Professional Documents

Culture Documents

01 - 102 Jaw 3

01 - 102 Jaw 3

Uploaded by

nvkjayanthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 - 102 Jaw 3

01 - 102 Jaw 3

Uploaded by

nvkjayanthCopyright:

Available Formats

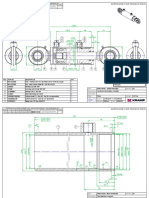

Date

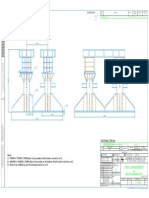

Revision Modification Name

Release

15

30

17

53

30

39

6.50

10

5 THRU ALL

2x

M6 - 6H THRU ALL

33.50 'Q'

9

8

Jaw 1

Jaw 2

Jaw 3

Dim Q

33.5

61.5

72

Qty

01

01

01

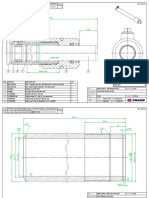

10

39

+0.2

19 +0.1

R9.50

FINISH :

Round off sharp angles

Face without machining 1

All dimensions are in mm

R19.50

M8

30.50 0.05

ALL MACHINED SURFACES TO FLAT

PARALLEL AND PERPENDICULAR TO WITHIN

0.015 T.I.R TO DATUMS A AND B AND

CONCENTRIC TO WITHIN 0.03 T.I.R

CASE HARDENING (CARBURIZING)

58+4 HRC; 0.8+0,4 LOW

WITHIN A GROUP OF HOLES

TOLERANCES CENTRE LINES DISTANCE

UNLESS OTERWISE SPECIFIED

0.03

BETWEEN TWO DOWELS

0.2

HOLE TO HOLE TOLERANCES

SURFACE FINISH

ALL DOWELS & TOOLING HOLES

ALL OTHER HOLES

Rz10

Part

WEIGHT

262.79

Material

EN-24

Treatment

Unless otherwise indicated

Stock

Rz25

Rz10

0 --> 150

0.25

0.20

0.15

150 --> 400

1.25

0.35

0.30

0.20

1.50

0.50

0.40

0.30

400

MACHINED

STOCK

Rz63 MATERIAL

0.2/1000

2/1000

0.2/1000

2/1000

ABB

ABB LIMITED

26/06/2014

Drawn by: Chetan

2.5/1000

Approved: Manjunath

LTD.

ROBOTICS DIVISON

14th CROSS, 4th PHASE

PEENYA INDUSTRIAL AREA

BANGALORE

INDIA - 560058

Tel : (080) 22 94 8364

CAD system:

Dwg file identify:

0.3/1000

70214006_01_102 jaw 3

This document is the property of ABB LTD and may not be reproduced

or given to anyone without prior written authorization.

Date:

Rz10

Description: part, sub assembly or assembly.

Hrdn 30-35 HRc

Rz63

Rz25

Part

GENERAL TOLERANCES

STOCK

MATERIAL

Rz63

SOLID WORKS

Scale

SCALE:2:1

Sheet

1 CM

Format

A3

1/

SHEET:A3

S

O

L

I

D

W

O

R

K

S

You might also like

- Cone DevlpmentDocument12 pagesCone Devlpmentanil4u29100% (3)

- MFC MB 003 07 Key ShaftDocument1 pageMFC MB 003 07 Key ShaftMaman FirmansyahNo ratings yet

- 582126307901Document1 page582126307901vinu1175No ratings yet

- Handel Pemutar A4: 2. POROS (N7) 3. ScrewDocument1 pageHandel Pemutar A4: 2. POROS (N7) 3. ScrewSantika AjiNo ratings yet

- 49 2X30 Typ: Title Drawing No MDY001-50-001Document1 page49 2X30 Typ: Title Drawing No MDY001-50-001danielsasikumarNo ratings yet

- Jack Stool Assembly R2Document1 pageJack Stool Assembly R2Olivia JacksonNo ratings yet

- Handel Pemutar A4: 1. CHASING (N6/N8)Document1 pageHandel Pemutar A4: 1. CHASING (N6/N8)Santika AjiNo ratings yet

- 2Document4 pages2itsmephilNo ratings yet

- Foudation Plan SC100 Rev ADocument1 pageFoudation Plan SC100 Rev AkrmchariNo ratings yet

- GearDocument1 pageGearSajay SuryaNo ratings yet

- Stroke Tol. +1.8 - 1.6Document4 pagesStroke Tol. +1.8 - 1.6Todor NedyalkovNo ratings yet

