

Ratio of Deflection limits

= span /

Deflection limits,

dl = 38.50 mm O.K.

35.25 mm

kg/m

x 10^6 mm4

x 10^3 mm3

x 10^3 mm3

6.64 kNm

For BS5950, Part 5 1987 Cl 5.2.2.2

Max. Allowable Bending Stress, Po =

Deflection, D =

4.7

3.8

37.44

7.09

345 N/mm (MPa)

345 N/mm (MPa)

(BS5950: PART 5 CL.3.32)

(High tensile galvanised steel)

Bending Stress Calculation

~~~~~~~~~~~~ ~~~~~~~ ~~~~~~

Design Moment,

Mx =

Bending Stress At x-x,

YCP 2016

200

1.68

0.60

Unity Check=

0.87

<

1.0

OK !

You might also like

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Base Plate CalculationDocument9 pagesBase Plate CalculationAatifNo ratings yet

- Metal Sheet Calculations for 44-195 ProfileDocument29 pagesMetal Sheet Calculations for 44-195 ProfileAnonymous HkX2aE9FxNo ratings yet

- Loadings and structural analysis of buildingDocument38 pagesLoadings and structural analysis of buildingarif_rubinNo ratings yet

- Design of Slab As Per IS:456-2000: Input DataDocument6 pagesDesign of Slab As Per IS:456-2000: Input DataMainali IshuNo ratings yet

- Check For The Edge Distance and Stress in Plates Connected in ROB in Lieu of LC No. KA-161Document5 pagesCheck For The Edge Distance and Stress in Plates Connected in ROB in Lieu of LC No. KA-161SERNo ratings yet

- 220kv - NMC - Type Tower-CorrectedDocument19 pages220kv - NMC - Type Tower-Correctedpavan3961No ratings yet

- Shiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Document3 pagesShiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Naveen RohiraNo ratings yet

- Isoloated Footing DesignDocument7 pagesIsoloated Footing Designvijay moreNo ratings yet

- Foundation ForcesDocument9 pagesFoundation ForcesHemant SonawadekarNo ratings yet

- Punching Shear design and reinforcement calculationDocument4 pagesPunching Shear design and reinforcement calculationMohafisto SofistoNo ratings yet

- Combined Footing Design CF4-2Document10 pagesCombined Footing Design CF4-2Saugat ThapaNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- ACI Beam DesignDocument1 pageACI Beam DesigndantevariasNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- Columna de SotanoDocument38 pagesColumna de SotanoLivian TeddyNo ratings yet

- Isolated Footing DesignDocument24 pagesIsolated Footing DesignSANJEEV GANDOTRANo ratings yet

- Beam Design 1Document22 pagesBeam Design 1shamen amarasekaraNo ratings yet

- AOC AW INSP 010 Rev04 AOC Base Inspection ChecklistDocument6 pagesAOC AW INSP 010 Rev04 AOC Base Inspection ChecklistAddisuNo ratings yet

- Rate of Grease Penetration of Flexible Barrier Materials (Rapid Method)Document3 pagesRate of Grease Penetration of Flexible Barrier Materials (Rapid Method)DanZel Dan100% (1)

- Footing DesignDocument4 pagesFooting DesignpnbastolaNo ratings yet

- Design of Weld For Gantry1Document4 pagesDesign of Weld For Gantry1pragneshNo ratings yet

- ACI 318-05 Concrete Column DesignDocument3 pagesACI 318-05 Concrete Column DesignManuel SueroNo ratings yet

- Wind load calculation MWH buildingDocument4 pagesWind load calculation MWH buildingajatNo ratings yet

- Design of gantry girder STAAD inputDocument5 pagesDesign of gantry girder STAAD inputDarsHan MoHanNo ratings yet

- 2 Way SlabDocument22 pages2 Way SlabAhmed Al-AmriNo ratings yet

- Building seismic analysis data sheetDocument20 pagesBuilding seismic analysis data sheetBilal A BarbhuiyaNo ratings yet

- Indian Railway Bridge Design ProcessDocument18 pagesIndian Railway Bridge Design ProcessCivil Engineer100% (1)

- Fdocuments - in Insert Plate Design LugsDocument8 pagesFdocuments - in Insert Plate Design Lugsarchetype designNo ratings yet

- Cladding& Runner DesignDocument1 pageCladding& Runner DesignDeepmalaJayeshNo ratings yet

