Professional Documents

Culture Documents

Din 2559-73 PDF

Din 2559-73 PDF

Uploaded by

hasan_6764896160 ratings0% found this document useful (0 votes)

1K views12 pagesOriginal Title

DIN 2559-73.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views12 pagesDin 2559-73 PDF

Din 2559-73 PDF

Uploaded by

hasan_676489616Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

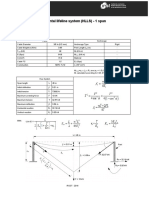

UMRAN PAGE 82

29/05/2002 17:29 ° 98-2122494343

DEUTSCHE NORMEN

ON wwe 6245799;081 1 621.791.052.4

Edge Preparation for Velding *

Directions regards

Fusion Welding of Suet doiiee ts

5 Tealinereninwe, MGT ES RT

‘3 ScbReleschweiGea voa Stumpfatoden an Stabirobren

35

§2

£2

fs

i

é

3b Limite for design and not toler-

indicated repress

for fabrication, purpos

‘They spply to the welding, from one side only, of butt Joints in ateel

fubea; they aay also be applied as appropriate to oinilar Kinds of work,

The edge foras specified derived from the genarel edge forme

secording to DIN 8551,

These directions apply to

to the following conddtion:

joapletely throughewelded cross-sections subject

Eidlez seteds

gecprdiag ve DIN 9915 Sheet 1, DIN 8554 Sheet 4, DIN S558 Steet 1 (Preo

LEninacy"staccard)) Bay a57y duet ant ethene Wein ase sol tta eCPaRT

Bateriale and seidiog procénore epacttiea™

peiab:

Welding from cne aie by hand.

‘¥oldSng. post tions:

OL ay Be ne ke fo Ugecenting to DIN 1512 Shoes 9}, ta p

welaing Sn a'rixed position (afcuout Docatiag pipec)

Degteesion:

Designation ef an edge form with identifiedtion number 21;

+ Eage fora 21 DIN 2959

TURK STANDARDLASt EusTiTUst

KUTOPHAN ES}

Gontinued on page 2

Explacations on page 3

Aleincarhocl der Norm jah VaPlagOMOM, Bern JO urd Kalo DIN 2559 Bl. 1 ane]. Preieer 4

Dtarentone

Heat] ptt Joenentnation| spate”) ge forme B | oun [ony septs] BME | wratag proceenne 7

Heetteal nines ana $

desre oot | ater | &

= b « h dager | derere 8

i T_ 7 8

1 fees [ee l| AEA SSI - | - [ows] - | - fsaen | — 2 *

5 3

= 7

- 40 te 60 8

a eww fees, | \/ Time | - fows| - | - a

for a

. Ea Esc, BR:

[ A oy 8

& 3

7 asd 3

40 te 60 .

zz feos | tee, a] | | ome beter | — i

60 for i

eee :

E, 5G, G3).

2° 4

3 fate tz | RP ade - B | Os beer | — 3

SG

+ fom [SEE | LY

oe

“ Vv

5) tan dtnsvetons apecieied apply be the tacked sondition..

12) ta te case of statenttterctects oniy vith the perchenve’a agrecsents

; :

:

io! | —

1) yor editions ayaboLe, see DIM 1932.

|

-

£8 300d

DIN 2559 Sheet 1 Page 3

Enlanationt

‘Tale reviaton taken account of changes temlting free the

the July 1962 inane,

Ta the Atecuantons care was taken to ensure that the proposed edge forma have general validity. For this

Fieasn edgy fore variahtons datonded nly fer apecitte procennee vere dlerequrted. Zs They ofthe cowpre-

Renaive atope sought io thin vay it has oaly beva peasible to specify sumerdcel values for inclused angle,

(een, gap depth and flank depth within vide taite. Where 1¢ appease acesuary for a specific application

erde"se, apectal works standards abevld be Green up ¢iviag the dentpuer detasied partioulare ehilet

ohaerving the directions laid dovn in this Standard,

The designation of the edge forax should provide the taferantion vithout aay possibility of error. Vere

agdgeesers the deoigantion aay be tngaented by farther onecitie Qetetia eeiating, #nt,, t0 the thcinded

‘Tua edge fore vith tne {dentitioation auaber 22 bas been adopted in response te a mugnestion fron the pipe

construction Aacuatry an order to saclude a type of edge fore in comon use for welded joints to mest

euacting quality raquirewea!

