Professional Documents

Culture Documents

1

Uploaded by

Venu Gopal RaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1

Uploaded by

Venu Gopal RaoCopyright:

Available Formats

Doc Rev.No & date.

:4 & 03/10/2011

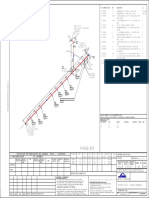

PROCESS FLOW DIAGRAM

Nash Ind., ( BIA ) Bangalore Part Name :

XPS GATE DRIVE AND SIGNAL PWA CARRIER

Doc.Ref : NPD- F - 03 PFD No. : XPS/PFD/2 Rev &date:01; 12/10/2011

Part Number :5165405 Rev -10

DATE :

10-12-2011

Start (RMCR1.5mm)

10 RM 20

Punching

Inspection

Retrun to Supplier

30 Deburing 40 50 Bending 60 70 Spot welding

CTQ Inspection

CTQ

Inspection

Replace a good Part,& Validated at the program time of product lunching ,Revalidation & Re-approval in case of any change

Start/End Process

80

Buffing or Finishing 90

Welding Inspection

Inspection/ Decission Rework/Reject

Mohan Plater

100

Document

Plating

110 120 IncommingI nspection

Transport Link to next Operation

Num

Pem Fixing

130

Process Num

Pem fix Inspection

Nash Eou

140

Screen Printing

150

Incomming Inspection

160

Final Inspection

170

Packing

Despatch

END

Prepared By : JPK Approved By : JAYAPRAKASH.KARUR

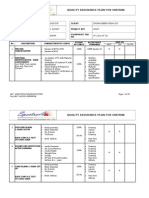

NASH INDUSTRIES CONTROL PLAN

Proto type Prelaunch Production Control Plan No. : GE-XPS-CP2-2011 Part No : 5165405DDW Part Name: XPS GATE DRIVE AND SIGNAL PWA CARRIER Latest Change level : Rev 5 Plant Customer Part / Process no. : : NASH INDUSTRIES GE-Medical System Process Name / Operation Description. Machine, Device, Jig, Tools for Mfg. Characteristics Spl. Process Char. Class Product / Process Specification/ Tolerance Methods Evaluation Measurement Techniques Size Sample Freq

Doc. Ref. : NPD - F - 05 Rev. No. : 01 Date : 03/10/2011

Date (Orig) : Customer Engg. Approval / Date. Customer Quality Approval / Date 30.09.2011 Page: 1 of 3

Key Contact Core Team Plant Approval / Date Other Approval / Date

H.Manjunath / Jayaprakash.Karur J.Manivannan,D.Chidambara,Girish,Achary,Gowrish,

Other Approval / Date

No.

Product

Control Method

Reaction Plan

10

RM Inspection

1 2 3 4 5 CNC Punching Machine (Strippit V20 LVD Make) Pnuematic Hand M/c withDisc Abrasive wheel (M/c Ingersoll Rand Make)

Weight Thickness Visual Inspection Chemical Composition Mechanical Properties Visual Inspection

20

Punching

As Per DC /P.O Steel CRCA 1.5mm 0.1 Must be free from rust,dents, scratches Grade : As per standard Free from Dent & Burr ,Rust Enshuare tool & Program

Weighing Machine Micrometer Visually Third party Iab Verify T.C Visual

100% 5 Nos 5 Nos Sample Supplier All Parts

Every Lot Every Lot Every Lot Every 6 Month Every Batch Every component

MIS and Raw Material Test Certification Lab Test Certificate Material Spec visual

Reject /Send Back to supplier Reject /Send Back to supplier Rework & Segregate

Free from all burr & sharp corners

30 Deburring

All micro joints to be removed Visual All component Must be free from scratch & dent on the part & profile Refernce to GE Dwg.No.5174504-Rev-5 , Validate CNC Program , Approve First 5 smaple with all CTQ dimesion & Blank size ,thikness, etc

Finishing Steel CRCA 1.5mm 0.1 CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ Micrometer