- Design of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnDocument2 pagesDesign of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnAdarsh Kumar SNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Portal Method: For Transversal/Longitudinal SectionDocument70 pagesPortal Method: For Transversal/Longitudinal SectionJoseph Tan LantoNo ratings yet

- Design of Brace Connection PlateDocument6 pagesDesign of Brace Connection PlateJonatas PrandiniNo ratings yet

- Describe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementDocument3 pagesDescribe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementAlemayehu Demeke80% (5)

- Load calculation and wind analysis of temporary barricationDocument2 pagesLoad calculation and wind analysis of temporary barricationBrandon HaleNo ratings yet

- Four Pile Caps StructvilleDocument6 pagesFour Pile Caps Structvillemabuhamd100% (1)

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandNo ratings yet

- Polytechnic University of the Philippines Civil Engineering Quiz SolutionDocument4 pagesPolytechnic University of the Philippines Civil Engineering Quiz SolutionJerome M. GuetaNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuNo ratings yet

- Purlin SheetDocument5 pagesPurlin SheetSher AfganNo ratings yet

- Design of Purlin: 1.15 M 4.2 M UPN120 1 5.71 Loads 13.3 KG/M 10 100 115 Bending Moment Loads Major Axis Minor Axis UnitDocument3 pagesDesign of Purlin: 1.15 M 4.2 M UPN120 1 5.71 Loads 13.3 KG/M 10 100 115 Bending Moment Loads Major Axis Minor Axis UnitSudhakar KrishnamurthyNo ratings yet

- Effective Length of Stepped ColumnDocument1 pageEffective Length of Stepped ColumnSunil PulikkalNo ratings yet

- ACI 318 Footing Design CalculationsDocument4 pagesACI 318 Footing Design CalculationsBoubakeur FerkousNo ratings yet

- Hetauda Seismic Analysis and InterpretationDocument94 pagesHetauda Seismic Analysis and InterpretationSurendra MaharjanNo ratings yet

- Zee Purlin Design Sheet AnalysisDocument4 pagesZee Purlin Design Sheet AnalysisShawkat Ali KhanNo ratings yet

- StruCad Evolution Getting Started TutorialDocument41 pagesStruCad Evolution Getting Started Tutorialnifty25No ratings yet

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesDocument2 pagesBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesAnandNo ratings yet

- Design of BracingDocument4 pagesDesign of Bracingankkeshmundra1No ratings yet

- Design Parameters For Corbel:1: B D D D 450Document3 pagesDesign Parameters For Corbel:1: B D D D 450Living LifeNo ratings yet

- Axle Design For Trolley CartDocument2 pagesAxle Design For Trolley CartHailemariam WeldegebralNo ratings yet

- Rectangular Combined Footing: Input DataDocument2 pagesRectangular Combined Footing: Input DataAnonymous 5pQf43AJwNo ratings yet

- Hydraulic Calculation - KengeriDocument1 pageHydraulic Calculation - KengeriyogeeshNo ratings yet

- Design Calculation Sheet For Purlins: WL (P) WL (S)Document1 pageDesign Calculation Sheet For Purlins: WL (P) WL (S)Ahsan SattarNo ratings yet

- Saikat SaraniDocument11 pagesSaikat SaraniPartha GangopadhyayNo ratings yet

- Short Span Coefficient: (Alpha - X: Depth Ok Move OnDocument4 pagesShort Span Coefficient: (Alpha - X: Depth Ok Move OnAmok BajracharyaNo ratings yet

- Calculation Sheet Connection DesignDocument1 pageCalculation Sheet Connection DesignJay SenjaliaNo ratings yet

- JassimDocument29 pagesJassimZain Communication0% (1)

- Retaining wall design calculationsDocument13 pagesRetaining wall design calculationsHanafiahHamzahNo ratings yet

- Plate Loads CalculationDocument2 pagesPlate Loads CalculationarabindaNo ratings yet

- Design of Steel Compression MembersDocument3 pagesDesign of Steel Compression MembersBhanu PratapNo ratings yet

- Loading XL SheetDocument9 pagesLoading XL Sheetgobinathcivil mpNo ratings yet