DIN 2539 Shoot 2 (at present stilt edzcutating an draft) sonteine edge forms for circunformtial welds

vith ppecifind thleran 8 demarcation purponen, and for ‘onatruction invely=

Ang rerritic ates] tubes.

yrelopaent whi

tana taken place compared with

tanita enay ba veprouuced witha te pris perooenin ol DWI Dentchas intl Ios hsirumg #¥ faut

Shure of out ie German langunge oneal Shawls be conaelivd as tha aniboatave eat

eo par oft

20:

17:23 -98-2122494349 UMRAN

PAGE 85

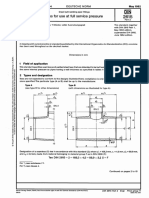

woe 621.791,082.4.021:621.643.2-4623-094.14 _ DEUTSCHE NORM February 1984

Edge preparation for welding

Matching of inside diameter for

circumferential welds on seamless pipes *

‘Schwelsunahtverbereitung: Anpassen der Innendurchmesse: fir Rundnainte ‘Supersedes Aprit 1976 edition

‘an nahtiosen Rohren °

In keeping with current practice in standards published by the International Orga!

a.comme has been Used throughout as the decimal marker. ~

tion for Standardization ISO), } '

Dimensions in mm

1 Scope Note, Although the wall thickness is given by the letter s

, in mandards deling withthe supply of pipes, this

‘This standard applies to butt joints welded on one side, , i

with groove shapes a1 shown in DIN 2569 Part I, on ean wes the ate which has bran tro

seamless steel pipes with dimensions as specified in duced In standards relating to welding,

DIN 2448 or DIN 2917 and permitsibie devi See table 4 for dimensions of matching diameters.

specified in DIN 17 17, The standard is used when con- See table 1 for permissible deviations for dy.

ip

Table 1, Permissible deviations for dy

hollow bodies, a8 appropriate. dy Permissiple deviation

¢ trom different suppliers by welding.

up t6 120

2 Dimensions ‘over 120 up to 320

‘The matching diameter dy and the pipe wall thickness ¢

are shown ia figures 1 and 2. over 320

Table 2. Formulas for calculating d, for pipes conforming to DIN 2448

5 Nominal watt Formula’) for ealculating Code number

Pipe outelie diameter thickness ‘the matching tor

ds 1 dy formula

\

i

w= 05-181 i |

|

upto 66

‘over 66up to 100 upto 4 ty 0.9925 4, —1,8¢

‘over 100 up to 130 UPTO Ay

geld, = 1ar

over 130 up to 320 over O.11d,

upto 66 over 4 ty 4-05 ~1,827

over 66up to 100 over 4 ly 0.90284, — 1,821

over 100 up to 130 over 4p ogeid, = 1.821

‘over 130 up to 320 upto 011d, j osatd, - 1.780

over 320 delowo.0a dy osed, 1,781

‘over 320 over 008d, sd, 7 1.8e

In the shove formulae

tis the nominal wall thickness and

ty it the standard wall thickness

1} The formulse for dy are beted on the permissible devistions in diameter and wall thickness specified in