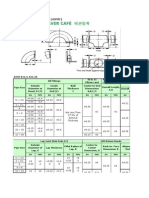

- Juntas SMC MQR PDFDocument10 pagesJuntas SMC MQR PDFhexapodoNo ratings yet

- 2 X 7 Thru All: KRISAM AutomationDocument1 page2 X 7 Thru All: KRISAM AutomationmounicavadaliNo ratings yet

- Coils: Common Alloys DimensionsDocument3 pagesCoils: Common Alloys DimensionsRoshan ShanmughanNo ratings yet

- Base PlateDocument2 pagesBase PlateYathi RajuNo ratings yet

- Erection of 33KV Line With 1no. M+12 GI Towers For NH5 Crossing S.No Description of Work Qty Rate Per AmountDocument3 pagesErection of 33KV Line With 1no. M+12 GI Towers For NH5 Crossing S.No Description of Work Qty Rate Per AmountDorababu MutyalaNo ratings yet

- C Detail C Scale 2: 1 2Document14 pagesC Detail C Scale 2: 1 2GPNo ratings yet

- Shell BWDocument7 pagesShell BWdraj1875977No ratings yet

- SK1530 Queen PDFDocument1 pageSK1530 Queen PDFAndre Sebastian Meza LozanoNo ratings yet

- End MillsDocument140 pagesEnd MillsGuru PrasadNo ratings yet

- TM 5-3805-280-24P Part 2 John Deere MDL 230 LCRDocument348 pagesTM 5-3805-280-24P Part 2 John Deere MDL 230 LCRAdvocateNo ratings yet

- PLDocument4 pagesPLselvamuthukumarNo ratings yet

- Inventorwizard: Miniature Steam Engine Vertical Twin Steam Engine With Reverse Gear Crankrod PinDocument1 pageInventorwizard: Miniature Steam Engine Vertical Twin Steam Engine With Reverse Gear Crankrod PinksNo ratings yet

- SPECIFICATIONSDocument9 pagesSPECIFICATIONSRicardo VelozNo ratings yet

- SpecificationsDocument9 pagesSpecificationsAbdul Syukur ZNo ratings yet

- High Speed Wind Tunnel Support System PDFDocument27 pagesHigh Speed Wind Tunnel Support System PDFShalan HooseriaNo ratings yet

- Torque CalculatorDocument34 pagesTorque Calculatorochappui100% (1)

- Cf53 DIN 1Document1 pageCf53 DIN 1empty_No ratings yet

- MTB ComponentsDocument5 pagesMTB ComponentsAlifantis10No ratings yet

- Fitting Dimensional TolerancesDocument13 pagesFitting Dimensional TolerancesJinGuk JangNo ratings yet

- BS 4360Document1 pageBS 4360sarfarazNo ratings yet

- Autodesk Robot Structural Analysis Professional 2019Document6 pagesAutodesk Robot Structural Analysis Professional 2019Blond MecinajNo ratings yet

- Chapter 6aDocument7 pagesChapter 6asurjitNo ratings yet

- Inventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDocument1 pageInventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDwi DarsonoNo ratings yet

- Universal Vice (Revision 1)Document4 pagesUniversal Vice (Revision 1)gundhiufsNo ratings yet

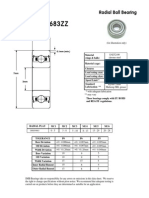

- Part Number: 683ZZ: SMB Bearings Radial Ball BearingDocument1 pagePart Number: 683ZZ: SMB Bearings Radial Ball BearingHà Văn TúNo ratings yet

- AmbumentDocument7 pagesAmbumentGaurav MadgaonkarNo ratings yet

- Production 09Document3 pagesProduction 09gdgokhale_76No ratings yet

- Sprue Bushing JIS B Type 635-636Document1 pageSprue Bushing JIS B Type 635-636NazriNo ratings yet

- King Pin Retention Plate: NotesDocument1 pageKing Pin Retention Plate: NotesJatin GoelNo ratings yet

- Maryland Metrics Acabado SuperficialDocument1 pageMaryland Metrics Acabado SuperficialalviarezalvarezNo ratings yet

- Doubly Reinforced BeamDocument10 pagesDoubly Reinforced Beamkalpanaadhi50% (2)

- I Beam DrawingDocument1 pageI Beam DrawingOlivia JacksonNo ratings yet

- Manual de Partes Moto Rg200Document573 pagesManual de Partes Moto Rg200Frankenstein H CasillasNo ratings yet

- Price List For Hot Rolled Products January 1 2009Document3 pagesPrice List For Hot Rolled Products January 1 2009tdecebalusNo ratings yet

