Professional Documents

Culture Documents

Viscosity Information

Viscosity Information

Uploaded by

Zamora PonchoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity Information

Viscosity Information

Uploaded by

Zamora PonchoCopyright:

Available Formats

Viscosity Information

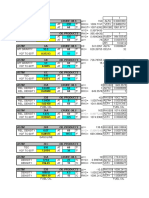

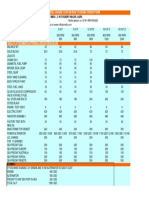

CPS

1

2

3

3

8

11

14

18

20

40

50

68

75

88 - 206

94

103

110

125 330

180

200 - 540

319 - 970

320

435

540 2000

648 - 800

720 18.000

750

800

1000

1000

1000 - 3000

1210

1500 70.000

1500

Temp

65 F

60 F

40 F

68 F

70 F

60 F

60 F

60 F

40 F

65 F

70 F

100 F

70 F

60 F

60 F

60 F

60 F

60 F

65 F

60 F

60 F

60 F

68 F

60 F

69 F

60 F

65 F

80 F

80 F

70 F

60 F

70 F

85 F

100 F

Fluid

water

turpentine

milk

kerosene

gasoline

# 2 fuel oil

# 2 diesel

beer

cream

vegetable oil

sugar syrup (sucrose) 60 Brix

raw honey

liquid wax

SAE 10 motor oil

sesame oil

peanut oil

coconut oil

SAE 20 motor oil

tomato juice

SAE 30 motor oil

SAE 40 motor oil

varnish

maple syrup

SAE 50 motor oil

100% glycerine

molasses

latex paint

HFCS high fructose corn syrup

horse radish sauce

spaghetti sauce

SAE 60 motor oil

sugar syrup (sucrose) 74 Brix

mustard

honey

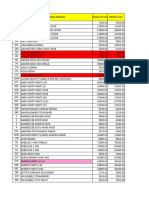

CPS

1600 17.400

2000

2200

2250

2400

2600

3000 65.000

3800

4000

5000

5000

5000

5000

5000

5000

5000

5000 40.000

6000

10.000

10.000

10.000

15.000

15.000

18.000 35.000

20.000

20.000

36.000

40.000

50.000

64.000

65.000

100.000

250.000

Temp

60 F

75 F

70 F

62 F

70 F

40 F

65 F

70 F

60 F

160 F

75 F

70 F

65 F

65 F

38 F

62 F

70 F

70 F

70 F

40 F

60 F

60 F

45 F

100 F

60 F

60 F

80 F

100 F

65 F

65 F

65 F

120 F

65 F

Fluid

SAE 70 motor oil

barbecue sauce

pancake batter

chocolate syrup

water based paint

tomato sauce

glue

lard

newspaper ink

titanium dioxide

salad dressing

shampoo

hand lotion

epoxy resin

OJ concentrate

neoprene latex

mayo

sweetened condensed milk

butter

yogart

icing

corn syrup 41 be

sour cream

corn syrup 44 be

baby food

printers ink

hot fudge

blackstrap molasses

ketchup

petroleum jelly

PVA resin

cream cheese

peanut butter

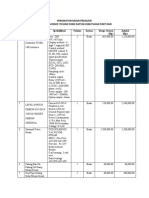

Tomato Paste: 26% & 37% cold break & 31% hot break has been pumped using Flux #F560GS3A50/21 tubeset & F 458-1 motor

Consideration of pumps for viscous liquid applications requires a thorough discussion of

the viscous nature of the liquid and piping system. The viscous characteristics of the

liquid --- Newtonian, Thixotropic, Dilatant, Colloidal or Rheopectic should be established

when providing viscosity data. Most all calculations for pressure drops and pipeline

losses for viscous liquids are in laminar flow patterns.

