Professional Documents

Culture Documents

Analytical Hierarchy Process Applied To Vendor Selection Problem: Small Scale, Medium Scale and Large Scale Industries

Analytical Hierarchy Process Applied To Vendor Selection Problem: Small Scale, Medium Scale and Large Scale Industries

Uploaded by

venkateswarantOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analytical Hierarchy Process Applied To Vendor Selection Problem: Small Scale, Medium Scale and Large Scale Industries

Analytical Hierarchy Process Applied To Vendor Selection Problem: Small Scale, Medium Scale and Large Scale Industries

Uploaded by

venkateswarantCopyright:

Available Formats

2009

Sanjay Kumar, Neeraj Parashar, Abid Haleem

Analytical Hierarchy Process Applied to Vendor

Selection Problem: Small Scale, Medium Scale and Large

Scale Industries

Sanjay Kumar, Neeraj Parashar,

Dr. Abid Haleem

Abstract

Vendor selection is an important process for an effective inventory management. This paper deals with

a brief review of the literature regarding AHP technique and its relevancy to its application in vendor

selection process. Vendor selection is a complicated process. This process needs evaluation of multiple

criteria and various constraints associated with them.

This paper has been developed based upon the views of various experts. A well researched methodology

has been adopted for the synthesis of priorities and the measurement of consistencies. A consistency ratio

has also been calculated. Industries has been classifies into small scale, medium scale and large scale.

Various criteria for vendor selection process as received from the expert have been identified. These criteria

have been compared using average matrix, priority matrix and overall priority matrix.

After analysis of the results we found that for large scale industries, vendor reliability, product quality

and vendor experience are the top three vendor selection problems that needs to be taken up on priority for

effective vendor selection.

Keywords: Vendor Selection, Analytical Hierarchy Process

S. Kumar, N. Parashar, A. Haleem - Analytical Hierarchy Process Applied to Vendor Selection Problem

355

Business Intelligence Journal

356

Introduction

This paper endeavors to investigate the problem

of vendor selection using Analytical Hierarchy

Process (AHP) in Small-scale industries (SS),

Medium-scale industries (MS) and Large-scale

industries (LS) under different criteria for the

same. In India, industries having investment in

plant and machinery less than rupees ten million

are called small-scale industries (Singh et al,

2003). Similarly, industries having investments

between ten million and one thousand million in

plant and machinery are considered as medium

scale industries (Karandikar, 1999), whereas for

large scale industries, investments in plant and

machinery is more than one thousand million has

been considered as criteria (Singh et al, 2005).

Decision criteria used for vendor selection can

be different depending on the size of a buyer

organisation. Large companies use a different set

of criteria and a formal approach when selecting

suppliers compared to small and medium sized

enterprises (Pearson et. al., 1995).

AHP makes the selection process very

transparent. It also reveals the relative merits of

alternative solutions for a Multi Criteria Decision

Making (MCDM) problem. (Drake, P.R., 1998).

AHP approach is a subjective methodology (Cheng

and Li, 2001); information and the priority weights

of elements may be obtained from a decisionmaker of the company using direct questioning or

a questionnaire method. It is generally agreed in

the literature that the following makes the supplier

selection decision making process difficult and/or

complicated (de Boer, 1998, Murlidharan et.al.,

2001):

Selection of

Criteria from

literature and

experts.

Rating of Criteria by

using questionnaire

filled by experts

from industry and

academia

Development

of Hierarchy

August

Multiple criteria both qualitative and

quantitative

Conflicts amongst criteria conflicting

objectives of the criteria

Involvement of many alternatives due to

fierce competition

Internal and external constraints imposed on

the buying process

Objectives & Issues

In modern era of industrialization and

globalization, every organization has to ensure that

their product must meet the international standards

and quality requirements to remain competent in

this rapidly changing industrial environment. To

achieve this, it is a necessary requirement that

vendor from which the organization is getting

the supply of raw material or any other kind of

necessary inputs should be selected correctly. This

multi criteria decision making problem is now a

part of day to day affair of all the organizations.

