Professional Documents

Culture Documents

Jute Bag

Jute Bag

Uploaded by

Ashish KohaleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jute Bag

Jute Bag

Uploaded by

Ashish KohaleCopyright:

Available Formats

PROJECT PROFILE

ON

JUTE BAG

PRODUCT

PRODUCT CODE

: JUTE BAG

: ASICC-42112

NIC CODE

: 25204

QUALITY

STANDARD

: As per Customers

Specification & Design

PRODUCTION

: QTY. : 75000 Nos.

CAPACITY (P.A):

VALUE:Rs. 26,25,000.00

MONTH & YEAR OF

PREPARATION

: January, 2011

PREPARED BY

Cane Making Division,

MSME - DEVELOPMENT INSTITUTE

GOVERNMENT OF INDIA,

111 & 112, B.T.ROAD, KOLKATA-700108

E.mail director@sisikolkata.gov.in

Visit us: www.sisikolkata.gov.in

Ph: 2577-0595/97/98/2596

MODEL PROJECT PROFILE ON JUTE BAG

1. Introduction

As the name itself implies the jute bags are used for shopping purpose.

Now a day the printed jute bags are used for travel purposes too. All the

machineries and raw materials used for its manufacture are easily

available from indigenous sources and as not much technology is

involved, factory can be established at rural and urban areas.

2. Plant Capacity per annum

Items

Quantity

Printed & Decorated Jute Shopping Bags

100000 Pcs

3. Market & Demand Aspect

Every responsible citizen considering the black future of ours next

generation shall stop using plastic carrier bags used for shopping as much

as possible. Plastic bags in general take anywhere from 20 to 1000 years

to breakdown in the environment. The natural alternative is jute bag.

Decorated jute bags and shopping bags are very much in demand both for

domestic and international market.

With the increase of population the scope of trade and industry is also

increasing. As the bags are an essential commodity for human, so the

demand of the product is growing day by day. The demands of the

product remain consistent through out the year. So, it is presumed that

there is a good scope for starting of such type of industry with a huge

export potential.

4. Raw Materials

The raw materials required for printed and decorated jute shopping bags

are jute fabrics, dye stuff, printing gum, chemicals and auxiliaries, PVC

buckle and bamboo sticks, sewing thread, packing materials, label etc.

used. All the above raw materials are available locally.

5. Manufacturing process & Source of Technology

The Woven jute fabric is procured from the market and spread on printing

table and fixed by requisite auxiliaries/ingredients. Then it is printed by

screen as per requisite design and colours. The printed fabric is washed

and dried under sun light or through drier.

The printed fabric is cut as per required design and sizes of the bag. The

cut pieces are stitched by lock stitch machine. Then the PVC buckle or

bamboo stick etc. is attached manually. The bags are packed for

marketing.

6. Basis of Project Selection

There are good numbers of manufacturers of printed and decorated jute

bags situated around Kolkata. Expert craftsmen are available here at a

lesser cost in comparison with other metro cities. Basic raw material i.e.

jute is available mainly in eastern India like West Bengal and they are

easily available in kolkata market. More over ports are available in

kolkata which helps export to other countries.

7. Presumption

a) The cost in respect of plant and machinery, raw materials and selling

price of finished product are those generally obtained at the time of

preparation of project profile and may vary depending upon other various

factors.

b) The salary and wages of staff and labours has been taken as per present

market rate.

c) Production utilization capacity is considered initially at 75% of the

total capacity. The time period for achieving full envisaged capacity

utilization is three years.

d) Working days per year is considered 300 days and working hours is 8

hour per day considering single shift.

e) The rate of interest on Bank loan has been considered as 12% p.a.

which may vary from time to time.

8. Production Capacity per annum (at 75% capacity utilization):

Items

1. Printed & Decorated Jute

Shopping Bags

Total Turnover (incl. tax)

Nos.

