Professional Documents

Culture Documents

Felt Seal Bearing

Uploaded by

Arizal Sita Ahmad0 ratings0% found this document useful (0 votes)

28 views3 pagesnhmvbnvbn

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnhmvbnvbn

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views3 pagesFelt Seal Bearing

Uploaded by

Arizal Sita Ahmadnhmvbnvbn

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Old World Wool Seal Making

Wool felt front wheel seal

Today Peter created new bearing seals for the 1934 Lagonda M45 Rapide. The seals of the day

did much the same job as todays plastic over steel equivalent. The main sealing surface is wool

felt that, soaked in oil, does a good job holding most of the oil and grease in place. The tools of

the trade are pretty simple ones: a spoon, a ball-peen hammer, scissors and a razor blade. The

thick wool felt is traced and cut via razor blade.

To make the wool a bit proud to stick out like the chin of a duke paper gasket material can

be cut and built up behind the wool. A spoon and a ball-peen hammer are all that is needed to

make an imprint to cut out.

This twenties automotive seal technology was used in agricultural equipment for decades such as

wheel seals on an Oliver or Cockshut tractor.

Using the ball-peen hammer to trace the inner lip on the gasket

A spoon has a nice radius for tracing the outer edge of the seal

Lagonda M45 Rapide front brake shoes and axle with hub removed

You might also like

- MidgetDocument3 pagesMidgetapi-209049915No ratings yet

- Rapt or 4Document1 pageRapt or 4code933kNo ratings yet

- MRF Introduction and Industry ProfileDocument8 pagesMRF Introduction and Industry ProfileS.Abyisheik Reddy100% (2)

- Bhavik Goyal Zippo Lighter Group 1, 2019EE30563Document5 pagesBhavik Goyal Zippo Lighter Group 1, 2019EE30563Anirudha KulkarniNo ratings yet

- AutoWeek ADocument2 pagesAutoWeek Apaulomarques22No ratings yet

- Actuators in An Hour WebDocument17 pagesActuators in An Hour WebBrunoNo ratings yet

- Modelling a Tiger I Gruppe Fehrman, Germany 1945: In 1/35 scaleFrom EverandModelling a Tiger I Gruppe Fehrman, Germany 1945: In 1/35 scaleNo ratings yet

- Group 12 - SCM - Exp LearningDocument32 pagesGroup 12 - SCM - Exp Learningahmad.yusuf.29598No ratings yet

- AK Catalogue ED7 150dpiDocument68 pagesAK Catalogue ED7 150dpiJurun_BidanshiNo ratings yet

- A Study On Comparative Analysis of Radial Tyres in Multi Axle Vehicles Among Fleet Operators at ShengottaiDocument68 pagesA Study On Comparative Analysis of Radial Tyres in Multi Axle Vehicles Among Fleet Operators at ShengottaithamiraenterpriseNo ratings yet

- Resin Casting Slot CarsDocument13 pagesResin Casting Slot CarsJohn Howard Green100% (1)

- Modelling a Tiger I s.PZ.Abt.501, Tunisia 1943: In 1/35 scaleFrom EverandModelling a Tiger I s.PZ.Abt.501, Tunisia 1943: In 1/35 scaleRating: 5 out of 5 stars5/5 (1)

- 2020-06-01 Scale AutoDocument76 pages2020-06-01 Scale Autonaruemon khongmiNo ratings yet

- V85 TT - V85 TT Adventure E5Document27 pagesV85 TT - V85 TT Adventure E5Harish KumarNo ratings yet

- Theories of Machine - S.s.rattanDocument16 pagesTheories of Machine - S.s.rattanRohitsingh JadaunNo ratings yet

- Svenska Kungen: Jari Hamilia's Swedish King TigerDocument70 pagesSvenska Kungen: Jari Hamilia's Swedish King Tigerzveicohen100% (4)

- AFVModellerIssue70 PDFDocument68 pagesAFVModellerIssue70 PDFMarkedjani72100% (13)

- Hubcap - Wikipedia PDFDocument7 pagesHubcap - Wikipedia PDFAce ActionNo ratings yet

- Ferrari 365gt2+2 - Buyers - Guide PDFDocument10 pagesFerrari 365gt2+2 - Buyers - Guide PDFBennyLouPlummerNo ratings yet

- MY23 GR86 Accessory EBrochureDocument14 pagesMY23 GR86 Accessory EBrochureFerNo ratings yet

- Bear Grylls OutdoorDocument3 pagesBear Grylls Outdoorandreea conduracheNo ratings yet

- Nissan Classic Parts NumbersDocument170 pagesNissan Classic Parts NumbersAkram Al-marzooq100% (2)

- Slot I28 03.04 2018Document68 pagesSlot I28 03.04 2018Angel Erguera MartinezNo ratings yet

- Yamaha Project ReportDocument19 pagesYamaha Project ReportRohit OberoiNo ratings yet