The main objective of the paper is to rate vendors

(large scale, medium scale and small scale) with

respect to various criteria. Here in this paper we

are presenting an easy to understand approach

for solving this problem. For this, a questionnaire

based study has been adopted and views of experts

from industry and academia have been taken.

Methodology

Problem of selection of vendor has been

dealt with by using questionnaire based study. A

structured questionnaire was framed and all the

criteria are rated by the professional of various

fields. The framework adopted for this study is as

shown in figure1.

Synthesis of

Priorities

Selection of Vendor Using AHP

Figure 1: Framework of the study

Business Intelligence Journal - August, 2009 Vol. 2 No. 2

Measurement

of consistency

Final

Decision

Making i.e.

Selection of

Vendor

Sanjay Kumar, Neeraj Parashar, Abid Haleem

2009

357

Analytical Hierarchy Process: A

Brief Review

S.No.

Preference Definition

weights/

level of

importance

Explanation

The foundation of the Analytic Hierarchy

Process (AHP) is a set of axioms that carefully

delimits the scope of the problem environment

(Saaty 1986). It is based on the well- defined

mathematical structure of consistent matrices and

their associated eigenvectors ability to generate

true or approximate weights, Merkin, (1979); Saaty

(1980, 1994). The AHP methodology compares

criteria, or alternatives with respect to a criterion,

in a natural, pair wise mode. To do so, the AHP

uses a fundamental scale of absolute numbers

that has been proven in practice and validated by

physical and decision problem experiments. The

fundamental scale has been shown to be a scale

that captures individual preferences with respect

to quantitative and qualitative attributes just

as well or better than other scales (Saaty 1980,

1994). It converts individual preferences into ratio

scale weights that can be combined into a linear

additive weight for each alternative. The resultant

can be used to compare and rank the alternatives

and, hence, assist the decision maker in making a

choice.

In this study, all the criteria have been rated

from 1 to 9 versus all other criteria as well as

versus small scale, medium scale and large scale

industries, accordingly as stated in the Table 1

(Crowe et al., 1998; Saaty, 2000; Hafeez et al.,

2002)

Very strongly

preferred

An activity is

strongly favoured

over another and

its

dominance

demonstrated in

practice

Extremely

preferred

The evidence

favouring one

activity over

another is

of the highest

degree possible

of affirmation

2,4,6,8

Intermediates

values

Used to represent

compromise

between the

preferences listed

above

Reciprocals

Reciprocals for inverse comparison

Table 1: Scale of Preference between Two Elements

Based on the ratings obtained through the

questionnaire, matrices are formed and the

priorities are synthesized using the methodology

of AHP. Following are the steps used in this

process:

Synthesis of priorities for all the criteria and

measurement of Consistency Ratio (CR).

Prioritizing of small scale, medium scale and

large scale industries as against all the criteria

of vendor selection separately.

Synthesis of overall priority matrix of

small scale, medium scale and large scale

industries.

S.No.

Preference Definition

weights/

level of

importance

Explanation

Synthesis of Priorities and the

Measurement of Consistency

Equally preferred

Two activities

contribute equally

to the objective

Moderately

preferred

Experience and

judgment slightly

favour one activity over another

Strongly preferred

Experience and

judgment strongly or essentially

favour one activity over another

The pair-wise comparisons of the criteria of

vendor selection problem generate a matrix of

relative rankings for each level of the hierarchy.

The number of matrices depends on the number

of elements at each level. The number of elements

at each level decides the order of every matrix

of the next higher level. After all matrices are

developed, eigenvectors or the relative weights

(the degree of relative importance amongst the

elements) and the maximum eigenvalue (max)

S. Kumar, N. Parashar, A. Haleem - Analytical Hierarchy Process Applied to Vendor Selection Problem

Business Intelligence Journal

358

for each matrix are calculated. The max value

is an important validating parameter in AHP. It

is used for calculating the consistency ratio CR

(Saaty, 2000) of the estimated vector in order to

validate whether the pair-wise comparison matrix

provides a completely consistent evaluation. The

consistency ratio is calculated as per the following

steps:

matrix has occurred and the evaluation process

should therefore be reviewed, reconsidered and

improved. An acceptable consistency ratio helps

to ensure decision-maker reliability in determining

the priorities of a set of criteria.

