Professional Documents

Culture Documents

Energy Distribution of Columnar Explosive Blasting in Rock: Cai Feng, Liu Ze-Gong

Uploaded by

Gembel Couvlac ElitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Distribution of Columnar Explosive Blasting in Rock: Cai Feng, Liu Ze-Gong

Uploaded by

Gembel Couvlac ElitCopyright:

Available Formats

Energy Distribution of Columnar

Explosive Blasting in Rock

Cai Feng1,2,3, Liu Ze-gong1, 2

1.Key Laboratory of Safe and Effective Coal Mining (Anhui University of Science

and Technology), Ministry of Education, Huainan 232001, China;

2.School of Resource and Safety, Anhui University of Science and Technology,

Huainan 232001, China

3.Key Laboratory of Integrated Coal Exploitation and Gas Extraction of

Anhui Province, Anhui University of Science and Technology, Huainan

232001, China

ABSTRACT

The energy generated during blasting in rock can be divided into tow parts, that is blasting

shock wave energy and blasting gas energy. The theoretic analysis on distribution of blasting

energy can be helpful to improve the blasting technology, and to increase the blasting results.

On the condition of columnar explosive, the deformation and damage characteristics of rock

under the impact of blasting shock waves are analyzed. And the cavity expansion effect of

blasting gas is studied. Taking consideration of the damage of rock, drive cracks effect of

blasting gas is analyzed. The research results show that, when columnar explosive blasting in

rock and the the depth of burial below the critical depth, the energy of blasting shock wave

accounts for 40% of the total explosion energy. And only 23% and 37% of the rest of blasting

energy is used to expand cavity and main cracks, and to increase the number of cracks by

blasting gas, and other blasting energy is lost.

KEYWORDS: columnar explosive; energy distribution; shock wave; blasting gas

INTRODUCTION

Both theoretical research and productive practice[1] show that the damage and throw of

broken rock is the result of joint action of blasting shock waves and blasting gas. The blasting

energy transfers to rock through blasting shock waves and blasting gas[2]. Blasting shock

waves mainly consumed in the process of cavity expansion, and this results to deformation of

rock, forms broken rocks zone, and generates main cracks[3]. Blasting gas is used to expand

cavity, extends main cracks, generates branches of cracks, and throws away the broken

- 4221 -

Vol. 19 [2014], Bund. S

4222

rocks[4]. In terms of explosives, under water blasting energy experiments show that, the

blasting energy can be divided into shock wave energy and blasting gas wave energy two

parts, and the distribution of these two parts are different along with different explosives.

Taking level three coal-mine water-gel explosive example, shock wave energy and blasting

gas wave energy respectively accounts 48% and 52% of total blasting energy[3]. Additionally,

high-speed photographies during blasting in open-pit mine[5] show that under general

conditions, the spalling and throwing time of step surface is 20-30ms after detonate, and the

actuation duration of blasting shock waves is less than 5-6ms, and the rest time is quasi static

action time of gas explosion. So, it is proper to divided the blasting energy in rock into shock

wave energy and blasting gas wave energy two parts.

After charging explosives and detonation, blasting shocks waves generated by explosion

radial and drastically shock and compress surrounding rock and form broken rocks zone,

meantime, this leads to displacement of rock mass and blasting cavity expansion. Blasting

shock waves apply works on rocks, and blasting energy attenuates sharply. At the edge of

broken rocks zone, blasting shock waves successively attenuate into plastic and elastic stress

waves, and the propagation of stress waves tangentially strength rocks and generate new

radial cracks. During generating and extending these new cracks, the energy of stress waves

successively attenuates , and the intensity of stress waves decreases, so that these stress waves

can only cause the elastic deformation and vibration of rock out of cracks zone. Following the

shock waves, the explosion gas continues to expand and further expand the cavity, and wedge

in the cracks to extend them. At last, broken rocks are thrown outside under the effect of

remaining energy of blasting gas. When the explosive charge is constant, With the decrease of

burial depth, the blasting energy transferred to the ground rock will increase, and the ground

rock will be damaged if the burial depth is small enough. According to the different rock

properties, brittle rock will have a "slice off phenomenon", and plastic rock will produce

"bulge phenomenon" accompanied by cracks. Under this condition, burial depth of explosives

is called the critical depth. This paper mainly discusses the blasting energy distribution of the

columnar explosives blasting in rock, and the burial depth of explosives are larger than

critical depth.