DIN17 178, May 1878 edition, (see also Exaianatory notes, pars.e)). The values of dp in table 4 are

vet Gt 1 wan male millimatcas Tha same ng for the values of dp to be

caleulated {rom table 3. Es ime runing ahawld BE EMH P

Cominued on pages 2 10 4

nearcr TOW NONmeR) DIN 2559 Part 2 Engl, Price group §

‘Stet No, 0108,

23/05/2002

x

“an 2850 Part 2

roove inde and their dimansions are specitied in

DIN 2850 Part 1. -

iMustrations ate examples of groove shapes,

‘igure 1. DIN 2589-21 groove shape,

with the edges matched

ure 2. DIN 2659-4 groove shape,

with the edges matched

/ 3i¢3, Formula for calculating d, for piper

conforming to DIN 2817

Formute 1)

for calculating the

matching diamater

dy

Pipe inside

Designation

IN 2558-21 groove shape (21), with the edges

‘chet. a pine of dy = 127 (127) and (= 88 with

table 4

Sroove shape DIN 2559 — 21 — 127-110

Jhaping process

‘The shape can be produced by cutting oF non:

‘Wg manufacturing processes, The worked internal

snall have & smooth transition without projections

1m average siirface, roughness R, not exceeding

m

4.2. Working of the internal faces can be dispensed with

if the existing Inside diarneter exceeds d,,

4.3 If differant matching diameters have been det

‘mined for the two faces to be connected, e.g. wien con-

ecting pipes with different nominal diameters, a connec:

tion of both faces with the larger matching diameter is

Possible provided that 2 further calculation shows that

‘the remaining wall thickness is within the permissible

liens,

4.4 A misalignment of the edges ¢ which has to be

agreed {ts permitted in accordance with the

in DIN 8563 Part 3,

4.5 If the conditions given in audelauses 4.3 and 4.4 are.

‘ot complied with, other manufacturing processes, such

‘85 tapering, surfacing or widening shall be used Instead,

t= is the calculated wall thickness

4) Inside diametar matchad/actual dimension of inside

diameter not matched,

‘|

BI Actuat‘dimensions of inside diameter not matched,

Figure 3, “Examples showing the permissible

‘misalignment af the edges ¢

Ay See page 7.

2) Seq subelause 4.2,

c

PAGE @1

UMRAN

902122494349

2802 18:05

DIN 2559Part2 Page 3

4

s za

ae

\

eo

Cot Tio

f

@

fone wae

Sree ere eee Lee eee oben eT

Tern

Teen

73/05/2002 18:05 — 98-2122494349 Pace a2

7 5

DIN 2859 Part?

otendards referred to

DIN 2448 ‘Seamiess steel pipés, dimensions, masses per unit length e

DIN 2589 Part 1 Edge preparation fr welding; guidelines regerding groove shapet; fusion welding of butt joints in

steel pes

DIN. 2917 ‘Seamless steel pipes for superheated steam pipelines and headers

DIN 8563 Part 3 Quality assurance of welding operations; fusion-welded joints in steel, requirements, evaluation

roups :

DIN17175 ‘tamless pipes made of heat resistant steels; technical delivery conditions

Previous edition

DIN 2559 Part 2: 04.76

Amendments

“The following envernavais have beer ma in wamnparlagn whl che Apt! 1870 edition.

3) The content has been revised.

b) The standacd hat been aligned with the dimensional deviations far seamless pipes specified in DIN 17176.

©) The table specifying matching diameters has been completed.

xplanatory notes

‘The permitsible dimensional deviations specified in the naw ecitlon of DIN 17 175 {May 1979 edition) made t

necessary 10 list the values cbtained for dy in a table, as wall at the formulae for the matching diameter dp @

b) {tis intended to extend the scope to Include welded pipes conforming to DIN 2468 (dalivery conditions specified i

DIN 1626 and DIN 17 177) in the fuwure.

The dimensions and permissible dimansional deviations specified in these standards give spetial formulae for calculating

‘the matching diameters d and will be daalt with in a future part of DIN 2859, if necessary,

cc) The standard shalt engure correct preparation of welds when welding pipes trom different suppliers without expensive

remachining. -

‘This standard is » dimensional standard for matehing diameter dp, in which some manufacturing processes are given as

examples, by which the tequired dimensions can be produced. It does not give instructions for processing,

Gasis of formulae for calculating dp.