Step 1 Calculate the eigenvector or the relative

weights and max for each matrix of order n

Step 2 Compute the consistency index for each

matrix of order n by the formulae:

CI = (max -n)/ (n-1)

Step 3 The consistency ratio is then calculated

using the formulae:

CR = CI/RI

The pair wise comparison of all criteria

separately for each type of industries is executed

in this step. For each criterion, a priority matrix is

obtained for small scale, medium scale and largescale industries by following the same procedure

as stated in previous step 3.2.1.

where Random Consistency Index (RI) varies

depending upon the order of matrix. Tables 2

shows the value of the Random Consistency

Index (RI) for matrices of order 1 to 10 obtained

by approximating random indices using a sample

size of 500 (Saaty, 2000).

After the synthesis of priority matrices for the

criteria of vendor selection as well as for the type

of industry in 3.2.1 and 3.2.2 for every criteria, an

overall priority matrix is synthesized. This priority

matrix is obtained by multiplying the priority

matrix obtained for each criterion for various types

of industry with the priority matrix obtained by

the comparison of criteria itself. The matrix thus

synthesized will give the overall priority matrix

for small-scale, medium-scale and large-scale

industries using the criteria of vendor selection as

criteria for the selection of type of industry.

Table 2: Average random index (RI) based on Matrix

Size (Saaty, 2000)

S.

No.

1

2

3

4

5

6

7

8

9

10

Size of Matrix (n)

1

2

3

4

5

6

7

8

9

10

Random Consistency Index

(RI)

0

0

0.52

0.89

1.11

1.25

1.35

1.40

1.45

1.49

The acceptable CR range varies according to the

size of matrix i.e. 0.05 for a 3 by 3 matrix, 0.08 for

a 4 by 4 matrix and 0.1 for all larger matrices, n>=

5 (Saaty, 2000, Cheng and Li, 2001). If the value

of CR is equal to, or less than that value, it implies

that the evaluation within the matrix is acceptable

or indicates a good level of consistency in the

comparative judgments represented in that matrix.

In contrast, if CR is more than the acceptable

value, inconsistency of judgments within that

Prioritizing of Small Scale, Medium Scale

and Large Scale Industries

Synthesis of Overall Priority Matrix

Vendor Selection Using AHP

Evaluation and selection of vendors is a typical

multiple criteria decision making (MCDM)

problem involving multiple criteria that can be

both qualitative and quantitative (Sonmez, M.,

2006). Vendor Selection problem involves tangible

and intangible criteria. These criteria may vary

depending on the type of product being considered

and include many judgmental factors (Sarkis,

Alluri, 2002), (Jayaraman, Srivastava, Benton,

1999). The various criteria that are important for

vendor selection, as evident in literature and from

discussions with experts, are price, transportation

cost, quality, quality certification, lead time, buffer

stock needed, goodwill and reliability of the

Business Intelligence Journal - August, 2009 Vol. 2 No. 2

August

Sanjay Kumar, Neeraj Parashar, Abid Haleem

2009

vendor, experience of the vendor in the same field

etc as shown in figure 2. (Weber et al, 1991; Bajaj

et al, 2005). The problem is how to select vendors

who can perform optimally on the desired criteria.

AHP (Analytical Hierarchy Process) is one of the

Price of

Product

359

most extensively used MCDM methods because

of ease with which it handles the multi criteria.

The criteria based on which the vendor selection

problem has been solved in this paper have been

tabulated in Table 3 with their used abbreviations.

