Professional Documents

Culture Documents

Gingery-Sheet Metal Technology

Gingery-Sheet Metal Technology

Uploaded by

Jennifer HaasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gingery-Sheet Metal Technology

Gingery-Sheet Metal Technology

Uploaded by

Jennifer HaasCopyright:

Available Formats

http://www.lindsaybks.com/dgjp/djgbk/sheetmetal/index.

html

Sheet Metal Technology

by Dave Gingery

Dave's last book! It was written in the late 1980's but is only now being publis

hed. Dave's gone. I miss him. I wish he were still here so I could choke him for

having put such a boring title on such an interesting book. I would have called

it something like "How to Learn to Work Sheet Metal by Fabricating Something Th

at Is Actually Very Useful."

Excerpts from the preface and introduction presented here better explain the boo

k than I can. And the photographs speak for themselves. Neat stuff.

What I find quite interesting are the plans for the 24" leaf brake built primari

ly from hardwood. Before you thumb your nose at a wooden brake, both Dave and I

must remind you that most early sheet metal brakes were wooden. This would be a

great project for the model maker, the radio builder, or an artist who needs onl

y a lightweight unit. Hardwood and piano hinges are commonly available.

Maybe you could build the grill, and from the lessons learned scale it up to bui

ld that monster barbeque grill you always wanted to mount in the bed of your fou

r by four. Well... maybe not.

Great book. Gingery quality as usual. Get one. 5-1/2 x 11 softcover 114 pages

No. 1588 ... $14.95

Dave's Working Sheet Metal --->

Introduction

...The central theme of this book is the vocational application of sheet metal t

echnology, based upon the author's experience as technician, model builder and p

roduct design engineer in the sheet metal manufacturing industry. The intention

is to present the material as it is presented to those newly employed.

...In chapter II we discuss the origin and nucleus of a manufacturing and market

ing enterprise in its most elemental form. This is the source of employment and

there are many vocations within the system that spring from this basic craft...

It is likely that many will feel intimidated by the pattern development discussi

on and exercises in chapter III. In fact, not everyone can absorb such material

and so it should not be a critical grading factor for every student...

...The text in the pattern development section is deliberately brief because suc

h material simply can't be presented in lecture form. It absolutely must be demo

nstrated by the instructor, and the student must do the exercises in order to ab

sorb the material. It is a step by step process rather like crossing a stream on

submerged stepping stones,. You must do it several times to get good at it.

...The procedures and systems for forming and joining sheet metal are infinite i

n number and constantly changing. Little by way of instruction is required to un

derstand any of them. But a discussion of the more common and most interesting s

ystems are outlined in chapter IV.

...The basic shop in chapter V is kept very simple even though a fully equipped

shop might be the preferred teaching accommodation.

...The projects are presented in a series of drawings that very much resemble sh

op drawings that might be used in an actual employment situation. The text on ea

ch project is deliberately brief because it would be extremely tedious to merely

expound upon what one might encounter in carrying out the project...

Preface

...The book you hold in your hand was written in the mid to late 1980's,

but never published. The manuscript has been in my possession since 1994 when D

ad retired and I had actually forgotten about it until recently. The type set of

the manuscript was from one of the earlier dot matrix printers and my OCR softw

are would not recognize it. As a result, the text had to be manually re-typed. A

nd the original drawings, though adequate, were hand drawn so I took the opportu

nity to recreate them on the computer as well.

Very little actual editing was necessary and as I worked through the book it was

almost as if Dad were standing over my shoulder talking to me. So bringing this

book to life has been an absolute joy and I have looked on the project as an op

portunity to spend a few more months with him.

You will find the projects to be progressive in nature. That is, as you progress

in knowledge, less information is supplied in the form of written instruction.

The information is still there, but it is in the form of layout drawings giving

you the opportunity to figure out methods to form and assemble the parts on your

own. And that's what Dad had in mind. He wanted us to learn how to use our brai

ns.

To prepare for constructing the projects in the book, I purchased a 24" pan & bo

x brake Model #G0557 from Grizzly industrial for $189.00 and a spot welder for $

300.00. The other necessary tools such as tin snips, scriber and straight edge e

tc., I already had in my possession. I was amazed at what I was able to produce

and the quality I was able to achieve with such a small investment. And that inv

estment could have been reduced to near zero if I had chosen to use the wooden b

rake presented in the book, and pop rivets instead spot welds.

The charcoal grill and the three drawer tool chest were intimidating at first gl

ance, but I just dug in and took the projects one step at a time. Before long it

became clear that what was at first perceived a difficult challenge turned out

to be a breeze. And that's what Dad always emphasized. "Nothing is impossible. Y

ou can know what others know, and you can do what others do." I can testify to t

hat from first hand knowledge....

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Geomancy in Theory Practice 465263Document5 pagesGeomancy in Theory Practice 465263parand200333% (6)

- Reading and Writing Skills LE Week 5Document3 pagesReading and Writing Skills LE Week 5Glen Welle SuarezNo ratings yet

- 3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFDocument65 pages3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFVenu Gopal Rao100% (2)

- 5 Senses Oral AssessmentDocument6 pages5 Senses Oral AssessmentAmisSaintGabrielRabatNo ratings yet

- Syllabus: Summary of Information On Each Course Measurement and Instrumenttation DEB2332Document9 pagesSyllabus: Summary of Information On Each Course Measurement and Instrumenttation DEB2332suhailamatnayanNo ratings yet

- Calculation of Screw JackDocument20 pagesCalculation of Screw JackVenu Gopal RaoNo ratings yet

