Professional Documents

Culture Documents

2-Dec-2014 Food: PM Group (Spray Drier)

2-Dec-2014 Food: PM Group (Spray Drier)

Uploaded by

mdalt9180Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2-Dec-2014 Food: PM Group (Spray Drier)

2-Dec-2014 Food: PM Group (Spray Drier)

Uploaded by

mdalt9180Copyright:

Available Formats

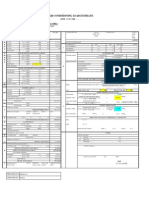

Bry-Air....

# 1 in Dehumidification

PHYSICAL FACTS AND ASSUMPTIONS

PROJECT / CLIENT NAME

PM GROUP( SPRAY DRIER )

1..

SPACE TO BE DEHUMIDIFIED

FOOD

2..

SIZE OF DEHUMIDIFIED SPACE

Volume

3..

ROOM VOLUME :

24666.0

4..

ROOM DESIGN CONDITIONS

Cubic Ft.

Temperature DBT

66

+/- 5 Deg.F

Relative Humidity

40.00

+/- 5 % RH

Opening(s)/Hour

Quantity

9462

cfm

Temperature DBT

55

Deg.F

Temperature WBT

55

Deg.F

Absolute Humidity

68.9

Grs/Lb

NO. OF OCCUPANTS /ACTIVITY LEVEL

10

6..

DOOR SIZE/ OPENING FREQUENCY/HR

112.00

7..

FRESH AIR INTAKE

CONSTANT OPENING

9..

PRODUCT / OTHER MOISTURE LOAD

2-Dec-2014

FT3

5..

8..

Date

Sq.Ft.

10.. ALTITUDE ABOVE SEA LEVEL

1834

11.. AMBIENT DESIGN CONDITION

Temperature DBT

83

Deg.F

Temperature WBT

79

Deg.F

Absolute Humidity

154.6

Grs/Lb

Temperature DBT

83

Deg.F

Temperature WBT

79

Deg.F

Absolute Humidity

154.6

Grs/Lb

12.. SURROUND DESIGN CONDITION

ASSUMPTIONS :-

1.There are no other openings or cracks in the construction in the above mentioned space. All windows and doors will be of standard construction

and will be weather stripped.

2. The room will be standard construction i.e. with brick walls and concrete ceiling. Entire space will be given two coats of

vapour

proof paint.

3. If there is any action ducting connected to this space, the same shall be sealed vapour tight / caulked.

4. The aircon used for temperature control shall not mix dehumidified air with air of any other area at different humidity level than this space.

5. If there is any false ceiling, the same shall be of vapour proof type and joints will be sealed vapour tight.

You might also like

- Study of A Refrigeration Unit (R633)Document52 pagesStudy of A Refrigeration Unit (R633)mahbub133294% (17)

- DHRC Catalog - F164LR.Document28 pagesDHRC Catalog - F164LR.mdalt9180No ratings yet

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System DesignDocument12 pagesASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System Designmdalt9180No ratings yet

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- HVAC Basics Lunch & LearnDocument64 pagesHVAC Basics Lunch & Learnreyes500100% (2)

- Lab 2 ThermalDocument18 pagesLab 2 ThermalMuhamad Arif100% (1)

- 2012 Comprehensive StudyDocument13 pages2012 Comprehensive Studymdalt9180No ratings yet

- PET Bottle TroublesDocument6 pagesPET Bottle Troublesvnbhtpp100% (1)

- RefrigerationDocument65 pagesRefrigerationUMA MAHESHNo ratings yet

- Rotary Drum Dryer ManualDocument14 pagesRotary Drum Dryer ManualShoaib PathanNo ratings yet

- Rakesh ReportDocument81 pagesRakesh ReportRakesh SharmaNo ratings yet

- Plate ExchangerDocument2 pagesPlate ExchangerEDUARDONo ratings yet

- Stairwell & Lift Pressurization CalculationsDocument31 pagesStairwell & Lift Pressurization CalculationsAneng2882% (11)

- CHE504 Lab Report DryingDocument17 pagesCHE504 Lab Report DryingJaymacNo ratings yet