- The Hashemite University Faculty of Engineering Civil Engineering DepartmentDocument31 pagesThe Hashemite University Faculty of Engineering Civil Engineering DepartmentengsalamNo ratings yet

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- Bernard M. BaruchDocument1 pageBernard M. Baruch_jessecaNo ratings yet

- ABP12 - Q - AASHTO Vessel Collision Design of Highway Bridges (2009)Document60 pagesABP12 - Q - AASHTO Vessel Collision Design of Highway Bridges (2009)_jesseca0% (1)

- Live As If You Were To Die Tomorrow Learn As If You Were To Live ForeverDocument1 pageLive As If You Were To Die Tomorrow Learn As If You Were To Live Forever_jessecaNo ratings yet

- Broshure Fom Fon BMDocument2 pagesBroshure Fom Fon BM_jessecaNo ratings yet

- You Must Be The Change You Wish To See in The WorldDocument1 pageYou Must Be The Change You Wish To See in The World_jessecaNo ratings yet

- Albert EinsteinDocument1 pageAlbert Einstein_jessecaNo ratings yet

- "So Many Books, So Little Time." : Frank ZappaDocument1 page"So Many Books, So Little Time." : Frank Zappa_jessecaNo ratings yet

- First They Ignore You, Then They Laugh at You, Then They Fight You, Then You WinDocument1 pageFirst They Ignore You, Then They Laugh at You, Then They Fight You, Then You Win_jessecaNo ratings yet

- "A Room Without Books Is Like A Body Without A Soul." : Marcus Tullius CiceroDocument1 page"A Room Without Books Is Like A Body Without A Soul." : Marcus Tullius Cicero_jessecaNo ratings yet

- Children's Victory Over EvilDocument1 pageChildren's Victory Over Evil_jessecaNo ratings yet

- Method Statement: 1) Cut Close Along Edge of Joint For Installation of Bridge JointDocument1 pageMethod Statement: 1) Cut Close Along Edge of Joint For Installation of Bridge Joint_jessecaNo ratings yet

- Ms-Bridge 419 Klang Banting - 1Document1 pageMs-Bridge 419 Klang Banting - 1_jessecaNo ratings yet

- Ms Column StiffenerDocument1 pageMs Column Stiffener_jessecaNo ratings yet

- Ms-Crack Sealing Using Epoxy CompoundDocument1 pageMs-Crack Sealing Using Epoxy Compound_jessecaNo ratings yet

- Ms-Bridge 419 Klang Banting - 1Document1 pageMs-Bridge 419 Klang Banting - 1_jessecaNo ratings yet

- Jesus Christ Knocks and Invites You InDocument1 pageJesus Christ Knocks and Invites You In_jessecaNo ratings yet

- "Two Things Are Infinite: The Universe and Human Stupidity and I'm Not Sure About The Universe."Document1 page"Two Things Are Infinite: The Universe and Human Stupidity and I'm Not Sure About The Universe."_jessecaNo ratings yet

- For Everyone Who Exalts Himself Will Be Humbled, and Everyone Who Humbles Himself Will Be Exalted. Jesus ChristDocument1 pageFor Everyone Who Exalts Himself Will Be Humbled, and Everyone Who Humbles Himself Will Be Exalted. Jesus Christ_jessecaNo ratings yet

- So I Say To You, Ask and It Will Be Given To You Search, and You Will Find Knock, and The Door Will Be Opened For You. Jesus ChristDocument1 pageSo I Say To You, Ask and It Will Be Given To You Search, and You Will Find Knock, and The Door Will Be Opened For You. Jesus Christ_jessecaNo ratings yet

- 10Document1 page10_jessecaNo ratings yet

- Give To Everyone Who Begs From You and of Him Who Takes Away Your Goods Do Not Ask Them Again. and As You Wish That Men Would Do To You, Do So To Them. Jesus ChristDocument1 pageGive To Everyone Who Begs From You and of Him Who Takes Away Your Goods Do Not Ask Them Again. and As You Wish That Men Would Do To You, Do So To Them. Jesus Christ_jessecaNo ratings yet

- Let The One Among You Who Is Without Sin Be The First To Cast A Stone. Jesus ChristDocument1 pageLet The One Among You Who Is Without Sin Be The First To Cast A Stone. Jesus Christ_jessecaNo ratings yet

