Professional Documents

Culture Documents

Corrosion TCR

Corrosion TCR

Uploaded by

Ranferi DomínguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion TCR

Corrosion TCR

Uploaded by

Ranferi DomínguezCopyright:

Available Formats

Corrosion Testing

TCR Engineering Services

A Material Testing Laboratory in India

TCR Engineering Services Pvt. Ltd.

35 Pragati Industrial Estate,

N. M Joshi Marg, Lower Parel,

Mumbai - 400 011, India

Tel : 23073390, 23092347, 23097921

Tel : 23097923, 23091938, 23053930

Fax :+ 91-22-23080197

E-Mail: sales@tcreng.com

Website: www.tcreng.com

TCR Engineering Navi Mumbai

Plot No. EL-182, MIDC-TTC,

Electronic Zone, Behind Nelco,

Mhape, Navi Mumbai-400 705

Maharashtra, India

Tel: 27612324, 27631508

Tel: 27610921-22-23

Tel: 30936355, 56160805, 56168100

Tel: +91-(22)-56168200

Fax: +91-(22)-27612044

E-Mail: navimumbai@tcreng.com

Corrosion Testing

Table of Contents

TABLE OF CONTENTS .................................................................................... 2

CORROSION TESTING IN INDIA ................................................................... 3

PITTING CORROSION TEST AS PER ASTM G48 METHOD B SPECIFICATION .. 3

SALT SPRAY (NEUTRAL / FOG), ASTM B117 ................................................. 3

CORROSION TEST AS PER ASTM G 35 SPECIFICATION ................................. 3

INTER GRANULAR CORROSION TEST (IGC) PER ASTM A-262 ....................... 4

HYDROGEN-INDUCED CRACKING (HIC) TEST, NACE TM0284 ....................... 5

SULFIDE STRESS CORROSION CRACKING (SSCC), NACE TM0177 ................. 6

ABOUT TCR ENGINEERING SERVICES ........................................................... 7

ISO 17025 ACCREDITED LABORATORY IN INDIA ......................................... 7

MATERIAL TESTING LABORATORY SERVICES ............................................... 8

LOCATIONS .................................................................................................. 9

August 08

Page 2 of 9

Corrosion Testing

Corrosion Testing in India

TCR Engineering Services (TCR), a NABL and ISO 17025 accredited independent

material testing laboratory in Mumbai, India undertakes a wide range of corrosion

and stress corrosion test per ASTM, NACE or as per an individual clients

requirements.

Senior staff members with specific industry expertise cover a variety of corrosion

problems that are encountered in industries such as oil and gas production, oil and

gas transmission, energy conversion systems, and nuclear power systems. A wide

variety of corrosion related tests can be undertaken at TCR Engineering Services in

India to determine weight loss corrosion, intergranular attack, pitting corrosion,

corrosion fatigue, stress corrosion cracking, sulfide stress cracking, and hydrogeninduced cracking.

TCR offers comprehensive material testing of corrosion problems, including:

Pitting Corrosion test as per ASTM G48 Specification

Salt Spray Test

Corrosion test as per ASTM G35 specification

Inter granular Corrosion Test (IGC) per ASTM A-262 Practice A B C D E & F

Hydrogen-Induced Cracking Test (HIC) as per NACE TM 0284

Sulfide Stress Corrosion Cracking Test (SSCC) as per NACE TM 0177

Chloride Stress Corrosion Test as per ASTM G36 Specification

Ammonia Vapor Test

Corrosion test as per ASTM A761 Specification

Pitting Corrosion test as per ASTM G48 Method B Specification

This Procedure is used to assist in the selection of test methods that can be used in

the identification and examination of pits and in the evaluation of pitting corrosion to

determine the extent of its effect. ASTM G48 Method B, Ferric Chloride Test involves

exposing a specimen to a highly oxidizing acid chloride environment. The importance

of this evaluation is to be able to determine the extent of pitting, either in a service

application where it is necessary to predict the remaining life in a metal structure, or

in laboratory test programs that are used to select the most pitting-resistant

materials for service.

Salt Spray (Neutral / Fog), ASTM B117

This is the most commonly used salt spray for testing of inorganic and organic

coatings, especially where such tests are used for material or product specifications.