Every component

visual

Rework & Segregate

1 Thickness

2 Hole pitch 3 Hole pitch 4 Hole pitch 5 Hole pitch 6 Hole pitch 7 Hole pitch 8 Hole pitch 9 Hole pitch 10 Hole pitch 11 Hole pitch 12 Hole pitch 13 Hole pitch 14 Dimensions 15 Dimensions 16 Hole pitch 17 Hole pitch 18 Hole pitch 19 Dimensions 20 Dimensions 21 Dimensions 22 Dimensions 23 Dimensions 24 Dimensions 25 Dimensions 26 Dimensions 27 Dimensions 28 Dimensions 29 Dimensions 30 Dimensions 16 Dimensions 17 Dimensions 18 Diameter 19 DD CUTOUT 20 Diameter 21 Diameter 22 Diameter 23 Diameter

40

CTQ Inspection (Validated at the time of product launching) . Revalidation & Reapproval in case of any change ,maintain records of nested layout programme approval sheet

50

Bending Bending CTQ Prepared By : JPK

60

1 Thickness 2 Part direction & Other Details 1 Bending ht 2 Thickness AII DIMENSION'S ARE IN MM UNLESS OTHERWISE SPECIFIED CNC Amada RG35-M2

7.442+/-0.3mm 89.9+/-0.3mm 12.22+/-0.3mm 162.22+/-0.5mm 158.45+/-0.5mm 162.05+/-0.5mm 160.75+/-0.5mm 33.35+/-0.3mm CTQ 147.4+/-0.5mm CTQ 192.81+/-0.5mm CTQ 219.55+/-0.5mm CTQ 99.21+/-0.3mm CTQ 290.95+/-0.5mm PCTQ 172+/-0.5mm CTQ 8+/-0.3mm CTQ 95.5+/-0.3mm CTQ 67.26+/-0.3mm CTQ 52.7+/-0.3mm CTQ 85.7+/-0.3mm x2 CTQ 64.75+/-0.3mm CTQ 28.33+/-0.3mm CTQ 65.95+/-0.2mm CTQ 67.74+/-0.3mm CTQ 14.16+/-0.3mm CTQ 19.91+/-0.3mm CTQ 37.61+/-0.3mm CTQ 96.1+/-0.3mm CTQ 18.23+/-0.2mm CTQ 41.91+/-0.3mm 147+/-0.5mm 25+/-0.3mm 5,+/-0.3mm 6placess 10.5x 9.4 +/-0.3mm 1placess 2.5+/-0.3mm 4Placess 3+/-0.3mm 6placess 7.14+0.08mm 17 placess 6.4+0.08mm 2placess CRCA 1.5mm 0.1 Refer Dwg /WI PCTQ 17.52+/-0.3mm

Steel CRCA 1.5mm 0.1

Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge vernier caliper Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge 5 Nos Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Pin Gauge Pin Gauge Pin Gauge Pin Gauge Pin Gauge Pin Gauge All Parts Micrometer All Parts Visual Vernier caliper 5nos All Parts Micrometer Approved By : JAYAPRAKASH.KARUR

Every Setup

Inprocess

Reject / Rework

Every component Every component Every set up Every component

Inprocess Visual Visual Inprocess

Reject / Rework Reject / Rework Reject / Rework

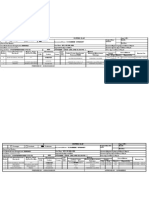

NASH INDUSTRIES CONTROL PLAN

Proto type Part No : 5165405DDW Part Name: XPS COLD PLATE MTG BRKT Latest Change level : Rev 5 Plant Customer Part / Process no. : : NASH INDUSTRIES GE-Medical System Process Name / Operation Description. Machine, Device, Jig, Tools for Mfg. Characteristics Spl. Process Char. Class Product / Process Specification/ Tolerance Methods Evaluation Measurement Techniques Size Sample Freq Prelaunch Production Control Plan No. : GE-XPS-CP2-2011

Doc. Ref. : NPD - F - 05 Rev. No. : 01 Date : 03/10/2011

Date (Orig) : Customer Engg. Approval / Date. Customer Quality Approval / Date 30.09.2011 Page: 2 of 3

Key Contact Core Team Plant Approval / Date Other Approval / Date

H.Manjunath / Jayaprakash.Karur J.Manivannan,D.Chidambara,Girish,Achary,Gowrish,

Other Approval / Date

No.