Formulae 1 to 9 are produced from the basic formula dy = deinimum = 2X tminimum.

, Addition to calculated wall thicknest fy to taka the parr

evintions in wall thickness specified in

a

fe minus

DIN17 17S into account. i

i

ie

33

te 7

ae LLL A 3

Formula 10 Z ws 2

dpm d,x1.01 - we 6

takes the wall thickness of thoxe pines with nominal inside diameters into account, whieh have to be made larger

beceute of waakening {holes). For seamiets pipes conforming tO DIN 2917 without « weakening coefficient for calcu:

Iating the wall thickriess being given, the matching diameter di shall be selacted taking ito account the caleutated wall

thickness (2).

For seamlese pipes with permissible dimensional deviations for diameters and wall thicknesses as specified in DIN 1629

Part 3°), January 1961 edition, and DIN 17 178, May 1979 edition, the matching diameters dp are co be determined

by the following forrnul * 7

for d.<130: dy where dis the pipe outside diameter and

for d, > 130< 320: dpm te isthe mean wall thickness (aominal wall thickness).

ford>320: dpm 0.99d,—1.701,

For reamiess header pipes or headers with the tolerances for minimum wall thickness specified in TRD 105, Agrit

1973 {withdrawn and replaced by TRD 102 and TRD 203, April 1960), the matching diameters dp are to be deter

mined by the follawing formulae:

tor dyz 76.1: dy=d,~ tq where di. is the nominal inside diameter and

ford, 270: dy 3.0td tm is the minimum wall thickness (naminal wall thickness).

fi

International Patent Classification

821: 37-08 B23K

5) Draft Stanriaret QIN 1629 “Unalloved steel seamiecs pies mesting special requirements; technical delivery enaritinns’”

ig available as the planned revised edition,

5/2002 18:05

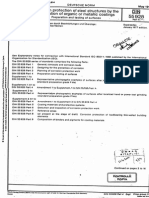

nee UDG 621.701052.4021-621,849.2-462.2-00414

(© No pt of iis sland roay bo regrouvtod mah Ue pris permission of FN Dowlscies hsb ir Nor,

reas of doubt the Gormat-lrnquay ergnal should be conse a3 the authortatre fot

99-2122494349

DEUTSCHE NORM

Weld preparation

Inside diameters of steel pipes required for circumferential

butt welding

‘Schweinantvorbereitung; Anpassen dar Innendurchmesser fir Fundnahte an geschweldten Rohren

In keeping

comma nas

current practice in stangards published by

used throughout as the decimal marker

Been

the International Organization for Standardization (180).'a

Dimensions in mm

1 Scope and field of application

‘This standard species tho inside diameters which welded

‘tee! pipas In complance with DIN 2488 and DIN 17177

fare required 10 have in order 10 be Dutt welded on one

side, having groove shane a8 soecified in DIN 2850 Part 1

4nd measures to obiain such cameras, I is normally used

for weiding pipes from ditferent suppliers, and may be

‘applied by analogy to ether cylindrical hollow bodias.

2 Dimensions

‘The requited inside ciameter (dimension d,: ct. igure 1) is

10 be calculated using the formulae numbered 1 rough 13

~ to i8 atleast equal

10 the design wall

thickness. 1,

Figure 1, Recuited inside clamete,d,

Table 2

Formutae for catculating ¢, for cold formed pipes

in tables 2 to 4, which are based on the folowing batic

‘equation;

4,7 ton” 2% rn -

For certain combinations of pipe outsige diameter (a

‘sion d,) and nominal wall thickness (dimension 7), the cal-

‘culation of d, may have Deen based on either of two difer-

ent formulae’ (ct. table 2). In such cases, the values spec:

‘ed in table $ shall nonetheless bé complied wih.

Requited Inside diameters, which are subject to the lit

deviations spectiad in table 1, are given in tables 5 107

Examples of d, as a function of

two diferent dove shapes are ilustrated in igures 2

and 3.