Salt Spray testing is a tool for evaluation the uniformity of thickness and degree of

porosity of metallic and nonmetallic protective coatings. A number of samples can be

tested at once depending upon their size.

Corrosion test as per ASTM G 35 specification

The polythionic acid (sulfurous acid and hydrogen sulfide) environment provides a

way of evaluating the resistance of stainless steels and related alloys to inter

granular stress corrosion cracking. This practice can be applied to wrought products,

castings, weld metal of stainless steels or other materials to be used in environments

containing sulfur or sulfides.

August 08

Page 3 of 9

Corrosion Testing

Inter Granular Corrosion Test (IGC) per ASTM A-262

At TCR Engineering Services, several methods exist for the testing of intergranular

corrosion. To conduct these tests, we carefully choose a method which is suitable for

the steel grade and grain boundary composition to be tested.

The following tests are carried out by TCR Engineering Services in India as per the

ASTM A262 specification.

Oxalic Acid Test, ASTM A262, Practice A (Oxalic Acid Etch)

The oxalic acid etch test is a rapid method of screening those specimens of certain

stainless steel grades which are essentially free of susceptibility to inter granular

attack associated with chromium carbide participates. The test is used for acceptance

but not rejection of material.

Ferric Sulfate - Sulfuric Acid, ASTM A262 - Practice B (Streicher Test)

This test is based on weight loss determinations and provides a quantitative measure

of the relative performance of the material evaluated. The procedure includes

subjecting a specimen to a 24 to 120 hour boil in ferric sulfate - 50% sulfuric acid.

This procedure measures the susceptibility of stainless steels and nickel alloys to

inter granular attack associated with the precipitation of chromium carbides at grain

boundaries.

Nitric Acid, ASTM A262, Practice C, (Huey Test)

The specimens are boiled for five periods, each of 48 hours, in a 65 per cent solution

of nitric acid. The corrosion rate during each boiling period is calculated from the

decrease in the weight of the specimens. Properly interpreted, the results can reveal

whether or not the steel has been heat-treated in the correct manner. The customer

must specify the maximum permissible corrosion rate and, in applicable cases, data

on sensibilizing heat treatment.

The Huey test environment is strongly oxidizing, and, is only used as a check on

whether the material has been correctly heat treated. This test is suitable for the

detection of chromium depleted regions as well as intermetallic precipitations, like

sigma phase, in the material. The Huey test is also used for materials that come into

contact with strongly oxidising agents, e.g. nitric acid. This procedure may also be

used to check the effectiveness of stabilizing elements and of reductions in carbon

content in reducing susceptibility to inter granular attack in chromium-nickel

stainless steels.

Copper - Copper Sulfate - 16% sulfuric acid, ASTM A262 - Practice E

(Strauss Test)

This procedure is conducted to determine the susceptibility of austenitic stainless

steel to inter granular attack associated with the precipitation of chromium-rich

carbides. Once the specimen has been subjected to the solution boil, it is bent

through 180 and over a diameter equal to the thickness of the specimen being bent.

This test is based on a visual examination of the bent specimen.

Copper - Copper Sulfate - 50% sulfuric acid, ASTM A262 - Practice F

This test is based on weight loss determination which provides a quantitative

measure of the relative performance of the material evaluated. It measures the

susceptibility of "as received" stainless steels to inter granular attack.

August 08

Page 4 of 9

Corrosion Testing

Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

TCR Engineering Services, corrosion testing laboratory in Mumbai (India) performs

HIC test to evaluate the resistance of pipeline and pressure vessel plate steels to

Hydrogen Inducted Cracking caused by hydrogen absorption from aqueous sulfide

corrosion. An unstressed test specimen is exposed to a solution at ambient

temperature and pressure and after a specified time, the test specimen is removed

and evaluated.

Specimen Size

To conduct the HIC test, TCR Engineering Services requires a set of three test bars

taken from specified locations around the circumference of a pipe ring, or at one end

and mid-width of the plate, with the longitudinal axis of each bar parallel to the

principal rolling direction of the plate. The bars should be 100 mm long x 20 mm

wide, with the full wall thickness of the sample up to a maximum of 30 mm. For wall

thickness greater than 30 mm, three or more overlapping bars are taken in order to

provide full coverage of the thickness.