Product

Control Method

Reaction Plan

Spot Welding 70 80 Buffing/Sandring Inspection 90

100 Plating

Spot welding M/c

1 Distance 2 Distance 3 1 Finishing 1 Nuget test

Finishing Parameter

Buffing M/c & Disc

7.7mm 0.25 54.51mm 0.25 Ref. Spot welding Parameter & WI GEXPS/1.5THK-2012 Remove the welding spater,Scratch Enshre the Req. strength

Ht Gauge

Ht Gauge

5nos 5nos

Every set up Every set up

Visual Visual

Reject / Rework Reject / Rework

As per GE-standards

All Parts Test pecimen All Parts

Every set up Every set up Every component Everycomponent Every Batch Everycomponent Everycomponent

Visual

Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework

2

Plating process

Ensure welding Defect,Spaters, Burn Mark, Dent

Zinc plate Fe/Zn 5c 1A Coting thickness

Visual

As per GE-standards Coat gauge Visual Visual

Visual As per GE-standards Inspection Visual Visual

Finishing

All component 5 Sample All component All component

110

Plating Incomming Inpection

Plating thickness

Ensure Palting defect , Scratch,Dent

As per GE-Standard-F-010 Per 46221814 Ref. Dwg for Printing Details Ref.XPS Screen WI-6405 Ensure Printing direction as shown in the direction & Fonts Size Ensure PrintingPostion & Print Quality as shown in the direction

SO M4-12-17nos PFHV-M4-0-2nos

Reject / Rework

120

Screen Printing Screen Printing Inspection

Screen Printing M/c

Ref. Dwg 5165405DDW Direction /Fonts Position

As per GE-standards As per GE-standards

All component All component 5 Nos 5 nos 5 nos 5 nos All sample All components All components

Everycomponent Everycomponent

As per GE-standards As per GE-standards

130

Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework Reject / Rework

140

Pem fixing

Hydropenumatic M/c

1 2 1 2

PEM NUT Ensure the Pem Qty & Pem type Ensure the Pem Qty & Pem type

Pull test Torque test Plug gauge & Visual Plug gauge & Visual

Per/her

Every set up

Setup approval Inprocess Setup approval Inprocess Visual

Inprocess

Refer Doc: PRD-SOP-ASSY-03

150

Pem Inspection

CTQ SO M4-12-17nos CTQ PFHV-M4-0-2nos Ensure crackes, burrs & Crimping, after Visual pem fixing Must free from scratch , Dent & Burr Ensure Part has to be as per customer dwg & above CTQ achive status./WI

CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ Steel CRCA 1.5mm 0.1

Per/her

Every set up

Every component

Every component

Finishing

Visual Visual

Micrometer

2 Check all the CTQ Dimensions 1 Thickness

2 Hole pitch

Every component

Inprocess

3 Hole pitch

4 Hole pitch 5 Hole pitch 6 Hole pitch 7 Hole pitch 8 Hole pitch 9 Hole pitch 10 Hole pitch 11 Hole pitch 12 Hole pitch 13 Hole pitch 14 Dimensions 15 Dimensions 16 Hole pitch

160

Final inspection

7.442+/-0.3mm 89.9+/-0.3mm 12.22+/-0.3mm 162.22+/-0.5mm 158.45+/-0.5mm 162.05+/-0.5mm 160.75+/-0.5mm 33.35+/-0.3mm CTQ 147.4+/-0.5mm CTQ 192.81+/-0.5mm CTQ 219.55+/-0.5mm CTQ 99.21+/-0.3mm CTQ 290.95+/-0.5mm PCTQ 172+/-0.5mm CTQ 8+/-0.3mm

Prepared By : JPK

AII DIMENSION'S ARE IN MM UNLESS OTHERWISE SPECIFIED

Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge 5 Nos Vernier caliper Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Approved By : JAYAPRAKASH.KARUR