- A4 BrochureDocument30 pagesA4 BrochureSenthil Kumar DharmarajNo ratings yet

- C4 Transmission Performance Rebuild - Mustang & Fords MagazineDocument9 pagesC4 Transmission Performance Rebuild - Mustang & Fords Magazineacmemail583100% (1)

- Tires 33 JIJFJDocument11 pagesTires 33 JIJFJMustafa HidayetNo ratings yet

- Royal Enfield Crusader Engine RebuildDocument11 pagesRoyal Enfield Crusader Engine Rebuildbill_wattNo ratings yet

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- P-38 With Metal FoilDocument6 pagesP-38 With Metal FoilErisie100% (1)

- Modelling a Tiger I s.SS.PZ.Abt.101, Normandy 1944: In 1/35 scaleFrom EverandModelling a Tiger I s.SS.PZ.Abt.101, Normandy 1944: In 1/35 scaleNo ratings yet

- 15 RH94234 Heritage FW NA 1214 LoresDocument28 pages15 RH94234 Heritage FW NA 1214 LoresmonkistNo ratings yet

- Quiet LandroverDocument9 pagesQuiet Landroverandrianjaka27No ratings yet

- Main ProjectDocument64 pagesMain Projectsandy1586No ratings yet

- The Lambretta StoryDocument5 pagesThe Lambretta StoryAntônio CastroNo ratings yet

- 1858 Remington ConversionDocument6 pages1858 Remington Conversionwienslaw5804No ratings yet

- 2012-Softail 2Document105 pages2012-Softail 2Yvon PaquinNo ratings yet

- 8th Gen Accord Saloon AccessoriesDocument11 pages8th Gen Accord Saloon AccessoriesAOCUK100% (1)

- Fast Car - September 2015 UKDocument116 pagesFast Car - September 2015 UKdapsidu100% (1)

- 30 Iconic Velomobile Designs From The Past 85 YearsDocument26 pages30 Iconic Velomobile Designs From The Past 85 YearsJulian Aleuy Santana100% (3)

- Hot Wheels: Garage of Legends: A Photographic Guide to Life-Size Versions of Your Favorite Die-Cast CarsFrom EverandHot Wheels: Garage of Legends: A Photographic Guide to Life-Size Versions of Your Favorite Die-Cast CarsNo ratings yet

- Moke Brochure 2008Document8 pagesMoke Brochure 20084x4No ratings yet

- Royal Enfield Group SpeechDocument2 pagesRoyal Enfield Group SpeechVedantVohraNo ratings yet

- American Woodworker #157 December 2011-January 2012Document68 pagesAmerican Woodworker #157 December 2011-January 2012Brian Neill100% (2)

- Exhaust System - ZedriderDocument15 pagesExhaust System - ZedriderSarah LoewenNo ratings yet

- AFV Modeller - Issue 18 - 2 - Tiger F13Document9 pagesAFV Modeller - Issue 18 - 2 - Tiger F13Emanuel Morales Zeke100% (1)

- Onguard 2015Document56 pagesOnguard 2015Lukasz BorowiczNo ratings yet

- The Lamborghini JournalDocument14 pagesThe Lamborghini JournalTechnomaniacNo ratings yet

- Hitchcock Crusader RebuildDocument11 pagesHitchcock Crusader RebuildcarphoneNo ratings yet

- CatalogueDocument60 pagesCatalogueroymungaNo ratings yet

- Tuning Fiat EnginesDocument21 pagesTuning Fiat Enginesezu11100% (5)

- Answer Penthouse and Dead AreaDocument1 pageAnswer Penthouse and Dead AreaArizal Sita AhmadNo ratings yet

- History of Aircraft Materials Instructor Notes r2010Document15 pagesHistory of Aircraft Materials Instructor Notes r2010Arizal Sita AhmadNo ratings yet

- Cover KPDocument1 pageCover KPArizal Sita AhmadNo ratings yet

- Contoh 1Document5 pagesContoh 1Arizal Sita AhmadNo ratings yet

- Calculate Excess Air TheoryDocument30 pagesCalculate Excess Air TheoryArizal Sita AhmadNo ratings yet

- Calculate Excess Air TheoryDocument30 pagesCalculate Excess Air TheoryArizal Sita AhmadNo ratings yet

- Junheng Liu, Anren Yao, Chunde Yao: HighlightsDocument9 pagesJunheng Liu, Anren Yao, Chunde Yao: HighlightsArizal Sita AhmadNo ratings yet

- Alur MotorDocument1 pageAlur MotorArizal Sita AhmadNo ratings yet

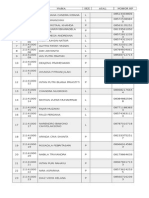

- Data Maba Mesin 2014Document11 pagesData Maba Mesin 2014Arizal Sita AhmadNo ratings yet

- Alur MobilDocument1 pageAlur MobilArizal Sita AhmadNo ratings yet

- Pinion: Pitch LineDocument1 pagePinion: Pitch LineArizal Sita AhmadNo ratings yet