For 6-5/8" OD tubulars and larger, a 6" long ring is requested. For smaller

diameters, a 15" long sample is requested.

For plate samples, a 6" x 8" piece is requested with the longer dimension

representing the principal rolling direction of the material.

TCR Engineering Services can perform sample machining upon request.

NACE TM0284 Test Solution

NACE TM0284 specifies either Solution A or Solution B. Solution A is acidified brine.

Solution B is simulated seawater prepared in accordance with ASTM D1141.52. In

either case, H2S is bubbled through the solution constantly throughout the test

period. NACE TM0284 specifies test duration of 96 hours.

Detailed Report

TCR Engineering issues a detailed written report upon completion of each test. Each

report includes a description of the test sample that was received, the test procedure

that was used, and the pH values of the test solution before exposure and after the

exposure. The test bars are cut into sections and examined under a microscope for

hydrogen-induced cracks. The dimensions of any such cracks are recorded and used

to compute the values in percentage for Crack Length Ratio (CLR), Crack Thickness

Ratio (CTR) and Crack Sensitivity Ratio (CSR).

Charges

The material testing charges at TCR Engineering for Hydrogen Induced Cracking

(HIC) Test as per NACE TM 0284 are as follows:

Material less than 80mm Thickness / diameter

US $450.00

Material greater than 80mm Thickness / diameter US $600.00.

Our corrosion testing laboratory in Mumbai, India requires 2 weeks to complete the

HIC test.

August 08

Page 5 of 9

Corrosion Testing

Sulfide Stress Corrosion Cracking (SSCC), NACE TM0177

Sulfide stress corrosion cracking (SSCC) is a form of hydrogen embrittlement

cracking which occurs when a susceptible material is exposed to a corrosive

environment containing water and H2S at a critical level of applied or residual tensile

stress. TCR Engineering Services in Mumbai, India conducts the NACE TM0177 tests

including Methods A and B for SSCC test, at our corrosion testing laboratory.

NACE TM0177 Test Details

NACE TM0177 tests at TCR includes the following methods:

Method A: Tensile Test (Proof Rings)

Method B: Bent Beam Test (3 or 4 Point Bends)

NACE TM0177 specifies Solution A (acidified), Solution B (acidified and buffered) and

Solution C (for martensitic stainless steel). Solution A is used in Methods A unless

the properties of Solution B or C are specified. In any case, H2S is bubbled through

the solution constantly throughout the test period.

Testing is performed in NACE solutions A and/or B, saturated with H2S at 24 and

90 Celsius. Stressed samples are exposed to sour environment for a pre-determined

time, after which they are removed and analyzed for crack detection. NACE TM0177

specifies test duration of 30 days (720 hours) for Method A or B test.

Specimen Size

The SSCC tests at TCR Engineering in India are performed routinely for customers

using tensile and bent beam specimens.

A 6-inch length of material is requested for the machining of SSCC specimens. The

minimum material thickness for standard Method A specimen is 0.350". Materials

with a thickness less than 0.350" can be used in Method B testing. TCR Engineering

Services can perform sample machining upon request.

Detailed Report

TCR Engineering issues a written report for each test, or group of tests performed.

This report includes a description of the test sample that was received and of the test

procedure that was used, the pH values of the test solution before and after the

exposure, the results of the hardness test performed on the test specimen and a

statement declaring the results of each test.

Charges

The charges at TCR Engineering for Sulfide Stress Corrosion Cracking (SSCC) Test as

per NACE TM0177 are as follows:

24 Celsius & ATM Pressure is

US $550.00

90 Celsius & 16 Bar pressure is

US $2800.00

TCR Engineering requires 6 weeks to complete the SSCC test.

August 08

Page 6 of 9

Corrosion Testing

About TCR Engineering Services

Founded in 1973, TCR Engineering Services (TCR) is India's most reputed and

established, NABL and ISO 17025 accredited independent material testing

laboratory. The core services TCR provides include Mechanical Testing, Chemical

Analysis, Positive Material identification (PMI), Non Destructive Testing,

Metallography, Corrosion Testing, Failure Analysis, Raw Material Inspection,

Metallurgical Product evaluation, Engineering Research and Consultancy.