- Do Not Let Your Hearts Be Troubled. Trust in God Trust Also in Me. Jesus ChristDocument1 pageDo Not Let Your Hearts Be Troubled. Trust in God Trust Also in Me. Jesus Christ_jessecaNo ratings yet

- Jesus' New Command: Love One AnotherDocument1 pageJesus' New Command: Love One Another_jessecaNo ratings yet

- Ifihadanhourtosolvea Problem I'D Spend 55 Minutes Thinking About The Problem and 5 Minutes Thinking About Solutions."Document1 pageIfihadanhourtosolvea Problem I'D Spend 55 Minutes Thinking About The Problem and 5 Minutes Thinking About Solutions."_jessecaNo ratings yet

- Jesus Christ's Quote 2Document1 pageJesus Christ's Quote 2_jessecaNo ratings yet

- Einstein QuoteDocument1 pageEinstein QuoteGabriel JimenezNo ratings yet

- Coral Redang Island ResortDocument2 pagesCoral Redang Island Resort_jessecaNo ratings yet

- General Notes For Post-Installed Reinforcing Bars SpecificationDocument1 pageGeneral Notes For Post-Installed Reinforcing Bars Specification_jessecaNo ratings yet

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- Friends or Lovers (A Novel by Rory Ridley-Duff) - View in Full Screen ModeDocument336 pagesFriends or Lovers (A Novel by Rory Ridley-Duff) - View in Full Screen ModeRory Ridley Duff92% (24)

- S3 Unseen PracticeDocument7 pagesS3 Unseen PracticeTanush GoelNo ratings yet

- Iwan Lab Guide v1.1 FinalDocument63 pagesIwan Lab Guide v1.1 FinalRicardo SicheranNo ratings yet

- Penetron Admix FlyerDocument2 pagesPenetron Admix Flyernght7942No ratings yet

- Mayne Pharma Annual Report 2012Document78 pagesMayne Pharma Annual Report 2012Deepa DevanathanNo ratings yet

- DAA UNIT-3 (Updated)Document33 pagesDAA UNIT-3 (Updated)pilli maheshchandraNo ratings yet

- D20 Q12Document7 pagesD20 Q12Luca PitocchiNo ratings yet

- Engg Maths Sem 3 Curve FittingDocument13 pagesEngg Maths Sem 3 Curve FittingRonak Raju ParmarNo ratings yet

- BTP Presentation - Sem 8Document24 pagesBTP Presentation - Sem 8Nihal MohammedNo ratings yet

- Connection StringsDocument18 pagesConnection Stringsapi-3808731100% (4)

- Advance Corporate StrategyDocument2 pagesAdvance Corporate StrategyPassionate_to_LearnNo ratings yet

- Pengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriDocument15 pagesPengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriNovita Rizki YustianiNo ratings yet

- The Influence of Culture Subculture On Consumer BehaviorDocument55 pagesThe Influence of Culture Subculture On Consumer Behaviorvijendra chanda100% (12)

- Somya Bhasin 24years Pune: Professional ExperienceDocument2 pagesSomya Bhasin 24years Pune: Professional ExperienceS1626No ratings yet

- SMAI Assignment 7 Report - 20161204 PDFDocument6 pagesSMAI Assignment 7 Report - 20161204 PDFAliNo ratings yet

- Veritas d1.6.1 FinalDocument28 pagesVeritas d1.6.1 FinalgkoutNo ratings yet

- CIVL 222 AXIAL MEMBERSDocument27 pagesCIVL 222 AXIAL MEMBERSskhan247100% (1)

- MP Process Flow - MBA - MM - MHRMDocument2 pagesMP Process Flow - MBA - MM - MHRMKAVITHA A/P PARIMAL MoeNo ratings yet

- Order From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedDocument9 pagesOrder From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedBeau YarbroughNo ratings yet

- Odoo JS Framework Rewrite Brings New Views and TestingDocument68 pagesOdoo JS Framework Rewrite Brings New Views and TestingglobalknowledgeNo ratings yet

- BSW, BS,,AF, BA and Metric Tool SizeDocument4 pagesBSW, BS,,AF, BA and Metric Tool SizeUNES100% (1)

- The Multi Faceted Nature of The Multi Grade TeacherDocument23 pagesThe Multi Faceted Nature of The Multi Grade TeacherTEDLYN JOY ESPINONo ratings yet

- mPassBook 161022 150423 2918Document4 pagesmPassBook 161022 150423 2918Ashish kumarNo ratings yet

- IsotopesDocument35 pagesIsotopesAddisu Amare Zena 18BML0104No ratings yet

- Design For Six Sigma Za PrevodDocument21 pagesDesign For Six Sigma Za PrevodSrdjan TomicNo ratings yet