Table 1_Limlt deviations of dy

Limit deviations

Pipe outcido diamotoe 4, | Naminal wall thickuwss, +

Formula")

used to calculate d,

Up 1038 [__vate2s

4,-025-2 (/-025)

Up to 38 Over 2.9 up 10 88

d,-025~2 (1-035)

3010 38 Up 10 18

44-03 2 (10.25)

1410 29.

+ 09925 d= 2 (1-025)

424 10 87 231029

0994 d=2 (1-025)

t

|

1

424 to 1837 i

424 10 1143 l

Over 29 up 10 10

(0904 d,-2 (10.98)

70102220 | Over 28upt0 10

(0.9825 d,~2 (1-05) 7

outside diameter and wail thickness. The values specified

L_milimetes.

1) The values used in ihe formulae are based on the tolerances specified in the May 1979 elton of DIN 17177 for vipe

Tabla. Formulae for calculating d, for hot reduced pipes

for dp in tables § to 7 have been rounded.to hall or whole

fama

Pipe outside diameter, d, | Nominal wail thickness, ¢

s02t0 635, 14 to 10

Formula)

used to calculate dy

4y-08-181 t

Raa

ee

70 10 138.7 1601

09925 4-186

{1824 to 1937

For"), $e table 2.

zon

‘Bavih Verleg GmbH. Berlin. hen fe esclunive rane 0) sale for German Standards (DINeNoemen),

099 dy-15 1 0

Continued on pages 2 to 6

DIN 2559 Pan Enal Price croup @

5/2002 18:85

98-2122494349

- DIN 2589 Part

sable 4. Formulae for ealouating d for hot reduced pipes, with at the pipe end subject to closer tolerances

Pine outsice cama. d, | Nomina wall eickness.¢ | a44/™le) ay | Forma no

12405 1400 88 i4=028-187 7

483 10 869 1410 10 04-187 2 ?

For") sea tba 2

The shape and dimensions of grooves shall be in com-

pilance with DIN 2559 Part 1,

The groove shapes itustrated below are intended to serve

a8 examples.

Figure 2. DIN 2869-21 groove, following matching of pipe

ends

Wall Wickes,

Figure 3. DIN 2589-4 groove, following matching of pipe

encs

3 Designation

Designation of a DIN 2589-21 groove (21) for a pipe witn

49n Cutside dlameter, d,, of 127 mm and a wall thickness,

404 &8 mm, with d, equal to 109 mm (cl. table 5): -

+ Groove DIN 2559-21 -127- 109 ~

4 Matching of pipe ends

41 The pipe ends may be formed by means of a non-

Cutting procass or by machining. Machined internal faces,

‘shall be smooth and have an average surface roughness,

R,, not exceeding 100 ym,

4.2 Tha internal faces need not be machined where the

actual insidg diameter is equal 10 o greater than d,, nor

where the misalignment of the pipe end (dimension «

oes not exceed the permissible misaligamant (of. sub-

clause 44),

4.3 Where ditlerent values of «i, hava been specified for

the pipes to be connected (@.g."in the case of different

wal thicknesses), it shall be ensured that the larger value

Of dp may be used for both ends, provided the size of the

rasidual wall thicknass so permis,

4.4 ° Misalignment of the welded pipe edds (aimension

‘shall be permitted, wh uch is in accordance with the

assessment groups specified in DIN 8563 Part3 (cf,

figure 4).

48 Where the requirements specified in subclausas 43,

48nd 44 are not met, other measures may be taken to prev

Bare the pipe ends for welding (e.g. tapering, expanding

fr surfacing the pipe ends, or fitting of a sultable vansi«

tion piece), care being taken to ensure that the materials

and processes used are in keaping with the recognized

rules of the art.