75000

Rate

Total

35.00 2625000.00

2625000.00

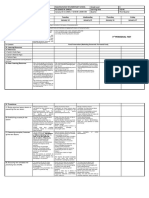

9. Financial Aspects

A: Fixed Capital:

1. Land & Building:

Workspace 1200 sq.mtrs on long term monthly rental basis

Rs. 1800.00

2. Plant & Machinery:

Sl.No. Particulars

Numbers

Rate

1.

Printing Section:

a) Wooden Printing Table

2

12500.00

b) Screen of Diff. Design

30

350.00

c) Rubber Wiper

10

125.00

d) Dye Paste Stirrer

4

3600.00

e) Water Drum

2

1900.00

f) Cottage Steamer

1

16500.00

g) Tubes, Steel Spoons,

Mugs, Bucket, Roper,

Clips, Stools etc.

Total

2.

Stitching Section:

a) Lock Stitch Machine

6

4700.00

b) Wooden Working Table

2

2000.00

c) Cutting Table

1

1800.00

d) Electric Fittings

e) Scissors, Measuring tape

and other Equipments

Total

Total Machinery

Total (Rs.)

25000.00

10500.00

1250.00

14400.00

3800.00

16500.00

6800.00

78250.00

28200.00

4000.00

1800.00

4500.00

2800.00

41300.00

119550.00

3. Furniture & Fixture:

Office furniture like almirah, table, chair, rack etc. Rs.12500.00

TOTAL NON RECURRING EXPENDITURE/ FIXED

CAPITAL:

1. Land & Development

Nil

2. Plant & Machinery

119550.00

3. Furniture & Fixture

12500.00

-----------132050.00

------------

TOTAL

B. Working Capital per month:

1. Monthly expenses for Salary & Wages:

Sl. Particulars

No.

a.

Manager cumSupervisor

b.

Clerk cum-Accountant

c.

Salesman

d.

Peon/ Chowkidar

e.

Master Printer/

Designer

f.

Master Cutter

h.

Stitching Machine

Operator

i.

Skilled Printer

j.

Unskilled Worker

Add: Perquisite @

20%

TOTAL

Employee Remuneration

Total (Rs.)

3000.00

3000.00

1

2

1

1

2000.00

2000.00

1000.00

2500.00

2000.00

4000.00

1000.00

2500.00

1

6

2200.00

1500.00

2200.00

9000.00

4

5

1500.00

1200.00

6000.00

6000.00

35700.00

7140.00

42840.00

2. Raw Material Consumption per month:

Sl.

No.

a.

b.

c.

d.

e.

f.

g.

Items

Dye Stuff

Printing Gum

Chemicals & Auxiliaries

Jute Fabric

PVC Buckle or Bamboo

Sticks

Sewing Thread

Packing Materials, Needle,

Label etc.

TOTAL (Incl. tax)

Total

Quantity

15 kg.

15 kg.

L.S.

7425 Mtrs.

11800 pcs.

L.S.

L.S.

Rate Total (Rs.)

550.00

50.00

10.00

1.50

8250.00

750.00

2800.00

74250.00

17700.00

2200.00

2200.00

108150.00

3. Monthly Other Expenses:

i. Rent

1800.00

ii. Tax & Insurance

1500.00

iii. Electricity & Utility

1500.00

iv. Office & Administrative Expenses

800.00

v. Travelling & Transportation

1200.00

vi. Repair & Maintenance

600.00

Vii. Misc. Expenses

700.00

viii. Sales Promotion

700.00

TOTAL

8800.00

C. Total Working Capital per month:

i. Raw Material Consumption

108150.00

ii. Salary & Wages

42840.00

iii. Other Charges

8800.00

TOTAL

159790.00

D. Total Working Capital for 3 months:

i. Raw Material Consumption

324450.00

ii. Salary & Wages

128520.00

iii. Other Charges

26400.00

TOTAL

479370.00

E. Total Capital Investment:

1. Fixed Capital

Rs.

2. Working Capital for 3 months

132050.00

479370.00

TOTAL

611420.00

10. Financial Analysis:

i)

Cost of Production per year:

1. Total Recurring Expenditure

Rs. 1917480.00

2. Depreciation on Plant & Machinery @ 15% p.a.

Rs.