CALCULATION OF BLASTING BROKEN ROCKS

ZONE

Blasting load when columnar explosive charge

In the condition of the coupling charge, columnar explosive blasts in rock and applies

shock load on surrounding rock. According to the acoustic approximation principle[6-8]:

Pd =

0 D 2 2 mC p

1 + mC p + 0 D

(1)

Vol. 19 [2014], Bund. S

4223

where Pd is initial shock pressure of transmissive shock waves into the rock; 0 and m is

respectively density of explosives and rocks; C p and D is respectively sound velocity in

rocks and detonation velocity of explosive; is adiabatic expansion coefficient of blasting

products, generally = 3 .

A large number of consumption on the shock waves energy results to sharply attenuation,

so that at the edge of broken rocks zone, blasting shock waves attenuate into stress waves.

When plane strain, the stress of rock caused by stress waves can be expressed as[9]:

t = Pd r

(2)

= r

(3)

z = (1 ) r

(4)

where r , , z is respectively radial stress, tangential stress, axial stress; r is

comparative distance, r = ri / rb , ri is the distance between calculative point with the center

of explosive, rb is the diameter of blasting hole; is pressure attenuation coefficient, 3

or = 2 + / (1 ) in shock waves area and = 2 / (1 ) in stress waves area,

according to some scholars research results[7,10], within the range of load rate of engineering

blast, = 0.8 0 , and 0 is static Poisson's ratio of rock; is lateral pressure coefficient,

and = / (1 ) .

Failure criterion of rock under explosion load

Failure criterion of materials under external load depends on the properties of materials

and actual stress state. The rocks belong to the brittleness material, and the tensile strength is

far less than compressive strength. According to the literature [9], the expression of the

effective stress i of rock can be expressed as:

i =

1

r (1 + )2 2 (1 )2 (1 ) + (1 + )2

2

1

2

(5)

According to Mises criterion, if i cd (broken rocks zone) or i td (cracks zone),

the rock will be damaged, where cd and td is respectively dynamic uniaxial compressive

strength and dynamic uniaxial tensile strength of rock. Because i of rock will increase with

the increase of loading strain rate, and different rocks have different sensitivity on loading

13

strain rate, so to normal rock, cd = c , where c is static uniaxial compressive strength

of rock, is loading strain rate. Some research results[11] show that when is between 100

and 104s-1, and in broken rocks zone, the value of is between 102 and 104s-1, and outside of

broken rocks zone, the value of is between 100 and 103s-1. Rocks td changes little with

Vol. 19 [2014], Bund. S

4224

loading strain rate, and within the range of load rate of engineering blast, td = t , where t

is static uniaxial tensile strength of rock.

The calculation of broken rocks zone and cracks zone

Under the conditions of Columnar coupling charging, after blasting, broken rocks zone

and cracks zone will be formed around explosives, according to equation (1), (2) and (5), and

makes i cd , the radius of broken rocks zone[9] can be calculated by:

PA

Rc = rb d

2 cd

(6)

where A = (1 + ) + 1 + 2 2 (1 ) 2 .

2

Meanwhile, the radius of cracks zone RT [9] can be calculated by:

RT = Rc cd

td

PA

= rb d

2 cd

cd

td

(7)

where = 2 (1 ) .

ANALYSIS OF SHOCK WAVES APPLYING WORK ON

ROCK

Cavity expansion effect of shock waves

Under the action of shock waves, the rock mass around blasting hole takes radial

displacement, and the diameter of blasting hole increase and the blasting cavity expands;

shock waves smash rocks, apply work on rock, and then sharply attenuate. When shock waves

propagate to the edge of broken rocks zone, the shock and compression process finishes, and

blasting expansion process caused by shock wave also finishes. During blasting, rock

complies with the conservation of mass, and can be expressed as[1,2]:

(r

rb2 m = 2 0 rdr

(8)

r1

where r is action radius of shock wave; r1 is the radius of blasting cavity.

Expanding law of blasting cavity under the action of shock waves[2] can be expressed as:

r1 = r 2 r 2 rb2 m / r

In broken rocks zone, r = Rc , final radius of blasting cavity is:

(9)

Vol. 19 [2014], Bund. S

4225

R1 = Rc2 Rc2 rb2 m / r

(10)

In the process of expanding cavity,

r =

a + bu

m

a + (b 1)u

(11)

where a and b is rock test constant; u is initial velocity of rock mass at blasting hole wall.