TCR has pioneered in introducing latest analytical facilities and has upgraded the

same every decade. TCR has state-of-the art testing facilities for testing of

Engineering Goods, Ferrous and Non-Ferrous Metals, Non-Metallic Materials such as

Polymers, Ceramics, Glass, etc.

More than 1000 Quality driven clients (in India and a select few globally) in

Aerospace, Automotive, Oil Refineries, Petrochemical plants, Chemical Processing,

Defense, Nuclear Power and Capital Goods manufacturing trust TCR to handle their

Material Testing and Research & Development requirements.

Engineers, Chemists, Metallurgists & Technicians, at TCR, have the qualifications, the

education and the experience to meet rigorous standards in the testing field, whether

serving the Private and Public Sector, Government or the Military.

Customer Service Representatives, at TCR, provide clients with up-to-the-minute

information on the status of your sample through our in-house laboratory

automation software. The need for responsiveness is something understood by

everyone in the company. We have improved turnaround time without sacrificing

quality by operating 12 hours a day in the lab, 16 hours a day in the machine shop.

TCR laboratories are located in Lower Parel, Mumbai and Electronic Zone, Navi

Mumbai with a sample collection office in the Mumbai Metal market. TCR Advanced

Services, a TCR Engineering affiliate company, has its laboratory in Baroda.

Engineering professionals travel across India to conduct on-site material testing.

International clients are served by a sales office in Washington DC, USA.

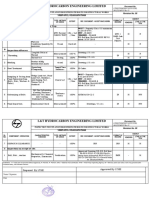

ISO 17025 Accredited Laboratory in India

TCR Engineering Services is a Bureau of Indian Standards and NABL accredited

laboratory. NABL approval is from Department of Science and Technology,

Government of India. NABL provides laboratory accreditation services to laboratories

that are performing tests / calibrations in accordance with ISO 17025.

TCR is one of the select few test houses, in India, to be on the approved list of such

organization as Bharat Heavy Electrical Ltd., Nuclear Power Corporation of India Ltd.

(NPCIL), Larsen & Toubro Ltd. (L&T), Engineers India Ltd. (EIL), Toyo Engineering

India Ltd., Oil & Natural Gas Commission (ONGC), Bhabha Atomic Research Centre

(BARC), Vikram Sarabhai Space Centre (VSSC), Dept. of Defense, DGS&D, Indian

Railways, Mumbai Municipal Corporation, Dept. of Telecommunications, Electronic

Corporation of India Ltd and others.

TCR is also approved by international recognition bodies such as American Bureau of

Shipping (USA), Bureau Veritas (France), Lloyds Register of Shipping (UK), DetNorske Veritas (Norway), SGS (India) Ltd. and others.

August 08

Page 7 of 9

Corrosion Testing

Material Testing Laboratory Services

TCR Engineering Services' ability to provide value to our metal testing customers is

based on organizing our talents into a focused set of technological capabilities. This

gives us the unique ability to apply appropriate combinations of capabilities and

expertise to provide multi-disciplinary solutions for our clients.

We have several testing services, but, no matter which discipline we use, one thing

is certain. When you send a sample to TCR, you can have confidence in the results,

because you are working with a company that has a reputation for being meticulous.

The list of services offered by TCR includes:

Mechanical and Physical Testing

Comprehensive range of Mechanical Testing with a dedicated machine shop to assist

in sample preparation. Capabilities include: Tensile, Impact, Weldability, Bend,

Compression, Flaring/Flattening, Hardness, Dynamic Loading, Drop Weight, Proof

Load, Fasteners, Hydraulic/Pneumatic, Component Testing, and more.

Chemical Analysis

State of the art Chemical Analysis laboratory allows our expert chemists to analyze

ferrous and non-ferrous metals, ceramics, glass, refractories, mineral and ferro

alloys in PPB or PPM level or in percentage. Our capabilities include: Wet Chemistry,

Optical Emission Spectroscopy (OES), Inductively Coupled Plasma (ICP)

Spectrometer, Automatic Combustion based Carbon and Sulfur determination, Glow

Discharge spectrometer for (GDS) chemical depth profiling, and more.