17933.00

3. Depreciation on Furniture @ 10% p.a.

Rs.

1250.00

4. Interest on total Capital Investment @ 12% p.a.

Rs.

73370.00

TOTAL

Rs. 2010033.00

ii)

Turnover per year:

Items

1. Printed & Decorated Jute

Shopping Bags

Total Turnover (incl. tax)

iii)

Nos.

75000

Rate

Total

35.00 2625000.00

2625000.00

Net Profit per year:

Turnover per year Cost of production per year

= Rs. 2625000.00 Rs. 2010033.00

iv)

Profit Ratio on Sale = 614967 x 100

2625000

v)

=23.43%

Rate of Return = 614967 x 100

611420

v)

= Rs. 614967.00

=100.58%

BEP Analysis:

Fixed Cost

1. Depreciation on Plant & Machinery

Rs.

17933.00

2. Depreciation on Furniture & Fixture

1250.00

3. Interest on Total Capital Investment

73370.00

4. Rent

21600.00

5. Insurance

18000.00

6. 40% Salary & Wages

7. 40% of other expenses excluding rent & insurance

205632.00

42240.00

380025.00

B.E.P. = Fixed Cost x 100

= 380025 x 100

Fixed Cost +Profit

380025+614967

= 38002500

994992

= 38.19%

11. Name & Address of Raw Materials Suppliers:

1.

M/s Chapdani Show Room

25, Princep Street,

Kolkata-700 001

2.

M/s Jutex India,

11, Shambhu Chatterjee Street

Near Grace Cinema Hall,

Kolkata-700 007

Phone 2241-1349

3.

M/s Deepa Meheta

Bara Bazar, Kolkata-700 007.

4.

All Jute Materials are available at Bara Bazar,

Khangra Patty,

Kolkata-700 007.

*****

You might also like

- Business Plan Paper Cups PDFDocument13 pagesBusiness Plan Paper Cups PDFAndrei DoditeNo ratings yet

- Accounting TemplatesDocument21 pagesAccounting TemplatesVaniamarie VasquezNo ratings yet

- This Is Your Lucky DayDocument4 pagesThis Is Your Lucky DayAllan Valiente Jr.100% (1)

- Module 5 Options Theory For Professional Trading MergedDocument385 pagesModule 5 Options Theory For Professional Trading MergedIndranil100% (1)

- RACIDocument1 pageRACIQuyên GấuNo ratings yet

- Cutting plastics pollution: Financial measures for a more circular value chainFrom EverandCutting plastics pollution: Financial measures for a more circular value chainNo ratings yet

- Bankable Project MangoDocument5 pagesBankable Project MangoAmit PandhareNo ratings yet

- Offset Printing Press (Job Work) : NtroductionDocument4 pagesOffset Printing Press (Job Work) : NtroductionMMjagpreetNo ratings yet

- Dairy PlantDocument6 pagesDairy PlantAmit PrajapatiNo ratings yet

- Final Dinesh ProjectDocument16 pagesFinal Dinesh ProjectAravindhan LNo ratings yet

- Paper Bags and PouchesDocument9 pagesPaper Bags and Pouchessam krNo ratings yet

- Offset Printing PressDocument11 pagesOffset Printing PressMujahid MalikNo ratings yet

- Standard CostingDocument4 pagesStandard CostingPankaj2cNo ratings yet

- Business Plan On Bagasse PDFDocument64 pagesBusiness Plan On Bagasse PDFbiswajitNo ratings yet

- Project Report On Medical Cotton Manufacturing PlantDocument10 pagesProject Report On Medical Cotton Manufacturing PlantSachin SharmaNo ratings yet

- David TIF Ch05Document23 pagesDavid TIF Ch05Jue Yasin64% (11)