Transportation

Cost

Buffer Stock

Required

Quality

Certification

Lead Time

Required

Quality of

Product

Vendor Selection

Process

Experience of

the Vendor

Reliability of the

Vendor

Goodwill of the

Vendor

Figure 2.Criteria for Vendor Selection Process

Table 3.Criteria and Abbreviations Used

S.No.

Criteria

Abbreviation Used

Price of product

PP

Transportation ease and cost

TC

Quality certification of the vendor (ISO, ISI certification)

QC

Quality of product (based on rejection rate)

QP

Goodwill of the vendor

GW

Reliability of the vendor

RV

Experience of the vendor in the same field

EV

Lead time

LT

Buffer stock of Inventory required

BS

After the ratings have been obtained through the questionnaire, the average matrix for these ratings has

been shown in table 4.

S. Kumar, N. Parashar, A. Haleem - Analytical Hierarchy Process Applied to Vendor Selection Problem

Business Intelligence Journal

360

Criteria

PP

TC

QC

QP

GW

RV

EV

LT

BS

Table 4.The Average Matrix for the Criteria of Vendor Selection

PP

TC QC

QP

GW

RV

EV

1

8

0.2

0.125

3

0.143

0.5

0.125

1

0.143

0.125

0.2

0.143

0.2

5

7

1

0.2

0.333

0.333

0.25

8

8

5

1

1

1

1

0.333

5

3

1

1

0.5

1

7

7

3

1

2

1

2

2

5

4

1

1

0.5

1

0.5

3

5

0.333

6

0.333

0.5

0.5

3

4

0.333

5

0.333

0.333

The maximum value of eigen vector for the

above matrix, max = 12.63

Consistency index, C.I. = (max -n)/ (n-1) =

0.45

Random Index for the matrix of order 9, R.I.

= 1.45

Consistency Ratio, C.R. = C.I./ R.I. = 0.3,

which is greater than 0.1.

August

LT

2

0.333

0.5

3

0.167

3

2

1

1

BS

2

0.333

0.25

3

0.2

3

3

1

1

The responses being taken over from a wide

range of experts from various fields, the consistency

ratio is found to be greater than the desired value.

The pair-wise comparison of all the criteria

of vendor selection problem generates a priority

matrix as given in the table 5.

Table 5. The Priority Matrix for the Criteria of Vendor Selection

S.No.

Criteria

Priorities

Rank

PP

0.089

VI

TC

0.020

IX

QC

0.070

VIII

QP

0.196

II

GW

0.086

VII

RV

0.203

EV

0.136

III

LT

0.106

IV

BS

0.093

The above table 5 shows that Reliability of the

Vendor (RV), Quality of the Product (QP) and the

Experience of the Vendor in the same field (EV)

are top three in the vendor selection problem.

The globalization of market after the economic

reforms have led to drastic changes in the approach

of small, medium and large scale organizations

for formulating their strategies and priorities for

investments and developing competencies. In

such a dynamic environment, organizations that

are able to continually build new strategic assets

faster and cheaper than those of competitors will

create long-term competitive advantage (Singh et

al, 2005). So, in this environment, vendor selection

is an important MCDM problem to be taken care

of. So, we are here prioritizing the type of industry

best suitable for this MCDM problem. As done in

the case of synthesizing a priority matrix for the

criteria of vendor selection, the priority matrices

for these criteria have been obtained for SMEs and

Large scale organizations.

Business Intelligence Journal - August, 2009 Vol. 2 No. 2

Sanjay Kumar, Neeraj Parashar, Abid Haleem

2009

361

Table 6. The Priority Matrices for the Criteria of Vendor Selection for Small Scale, Medium Scale and Large Scale