CONVERSION FACTORS

Centistokes = _Centipoises__

Specific Gravity

SSU* = Centistokes x 4.55

Degrees Engler* = Centistokes x 0.132

Seconds Redwood 1* = Centistokes x 4.05

*Where Centistokes are greater than 50

You might also like

- Mechanical VibrationsDocument57 pagesMechanical VibrationsHari Tej AvvaruNo ratings yet

- List of Fluid and ViscoityDocument7 pagesList of Fluid and Viscoityburhanuddin bhavnagarwalaNo ratings yet

- ASTM TablesDocument29 pagesASTM TablesStemo100% (1)

- OG OG Local Mass Transfer Coeff, Kya: Material Thermal ConductivityDocument2 pagesOG OG Local Mass Transfer Coeff, Kya: Material Thermal ConductivityJenny LlanesNo ratings yet

- Print - The Use and Misuse of CentrifugesDocument4 pagesPrint - The Use and Misuse of CentrifugestheislandboyNo ratings yet

- Viscosity Values From Cole-ParmerDocument1 pageViscosity Values From Cole-Parmergalaxy grandNo ratings yet

- Viscosity Guide ChartDocument2 pagesViscosity Guide Chartedlyn91No ratings yet

- Viscosity Guide ChartDocument2 pagesViscosity Guide ChartDeepikaNo ratings yet

- Rice Pudding Viscosity CHRTDocument1 pageRice Pudding Viscosity CHRTspartha_beNo ratings yet

- Viscosity: Viscosity Comparison Chart Material Viscosity (Centipoise)Document1 pageViscosity: Viscosity Comparison Chart Material Viscosity (Centipoise)Saepul RochmanNo ratings yet

- Motorna Ulja Pakovanje Pakovanje Jed. Mere V.P. Cena Cena (KOM)Document4 pagesMotorna Ulja Pakovanje Pakovanje Jed. Mere V.P. Cena Cena (KOM)Zoran Bogićević RakunNo ratings yet

- Harga Barang BaruDocument5 pagesHarga Barang BaruAgung Bagus SanjayaNo ratings yet

- Master List SparepartDocument10 pagesMaster List SparepartHanif SayyidNo ratings yet

- Lista de Stock Da Loja NicuadalaDocument3 pagesLista de Stock Da Loja NicuadalaferminojosecumbaneNo ratings yet

- Sales Sheet For FebDocument10 pagesSales Sheet For FebAnimie ForeverNo ratings yet

- Lubricantes Recomendados SD105Document3 pagesLubricantes Recomendados SD105Vale DudaNo ratings yet

- Nissan SXDocument1 pageNissan SXmarino246No ratings yet

- Desmet Ballestra GroupDocument25 pagesDesmet Ballestra GroupDesa MadukaraNo ratings yet

- Inventory ReportDocument158 pagesInventory ReportAdèity TVNo ratings yet

- Closong Stock 1 To 5 NovDocument5 pagesClosong Stock 1 To 5 Novpavan kumarNo ratings yet

- Harga Jual PrintDocument127 pagesHarga Jual PrintShabillNo ratings yet

- Inventory Kitchen March31Document238 pagesInventory Kitchen March31cynthiaNo ratings yet

- Closing Stock Nov 1 To 12Document4 pagesClosing Stock Nov 1 To 12pavan kumarNo ratings yet

- PRODUITS Longrich PDFDocument1 pagePRODUITS Longrich PDFMohamed Fouad Bissiriou50% (4)

- Closing Stock 1 To 31 OctDocument5 pagesClosing Stock 1 To 31 Octpavan kumarNo ratings yet

- Ilog Maria Order SeptemberDocument4 pagesIlog Maria Order Septembersales officeNo ratings yet

- Metal or Alloy Kg/cu.mDocument17 pagesMetal or Alloy Kg/cu.mElixir CabsNo ratings yet

- Daftar Harga PelumasDocument12 pagesDaftar Harga Pelumas07071201730% (1)

- ZAKOLÉDocument7 pagesZAKOLÉMelissa OteroNo ratings yet

- Survei Harga Kompetitor JULI 2020-1Document6 pagesSurvei Harga Kompetitor JULI 2020-1Achmad TurmuziNo ratings yet