Dimension ¢, represabs the design wall thickness,

4} Inside olamatar (,) nas been matched (lat) /

lnsideciamater(d) ha not Been matched (git)

T

) Inside diameters (d,) hava not been matched

Figure 4 Examples of misalignment (dimension «)

‘subclause 42,

6

PAGE 05

UNRAN

7/05/2082 18:05

«

99-2122494349,

: ape tes pet

+E fee ee

ate ee f

t te coh ete

She pee ee

= a Stete

ates ae =

te epee Ce eae

= Fa re we | Fae [eee [oe = =i me

= hehe = =

ie Se

t cs

|

| fs 32 l= #43131) 9h)

lolol efale eal alos

| 5] | sl 5| 3,3

of wo} x28] mf) 312) 8

a} 8

TeTeTe Tele] we,

eases coma essen

Fed pou ea amare ape FOOL

5

#

r = =

: EE ean

= = ebm ae

7 Ff pee a

i : psa wafer 3

eae eee =

= = wate oe

a = == ee cs

= = = = =

= 7 on =

7 ate ore tae

= = he Shee

» = =e ete =|

g at ate Stet

a 8 = a pepe

§ : z= a fe

aL 2 = =

i < Sher

‘ = he

|

Tene aay

“Teles fel Pe eT pele Peep] alee

ene eso ee Benen ee eee a

ry 18205

‘coma wes 000

‘unmos onoe oka pm edd Ww Presa erp mL RCD OPN PEDO) ORE

23/95/2002 18:05 — 90-2122494349

“ye6 DIN2889 Parts

Standards referred to

DIN 2458 ‘Welded steel pines and tubes: dimensions and mass r)

IN 2589 Part 1 Weld preparation: guidelines for grosve shapes: fusion wekled but joints on alee! mbes

DIN 8863 Pert 3 Guat assurance of welding operations: ganetal principles .

DIN 17177 Electric pressure-welded steel tubes with elevated temperature properties: technical defivery conditions

'

International Patent Classification

823K 9/235,

823K 33/00

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Horizontal Life Line CalculationDocument1 pageHorizontal Life Line Calculationhasan_676489616100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Method of Statement Piping Fab. ErectionDocument22 pagesMethod of Statement Piping Fab. Erectionhasan_676489616100% (1)

- DIN 2615-2 Ing.Document15 pagesDIN 2615-2 Ing.hasan_676489616No ratings yet

- Din 2614Document11 pagesDin 2614hasan_676489616No ratings yet

- Acid PipingDocument1 pageAcid Pipinghasan_676489616No ratings yet

- Delayed PWHTDocument4 pagesDelayed PWHThasan_676489616No ratings yet

- LNG Tank Dismantling MS RevCDocument14 pagesLNG Tank Dismantling MS RevChasan_676489616100% (1)

- ITP For Piping WorksDocument91 pagesITP For Piping Workshasan_676489616100% (1)

- ITP For Piping WorksDocument91 pagesITP For Piping Workshasan_676489616100% (1)

- Cross Cut TestDocument1 pageCross Cut Testhasan_676489616No ratings yet

- Steel Grades ComparisonDocument14 pagesSteel Grades Comparisonhasan_676489616No ratings yet

- E SN883Document2 pagesE SN883hasan_676489616100% (1)

- OSHA - 29CFR - Construction StandardsDocument22 pagesOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- E SN834Document3 pagesE SN834hasan_676489616No ratings yet

- ASME B16.47 Series B FlangeDocument4 pagesASME B16.47 Series B Flange41h189No ratings yet

- Din 2559-73 PDFDocument12 pagesDin 2559-73 PDFhasan_676489616No ratings yet

- Din 55928Document16 pagesDin 55928hasan_676489616No ratings yet

- Din 2605-1 eDocument6 pagesDin 2605-1 ehasan_676489616No ratings yet

- Din 2461-66Document7 pagesDin 2461-66hasan_676489616No ratings yet

- DIN1592 Schwer PDFDocument1 pageDIN1592 Schwer PDFhasan_676489616No ratings yet

- Din en Iso 4014Document16 pagesDin en Iso 4014hasan_676489616100% (7)