Organizations

PP

Scale

SS

MS

LS

SS

MS

LS

QP

1

0.333

0.25

3

1

0.333

4

3

1

Scale

SS

MS

LS

SS

MS

LS

EV

1

5

7

0.2

1

5

0.143

0.2

1

Scale

SS

MS

LS

SS

MS

LS

1

7

7

0.143

1

4

0.143

0.2

1

Priority

Matrix

0.608

0.274

0.121

Priority

Matrix

0.072

0.232

0.696

Priority

Matrix

0.067

0.270

0.663

TC

Scale

SS

MS

LS

SS

MS

LS

GW

1

3

5

0.333

1

4

0.2

0.25

1

Scale

SS

MS

LS

SS

MS

LS

LT

1

6

5

0.167

1

4

0.2

0.25

1

Scale

SS

MS

LS

SS

MS

LS

1

0.2

0.143

5

1

0.2

7

5

1

Priority

Matrix

0.104

0.231

0.665

Priority

Matrix

0.084

0.288

0.627

Priority

Matrix

0.696

0.232

0.072

QC

Scale

SS

MS

LS

SS

MS

LS

RV

1

5

7

0.2

1

5

0.143

0.2

1

Scale

SS

MS

LS

SS

MS

LS

BS

1

6

6

0.167

1

4

0.167

0.25

1

Scale

SS

MS

LS

SS

MS

LS

1

0.2

0.2

5

1

0.25

5

4

1

Priority

Matrix

0.111

0.444

0.444

Priority

Matrix

0.076

0.277

0.647

Priority

Matrix

0.571

0.184

0.094

PP

TC

QC

QP

GW

RV

EV

LT

BS

SS

0.608

0.104

0.111

0.072

0.084

0.076

0.067

0.696

0.571

MS

0.274

0.231

0.444

0.232

0.288

0.277

0.270

0.232

0.184

LS

0.121

0.665

0.444

0.696

0.627

0.647

0.663

0.072

0.094

From the priority matrices for the criteria of

TC, QP, GW, RV and EV, we obtain that large scale

organization are best suitable, priority matrices for

Qc medium scale and large scale both are equally

good whereas for the criteria of PP, LT, BS, small

scale organizations are preferable.

Table7: Overall Priority Matrix

S.No. Type

of Priorities

Rank

Industry

1

SS

0.236

III

2

MS

0.265

II

3

LS

0.483

I

The overall priority matrix suggests that large

scale industries are the best suitable alternative.

Findings

Here we found, through our analysis of MCDM

problem of vendor selection, that Reliability

of the Vendor (RV), Quality of the Product

(QP) and the Experience of the Vendor in the

same field (EV) are top three in the vendor

selection problem (as shown in Table 5) and

Large Scale (LS) organizations are found the

best alternative as compared to Small Scale

(SS) and Medium Scale (MS) organizations

(as shown in Table 7).

Conclusion

The expert views as obtained through a

questionnaire and then quantifying the obtained

subjective views, using Analytical Hierarchy

Process helped to conclude the above findings. It

suggests that while large scale industries are the

best alternative solution for the vendor selection

problem, reliability of the vendor, product quality

and the vendor experience are the top three

problems in the vendor selection problem.

References

Bajaj, P.K., Mahanti, N.C., Verma, R., 2005,

Selection of Vendors Using AHP Based on Fuzzy

Preference Programming, Intelligence Based

Materials and Manufacturing, PP 298-301.

Cheng, E.W.L. and Li, H., 2001. Information PrioritySetting for Better Resource Allocation Using

Analytic Hierarchy Process (AHP). Information

Management and Computer Security, 9(2),

PP.61-70.

Crowe, T. J., Noble, J. S. and Machimada, J.S.,

1998. Multi-Attribute Analysis Of ISO 9000

S. Kumar, N. Parashar, A. Haleem - Analytical Hierarchy Process Applied to Vendor Selection Problem

362

Business Intelligence Journal

Registration Using AHP, International Journal of

Quality And Reliability Management, 15(2), PP.

205-222.

Cheng, E.W.L. And Li, H., 2001. Information

Priority-Setting for Better Resource Allocation

Using Analytic Hierarchy Process (AHP).

Information Management and Computer

Security, (2), PP 61-70.

De Boer, L., Van Der Wegen, L. And Telgen, J.,

1998, Outranking Methods in Support of Supplier

Selection. European Journal of Purchasing &

Supply Management, 4: PP. 109-118.