Shock wave energy consumption equals to the work shock waves applying on the rock, so

the work shock waves applying on the rock during expanding cavity is:

R1

W1 = 2r r dr

(12)

rb

Take peak pressure attenuation equation of shock waves r = Pd r

and then integrate it, acquire:

r

W1 = 2rb2 Pd 1 b

R1

into equation (12),

(13)

Shock waves do work during generating radial cracks

Outside of broken rocks zone, blasting shock waves attenuate into plastic and elastic

stress waves, and propagation of stress waves tangentially strength rocks and generate new

radial cracks. Former research results[12] show that plane wedge crack model is proper to

study this cracks. Meanwhile, according to the rock fracture mechanics, considering columnar

explosive blasting

can be seen as plane strain problem, energy release rate can be acquired as:

1 2 2

G1 =

K1 , K1 is stress intensity factors. So, the work done by tangential stress during

E

cracks extending can be expressed as:

W2 = n1

RT

rb

(1 ) K

2

2

1

dr

(14)

where n1 is the number of radial cracks.

According to experiments[9], the number of main cracks is 4-12, and take its value as 8

( n1 = 8 ). For the open cracks, along their extension lines ( = 0 ), the relationship between

K1

tangential stress and its stress intensity factors at cracks end is: =

, where r j is the

2

r

j

distance between the center of blasting hole and cracks end, and taking this equation into

equation (14) and then integrating it can get:

Vol. 19 [2014], Bund. S

4226

n 2 Pd2 rb2 1 2

W2 = 1

E (1 )

) R

r

b

2 (1 )

(15)

Elastic deformation caused by stress waves

Outside of cracks zone, stress waves can only cause elastic deformation. During

calculating consumed energy during elastic deformation, elastic deformation energy per unit

volume of rock[2] is:

r2

1

E = ( r r + ) =

1 + 2

2

2E

(16)

So, the work during stress waves and shock waves leading to elastic deformation of rock

is:

W3 =

rb

(1 + 2 ) Pd2 rb2

2rEdr =

E

2(1 )

(17)

ANALYSIS ON THE WORK APPLIED BY BLASTING

GAS ON ROCK

After the process of shock waves expanding, blasting gas rapidly expands and fills cavity,

and continues to act on the rock in the form of quasi static pressure. This results to further

radial displacement of rock mass around blasting cavity, and this expands the cavity. With the

increase of cavitys volume, blasting gas pressure drops. And when blasting gas pressure

drops to the surrounding rock pressure, blasting expansion process ends.

Expand cavity by blasting gas

Following the shock waves, blasting gas continues to expand the cavity. When the

blasting gas pressure P equals to surrounding rock pressure Ps , blasting expansion process

ends. During blasting expansion process, the surrounding rock pressure[13] is:

Ps = Patm + s + m

(18)

where Patm is atmospheric pressure; s is the ultimate compressive strength of rock

1

under multiaxial stress conditions, s = mC p2 c 4 c , m is rocks severe; is burden.

Because Patm and m is much less than s , so Ps = s . To simplify the calculation, gas

leakage is ignored. So, to blasting gass expanding law in blasting cavity is[1]:

Vol. 19 [2014], Bund. S

4227

P0 (rb / r2 )6

P=

8

Pk (rk / r2 ) 3

(P Pk )

(P < Pk )

(19)

where P is instantaneous pressure of blasting gas; P0 is initial pressure of blasting gas, when

coupling charge, its value equals to detonation pressure, P0 = 0 D 2 (2 + 2 ) ; r2 is

instantaneous radius of blasting cavity; Pk and rk is respectively critical pressure and critical

radius of blasting cavity when blasting gas is on adiabatic expansion. Change the format of

equation (19) can acquire the expanding laws of blasting cavity under the action of blasting

gas, that is:

16

rb (P0 / P )

r2 =

16

38

rb (P0 / Pk ) (Pk / P )

(P Pk )

(P < Pk )

(20)

Replace P in equation (20) with Ps , final radius of blasting cavity can be acquired as:

16

rb (P0 / Ps )

R2 =

16

38

rb (P0 / Pk ) (Pk / Ps )

(Ps Pk )

(Ps < Pk )

(21)

So, work done by blasting gas to expand cavity can be expressed as:

R2

W4 = 2rPdr

(22)

R1

Substitute equation (19) into equation (22), and then integrate, get:

4

4

P0 rb2 rb R1

1

2 R1 R2

W4 =

49

23

23

2

R1

4Pk rb P0 rb

1

3 Pk R1 R2

(Ps Pk )

(23)

(Ps < Pk )

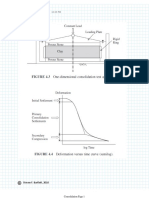

Blasting gas driving the cracks

The damage and cracks are the result of the combination action of stress waves and

blasting gas[14]. This theory is that: firstly, under the action of stress waves, initial crack

network is generated in rock around the hole, and then, under the quasi static action of

blasting gas, the initial cracks will be further extended. Considering the mechanical effect of

stress wave propagation in advance, that is before the damage of rock mass, the rocks

microscopic structure has been changed. Kutter and Fairhurst[14] thinks that: stress waves play

a pre-load role on rock. According to this, plane wedge crack model of quasi static blasting

gas driving cracks can be shown as Figure 1. In Figure 1, L(t ) is total extended length driven

Vol. 19 [2014], Bund. S

4228

by blasting gas; L1 (t ) is filling length of blasting gas; L0 is initial length of radial cracks

under the action of stress waves.