Positive Material Identification (PMI)

TCR Engineering's Positive Material Identification service is fast becoming an integral

part of process safety management in the petroleum refining, petrochemical and

electric power generation industries in India, Middle-East and Asia-Pacific. Our

capabilities include: Portable Optical Emission Spectrometer and a number of

Portable X-Ray Florescence (XRF) Spectrometers.

Failure Analysis and Metallography Testing

Our facilities include Optical Microscope with Image Analysis system, Micro Hardness

Tester, In-situ Metallography Kits, Stress Analyzer, Dilatometer, and Electronic

Polishing and Etching system. TCR can procure on-hire basis, a scanning electron

microscope and an elemental analysis by EDAX.

Corrosion Testing

TCR performs a wide range of Corrosion and Stress Corrosion Tests as part of the

AST, NACE or client supplied specifications. Senior staff members are available to

help and advise on corrosion problems or materials selection in laboratory or on-site

inspection. Routine tests undertaken to evaluate the corrosion resistance of materials

to environmental corrosion, pitting corrosion, resistance of materials to stress

corrosion and inter-granular attack, including HIC, and SSCC tests.

Specialized Non Destructive Testing (NDT) Services

Radiography Testing, Ultrasonic Flaw detection, Magnetic Particle and Liquid Dye

Penetrant Testing, Portable Hardness detection, Ultrasonic Thickness Gauging survey

and Raw Material Inspection. Residual Life Assessment (RLA) of Boilers and pressure

vessels.

August 08

Page 8 of 9

Corrosion Testing

Locations

We welcome service and technical inquiry, from simple questions to more involved interpretations of

codes and specifications. We are located at:

TCR Engineering Services Pvt. Ltd.

35 Pragati Industrial Estate,

N. M Joshi Marg, Lower Parel,

Mumbai - 400 011, India

Tel : 23073390, 23092347, 23097921

Tel : 23097923, 23091938, 23053930

Fax :+ 91-22-23080197

E-Mail: sales@tcreng.com

Website: www.tcreng.com

TCR Engineering Services

Plot No. EL-182, MIDC-TTC, Electronic

Zone, Behind Nelco, Mhape, Navi Mumbai-400 710

Maharashtra, India

Tel: 27610921/22/23, 27612324, 27631508

Tel: 32936355, 65160805, 65168100/8200

Fax: +91-22-27612044

24 hours Cellular Phone: +91-9323397295

E-Mail: navimumbai@tcreng.com

(USA, China, Asia-Pacific, and Europe)

TCR World Inc., USA

14625 Baltimore Ave, Box 109

Laurel, MD 20707, USA

Tel: +1-240-505-0739

E-Mail: usa@tcreng.com

TCR Advanced Engineering, Baroda

36/2/9, First Floor, Abhishek Complex

G.I.D.C., Makarpura

Vadodara - 390 010, Gujrat, India

Tel: +91-(0265)- 2657233, 2643024

Fax: +91-(0265)- 2634375

E-Mail: baroda@tcreng.com

Website: www.tcradvanced.com

TCR Arabia

C/o GAS Arabian Services

P.O.Box 3422, King Saud Street

Opp. Juffali Showroom,

Dammam 31471, Saudi Arabia

Tel: +966-5049-97683

E-Mail: saudi@tcreng.com

Website: www.tcr-arabia.com

TCR Kuwait

Fahaheel-64023

Ahmadi, Kuwait

Tel: +965-5072765

E-Mail: kuwait@tcreng.com

TCR ENGINEERING MALAYSIA

2D-03-06 Mutiara Idaman,

Solok Tengku Jelutong,

George Town Pulau Pinang

11600 Malaysia.

Tel/Fax : +604 - 2817477

Mobile : +6016 - 445 8283

: malaysia@tcreng.com

Mumbai Metal Market

TCR Engineering Services

2/10, Kikabhai Mansion,

7 Kika Street,

Mumbai - 400 004

Maharashtra, India

Tel : +91-22-23428642, 56363267

Sample collection centers in India:

KHB Engineering Services

C/o. K. K. Engg. Works

Shed No. 10 of M. P. L. U. N.,

Behind Allahabad Bank, 'A' Sector, Industrial

Area,

Govindpura, Bhopal, Madhya Pradesh, India

Tel : +91-(0755)-2586531, 5261264

Fax : (+91)-(0755)-5261297

August 08

Navi Mumbai Metal Market

Shop No. 44, Mahesh Shopping,

Sector 15 CBD Belapur (East), Konkanbhavan,

Navi Mumbai 400 614,Maharashtra, India

Tel : +91-(022)-27577650, 27576185,

Cell: +91-9223235114

Page 9 of 9

You might also like

- Method Statment Installation LifelineDocument3 pagesMethod Statment Installation LifelineFirdaus Zainal100% (4)

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Pipework Support Design User Guide PDFDocument74 pagesPipework Support Design User Guide PDFshanmugamNo ratings yet

- Fdocuments - in 23368109 04 Wis5 Mechanicaltesting 2006Document114 pagesFdocuments - in 23368109 04 Wis5 Mechanicaltesting 2006kaelcorbettNo ratings yet

- Astm A265 (1999)Document5 pagesAstm A265 (1999)P SHANKAR BABUNo ratings yet

- Stp1151-Eb 25437Document241 pagesStp1151-Eb 25437CharlesWilliamRichardNo ratings yet

- Astm B423Document4 pagesAstm B423pritam sarkarNo ratings yet

- Is.4163.2004 Inclusion RatingDocument43 pagesIs.4163.2004 Inclusion Ratingmass3444100% (1)

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- Astm A 385 PDFDocument9 pagesAstm A 385 PDFNizarHamrouniNo ratings yet

- BS 1881 - 201 (1986)Document29 pagesBS 1881 - 201 (1986)K4100% (1)

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveNo ratings yet

- Difference Between Cost Accounting and Financial AccountingDocument3 pagesDifference Between Cost Accounting and Financial AccountingabdulrehmanNo ratings yet

- HIC Failure Investigation ReportDocument25 pagesHIC Failure Investigation Reportravindra_jivaniNo ratings yet

- ASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesRoger SchvepperNo ratings yet

- Polymers and Its TypesDocument9 pagesPolymers and Its TypesZarnain khanNo ratings yet

- NDT ACC CriteriaDocument6 pagesNDT ACC Criteriavsnaiduqc100% (1)

- Heavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForDocument4 pagesHeavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForAvinash SilimkarNo ratings yet

- Phased Array Lab Exercises REV 1.0Document19 pagesPhased Array Lab Exercises REV 1.0Marcus AntoniusNo ratings yet

- CTOD Testing: Job Knowledge 76Document3 pagesCTOD Testing: Job Knowledge 76kevin herryNo ratings yet

- WPS PQR-06Document9 pagesWPS PQR-06Ranjan KumarNo ratings yet

- Rmo No. 20-90 PDFDocument2 pagesRmo No. 20-90 PDFMary Rose LiNo ratings yet

- Chloride Diffusion Coefficient CalculationDocument1 pageChloride Diffusion Coefficient CalculationYash DhabaliaNo ratings yet

- Intergranular Corrosion Test As Per ASTM A262Document1 pageIntergranular Corrosion Test As Per ASTM A262Muhammad RidwanNo ratings yet

- Hornbeck Offshore Services IncDocument107 pagesHornbeck Offshore Services IncmdshoppNo ratings yet

- NDT Method SummaryDocument3 pagesNDT Method SummaryNguyen Anh TungNo ratings yet

- As 4120-1994 Code of TenderingDocument7 pagesAs 4120-1994 Code of TenderingSAI Global - APAC0% (5)

- General Requirements For Accreditation of ISO 17025Document25 pagesGeneral Requirements For Accreditation of ISO 17025youni_2005No ratings yet

- Oblicon Lyceum ReviewerDocument86 pagesOblicon Lyceum ReviewerTasneem C BalindongNo ratings yet

- Thames Trader EngineDocument1 pageThames Trader EngineIanNo ratings yet

- 3455 1971 Reff2020Document17 pages3455 1971 Reff2020Ashish DubeyNo ratings yet

- Corrosion Testing of Welds - Review Methods - Pettersson2007Document28 pagesCorrosion Testing of Welds - Review Methods - Pettersson2007MatnSambuNo ratings yet

