Professional Documents

Culture Documents

WPQ WELDER QUALIFICATION 16MM PLATE SMAW

Uploaded by

niket0Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQ WELDER QUALIFICATION 16MM PLATE SMAW

Uploaded by

niket0Copyright:

Available Formats

QW-484A WELDER PROFORMANCE QUALIFICATION (WPQ)

Date:

Welders Name :

Mr. Ravi Jivaji Sargara

Identification of WPS followed:

TEWPS-102

Specification of base metal(s):

C 45

Identification No:

WEL SMAW-01

Test Description

Y

Test

Production weld

coupon

Thickness:

Welding process :

Testing Conditions and Qualification Limits

Welding Variables (QW-350)

Actual Values

: SMAW

16mm

Range Qualified

SMAW

Type (ie. manual, semi-auto) used :

Backing (metal, weld metal, double-welded, etc.) :

:

:

Manual

Without Backing

Plate Pipe (enter diameter if pipe or tube) :

Plate: 16 mm

Base metal P or S Number to P or S Number :

Filler metal or electrode specification(s) (SFA) (info. only) :

:

:

P1

5.1-SMAW

Manual

With/withoutBacking

only

Plate all thk. & Pipe: > 73

mm OD

P1 TO P11

5.1-SMAW

Filler metal or electrode classification(s) (info. only) :

Filler metal F-Number(s) :

:

:

E 7018

F4

F-4,3,2,1

Consumable insert (GTAW or PAW) :

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) :

Deposit thickness for each process :

Process (1)

SMAW 3 Layer Min.

No

Yes

:

:

:

N.A.

--

N.A.

--

SMAW-16

MAXIMUM TO BE

WELDED

3G

:

:

:

:

:

------------DCEP

Plate& Pipe:>24OD F,V

Plate & Pipe<24OD:F

Fillet : F,H,V #

------------DCEP

Process (2)

3 Layer Min.

Position qualified (2G, 6G, 3F, etc.) :

Yes

No

Vertical progression (uphill or downhill) :

Type of fuel gas (OFW) :

Inert gas backing (GTAW, PAW, GMAW) :

Transfer mode (spray/globular or pulse to short circuit-GMAW) :

GTAW current type/polarity (AC, DCEP, DCEN) :

RESULTS

Visual Examination of Completed Weld (QW-302.4) :

Satisfactory

+Bend test: Transverse root and face (QW-462.3(a) :Longitudinal root and face(QW-462.3(b):+Side (QW-462.2):

Macro test for fusion (QW-462.5(b) Macro test for fusion (QW-462.5(e)

Type

Result

Type

Result

Type

Result

Alternative radiographic examination results (QW-91):

RT DATED:

Fillet weld - fracture test (QW-180) :

Length and percent of defects: Macro examination (QW-184) Fillet size (in.):

Concavity/convexity

(in.):

Other tests:

Film or specimens

Company: Tripcon Engineering Pvt Ltd.

evaluated by:

Mechanical tests

conducted by:

Laboratory test No: ___________________

Welding supervised by: Mr. J.H. Trivedi.

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Code.

# Note: Pipe 27/8 (73 mm)OD and above

Date :

By :

Welding Engineer

You might also like

- 1015 To Hastelloy VickoDocument14 pages1015 To Hastelloy Vickovgestantyo100% (1)

- PT ZUG WELDING QUALIFICATIONDocument1 pagePT ZUG WELDING QUALIFICATIONMuhammad Fitransyah Syamsuar Putra100% (1)

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- 0301e - Guidebook For Inspectors - 2018-3Document6 pages0301e - Guidebook For Inspectors - 2018-3FranciscoNo ratings yet

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Pressure Vessel Plate InspectionDocument5 pagesPressure Vessel Plate InspectionSadashiw PatilNo ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- 2019 ASME Section IX SynopsisDocument31 pages2019 ASME Section IX SynopsisFaiez GhrabNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- Api - 1104 - 1Document2 pagesApi - 1104 - 1aditya bhideNo ratings yet

- ASME 9 Calculator Approval RangesDocument2 pagesASME 9 Calculator Approval RangesEmel Besir100% (1)

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Multi Process Welding Procedures QW200.4 (ASME IX)Document1 pageMulti Process Welding Procedures QW200.4 (ASME IX)HoangNo ratings yet

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocument5 pagesWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Document1 pageWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamNo ratings yet

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- Asme Sec Ix WPS PQRDocument41 pagesAsme Sec Ix WPS PQRwentroprem100% (1)

- SCWI BokDocument2 pagesSCWI Bokrajeshmohana100% (1)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- AWS Part BDocument32 pagesAWS Part Balefeli260% (2)