- AT4 HumidifierDocument64 pagesAT4 Humidifiermdalt9180No ratings yet

- DAT Exchanger PlateDocument2 pagesDAT Exchanger PlateEDUARDONo ratings yet

- Sunil ProjectDocument83 pagesSunil ProjectRakesh SharmaNo ratings yet

- Project Report On Liquid NitrogenDocument23 pagesProject Report On Liquid Nitrogenneeltambe100% (2)

- CoC Oral Exam Preparation 8-Air CompressorDocument6 pagesCoC Oral Exam Preparation 8-Air CompressorThusitha DalpathaduNo ratings yet

- ACMV Systems PDFDocument171 pagesACMV Systems PDFrujhan76100% (4)

- Tank Normal Venting (ISO)Document2 pagesTank Normal Venting (ISO)Saeid Rahimi Mofrad0% (1)

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocument20 pagesASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180No ratings yet

- NDCTDocument127 pagesNDCTYousuf Ali100% (1)

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Heat Loss /vesselDocument2 pagesHeat Loss /vesselSapariya Hitesh50% (2)

- Report Tray DryerDocument21 pagesReport Tray DryeramirulNo ratings yet

- 19-Mar-2015 Food: PM Group (Sampling Area)Document1 page19-Mar-2015 Food: PM Group (Sampling Area)mdalt9180No ratings yet

- 2-Dec-2014 Food: PM Group (Weighing Room)Document1 page2-Dec-2014 Food: PM Group (Weighing Room)mdalt9180No ratings yet

- 27-May-2011 Food: Itc Limited (Room1)Document1 page27-May-2011 Food: Itc Limited (Room1)Nandini NagrajNo ratings yet

- Equipment and System Dehydrating, Charging, and Testing: Related Commercial ResourcesDocument7 pagesEquipment and System Dehydrating, Charging, and Testing: Related Commercial ResourcesBurning TrainNo ratings yet

- Reporte 1 Evaporador FinalDocument25 pagesReporte 1 Evaporador FinalZucely CastilloNo ratings yet

- Tray Dryer PDFDocument17 pagesTray Dryer PDFAdibah AyuniNo ratings yet

- Building Residential Mech VentDocument2 pagesBuilding Residential Mech VentLTE002No ratings yet

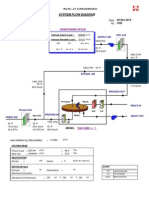

- System Flow Diagram: HVB 02-Dec-2014 PM Group Spray DrierDocument1 pageSystem Flow Diagram: HVB 02-Dec-2014 PM Group Spray Driermdalt9180No ratings yet

- United States Patent (191: Schaper Et A1Document3 pagesUnited States Patent (191: Schaper Et A1Juan Pablo EspinosaNo ratings yet

- Time Schedule Cleaning Condensor PT. SASDocument12 pagesTime Schedule Cleaning Condensor PT. SASsuhairianasNo ratings yet

- 21 254 Dehumidification For ElectronicsDocument12 pages21 254 Dehumidification For ElectronicsJose LopezNo ratings yet

- Final ReportDocument30 pagesFinal ReportAjith JoeNo ratings yet

- Maufacture of 1,1,1,2 TetrafluoroethaneDocument10 pagesMaufacture of 1,1,1,2 TetrafluoroethaneAshwin GNo ratings yet

- Heat Load TEMPDocument1 pageHeat Load TEMPindrajeewaNo ratings yet

- HTTP WWW - Bryair.com Manuals Man07Document17 pagesHTTP WWW - Bryair.com Manuals Man07rama deviNo ratings yet

- Moisture Loss During FreezingDocument1 pageMoisture Loss During FreezingIvana TomazNo ratings yet

- Mechanical Engineering Department Date: 28/ 09/ 2017 Course Code: MDB 2063Document6 pagesMechanical Engineering Department Date: 28/ 09/ 2017 Course Code: MDB 2063Kailash NairNo ratings yet

- Lab Report: Refrigeration SystemDocument5 pagesLab Report: Refrigeration SystemFarhan AizatNo ratings yet

- R&T 2001 - Cold Storage Warehouse Dock Study - JekelDocument12 pagesR&T 2001 - Cold Storage Warehouse Dock Study - JekelPRKrauseNo ratings yet