L0

L1(t)

L(t)

Figure 1: Plane wedge crack model of quasi static blasting gas driving cracks

Initial cracks are caused by shock waves, and then the cracks keep growing under the

action of blasting gas. When engineering calculating, when the length of crack is larger than

the diameter of blasting hole, the blasting hole can be seen as a part of crack. Stress intensity

factor of crack discontinuity of this model[12,15,16] can be expressed as:

2 L(t ) + rb

K1 =

1 D

12

L (t )+ rb

P ( x, t )

{[L(t ) + r ] x }

2

2 12

dx

(24)

where P( x, t ) is the distribution of gas pressure along the direction of crack length; is the

far field stress perpendicular to the direction of crack surface; D is damage of the end of

crack tip. When the crack stop growing, set P as pressure of gas in cavity, and L as the final

crack length, then,

K1 =

2 L + rb

1 D

12

L + rb

{[L + r ]

x2

12

dx = K a

(25)

where K a is the arrest toughness of rock.

According equation (25), final crack length under the action of stress waves and blasting

gas can be acquired, and the work done by blasting gas on the growth of crack is:

W5 = n1

RT

(1 ) K

2

2

1

dr

(26)

THE CALCULATION AND ANALYSIS

In the process of blasting, the work equals to consumed energy. The energy of unit length

explosive is E0 = rb2 0Q , where Q is explosive heat. The explosive heat of #2 Rock

Ammonium Nitrate Explosive ( 0 =1000kg/m3, v =3600m/s) is 3.76MJ/kg, and the physical

Vol. 19 [2014], Bund. S

4229

parameters of rock is shown as Table 1. The calculated results are shown in Table 2. From

Table 2, it can be found that: The ratio of consumed energy by shock waves to total blasting

energy is about 40%; the ratio of blasting gas energy to total blasting energy is about 60%,

among them, the energy of blasting gas used to expand cavity and cracks is 23% of blasting

gas energy, the energy blasting gas used to create new cracks is 37% of blasting gas energy,

and the other energy is lost. The calculated results is very close to relative literatures.

Table 1: Physical and mechanical properties of rock and the value of a and b

Rock type

m/kg.m3

Cp/m.s-1

c/MPa

t/MPa

E/GPa

a/m.s-1

Granite

2670

5500

180

15

70

0.24

3600

1.0

Basalt

2670

6200

250

18

100

0.25

2600

1.6

Marble

2700

5000

160

12

80

0.26

4000

1.32

Gabbro

2980

6000

240

18

80

0.25

3500

1.32

Table 2: Calculated results of distributions of blasting energy

Rock type

W1/E0

W2/E0

W3/E0

W4/E0

W5/E0

Others

Granite

27.6

5.9

7.1

5.0

17.7

37.3

Basalt

31.9

4.8

5.3

3.0

14.4

40.6

Marble

27.5

6.7

7.0

5.9

20.1

32.8

Gabbro

22.7

6.1

6.8

6.9

18.3

39.2

CONCLUSIONS

Through theoretical analysis, it can be found that the damage and throw of broken rock is

the result of joint action of blasting shock waves and blasting gas. The blasting energy

transfers to rock through blasting shock waves and blasting gas. Blasting shock waves mainly

consumpt in the process of cavity expansion, and this results to deformation of rock, forms

broken rocks zone, and generates main cracks. Blasting gas is used to expand cavity, extends

main cracks, generates branches of cracks, and throws away the broken rocks

Through calculation and analysis, it can be found that: The ratio of consumed energy by

shock waves to total blasting energy is about 40%; the ratio of blasting gas energy to total

blasting energy is about 60%, among them, the energy of blasting gas used to expand cavity

and cracks is 23% of blasting gas energy, the energy blasting gas used to create new cracks is

37% of blasting gas energy, and the other energy is lost.

Currently, the blasting energy distribution laws of the blast under the condition of

different rocks and burial depth being less than critical depth need to be further studied.