- Diehl Metall Strips MB30 V2 M-SM PDFDocument2 pagesDiehl Metall Strips MB30 V2 M-SM PDFVinoth KumarNo ratings yet

- 5812 JTDocument1 page5812 JTingeisaaclgNo ratings yet

- 2010 Catalogueen LbiDocument48 pages2010 Catalogueen LbipashaulNo ratings yet

- Figure (1) Condenser Overall Heat Transfer CoefficientDocument10 pagesFigure (1) Condenser Overall Heat Transfer CoefficientViola ZakariaNo ratings yet

- Green Pin Standard Hydraulic ShackleDocument1 pageGreen Pin Standard Hydraulic ShackleAthox QhurienNo ratings yet

- Pressure Loss - Transformer YardDocument1 pagePressure Loss - Transformer Yardkarthikraja21No ratings yet

- Pressure Loss - TG BuildingDocument1 pagePressure Loss - TG Buildingkarthikraja21No ratings yet

- IIT Bearing DesignDocument19 pagesIIT Bearing Designmadanpal29No ratings yet

- BMP - (Class 24 - Class-26) - Metal FormingDocument22 pagesBMP - (Class 24 - Class-26) - Metal FormingAsesh PramanikNo ratings yet

- Insertos KYOCERA RoscadoDocument3 pagesInsertos KYOCERA RoscadoCristian AlonsoNo ratings yet

- Comparision of Fabrication TolerancesDocument4 pagesComparision of Fabrication TolerancesSatish Keskar100% (1)

- Package Outline Drawing: Plastic Packages For Integrated CircuitsDocument1 pagePackage Outline Drawing: Plastic Packages For Integrated CircuitsArdvaakNo ratings yet

- D3 GJJJDocument5 pagesD3 GJJJTodor NedyalkovNo ratings yet

- Filter - Inline - HFR: (Threads To Depth 20mm)Document2 pagesFilter - Inline - HFR: (Threads To Depth 20mm)nvkjayanthNo ratings yet

- Spring Push LVDT HB LVDT HB LVDT HB LVDT HB: Measurement PerformanceDocument2 pagesSpring Push LVDT HB LVDT HB LVDT HB LVDT HB: Measurement PerformancenvkjayanthNo ratings yet

- Nnospace Rofile: 2.0 Company HistoryDocument11 pagesNnospace Rofile: 2.0 Company HistorynvkjayanthNo ratings yet

- Power Entry ComponentsDocument40 pagesPower Entry ComponentsnvkjayanthNo ratings yet

- Simple / Special Order Sheet: Assembly Break-Up and Price CalculationDocument1 pageSimple / Special Order Sheet: Assembly Break-Up and Price CalculationnvkjayanthNo ratings yet

- DVP201/202/211LC-SL Load Cell Module Operation Manual: Industrial Automation HeadquartersDocument41 pagesDVP201/202/211LC-SL Load Cell Module Operation Manual: Industrial Automation HeadquartersnvkjayanthNo ratings yet

- Digix-2Document2 pagesDigix-2nvkjayanthNo ratings yet

- Dec Eb BillDocument1 pageDec Eb BillnvkjayanthNo ratings yet

- 9964 MFHB07343 MFHD02744 EngbDocument2 pages9964 MFHB07343 MFHD02744 Engbnvkjayanth0% (1)

- Gravity Plate - Sheet1Document1 pageGravity Plate - Sheet1nvkjayanthNo ratings yet

- DesktopDocument12 pagesDesktopnvkjayanthNo ratings yet

- Large Spring - Sheet1Document1 pageLarge Spring - Sheet1nvkjayanthNo ratings yet

- Challenger Computer: Boards For Extreme Edition (LGA2011 v3) Intel Sixth Gen Processor SkylakeDocument9 pagesChallenger Computer: Boards For Extreme Edition (LGA2011 v3) Intel Sixth Gen Processor SkylakenvkjayanthNo ratings yet

- Single-Direction Thrust Ball BearingsDocument14 pagesSingle-Direction Thrust Ball BearingsnvkjayanthNo ratings yet

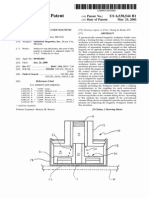

- United States Patent (10) Patent N0.: US 6,538,544 B1Document7 pagesUnited States Patent (10) Patent N0.: US 6,538,544 B1nvkjayanthNo ratings yet

- To Calculate:: To Calculate, Enter Your Figures Into The Grey AreasDocument4 pagesTo Calculate:: To Calculate, Enter Your Figures Into The Grey AreasnvkjayanthNo ratings yet