Drake, P.R., 1998, Using the Analytical Hierarchy

Process in Engineering Education, International

Journal of Engineering Education, Vol. 14, No.

3, PP. 191-196.

Hafeez, K., Zhang, Y. and Malak, N., 2002.

Determining Key Capabilities of A Firm Using

Analytical Hierarchy Process, International

Journal of Production Economics, 76 (1), PP. 3951.

Jayaraman, V., Srivastava, R., Benton, W. C.,

1999, Supplier Selection and

Order Quantity

Allocation: A Comprehensive Model, The

Journal Of Supply Chain Management Spring,

PP.50 -58.

Karandikar, P.D., 1999, Udhyog Sadhna, Mumbai,

Udhyog Mantrlaya, India.

Merkin, B. G. 1979. Group Choice, John Wiley &

Sons, NY.

Muralidharan, C., Anantharaman, N. And

Deshmukh, S. G., 2001, Vendor Rating in

Purchasing Scenario: A Confidence Interval

Approach. International Journal of Operations

and Production Management, 21(10): PP. 13061325.

Pearson, J. M. And Ellram, L. M. (1995) Supplier

Selection and Evaluation In Small Versus Large

Electronics Firms. Journal of Small Business

Management, 33(4): PP. 53-65

Saaty, T. L. 1986. Axiomatic Foundation of The

Analytic Hierarchy Process, Management

Science, 32, PP. 841-855.

Saaty, T. L. 1980. The Analytic Hierarchy Process,

McGraw-Hill Book Co., N.Y.

Saaty, T. L. 1994a. How to Make a Decision: The

Analytic Hierarchy Process, Interfaces, 24, PP.

19-43.

Saaty, T. L. 1994b. Fundamentals of Decision

Making, RWS Publications, Pittsburgh, PA

Saaty, T.L, 2000. Fundamentals of Decision Making

and Priority Theory. 2nd ed. Pittsburgh, PA:

RWS Publications.

Sarkis, J. Talluri, S., 2002, A Model for Strategic

Supplier Selection. The Journal Of Supply Chain

Management Winter, PP.18 -28.

Singh, R.K., Garg, S.K., Deshmukh, S.G., 2003,

Opportunities and Challenges for Small and

Medium Enterprises in India, Proceedings for

National Conference on Recent Development

in Mechanical Engineering, Thapar Institue of

Engg and Tech., Patiala, India.

Singh, R.K., Garg, S.K., Deshmukh, S.G., 2005,

Development of Competences by Indian

Small, Medium and Large Scale Organizations,

Proceedings of 14th International Conference

on Mechanical Engineering in Knowledge Age,

Delhi College of Engineering, Delhi, India.

Sonmez, M., 2006, A Review and Critique of

Supplier Selection Processes and Practices,

Business Scholl Occasional Papers Series, Paper

2006:1.

Weber C.A., Current, J.R., Benton R., 1991, Vendor

Selection Criteria and Methods, European

Journal of Operational Research 50(2), PP 2-18.

Business Intelligence Journal - August, 2009 Vol. 2 No. 2

August

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Catia V5-Questions & AnswersDocument72 pagesCatia V5-Questions & AnswersPAn Di YAnNo ratings yet

- Yrc1000 InstructionDocument454 pagesYrc1000 InstructionNhạt'sNo ratings yet

- What Is Reverse OsmosisDocument6 pagesWhat Is Reverse OsmosisApril Reeves100% (1)

- Fire Safety Science News #36 - February, 2014Document41 pagesFire Safety Science News #36 - February, 2014IAFSSNo ratings yet

- Frac PackingDocument7 pagesFrac PackingJessica Arevalo Duran0% (1)

- Lightolier The Light Book 1981Document132 pagesLightolier The Light Book 1981Alan Masters100% (3)

- Reported Speech - 10anoDocument3 pagesReported Speech - 10anoChantal GoncalvesNo ratings yet