- ASME IX Interpretation-Part7Document37 pagesASME IX Interpretation-Part7kevin herryNo ratings yet

- Contact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Document4 pagesContact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Maulik PatelNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTwalitedisonNo ratings yet

- Saes W 013Document8 pagesSaes W 013Dhaval Patel100% (1)

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- ASME IX Welding Qualification RequirementsDocument33 pagesASME IX Welding Qualification RequirementsBabel THIAMNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- FILL COURSE ENROLMENT FORMDocument3 pagesFILL COURSE ENROLMENT FORMRaja Guru100% (1)

- Welding Metallurgy and Weldability of Nickel-Base AlloysFrom EverandWelding Metallurgy and Weldability of Nickel-Base AlloysRating: 5 out of 5 stars5/5 (1)

- mohanWPQ-1G 40NBDocument1 pagemohanWPQ-1G 40NBDeepakNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocument1 pageWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDocument2 pages161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Nicon Price List January 2021Document12 pagesNicon Price List January 2021niket0No ratings yet

- Ozar Make Bench Vice Vices Size 4Document76 pagesOzar Make Bench Vice Vices Size 4niket0No ratings yet

- 4Document1 page4niket0No ratings yet

- NEW PROSPECTS INDIADocument3 pagesNEW PROSPECTS INDIAniket0No ratings yet

- Bank MandateDocument1 pageBank Mandateniket0No ratings yet

- Ankit Enterprise 10.8.17Document1 pageAnkit Enterprise 10.8.17niket0No ratings yet

- Welmech-08 11 20 PDFDocument1 pageWelmech-08 11 20 PDFniket0No ratings yet

- Welmech-08 11 20 PDFDocument1 pageWelmech-08 11 20 PDFniket0No ratings yet

- 1'' Pitch X 23 Teeth SprocketDocument1 page1'' Pitch X 23 Teeth Sprocketniket0No ratings yet

- New Microsoft Word Document PDFDocument1 pageNew Microsoft Word Document PDFniket0No ratings yet

- DRAWINGDocument1 pageDRAWINGniket0No ratings yet

- Sprocket and Chain Specs for Floatation Cell Froth PedalDocument1 pageSprocket and Chain Specs for Floatation Cell Froth Pedalniket0No ratings yet

- Po SCH-18.03.17Document1 pagePo SCH-18.03.17niket0No ratings yet

- Alumina - e Catalogue PDFDocument52 pagesAlumina - e Catalogue PDFniket0No ratings yet

- User: MR Hemal Patel Organization: Tripcon Engineering Private LimitedDocument1 pageUser: MR Hemal Patel Organization: Tripcon Engineering Private Limitedniket0No ratings yet

- An Old Man Lived in the Village Short Story about Spreading UnhappinessDocument1 pageAn Old Man Lived in the Village Short Story about Spreading Unhappinessniket0No ratings yet

- Alumina - e Catalogue PDFDocument52 pagesAlumina - e Catalogue PDFniket0No ratings yet

- Balance Sheet yDocument4 pagesBalance Sheet yniket0No ratings yet

- XyzDocument9 pagesXyzniket0No ratings yet

- 1Document2 pages1niket0No ratings yet

- HelloDocument1 pageHelloniket0No ratings yet

- CAVDocument3 pagesCAVniket0No ratings yet

- Authorization Letter for Customs ClearanceDocument1 pageAuthorization Letter for Customs Clearanceniket0No ratings yet

- Investopedia explains importance of soft skillsDocument2 pagesInvestopedia explains importance of soft skillsniket0No ratings yet

- Enquiry/Tender 1763-14 for Paper Mills Due 16/03/2015Document1 pageEnquiry/Tender 1763-14 for Paper Mills Due 16/03/2015niket0No ratings yet

- Aroojb08 003 131003111616 Phpapp01 PDFDocument41 pagesAroojb08 003 131003111616 Phpapp01 PDFVasu GandhiNo ratings yet

- Sr. No Name Ac - No Basic Salary DaysDocument3 pagesSr. No Name Ac - No Basic Salary Daysniket0No ratings yet

- 4 Trends That Will Change The Way We Work: Information OverloadDocument18 pages4 Trends That Will Change The Way We Work: Information Overloadniket0No ratings yet

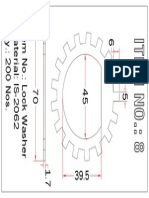

- Lock Washer PDFDocument1 pageLock Washer PDFniket0No ratings yet

- Preet Machines LimitedDocument2 pagesPreet Machines Limitedniket0No ratings yet