Every Setup

Inprocess

Reject /Segregate /Rework

NASH INDUSTRIES CONTROL PLAN

Proto type Part No : 5165405DDW Part Name: XPS COLD PLATE MTG BRKT Latest Change level : Rev 5 Plant Customer Part / Process no. : : NASH INDUSTRIES GE-Medical System Process Name / Operation Description. Machine, Device, Jig, Tools for Mfg. Characteristics Spl. Process Char. Class Product / Process Specification/ Tolerance Methods Evaluation Measurement Techniques Size Sample Freq Prelaunch Production Control Plan No. : GE-XPS-CP2-2011

Doc. Ref. : NPD - F - 05 Rev. No. : 01 Date : 03/10/2011

Date (Orig) : Customer Engg. Approval / Date. Customer Quality Approval / Date 30.09.2011 Page: 3 of 3

Key Contact Core Team Plant Approval / Date Other Approval / Date

H.Manjunath / Jayaprakash.Karur J.Manivannan,D.Chidambara,Girish,Achary,Gowrish,

Other Approval / Date

No.

Product

Control Method

Reaction Plan

17 Hole pitch

18 Hole pitch 19 Dimensions 20 Dimensions 21 Dimensions 22 Dimensions 23 Dimensions 24 Dimensions 25 Dimensions 26 Dimensions 27 Dimensions 28 Dimensions 29 Dimensions 30 Dimensions Bending CTQ

160

Final inspection Pem CTQ Plating process

1 Bending ht 1 Ensure the Pem Qty & Pem type 2 Ensure the Pem Qty & Pem type 1 Ensure plating defect

3 4

CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ CTQ PCTQ CTQ CTQ

95.5+/-0.3mm 67.26+/-0.3mm 52.7+/-0.3mm 85.7+/-0.3mm x2 64.75+/-0.3mm 28.33+/-0.3mm 65.95+/-0.2mm 67.74+/-0.3mm 14.16+/-0.3mm 19.91+/-0.3mm 37.61+/-0.3mm 96.1+/-0.3mm 18.23+/-0.2mm 41.91+/-0.3mm 17.52+/-0.3mm

SO M4-12-17nos PFHV-M4-0-2nos Plating Defects,Rust,Scratch

Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Ht Gauge Vernier caliper Plug gauge & Visual Plug gauge & Visual Visual

5 nos

Every set up

In process

Reject /Segregate /Rework

5nos 5 nos 5 nos 5 nos All components All components

Every set up

Visual

Per/her

Every set up Every set up

Setup approval Inprocess Inprocess

Inprocess Inprocess

Reject/ rework Reject / Rework Reject / Rework Reject / Segregate Reject / Rework Reject / Rework

Check the DWG Note: Label placement

Refer Dwg Note for specila requirments Visual & Parts Class As shown in the dwg Visual Ensure the label content as per the GEHC-Doc 46-274914 (Part no/rev/Manufacturing date/Suplier Visual code/country of origin)

Example: (516405 Rev:9 30/09/2011 680323 Made in INDIA)

Every component Every component

All components

Everycomponent

Inprocess

Reject / Rework

1 Packing

170

Packing & Despatch

2 Despatch

As per customer requirement with Packing slip/ Tagged Invoice/DC,

Visual

100%

Every Lot

Dc/ Invoice

Recount & Repack

Prepared By : JPK

AII DIMENSION'S ARE IN MM UNLESS OTHERWISE SPECIFIED

Visual Approved By : JAYAPRAKASH.KARUR

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- M/S Process Flow DiagramDocument6 pagesM/S Process Flow DiagramUttam SainiNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- Cost Sheet For NPLDocument10 pagesCost Sheet For NPLSachin MishraNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Control Plan: E.Vargas (Manufacture/Production) C.Ugalde (Maintenance) G.Florian (Quality)Document6 pagesControl Plan: E.Vargas (Manufacture/Production) C.Ugalde (Maintenance) G.Florian (Quality)Cesar MedinaNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Qap Rap PDFDocument1 pageQap Rap PDFtrushalpanchalNo ratings yet