- TWS1500-1.5TPD Bagasse Tableware Prodcution Line Project Jute Natural Chennai PDFDocument19 pagesTWS1500-1.5TPD Bagasse Tableware Prodcution Line Project Jute Natural Chennai PDFkgmaheswaranNo ratings yet

- Project ReportDocument20 pagesProject ReportSrihari Babu100% (1)

- Charter Parties: The Awesome NotesDocument8 pagesCharter Parties: The Awesome NotesRaymond ChengNo ratings yet

- Project Profile - LAP TOP BAGDocument8 pagesProject Profile - LAP TOP BAGAjay PrajapatiNo ratings yet

- Project Report On Copper ProductsDocument6 pagesProject Report On Copper ProductsEIRI Board of Consultants and Publishers100% (1)

- Project Profile On Computerized Machine (Job Work) : Such Specification For This ProductDocument8 pagesProject Profile On Computerized Machine (Job Work) : Such Specification For This ProductParijat RaiNo ratings yet

- SMEDA Absorbent CottonDocument22 pagesSMEDA Absorbent CottonManohar Waghela100% (2)

- Project Profile On Tissue Paper: ISISO 12625-1:2019 (En) 12625-1 Tissue Paper and Tissue Paper ProductsDocument9 pagesProject Profile On Tissue Paper: ISISO 12625-1:2019 (En) 12625-1 Tissue Paper and Tissue Paper ProductsAniket Jadhav100% (1)

- Pestel Facts of MaldivesDocument2 pagesPestel Facts of Maldivesafham8483% (6)

- Project Profile For A Boutique - Based On Assumption - Nagaveni - MA FMDocument10 pagesProject Profile For A Boutique - Based On Assumption - Nagaveni - MA FMvstyleinNo ratings yet

- Project Profile On Manufacturing of Palm PlateDocument9 pagesProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajNo ratings yet

- Paper Carry Bags PDFDocument2 pagesPaper Carry Bags PDFSuresh KaushikNo ratings yet

- Plaster of Par IsDocument6 pagesPlaster of Par IsHenock TsegayeNo ratings yet

- Pulses MillDocument2 pagesPulses Millram100% (1)

- Plywood Project Report by Yogesh AgrawalDocument22 pagesPlywood Project Report by Yogesh AgrawalYOGESH AGRAWALNo ratings yet

- Cold Chain Industry in India A ReportDocument5 pagesCold Chain Industry in India A ReportANKUSHSINGH2690No ratings yet

- A Research Project Report On Comparative Study of Vishal Megamart A..Document26 pagesA Research Project Report On Comparative Study of Vishal Megamart A..Avinash RathodeNo ratings yet

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaNo ratings yet

- Jute Bags Manufacturing Process InvolvesDocument5 pagesJute Bags Manufacturing Process InvolvesiffatbukhariNo ratings yet

- Pre-Feasibility Report On Injection Moulding Machine Products (PCSIR-PSTC Karachi)Document13 pagesPre-Feasibility Report On Injection Moulding Machine Products (PCSIR-PSTC Karachi)myounisgNo ratings yet

- Sergical Absorbent CottonDocument11 pagesSergical Absorbent Cottonzeine100% (1)

- Details About Our Besan PlantDocument4 pagesDetails About Our Besan Plantpratikgarg03No ratings yet

- Surgical Bandage PDFDocument5 pagesSurgical Bandage PDFJoe SparrowNo ratings yet

- Coir Pith Block Making UnitDocument3 pagesCoir Pith Block Making UnitMohan RajNo ratings yet

- Absorbent Cotton Manufacturing UnitDocument19 pagesAbsorbent Cotton Manufacturing UnitIbrahim MunirNo ratings yet

- Ms High Tensile Nuts and BoltsDocument11 pagesMs High Tensile Nuts and Boltsmax_ashi100% (1)

- Project On National Horticulture BoardDocument9 pagesProject On National Horticulture Boardrupeshmore145No ratings yet

- Surgical Bandage-Ok-35-R PDFDocument2 pagesSurgical Bandage-Ok-35-R PDFSuresh KaushikNo ratings yet