Meanwhile, according to different requirements of engineering blast, it should be studied and

analyzed to improve the explosion energy distribution of blasting in different rocks.

Vol. 19 [2014], Bund. S

4230

ACKNOWLEDGMENTS

Part of researches in this paper is supported by National Natural Science Foundation of

China (51304006), Natural Science Foundation of Anhui Province of China (1408085QE87).

REFERENCES

[1]

Cai Feng, Liu Zegong. Numerical simulation of improving permeability by deep-hole presplitting

explosion in loose-soft and low permeability coal seam[J]. Journal of China Coal Society, 2007,

32(5):499-503.

[2]

ZONG Qi, YANG Lu-jun. Shock energy distribution of column charge in rock[J]. Blasting, 1999,

16(2): 1-6.

[3]

YAN Shi-long. Distribution of the explosive energy consumed by concentrated charge in rock[J].

Journal of Huainan Mining Institute, 1993, 13(3): 82-88.

[4]

PAN Jing-lan. The discussion of rock mechanism by blasting[J]. Blasting, 1994, (4): 1-6.

[5]

Li Xiaotian, He Shuting. Fluid-solid coupling dynamics of a hydraulic drive with an impact

load[J]. Journal of Tsinghua University (Science and Technology), 2004, 44(3):338-341.

[6]

Lu Yong, Wang Zhongqi, Chong K. A comparative study of buried structures in soil subjected to

blast load using 2D and 3D numerical simulations[J]. Soil dynamics and earthquake engineering,

2005, 25(4):275-288.

[7]

Kubota S, Nagayama K, Saburi T, et al. State relations for a two-phase mixture of reacting

explosives and applications[J]. Combustion and flame, 2007, 151:74-84.

[8]

Yang Songyan, Yu Maohong, Fan Shouchang. An elasto-plastic damage model for saturated and

unsaturated geomaterials[J]. ACTA MECHANICA SINICA, 2000, 32(2):198-206.

[9]

Zheng Shaohe, Zhu Weishen. Theoretical analysis on a coupled seepage damage model of

fractured rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 2001, 20(2):156159.

[10]

Rutqvist J, Stephansson O. The role of hydro mechanical coupling in fractured rock

engineering[J]. Hydrogeology Journal, 2003, 11(2):7-40.

[11]

Lao Jun, Xiao Weiguo, Wang Xiaojun, Numerical simulation on underground cavity-decoupling

explosion[J]. Explosion and Shock Waves, 2009, 29(5)535-541

[12]

LU Wen-bo, TAO Zhen-yu. A study of fracture propagation velocity driven by gases of explosion

products[J]. Explosion and Shock Waves, 1994, 14(3):264-268.

[13]

Li Hongtao, Lu Wenbo, Shu Daqiang. An energy analysis method for blast-induced seismic based

on power spectrum[J]. Explosion and Shock Waves, 2009, 29(5)491-495

[14]

Kutter H K. Fairhurst. On the fracture process in blasting[J]. International Journal of Rock

Mechanics and Mining Sciences, 1971, 8(2): 181-202.

Vol. 19 [2014], Bund. S

[15]

4231

WANG Jia-lai, XU Ying. Damage effect in rock by strain waves and crack propagation by

explosion[J]. Explosion and Shock Waves, 1995, 15(3): 212-216.

[16]

XU Ying, MENG Yi-ping, ZONG Qi, et al. Study on range of cranny and length of fissure

expansion in fault zone[J]. Rock and Soil Mechanics, 2002, 23(1): 81-84.

2014 ejge

You might also like

- Rock Fracture and Blasting: Theory and ApplicationsFrom EverandRock Fracture and Blasting: Theory and ApplicationsRating: 5 out of 5 stars5/5 (2)

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- A Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryDocument15 pagesA Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryÁALNo ratings yet

- A Numerical Approach On Dynamic Behaviour Induced by Tunnel Blast LoadsDocument10 pagesA Numerical Approach On Dynamic Behaviour Induced by Tunnel Blast LoadsHarold TaylorNo ratings yet

- Rock Breakage and Blast Design Considerations in OpenpitDocument34 pagesRock Breakage and Blast Design Considerations in Openpitpartha das sharma100% (5)

- Paper - Rock Fracturing Mechanisms by BlastingDocument18 pagesPaper - Rock Fracturing Mechanisms by BlastingKevinEqNo ratings yet

- Modeling Seismic Vibrations Under Massive Blasting in Underground MinesDocument7 pagesModeling Seismic Vibrations Under Massive Blasting in Underground MinesMatheus Gonçalves Peixoto da SilvaNo ratings yet