- Bill DSC14 MagnaDocument1 pageBill DSC14 MagnaVenu Gopal RaoNo ratings yet

- 085 - Hadee ForgingsDocument6 pages085 - Hadee ForgingsVenu Gopal RaoNo ratings yet

- 086 - Hadee ForgingsDocument2 pages086 - Hadee ForgingsVenu Gopal RaoNo ratings yet

- Vsa FinalDocument60 pagesVsa FinalVenu Gopal RaoNo ratings yet

- The Price Action Trading StrategyDocument11 pagesThe Price Action Trading StrategyVenu Gopal RaoNo ratings yet

- Buy Options Using Technical AnalysisDocument34 pagesBuy Options Using Technical AnalysisVenu Gopal RaoNo ratings yet

- 14 The Horses Are at The Gate and There They GoDocument3 pages14 The Horses Are at The Gate and There They GoVenu Gopal RaoNo ratings yet

- 15 How We View The Market Often Delivers Far Different PerspectivesDocument3 pages15 How We View The Market Often Delivers Far Different PerspectivesVenu Gopal RaoNo ratings yet

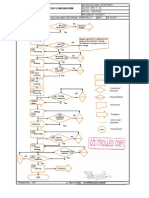

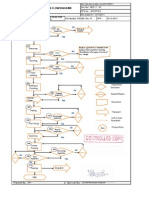

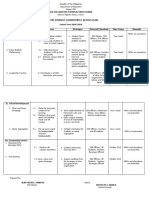

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument1 pageProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- Process Flow Diagram: Bangalore Nash Ind., (BIA)Document1 pageProcess Flow Diagram: Bangalore Nash Ind., (BIA)Venu Gopal RaoNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument1 pageProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- Socio-Emotional ReportDocument4 pagesSocio-Emotional Reportapi-392251988No ratings yet

- My Student Teaching JournalDocument9 pagesMy Student Teaching Journalapi-209380023No ratings yet

- Organic Chem Reactions Mindmap PDFDocument7 pagesOrganic Chem Reactions Mindmap PDFgsbabil100% (1)

- The Learner's Development and Environment: Field StudyDocument75 pagesThe Learner's Development and Environment: Field StudyFlorlyn Mae Sudio RemegioNo ratings yet

- Freedom Preparatory Academy Birmingham Campus ApplicationDocument91 pagesFreedom Preparatory Academy Birmingham Campus ApplicationTrisha Powell CrainNo ratings yet

- The End of TheoristsDocument24 pagesThe End of TheoristsHarumi FuentesNo ratings yet

- Cutting Classes Towards The Academic Performance of SeniorDocument10 pagesCutting Classes Towards The Academic Performance of SeniorJerwin SanchezNo ratings yet

- Production Engineering PDFDocument6 pagesProduction Engineering PDFRohan DobriyalNo ratings yet

- August 19-23 Lesson PlanDocument1 pageAugust 19-23 Lesson Planapi-282162606No ratings yet

- Supreme Student Government Action Plan: Old San Agustin National High SchoolDocument3 pagesSupreme Student Government Action Plan: Old San Agustin National High SchoolJean Mitzi MoretoNo ratings yet

- Schools in BritainDocument30 pagesSchools in Britaintatyana shevtsovaNo ratings yet

- Angelo Lesson Plan and Delivery Evaluation 2Document4 pagesAngelo Lesson Plan and Delivery Evaluation 2api-549738190No ratings yet

- (JPKM) Jurnal Pengabdian Kepada Masyarakat UNTAN: Editorial BoardDocument3 pages(JPKM) Jurnal Pengabdian Kepada Masyarakat UNTAN: Editorial BoardSoeharto SoehartoNo ratings yet

- AbrsmDocument130 pagesAbrsmCadenia Learning Centre100% (1)

- Manpower Handling TrainingDocument20 pagesManpower Handling TrainingbuddeyNo ratings yet

- A Brief History of English Language TeachingDocument4 pagesA Brief History of English Language Teachingİbrahim Çelik100% (21)

- Lifelong Learning Notes: From LIFELONG LEARNING AND HIGHER EDUCATION Christopher K Knapper, Arthur J CropleyDocument3 pagesLifelong Learning Notes: From LIFELONG LEARNING AND HIGHER EDUCATION Christopher K Knapper, Arthur J CropleyGe VergaNo ratings yet

- Conflict Management in SchoolDocument35 pagesConflict Management in SchoolCrimson PidlaoanNo ratings yet

- Verbal and Non Verbal CommnunicatioDocument5 pagesVerbal and Non Verbal Commnunicatioyasir_memon89_334319No ratings yet

- Best Distance Learning - SpychologyDocument22 pagesBest Distance Learning - Spychologykurios33No ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesEdsel CabacunganNo ratings yet

- ILAC Kiss PW Student Calendar Updated September 28th, 2020Document2 pagesILAC Kiss PW Student Calendar Updated September 28th, 2020Emilio JuárezNo ratings yet

- Challenges in The Philippine Basic Education SystemDocument16 pagesChallenges in The Philippine Basic Education SystemJovito R. Jobo, Jr93% (14)

- CSA 101. COURSE OutlineDocument6 pagesCSA 101. COURSE OutlineHanna LingatongNo ratings yet

- SNAP 2013 Results To Be Announced by Midnight of 9 JanuaryDocument1 pageSNAP 2013 Results To Be Announced by Midnight of 9 JanuaryMba UniversNo ratings yet

- Classroom Management: Some Times It Feels Like We Are Herding CatsDocument22 pagesClassroom Management: Some Times It Feels Like We Are Herding CatsAhmad SherNo ratings yet