- Project Profile ON Hot Forged Bolts & Nuts : Dcdi-Patna@dcmsme - Gov.in WWW - Msmedipatna.bih - Nic.inDocument10 pagesProject Profile ON Hot Forged Bolts & Nuts : Dcdi-Patna@dcmsme - Gov.in WWW - Msmedipatna.bih - Nic.insanjay_lingotNo ratings yet

- Backward and Forward Linkage Between The Agriculture, EcoDocument11 pagesBackward and Forward Linkage Between The Agriculture, Ecomediquip50% (4)

- Project Report PDFDocument11 pagesProject Report PDFamit22505No ratings yet

- Groundnut Processing Guide by Mynampati Sreenivasa RaoDocument5 pagesGroundnut Processing Guide by Mynampati Sreenivasa RaoPandu MynampatiNo ratings yet

- A Project ReportDocument24 pagesA Project ReportshariquesayeedNo ratings yet

- Project Report On Courier Bags and Air Bubble PackagingDocument9 pagesProject Report On Courier Bags and Air Bubble PackagingSachin SharmaNo ratings yet

- MIAC Tissue 2017Document57 pagesMIAC Tissue 2017Bheemendra NarayanNo ratings yet

- Project Report On Coal BriquettesDocument10 pagesProject Report On Coal BriquettesSachin SharmaNo ratings yet

- PROJECT REPORT Converted CompressedDocument21 pagesPROJECT REPORT Converted CompressedVarun Jain0% (1)

- Presentation On Tennis Balls ManufacturingDocument8 pagesPresentation On Tennis Balls Manufacturingadiall4uNo ratings yet

- Avani Catalogue 2018-Product OnlyDocument29 pagesAvani Catalogue 2018-Product OnlyAndika SuryaNo ratings yet

- Besan Mill ProjectDocument14 pagesBesan Mill Projectshreyans01100% (1)

- Milk Dairy Management System: Submitted ToDocument29 pagesMilk Dairy Management System: Submitted ToDipali KantaleNo ratings yet

- Report On Baby DiaperDocument39 pagesReport On Baby DiapersolomonNo ratings yet

- CLC Project ReportDocument10 pagesCLC Project ReportVaibhav KhodakeNo ratings yet

- Rice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Document22 pagesRice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Junaid AhmedNo ratings yet

- Marketing - BisleriDocument23 pagesMarketing - BisleriamazonbaseNo ratings yet

- Plastic Carry Bags: Profile No.: 81 NIC Code: 17024Document8 pagesPlastic Carry Bags: Profile No.: 81 NIC Code: 17024SRI DATTA SAI SEVA SADANNo ratings yet

- Egg Tray MachineDocument4 pagesEgg Tray MachineJain SumeetNo ratings yet

- Chemicals, Fertilizers, Agriculture & SugarDocument66 pagesChemicals, Fertilizers, Agriculture & Sugarfzhaque3525No ratings yet

- Precision Turned Products World Summary: Market Values & Financials by CountryFrom EverandPrecision Turned Products World Summary: Market Values & Financials by CountryNo ratings yet

- Project of Rexin BagDocument11 pagesProject of Rexin BagShayan Pitruja100% (1)

- Infant Garments: NtroductionDocument5 pagesInfant Garments: NtroductionAnonymous wA6NGuyklDNo ratings yet

- Pen PPRDocument29 pagesPen PPRVijay RaiyaniNo ratings yet

- Market Research and Analysis - HyundaiDocument46 pagesMarket Research and Analysis - HyundaiMithesh Phadtare75% (4)

- Automobile NepalDocument82 pagesAutomobile Nepalafham84100% (1)

- Methods For Optimisation and Decision Making in Lifetime Management of StructuresDocument134 pagesMethods For Optimisation and Decision Making in Lifetime Management of Structuresafham84No ratings yet