- Blast Design in Surface MiningDocument33 pagesBlast Design in Surface Miningpradeep dawerNo ratings yet

- Rock Breakage and Blast Design Considerations in Open PitDocument31 pagesRock Breakage and Blast Design Considerations in Open PitJessica WatsonNo ratings yet

- Research ArticleDocument17 pagesResearch ArticleSiddharth MohananNo ratings yet

- Blast Induced Damage and Its Impact On Structural Stability of Underground ExcavationsDocument10 pagesBlast Induced Damage and Its Impact On Structural Stability of Underground ExcavationsVeljko LapčevićNo ratings yet

- Wbi-Print5 0 07Document25 pagesWbi-Print5 0 07fedyNo ratings yet

- Concept of Blastability - An Update: Kaushik Dey & Phalguni SenDocument15 pagesConcept of Blastability - An Update: Kaushik Dey & Phalguni SenDanny Achahue0% (1)

- NingDocument8 pagesNingAnonymous atZc0NCNo ratings yet

- Visualizing The Blast-Induced Stress Wave and Blasting Gas Action EffectsDocument8 pagesVisualizing The Blast-Induced Stress Wave and Blasting Gas Action EffectsОкNo ratings yet

- Problem Analysis of Geotechnical Well Drilling in Complex EnvironmentDocument7 pagesProblem Analysis of Geotechnical Well Drilling in Complex EnvironmentElgi Zacky ZachryNo ratings yet

- Pre SplitsDocument8 pagesPre Splitsmosesnicholas46No ratings yet

- Numerical Simulation On Radiation and Energy of Blast-Induced Seismic Waves in Deep Rock MassesDocument18 pagesNumerical Simulation On Radiation and Energy of Blast-Induced Seismic Waves in Deep Rock MassesMatheus Gonçalves Peixoto da SilvaNo ratings yet

- Cost Effectiveness of Open-Pit Hard Rock Ore MiningDocument14 pagesCost Effectiveness of Open-Pit Hard Rock Ore Miningpartha das sharma50% (2)

- PAPER9 - Effect of Detonator Position On Rock Fragmentation Full-Scale Field Tests at Kevitsa Open Pit Mine - Q1Document11 pagesPAPER9 - Effect of Detonator Position On Rock Fragmentation Full-Scale Field Tests at Kevitsa Open Pit Mine - Q1Jorge GallardoNo ratings yet

- 1 Archiwum-66-4-05-Chandrahas - 2021Document18 pages1 Archiwum-66-4-05-Chandrahas - 2021ME-MNG-15 Ramesh100% (1)

- Borehole Geomechanics and Well DesignDocument6 pagesBorehole Geomechanics and Well DesignMourad B. WassefNo ratings yet

- EXPLOSIVEDocument21 pagesEXPLOSIVERiddhi TiwariNo ratings yet

- Numerical Solution For Circular Tunnel Excavated in Strain Softening Rock Masses Considering Damaged ZoneDocument17 pagesNumerical Solution For Circular Tunnel Excavated in Strain Softening Rock Masses Considering Damaged ZoneMahmoud SabryNo ratings yet

- Simulations of Explosion-Induced Damage To Underground Rock ChambersDocument11 pagesSimulations of Explosion-Induced Damage To Underground Rock ChambersPaola VillamilNo ratings yet

- Summary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingDocument37 pagesSummary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingBryan Franklin Vilca ChavezNo ratings yet

- Exploration GeologyDocument49 pagesExploration GeologyAshkimas DreamerNo ratings yet

- Experimental Investigation of Blast-Induced Fractures in Rock CylindersDocument16 pagesExperimental Investigation of Blast-Induced Fractures in Rock CylindersfelipeNo ratings yet

- The Squeezing Potential of Rocks Around Tunnels Theory and PredictionDocument27 pagesThe Squeezing Potential of Rocks Around Tunnels Theory and PredictionprazNo ratings yet

- Singh Investigation Blast Damage Underground StabilityDocument7 pagesSingh Investigation Blast Damage Underground StabilityllllcesarllllNo ratings yet

- Flac Blast LoadDocument4 pagesFlac Blast LoadKaram MiniNo ratings yet

- An Algorithm For Calculating Blasting Parameters of The Complex Surrounding Rock Tunnel Undercrossing Nearby RoadbedRussian Physics JournalDocument14 pagesAn Algorithm For Calculating Blasting Parameters of The Complex Surrounding Rock Tunnel Undercrossing Nearby RoadbedRussian Physics JournalChandra HasanNo ratings yet