- Is123 1996Document11 pagesIs123 1996Raji Satheesh100% (1)

- BS 1881 Part 201 86Document26 pagesBS 1881 Part 201 86YohanesGilbert100% (1)

- ASTM Practice For IGC TestingDocument38 pagesASTM Practice For IGC TestingNest Necture100% (6)

- BS en 10204Document14 pagesBS en 10204Kalyan Chakravathi A G100% (1)

- ASTM G150 99 (04) Critical Pitting Temperature of SS PDFDocument13 pagesASTM G150 99 (04) Critical Pitting Temperature of SS PDFRohil Julaniya100% (1)

- Is 1030 1998 PDFDocument8 pagesIs 1030 1998 PDFRitesh AnandNo ratings yet

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Non Destructive Evaluation PDFDocument22 pagesNon Destructive Evaluation PDFLungeloNo ratings yet

- Is 6925 1973Document13 pagesIs 6925 1973VijayKatariaNo ratings yet

- Is 2328 1995 Flattening TestingDocument5 pagesIs 2328 1995 Flattening Testinghhr2412No ratings yet

- Crystalline Durability Admixture PDFDocument1 pageCrystalline Durability Admixture PDFSean HarshaNo ratings yet

- CUTE-103 - Ultrasonic Testing Machine India - Canopus InstrumentsDocument7 pagesCUTE-103 - Ultrasonic Testing Machine India - Canopus InstrumentscanopusinstrumentsNo ratings yet

- Draft Indian Standard: Bureau of Indian StandardsDocument9 pagesDraft Indian Standard: Bureau of Indian StandardsPavan KumarNo ratings yet

- Precipitation Hardening in Metals - T GladmanDocument7 pagesPrecipitation Hardening in Metals - T GladmanSouryatanu SahaNo ratings yet

- Concrete Admixtures: Specification For Accelerating Admixtures, Retarding Admixtures and Water Reducing AdmixturesDocument21 pagesConcrete Admixtures: Specification For Accelerating Admixtures, Retarding Admixtures and Water Reducing AdmixtureskushanNo ratings yet

- Is 9417 1989Document15 pagesIs 9417 1989Ganesh RajaNo ratings yet

- Microindentation Hardness of Materials: Standard Test Method ForDocument28 pagesMicroindentation Hardness of Materials: Standard Test Method ForSarvesh MishraNo ratings yet

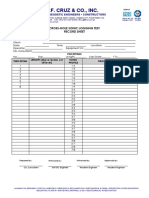

- Record Sheet For Sonic Logging TestDocument1 pageRecord Sheet For Sonic Logging Testkhraieric16No ratings yet

- Koc-P-002 Part 1 Rev 3Document29 pagesKoc-P-002 Part 1 Rev 3Hari KrishnanNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationVoyants Solution pvt. ltd.No ratings yet

- Is 14858 2000 PDFDocument12 pagesIs 14858 2000 PDFHimanku BoraNo ratings yet

- Nondestructive Testing Standards More Commonly Used ASTM NDT Standards or Guidelines Standards ExplanationsDocument2 pagesNondestructive Testing Standards More Commonly Used ASTM NDT Standards or Guidelines Standards Explanationsenquiry info100% (1)

- Is 1586Document22 pagesIs 1586RangaNo ratings yet

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- The New Era in Corrosion TestingDocument4 pagesThe New Era in Corrosion Testingnikopigni2No ratings yet

- As 4506-2005 Metal Finishing - Thermoset Powder CoatingsDocument7 pagesAs 4506-2005 Metal Finishing - Thermoset Powder CoatingsSAI Global - APAC100% (1)

- Is-5382-1998 Specification-for-Rubber-Sealing-Rings-for-Gas-Mains-Water-Mains-and-Sewage PDFDocument23 pagesIs-5382-1998 Specification-for-Rubber-Sealing-Rings-for-Gas-Mains-Water-Mains-and-Sewage PDFDeven Patle0% (1)

- Is 2250 1981 PDFDocument36 pagesIs 2250 1981 PDFChockalingamNo ratings yet

- Indian Standard (Second Revision) : Method For Bend TestDocument12 pagesIndian Standard (Second Revision) : Method For Bend Testhhr2412No ratings yet