- ALM Refrigeration Air DryerDocument34 pagesALM Refrigeration Air DryerJunaid AhmedNo ratings yet

- 4 - Rotary DryerDocument24 pages4 - Rotary DryerkhawarNo ratings yet

- Drying Curves of A Non-Porous SolidDocument6 pagesDrying Curves of A Non-Porous SolidRikun FauziNo ratings yet

- Construction of 1.5 HP Split Unit Air Conditioning SystemDocument43 pagesConstruction of 1.5 HP Split Unit Air Conditioning Systemikperha jomafuvweNo ratings yet

- RefrigerationDocument91 pagesRefrigerationKrishna BelelaNo ratings yet

- FfuijDocument5 pagesFfuijamulya singhNo ratings yet

- R417ADocument7 pagesR417Aaliakbar tavafiNo ratings yet

- Thermax BoilerDocument10 pagesThermax Boileramitrawal0100% (1)

- Olumide DryingDocument34 pagesOlumide DryingAnthony Oyindamola AdekoleoyeNo ratings yet

- United States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Document13 pagesUnited States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Javier Alejandro Rodriguez MelgozaNo ratings yet

- Psychromatic Calculator SheetDocument2 pagesPsychromatic Calculator SheetSyed Ali Shiraz AbidiNo ratings yet

- Dropwise and Filmwise CondensationDocument20 pagesDropwise and Filmwise CondensationRaviyank Patel100% (1)

- MODULE I Introduction To Refrigeration SystemsDocument3 pagesMODULE I Introduction To Refrigeration SystemsNELMIDA AIRISH JOY N.No ratings yet

- Sidem Company Profile Dec. 2011Document25 pagesSidem Company Profile Dec. 2011mbabar81No ratings yet

- Exp. 1 Drying Solid Material Using Tray Dryer UnitDocument5 pagesExp. 1 Drying Solid Material Using Tray Dryer UnitIera ThahirahNo ratings yet

- Ce 432 Water Quality Engineering Wastewater Treatment Design ProjectDocument6 pagesCe 432 Water Quality Engineering Wastewater Treatment Design ProjectjokishNo ratings yet

- Freeze DryingDocument58 pagesFreeze DryingVũ Phan Ánh VyNo ratings yet

- Siti Suhaila Mohd RohaniDocument24 pagesSiti Suhaila Mohd RohaniDavin WijayaNo ratings yet

- HVAC Commercial Cooling Load CalculationsDocument2 pagesHVAC Commercial Cooling Load Calculationsgechaves1No ratings yet

- Process Design ConditionsDocument8 pagesProcess Design ConditionsGerald RahanraNo ratings yet

- Easylab: Controller TCU3Document20 pagesEasylab: Controller TCU3mdalt9180No ratings yet

- MAYDAY CDX Drift Eliminator Rev ADocument1 pageMAYDAY CDX Drift Eliminator Rev Amdalt9180No ratings yet

- TL k5 2 2 1 Min Max de enDocument16 pagesTL k5 2 2 1 Min Max de enmdalt9180No ratings yet

- CLA-100-data Sheet PDFDocument5 pagesCLA-100-data Sheet PDFmdalt9180No ratings yet

- Adsorption Chiller Guide SpecificationsDocument6 pagesAdsorption Chiller Guide Specificationsmdalt9180No ratings yet

- T2700 Tower Specifications PDFDocument8 pagesT2700 Tower Specifications PDFmdalt9180No ratings yet

- Spcification - VolzDocument2 pagesSpcification - Volzmdalt9180No ratings yet

- Sopt TisDocument2 pagesSopt Tismdalt9180No ratings yet

- DHG Ro 20Document3 pagesDHG Ro 20mdalt9180No ratings yet

- Vero Vera (Raise Floor Panel)Document1 pageVero Vera (Raise Floor Panel)mdalt9180No ratings yet

- PIBCVDocument8 pagesPIBCVmdalt9180No ratings yet

- Vibration Absorption MountsDocument1 pageVibration Absorption Mountsmdalt9180No ratings yet

- Appreciation Letter DPS DalhousieDocument1 pageAppreciation Letter DPS Dalhousiemdalt9180No ratings yet