- 24.11.2015 EGI High Spot Dent IPPCDocument6 pages24.11.2015 EGI High Spot Dent IPPCrahul srivastavaNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Document10 pagesQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- CSCS Rods & BracketsDocument66 pagesCSCS Rods & BracketsshuklahouseNo ratings yet

- Inspection and Test Report Rev.0Document18 pagesInspection and Test Report Rev.0Dadaso Baburao JamdarNo ratings yet

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellNo ratings yet

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Document4 pagesTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNo ratings yet

- Belinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1Document10 pagesBelinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1ahsun habibNo ratings yet

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Document10 pages(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189No ratings yet

- Rodete PeltonDocument104 pagesRodete PeltonmanuelhuertaNo ratings yet

- INDEX of Part Numbers or Sub - Assembly Numbers Required To Make The Assembly Noted AboveDocument6 pagesINDEX of Part Numbers or Sub - Assembly Numbers Required To Make The Assembly Noted AboveLokesh NarasimhaiahNo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Belinda-MAQ-250-25BA-C Computer Control Safety Valve Test Bench R.0Document10 pagesBelinda-MAQ-250-25BA-C Computer Control Safety Valve Test Bench R.0ahsun habibNo ratings yet

- Capacity VerificationDocument5 pagesCapacity VerificationHarsha MP100% (2)

- EQT ChecklistDocument5 pagesEQT Checklistvijayachidu100% (1)

- FCC - Test Report: Report Number: Date of Issue: July 01, 2015Document35 pagesFCC - Test Report: Report Number: Date of Issue: July 01, 2015MMendes SilvaNo ratings yet

- Vendor Data Requirement List - VDRLDocument18 pagesVendor Data Requirement List - VDRLduongnh100% (3)

- Samples Inspection ReportDocument5 pagesSamples Inspection ReportArun GuptaNo ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Ppap For Neel MetalDocument40 pagesPpap For Neel MetalshuklahouseNo ratings yet

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- RLV SB Process SheetDocument155 pagesRLV SB Process SheetSudhakar PalletiNo ratings yet

- Hydrotechnik Full CatalogueDocument128 pagesHydrotechnik Full CatalogueEysakaylovasNo ratings yet

- Test Report: SGS-CSTC Standards Technical Services Co., Ltd. Shenzhen BranchDocument44 pagesTest Report: SGS-CSTC Standards Technical Services Co., Ltd. Shenzhen BranchPica-Pau AutoPartsNo ratings yet

- List of Documents For Plates & TubularsDocument6 pagesList of Documents For Plates & Tubularssudeep dsouzaNo ratings yet

- Control Valve DatasheetDocument2 pagesControl Valve DatasheetRahul DevaNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Consortium (Ioic) Inspection and Test Plan/Quality Control PlanDocument3 pagesConsortium (Ioic) Inspection and Test Plan/Quality Control PlanRushabh KapadiaNo ratings yet

- Ppap Spacer TubeDocument37 pagesPpap Spacer TubeSeenivasagam SeenuNo ratings yet

- 3208 - Coriolis Meter - Rev 1Document7 pages3208 - Coriolis Meter - Rev 1scribd_thakurNo ratings yet

- SWCDocument56 pagesSWCNageswar RaoNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- Part Submission Warrant: Supplier Information and DeclarationDocument32 pagesPart Submission Warrant: Supplier Information and DeclarationMadhavan Ram100% (1)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- HVAC TBA With AttachmentDocument48 pagesHVAC TBA With AttachmentumeshNo ratings yet

- Pilot Run Report 0702Document23 pagesPilot Run Report 0702Greg MackeyNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- FMEADocument2 pagesFMEAHeidi Dedication Pader NicolasNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Santu BabaDocument2 pagesSantu Babaamveryhot0950% (2)

- Calculation of Screw JackDocument20 pagesCalculation of Screw JackVenu Gopal RaoNo ratings yet

- 086 - Hadee ForgingsDocument2 pages086 - Hadee ForgingsVenu Gopal RaoNo ratings yet