- S3 Audi A3 - Vehicle Model Code 8P PDFDocument3 pagesS3 Audi A3 - Vehicle Model Code 8P PDFAlexNo ratings yet

- Red Line Synthetic 10W 60 Technical DatasheetDocument2 pagesRed Line Synthetic 10W 60 Technical DatasheetMario FliesserNo ratings yet

- Guideline SOS Sampling LoaderDocument1 pageGuideline SOS Sampling LoaderMuhammad fikhri Al AyubiNo ratings yet

- Said Jan Summary PaymentDocument1 pageSaid Jan Summary Paymentapi-3726455100% (1)

- BHL Recommended Maximum Labour Chart: GeneralDocument6 pagesBHL Recommended Maximum Labour Chart: GeneralMd. Ripon AliNo ratings yet

- Operational Mu-X 4x4Document1 pageOperational Mu-X 4x4Anindito W WicaksonoNo ratings yet

- Reference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Document1 pageReference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Engg DesignNo ratings yet

- Pump Sizing Calculation (Photo)Document25 pagesPump Sizing Calculation (Photo)anto3harrish3fdoNo ratings yet

- The Inventory Characteristics of The Refined Oils AreDocument2 pagesThe Inventory Characteristics of The Refined Oils AreA MNo ratings yet

- Untitled SpreadsheetDocument4 pagesUntitled SpreadsheetAsifa NoorNo ratings yet

- Laboratory Work BookDocument8 pagesLaboratory Work BookgadaubacNo ratings yet

- Steam TableDocument14 pagesSteam TableFata AmalNo ratings yet

- Perawatan Mesin Produksi Upt. Riau Science Techno Park Daftar Kebutuhan Part DanDocument2 pagesPerawatan Mesin Produksi Upt. Riau Science Techno Park Daftar Kebutuhan Part Danrozita izanNo ratings yet

- Viscosity TablesDocument4 pagesViscosity TablesAshwin ShettyNo ratings yet

- Industrial Gearbox Oils: Parthan EpDocument20 pagesIndustrial Gearbox Oils: Parthan EpChetan PrajapatiNo ratings yet

- G10 G11 G9 CanvasDocument1 pageG10 G11 G9 CanvasJair AyalaNo ratings yet

- Rate List 2019Document11 pagesRate List 2019tiks88No ratings yet

- Additional MilkDocument5 pagesAdditional MilkRestu FauzanNo ratings yet

- Lister Type Slow Speed Diesel Engine Custom Builts Engine Order FormDocument1 pageLister Type Slow Speed Diesel Engine Custom Builts Engine Order FormhamadaeidNo ratings yet

- Pump CalculationDocument8 pagesPump CalculationankitNo ratings yet

- Special LubsDocument2 pagesSpecial LubsidealparrotNo ratings yet

- Beverage ListDocument2 pagesBeverage ListBijoy DasNo ratings yet

- Parthan Ep: Industrial Gearbox OilsDocument1 pageParthan Ep: Industrial Gearbox OilsHesham MahdyNo ratings yet

- Recipe Hot and SpicyDocument4 pagesRecipe Hot and Spicyrezaakum13No ratings yet

- Equipment & Machinery Equipment Unit Price Total Cost (RS.) (RS.)Document13 pagesEquipment & Machinery Equipment Unit Price Total Cost (RS.) (RS.)Hamid NasirNo ratings yet

- Akb Lubricants Price List W.E.F. 15th May, 2022Document2 pagesAkb Lubricants Price List W.E.F. 15th May, 2022Lalremruata SingsonNo ratings yet

- Scale Price ListDocument17 pagesScale Price ListdrsamaratefNo ratings yet

- Lista de Precios Lubricantes ROSHFRANS 2018.12Document2 pagesLista de Precios Lubricantes ROSHFRANS 2018.12Anonymous eJwbx9WnNo ratings yet

- Suhu Terhadap Berat Bahan BakarDocument5 pagesSuhu Terhadap Berat Bahan BakarIlham Dwi ShaputraNo ratings yet