- HK CS2 - 2012Document50 pagesHK CS2 - 2012bobbyccwNo ratings yet

- TGN-PE-01 Hardness Testing of Welds PDFDocument6 pagesTGN-PE-01 Hardness Testing of Welds PDFTeoTyJayNo ratings yet

- A780 PDFDocument3 pagesA780 PDFMauricio Adame100% (1)

- Ferroxyl Test For Iron ContaminationDocument9 pagesFerroxyl Test For Iron ContaminationteokalNo ratings yet

- Intergranular Corrosion Test As Per ASTM A262Document1 pageIntergranular Corrosion Test As Per ASTM A262Muhammad RidwanNo ratings yet

- Bao Cao KQ Phun Muoi Tk2Document6 pagesBao Cao KQ Phun Muoi Tk2Đình Khoa PhanNo ratings yet

- IGC TestDocument2 pagesIGC TestHiren PanchalNo ratings yet

- Development and Production of Helical-Two-Step (HTS) Pipes: Grades Up To Api X70 For Sour Service ApplicationDocument10 pagesDevelopment and Production of Helical-Two-Step (HTS) Pipes: Grades Up To Api X70 For Sour Service ApplicationMarcelo Varejão CasarinNo ratings yet

- Vendor QualificationDocument2 pagesVendor QualificationDharmesh PatelNo ratings yet

- MS (Integer Programming)Document103 pagesMS (Integer Programming)Graham AkerNo ratings yet

- EC Certificate: Full Quality Assurance SystemDocument3 pagesEC Certificate: Full Quality Assurance SystemДелян МилчевNo ratings yet

- Annexure B.2Document1 pageAnnexure B.2Mayapur Communication100% (1)

- Mms-IV Sem FormateDocument7 pagesMms-IV Sem FormateVAISHNAVI SALGAONKARNo ratings yet

- Uas Bahasa Inggris SMK 2017Document13 pagesUas Bahasa Inggris SMK 2017Istye AnandraNo ratings yet

- Laravel FW-PHP s02Document15 pagesLaravel FW-PHP s02Ngo Quoc Khanh (Aptech HCM)No ratings yet

- Column User Guide For Agilent Reversed Phase ColumnDocument84 pagesColumn User Guide For Agilent Reversed Phase ColumnNanank DwiNo ratings yet

- 31st AFSAP (Brochure)Document4 pages31st AFSAP (Brochure)Hanna SasilNo ratings yet

- Maulana Azad National Institute of Technology, Bhopal - Wikipedia, The Free EncyclopediaDocument5 pagesMaulana Azad National Institute of Technology, Bhopal - Wikipedia, The Free EncyclopediarajyamgarNo ratings yet

- Liquid Penetrant TestingDocument44 pagesLiquid Penetrant TestingLeon Heart FCNo ratings yet

- Z80 - Basic Concepts - Answers of ExercisesDocument5 pagesZ80 - Basic Concepts - Answers of ExercisesHaddouNo ratings yet

- Strategic Management AssignmentDocument3 pagesStrategic Management Assignmenthzgl250% (1)

- New Application - eTMFile Instructions From IPODocument3 pagesNew Application - eTMFile Instructions From IPOmarkinfinitysportNo ratings yet

- 1000 State Bank of PakistanDocument4 pages1000 State Bank of PakistanRJNo ratings yet

- SDCS0218 Rev00Document24 pagesSDCS0218 Rev00coolamruth.arunNo ratings yet

- 2015 Grade 8 English HL TestDocument24 pages2015 Grade 8 English HL TestJoie Jeanette LombotoNo ratings yet

- Notice - RFP ImmigrationDocument4 pagesNotice - RFP ImmigrationVeenoyNo ratings yet

- Ps-Iso 16143 Part 1Document51 pagesPs-Iso 16143 Part 1Shaikh KamaluddinNo ratings yet

- qmc122 Mold Magnetic Clamping enDocument8 pagesqmc122 Mold Magnetic Clamping enAlper SakalsizNo ratings yet

- Peak Response of Non-Linear Oscillators Under Stationary White NoiseDocument29 pagesPeak Response of Non-Linear Oscillators Under Stationary White NoiseMaximum ChoiceNo ratings yet