- A Road Map For JuteDocument62 pagesA Road Map For Juteafham84No ratings yet

- The Effect of Switching Barriers Types On Customer Loyalty: Fredy-Roberto ValenzuelaDocument19 pagesThe Effect of Switching Barriers Types On Customer Loyalty: Fredy-Roberto Valenzuelaafham84No ratings yet

- Rigging Lifting 3dayDocument1 pageRigging Lifting 3dayTumwine Rooney.No ratings yet

- Geneva Tax AssessmentsDocument99 pagesGeneva Tax AssessmentscherylwaityNo ratings yet

- INTRODUCTION TO INTERNATIONAL BUSINESS TRADE InbtDocument2 pagesINTRODUCTION TO INTERNATIONAL BUSINESS TRADE InbtMariaNo ratings yet

- Economy of Strategic PlannningDocument10 pagesEconomy of Strategic PlannningCarey CaiNo ratings yet

- 02 Introduction PDFDocument12 pages02 Introduction PDFsongja kroNo ratings yet

- Compensation Business LawDocument29 pagesCompensation Business Lawrohan_jangid8No ratings yet

- Contractor's Bill Check List: OthersDocument8 pagesContractor's Bill Check List: OthersaseerNo ratings yet

- FBI Summary About Alleged Flight 175 Hijacker Hamza AlghamdiDocument21 pagesFBI Summary About Alleged Flight 175 Hijacker Hamza Alghamdi9/11 Document ArchiveNo ratings yet

- Summary Logistics Chapter 1 5 7-8-10 en 14.docx FDocument21 pagesSummary Logistics Chapter 1 5 7-8-10 en 14.docx FasdfasfasdfasdfasdfsdafNo ratings yet

- Achi Jaya TransportationDocument6 pagesAchi Jaya TransportationtaibiscuteNo ratings yet

- Barry Van Sickle Motion For Release of Driver's LicenseDocument8 pagesBarry Van Sickle Motion For Release of Driver's LicenseDocuments Archive0% (1)

- Pizza Hut Case Qualitative Analysis Sec D, Group 8: SynopsisDocument5 pagesPizza Hut Case Qualitative Analysis Sec D, Group 8: SynopsisSrinivaas GanesanNo ratings yet

- Handout 1 For Chapter 7 - Recognition and Valuation of Accounts ReceivablesDocument5 pagesHandout 1 For Chapter 7 - Recognition and Valuation of Accounts ReceivablesJamieNo ratings yet

- Bio-Cam2017-017 Umma Sankar GunasegaranDocument1 pageBio-Cam2017-017 Umma Sankar Gunasegaranmeenaloshini SatgunamNo ratings yet

- DLL HE Week 10Document4 pagesDLL HE Week 10Eunice GarciaNo ratings yet

- Summary of Legal Leases IDocument6 pagesSummary of Legal Leases IMohammed HussainNo ratings yet

- BCT 2105 Accounting Software - Marking SchemeDocument8 pagesBCT 2105 Accounting Software - Marking SchemeSylvia RatemoNo ratings yet

- Lean Concept Implementation Practices in Small and Medium Scale Pharmaceutical Industry - A Case StudyDocument10 pagesLean Concept Implementation Practices in Small and Medium Scale Pharmaceutical Industry - A Case StudyIJRASETPublicationsNo ratings yet

- Social Marketing in Public HealthDocument24 pagesSocial Marketing in Public HealthYaadrahulkumar MoharanaNo ratings yet

- AJAZ-ECO204 Applied Oligopoly Models-FORMULASDocument3 pagesAJAZ-ECO204 Applied Oligopoly Models-FORMULASGrace IdreesNo ratings yet

- PML Advert RatesDocument2 pagesPML Advert RatesAbdul'Azeez BelloNo ratings yet

- Project Management: Project Management Is The Discipline of Planning, Organizing, Securing, and ManagingDocument19 pagesProject Management: Project Management Is The Discipline of Planning, Organizing, Securing, and ManagingdibyaranjanbhrNo ratings yet

- Property OutlineDocument22 pagesProperty Outlinemarksy003No ratings yet