- PRECIOS PRODUCCION Vibalca 2020 (Boleta y Factura)Document7 pagesPRECIOS PRODUCCION Vibalca 2020 (Boleta y Factura)KEVIN MEJIANo ratings yet

- Force On Immersed BodiesDocument8 pagesForce On Immersed BodiesRam Krishna Singh100% (1)

- Modeling, Simulation and Scale-Up of A Batch Reactor: René O. Vargas and Francisco López-SerranoDocument7 pagesModeling, Simulation and Scale-Up of A Batch Reactor: René O. Vargas and Francisco López-SerranoRàhuł MathiasNo ratings yet

- Centrifugal Pumps Sterling Cap - 4Document75 pagesCentrifugal Pumps Sterling Cap - 4cuervohijoguachoNo ratings yet

- 2100 4016Document16 pages2100 4016aqccc120No ratings yet

- Graphene in R134aDocument7 pagesGraphene in R134achitta sandeep dattuNo ratings yet

- Intechopen 82278Document23 pagesIntechopen 82278Alex HariucNo ratings yet

- Moog Pumps RKP Catalog enDocument75 pagesMoog Pumps RKP Catalog enSantiago Bonilla RiveraNo ratings yet

- AP Hercules AfDocument1 pageAP Hercules AfSami KahtaniNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- Specification Sheet 3000 VIDocument4 pagesSpecification Sheet 3000 VImoh_ichwanuddinNo ratings yet

- Exp 2 Reynolds ApparatusDocument4 pagesExp 2 Reynolds ApparatusRaj PratyushNo ratings yet

- A Three-Fluid Model of Two-Phase Dispersed-Annular FlowDocument16 pagesA Three-Fluid Model of Two-Phase Dispersed-Annular FlowMolly0630No ratings yet

- Instruction MT Gede Galunggung GamalamaDocument1,350 pagesInstruction MT Gede Galunggung GamalamasilisyariefNo ratings yet

- Crumb Rubber Data - October 2021 - AFPADocument14 pagesCrumb Rubber Data - October 2021 - AFPAAlexandru LetNo ratings yet

- Physical Properties of Dental MaterialsDocument87 pagesPhysical Properties of Dental MaterialsManiBernardH100% (1)

- 06-Barite SagDocument9 pages06-Barite SagmarboudNo ratings yet

- Me304 2018 06Document7 pagesMe304 2018 06Kelvin Kindice MapurisaNo ratings yet

- CO2 Corrosion Rate Calculation ModelDocument18 pagesCO2 Corrosion Rate Calculation Modelmeshekhar700No ratings yet

- Drilling Fluid Properties - Drilling Formulas and Drilling CalculationsDocument10 pagesDrilling Fluid Properties - Drilling Formulas and Drilling CalculationsmohNo ratings yet

- DTU Polymer SyllabusDocument3 pagesDTU Polymer SyllabusHILL RANGAMATINo ratings yet

- Autofilt Rf3: Automatic Back-Flushing FilterDocument11 pagesAutofilt Rf3: Automatic Back-Flushing Filterandres12636No ratings yet

- Djokoto 2019Document7 pagesDjokoto 2019Oleksii BalitskyiNo ratings yet

- Unit - 1 Fluid Properties and Flow Characteristics Part-ADocument23 pagesUnit - 1 Fluid Properties and Flow Characteristics Part-Akarthickmech19874601No ratings yet

- Ics 12439Document15 pagesIcs 12439Rima AgustinaNo ratings yet

- 12 Liquids - General PDFDocument18 pages12 Liquids - General PDFBRUCE QUARENo ratings yet

- Deney 3Document22 pagesDeney 3baratniloy1No ratings yet

- Non-Newtonian Effects of Multigrade Oils On Journal Bearing PerformanceDocument12 pagesNon-Newtonian Effects of Multigrade Oils On Journal Bearing PerformanceJicheng PiaoNo ratings yet