- 085 - Hadee ForgingsDocument6 pages085 - Hadee ForgingsVenu Gopal RaoNo ratings yet

- Investment BooksDocument2 pagesInvestment BooksRohan GhoshNo ratings yet

- Bill DSC14 MagnaDocument1 pageBill DSC14 MagnaVenu Gopal RaoNo ratings yet

- Dasha Maha Devi For PlanetsDocument1 pageDasha Maha Devi For PlanetsVenu GopalNo ratings yet

- Vsa FinalDocument60 pagesVsa FinalVenu Gopal RaoNo ratings yet

- 2 Period RSI ReloadedDocument2 pages2 Period RSI ReloadedAnam Tawhid100% (2)

- 15 How We View The Market Often Delivers Far Different PerspectivesDocument3 pages15 How We View The Market Often Delivers Far Different PerspectivesVenu Gopal RaoNo ratings yet

- The Price Action Trading StrategyDocument11 pagesThe Price Action Trading StrategyVenu Gopal RaoNo ratings yet

- Buy Options Using Technical AnalysisDocument34 pagesBuy Options Using Technical AnalysisVenu Gopal RaoNo ratings yet

- Trend TradingDocument1 pageTrend Tradingamveryhot09100% (1)

- 14 The Horses Are at The Gate and There They GoDocument3 pages14 The Horses Are at The Gate and There They GoVenu Gopal RaoNo ratings yet

- 200 Low PE Ratio Stocks in India With LTP, Market Cap. & More - Samco PDFDocument4 pages200 Low PE Ratio Stocks in India With LTP, Market Cap. & More - Samco PDFVenu Gopal RaoNo ratings yet

- Incredible Charts - Hull Moving Average PDFDocument5 pagesIncredible Charts - Hull Moving Average PDFVenu Gopal RaoNo ratings yet

- 3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFDocument65 pages3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFVenu Gopal RaoNo ratings yet

- What Is Bull Spread - Bull Call Spread Strategy - Samco PDFDocument5 pagesWhat Is Bull Spread - Bull Call Spread Strategy - Samco PDFVenu Gopal RaoNo ratings yet

- What Is PE Ratio - PE Ratio Formula, Interpretation & Analysis - Samco PDFDocument10 pagesWhat Is PE Ratio - PE Ratio Formula, Interpretation & Analysis - Samco PDFVenu Gopal RaoNo ratings yet

- What Is Securities Transaction Tax (STT) - Learn More About STT With SAMCO Securities PDFDocument5 pagesWhat Is Securities Transaction Tax (STT) - Learn More About STT With SAMCO Securities PDFVenu Gopal RaoNo ratings yet

- What Is PE Ratio - PE Ratio Formula, Interpretation & Analysis - Samco PDFDocument10 pagesWhat Is PE Ratio - PE Ratio Formula, Interpretation & Analysis - Samco PDFVenu Gopal RaoNo ratings yet

- Forecasting Market Direction With Put - Call Ratios - Investopedia PDFDocument5 pagesForecasting Market Direction With Put - Call Ratios - Investopedia PDFVenu Gopal RaoNo ratings yet

- 200 Low PE Ratio Stocks in India With LTP, Market Cap. & More - Samco PDFDocument4 pages200 Low PE Ratio Stocks in India With LTP, Market Cap. & More - Samco PDFVenu Gopal RaoNo ratings yet

- 3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFDocument65 pages3 SMA (Simple Moving Average) Formulas and Trading Strategies - TradingSim PDFVenu Gopal Rao100% (2)

- Forecasting Market Direction With Put - Call Ratios - Investopedia PDFDocument5 pagesForecasting Market Direction With Put - Call Ratios - Investopedia PDFVenu Gopal RaoNo ratings yet

- Data Feeder Steps PDFDocument1 pageData Feeder Steps PDFVenu Gopal RaoNo ratings yet

- Intraday TradeDocument4 pagesIntraday TradeVenu Gopal RaoNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- Process Flow Diagram: Bangalore Nash Ind., (BIA)Document1 pageProcess Flow Diagram: Bangalore Nash Ind., (BIA)Venu Gopal RaoNo ratings yet