- Drill and Blast ForumDocument18 pagesDrill and Blast ForumBenjamin AmoahNo ratings yet

- Rock Blasting 11Document29 pagesRock Blasting 11Alvaro Andres Bustamante Montenegro100% (1)

- 1 s2.0 S2095268618306645 MainDocument5 pages1 s2.0 S2095268618306645 MainDaniel MoravanskýNo ratings yet

- Integrating Rock Mechanics and Structural Geology PDFDocument24 pagesIntegrating Rock Mechanics and Structural Geology PDFVincent EbinNo ratings yet

- Jafari2004 Article ExperimentalStudyOfMechanicalBDocument21 pagesJafari2004 Article ExperimentalStudyOfMechanicalBVijay KNo ratings yet

- Tunnel Blasting TechniquesDocument24 pagesTunnel Blasting TechniquesAbhishek MajiNo ratings yet

- Energies: Damage Evolution Mechanisms of Rock Induced by Blasting With The Aid of Empty-Hole EDocument21 pagesEnergies: Damage Evolution Mechanisms of Rock Induced by Blasting With The Aid of Empty-Hole EJesus Alberto Castillo GomezNo ratings yet

- Rock Mechanics and GeosciencesDocument95 pagesRock Mechanics and GeosciencesErdem Salih SeyfeliNo ratings yet

- 1.MIN 4015 Drilling and BlastingDocument59 pages1.MIN 4015 Drilling and BlastingChaka MbeweNo ratings yet

- Classifications WeakRockDocument13 pagesClassifications WeakRockrahulgeo05No ratings yet

- Estimating Flyrock Distance in Bench Blasting Through Blast Induced Pressure Measurements in RockDocument8 pagesEstimating Flyrock Distance in Bench Blasting Through Blast Induced Pressure Measurements in RockM Arif Satrio AgungNo ratings yet

- Application of Seismic Refraction Survey in Assessment of Jointing - PalmstromDocument8 pagesApplication of Seismic Refraction Survey in Assessment of Jointing - PalmstromkrainajackaNo ratings yet

- Index Properties of Intact RockDocument12 pagesIndex Properties of Intact RockChidi HenryNo ratings yet

- Basic Rock MechanicsDocument7 pagesBasic Rock MechanicsMohammad Mehdi100% (1)

- Explosives 1Document18 pagesExplosives 1hod miningNo ratings yet

- Rock Bolting TechniqueDocument9 pagesRock Bolting TechniquesamratNo ratings yet

- Control of Fragmentation by BlastingDocument9 pagesControl of Fragmentation by BlastingDinoYancachajllaNo ratings yet

- ISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up TimeDocument4 pagesISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up Timecastille1956No ratings yet

- JURNAL GelombangDocument10 pagesJURNAL GelombangAbdullah Badawi BatubaraNo ratings yet

- Shotcrete Lining in A TunnelDocument13 pagesShotcrete Lining in A TunnelNaveen R100% (1)

- Rock Blasting - BasicDocument20 pagesRock Blasting - BasicCesar FloresNo ratings yet

- Schmidt HammerDocument8 pagesSchmidt HammerIllud DulliNo ratings yet

- VALDIVIA CUEVAS, Ana Leyvis Vibraciones en VoladurasDocument14 pagesVALDIVIA CUEVAS, Ana Leyvis Vibraciones en VoladurassimonNo ratings yet

- Tunnel Blasting TechniquesDocument25 pagesTunnel Blasting TechniquesBaga Yoice100% (1)

- Basic Rock MechanicsDocument8 pagesBasic Rock Mechanicslopi98llkj55No ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Plate Boundaries and Natural HazardsFrom EverandPlate Boundaries and Natural HazardsJoao C. DuarteNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Preprod 2Document7 pagesPreprod 2Gembel Couvlac ElitNo ratings yet

- 1 Types of ExplosiveDocument22 pages1 Types of ExplosiveGembel Couvlac ElitNo ratings yet

- Discontinuity Analysis For Rock EngineeringDocument1 pageDiscontinuity Analysis For Rock EngineeringGembel Couvlac ElitNo ratings yet

- Sni 2825-2008Document14 pagesSni 2825-2008Rifqi Syahrial100% (1)

- Rigid Pavement: Postgraduate Studies Highways EngineeringDocument27 pagesRigid Pavement: Postgraduate Studies Highways EngineeringZohaibShoukatBalochNo ratings yet

- QUIZ-1 Mech MaterialDocument1 pageQUIZ-1 Mech MaterialAdil KhawajaNo ratings yet