- PRACRES Source Report: Use of Plastic Waste in Road ConstructionDocument9 pagesPRACRES Source Report: Use of Plastic Waste in Road ConstructionadingmarasiganNo ratings yet

- Esco Office - SD - Rev1 - 12aug22Document26 pagesEsco Office - SD - Rev1 - 12aug22Fãrìd QoikahNo ratings yet

- Robotics 2 Gnuplot: Giorgio Grisetti, Cyrill Stachniss, Kai Arras, Wolfram BurgardDocument11 pagesRobotics 2 Gnuplot: Giorgio Grisetti, Cyrill Stachniss, Kai Arras, Wolfram BurgardJino Goju StarkNo ratings yet

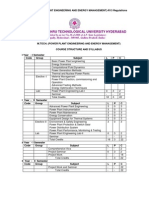

- Power Plant Engineering and Energy Management 2Document22 pagesPower Plant Engineering and Energy Management 2RAPRATSINNo ratings yet

- SAM Radar - StationsDocument25 pagesSAM Radar - StationsGilbert GlobalNo ratings yet

- Panasonic Sa Ak350e Sa Ak350eb Sa Ak350egDocument100 pagesPanasonic Sa Ak350e Sa Ak350eb Sa Ak350egted.klonNo ratings yet

- CS 32 Project 4, Spring 2014Document5 pagesCS 32 Project 4, Spring 2014everyotherwhereNo ratings yet

- Gilwell Fundays Activity Consent Form June2023 CONTACTDETAILS REMOVED (2041) - 4Document2 pagesGilwell Fundays Activity Consent Form June2023 CONTACTDETAILS REMOVED (2041) - 4Loredana DalabanNo ratings yet

- COAS TR P1 18ws1Document2 pagesCOAS TR P1 18ws1Mahmud RahmanNo ratings yet

- Cylinder Head, Pressure Test (First), D7CDocument4 pagesCylinder Head, Pressure Test (First), D7CAl BimaNo ratings yet

- Calibration Procedure For Pulse Function Arbitrary Noise Generator, Agilent Model 81150a - Tb-9-6625-2402-24Document35 pagesCalibration Procedure For Pulse Function Arbitrary Noise Generator, Agilent Model 81150a - Tb-9-6625-2402-24luroguita100% (2)

- Electric Rocket EngineDocument26 pagesElectric Rocket EngineSanal Raj100% (1)

- EE10-T / EE10-P: Room Temperature Transmitters and SensorsDocument2 pagesEE10-T / EE10-P: Room Temperature Transmitters and SensorsLullaby summerNo ratings yet

- Report Home CompostingDocument15 pagesReport Home CompostingneerajNo ratings yet

- DESINA Installation TechnologyDocument8 pagesDESINA Installation TechnologymansourNo ratings yet

- Advantages and Disadvantages of The InternetDocument6 pagesAdvantages and Disadvantages of The InternetBrightler PebamNo ratings yet

- Safe Concentration and Attention Test (SCAAT) : Practice TestsDocument3 pagesSafe Concentration and Attention Test (SCAAT) : Practice TestsGabor SzucsNo ratings yet

- BOG PPT Final Without Notes REVISEDDocument9 pagesBOG PPT Final Without Notes REVISEDWTXL ABC27No ratings yet

- VW CAN BT Installation Instructions WEBSITE August 2010Document9 pagesVW CAN BT Installation Instructions WEBSITE August 2010Luiz Malta MontenegroNo ratings yet

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 12 Jun 2018Document960 pagesPCAB List of Licensed Contractors For CFY 2017-2018 As of 12 Jun 2018Crystal DNo ratings yet

- Fix 10 Minute BanDocument1,051 pagesFix 10 Minute BanYãsmëèñ Kháñ60% (5)

- Ajay ResumeDocument3 pagesAjay ResumeMayank KatheriaNo ratings yet

- An Elnec EmmcDocument13 pagesAn Elnec Emmcأبو شفاءNo ratings yet