- Stress-Strain Diagram: Engr. Abdul Rahim KhanDocument26 pagesStress-Strain Diagram: Engr. Abdul Rahim KhanKashif TaRarNo ratings yet

- Column Buckling - Inelastic: A Long TopicDocument43 pagesColumn Buckling - Inelastic: A Long TopicMaria OrtizNo ratings yet

- IS Standard 3400Document11 pagesIS Standard 3400Anonymous ORBFjUf5No ratings yet

- Mechanical Engineering Interview Questions and AnswersDocument17 pagesMechanical Engineering Interview Questions and AnswersprasathbalaNo ratings yet

- Thick Shell TheoryDocument17 pagesThick Shell TheoryNitin SuryawanshiNo ratings yet

- ConsolidationDocument20 pagesConsolidationDEBASISNo ratings yet

- Sample Problem-StrainDocument6 pagesSample Problem-StrainNiaz KilamNo ratings yet

- Effect of Age On Concrete PropertiesDocument15 pagesEffect of Age On Concrete Propertiesyasirkazmi856No ratings yet

- Behaviour of Self Compacting Concrete Using Portland Pozzolana Cement With Different Levels of Fly Ash PDFDocument8 pagesBehaviour of Self Compacting Concrete Using Portland Pozzolana Cement With Different Levels of Fly Ash PDFDinakar PraneethNo ratings yet

- 507 33 Powerpoint-Slides Ch1 DRCSDocument94 pages507 33 Powerpoint-Slides Ch1 DRCSArun GoyalNo ratings yet

- Scalar and Vector-Valued Fragility Analysis of Typical Algerian RC Bridge PiersDocument14 pagesScalar and Vector-Valued Fragility Analysis of Typical Algerian RC Bridge PiersViewingFreePDFSShouldNotBeChargedFuckYouSCRIBDNo ratings yet

- CE7018 Lecture Notes & HomeworksDocument201 pagesCE7018 Lecture Notes & HomeworksUtku KaftanciogluNo ratings yet

- Hooke's Law and Property of MaterialsnotesDocument5 pagesHooke's Law and Property of MaterialsnotesPrithu PareekNo ratings yet

- 20-1-16 LS Dyna - SHPB Analysis FinalDocument7 pages20-1-16 LS Dyna - SHPB Analysis FinalJayDeep KhajureNo ratings yet

- Young's ModulusDocument3 pagesYoung's ModulusRjNo ratings yet

- Astm D790-15Document12 pagesAstm D790-15Rodrigo Ampuero100% (2)

- 2 Marks SOM RejinpaulDocument12 pages2 Marks SOM Rejinpaull8o8r8d8s8i8v8No ratings yet

- Comparison of Flange Stress Calculated by Asme Design Code and Finite Element AnalysisDocument8 pagesComparison of Flange Stress Calculated by Asme Design Code and Finite Element AnalysisMohammed EljammalNo ratings yet

- Dynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Impulse Excitation of VibrationDocument16 pagesDynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Impulse Excitation of VibrationNav TalukdarNo ratings yet

- Determination of Load Distribution in A Threaded ConnectionDocument10 pagesDetermination of Load Distribution in A Threaded ConnectionDelmouly CélineNo ratings yet

- Numerička Analiza Sendvič Panela Izloženi Trenutku OpterećenjaDocument6 pagesNumerička Analiza Sendvič Panela Izloženi Trenutku Opterećenjaabdulah_alagicNo ratings yet

- Effect of Soil Structure Interaction On The Dynamic Response of Reinforced Concrete StructuresDocument12 pagesEffect of Soil Structure Interaction On The Dynamic Response of Reinforced Concrete StructuresWilder BohorquezNo ratings yet

- Performance Analysis of Flexible Pavement Using Finite Element MethodDocument7 pagesPerformance Analysis of Flexible Pavement Using Finite Element MethodBijay banNo ratings yet

- Analysis and Design of Beams For Bending: Chapter 5 - 5-A. Symmetric Member in Pure BendingDocument16 pagesAnalysis and Design of Beams For Bending: Chapter 5 - 5-A. Symmetric Member in Pure BendingAaron CansinoNo ratings yet

- Lecture 1 - Properties of MaterialDocument59 pagesLecture 1 - Properties of MaterialKhushbu KumariNo ratings yet

- Ms Box 75x75x3mmDocument4 pagesMs Box 75x75x3mmNadir Khattak Jr.No ratings yet

- As Level Physics Key WordsDocument6 pagesAs Level Physics Key Words林仁超No ratings yet

- Creep PDFDocument49 pagesCreep PDFGurram VinayNo ratings yet