Professional Documents

Culture Documents

Air Compressor Sizing

Uploaded by

ppluis90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Compressor Sizing

Uploaded by

ppluis90Copyright:

Available Formats

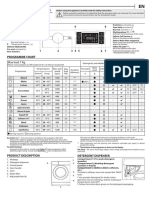

How to Size and Select an Air Compressor

Instructions

1. Pneumatic air tools require a volume of compressed air (CFM) at a specific pressure (PSIG) to

operate efficiently - they do not require a specific horsepower. Ignore the horsepower rating

when sizing and selecting a compressor.

Gather all of your pneumatic tools together. Write down the required CFM to operate the tool

(supplied by the manufacturer).

2. Add together the CFM requirements of all of the pneumatic tools you plan to run at the same

time. Now, add another 25% for additional tools, future growth and eventual air system leaks.

3. Determine the maximum pressure (PSIG) needed to run the air tools. You do not need to add

the PSIG values together like you did the CFM requirements, simply use the value of the tool

that requires the greatest amount of pressure.

4. Be sure the motor characteristics of the compressor are compatible.

Is your electrical supply single-phase or three-phase? What is the voltage? Residential and

commercial buildings usually have single-phase, 230 Volts, 50 cycle power, while industrial

buildings often have a three-phase power supply.

5. Small compressors should be used with an air receiver (storage tank). The receiver stores

compressed air and minimizes the loaded run time of the compressor. The air receiver should be

at least 5 gallons per CFM for optimal results.

6. Take your CFM, maximum pressure, motor characteristics and receiver size requirements to

your local compressor dealer or home improvement center and compare features among

brands. Keep the quality factor in mind. You will certainly get what you pay for with air

compressors.

There is no universal standard for rating air compressors, air equipment and tools. Common terms are:

CFM , ICFM , ACFM , FAD , ANR, SCFM , nl/min .

CFM

CFM (Cubic Feet per Minute) is the imperial method of describing the volume flow rate of

compressed air. It must be defined further to take account of pressure, temperature and

relative humidity - see below.

ICFM

ICFM (Inlet CFM) rating is used to measure air flow in CFM (ft3/min) as it enters the air

compressor intake.

# 22, 1st. Floor, 1st. Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore-560076, India.

T: 080-3297 0358, T/F: 080- 2648 1309, Email: sales@vivekengineers.net , Web: www.vivekengineers.net

How to Size and Select an Air Compressor

ACFM

ACFM (Actual CFM) rating is used to measure air flow in CFM at some reference point at local

conditions. This is the actual volume flow rate in the pipework after the compressor.

FAD

FAD (Free Air Delivery) (f.a.d) is the actual quantity of compressed air at the discharge of the

compressor. The units for FAD are CFM in the imperial system and l/min in the SI system. The

units are measured according the ambient inlet standard conditions ISO 1217 - 1 bar abs and

20oC.

1 m3/min (f.a.d) = 1000 liter/min (f.a.d) = 1000 dm3/min (f.a.d) = 16.7 l/s (f.a.d) = 16.7 dm3/s

(f.a.d) = 35.26 ft3/min (f.a.d)

ANR

ANR (Atmosphere Normale de Reference) is quantity of air at conditions 1.01325 bar absolute,

20oC and 65% RH (Relative Humidity).

SCFM

SCFM (Standard CFM) is the flow in CFM measured at some reference point but converted back

to standard or normal air conditions (Standard Reference Atmosphere) 14.4 psia, 80oF and 60%

RH (Relative Humidity).

nl/min

nl/min is the flow in l/min measured at some reference point but converted to standard or

normal air conditions 1.01325 bar absolute, 0oC and 0% RH (Relative Humidity).

ISO 1217

standard reference ambient conditions - temperature 20oC, pressure 1 bar abs, relative humidity

0%, cooling air/water 20oC, and working pressure at outlet 7 bar absolute.

Example - Rating a Compressor

FAD (CFM)

Description

11.1 cfm @ 7.5 Bar

The Free Air Delivery from the compressor is 11.1 CFM at 7.5 Bar

8.2 cfm @ 10 Bar

The Free Air Delivery from the compressor is 8.2 CFM at 10 Bar

A typical rating of a compressor may look like this.

# 22, 1st. Floor, 1st. Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore-560076, India.

T: 080-3297 0358, T/F: 080- 2648 1309, Email: sales@vivekengineers.net , Web: www.vivekengineers.net

You might also like

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjNo ratings yet

- Ammonia Plant Maint.Document11 pagesAmmonia Plant Maint.mahmadwasiNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- Parallel ChillerDocument2 pagesParallel ChillerSharon LambertNo ratings yet

- Broad Xii Non-Electric Chiller: Model Selection & Design ManualDocument50 pagesBroad Xii Non-Electric Chiller: Model Selection & Design ManualUmar MajeedNo ratings yet

- FM 1371 Centrifugal Fire Pumps In-Line TypeDocument37 pagesFM 1371 Centrifugal Fire Pumps In-Line TypeTasawwur Tahir0% (3)

- Ecoplus 806B-04-07C Eng PM PDFDocument32 pagesEcoplus 806B-04-07C Eng PM PDFIvanNo ratings yet

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- Flygt PumpsDocument56 pagesFlygt PumpsThe_RainmakerNo ratings yet

- Flow Meter ManualDocument70 pagesFlow Meter Manualrommel duranNo ratings yet

- Design Features and Operation of Jet EjectorsDocument2 pagesDesign Features and Operation of Jet EjectorsSamiYousifNo ratings yet

- Compressor SizingDocument84 pagesCompressor Sizingvineet3singhalNo ratings yet

- Vertical Turbine Pumps: Installation, Maintenance & Operation InstructionsDocument70 pagesVertical Turbine Pumps: Installation, Maintenance & Operation Instructionsagmibrahim5055No ratings yet

- Alfa LavalDocument24 pagesAlfa Lavaldroid11No ratings yet

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- Blackmer Autogas HandbookDocument32 pagesBlackmer Autogas HandbookMuhammad ImranNo ratings yet

- Water Cooled PackageDocument37 pagesWater Cooled PackageLeed EN100% (1)

- Axial Compressor - Wikipedia, The Free EncyclopediaDocument11 pagesAxial Compressor - Wikipedia, The Free EncyclopediaSurendra ReddyNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- VAM System DesignDocument11 pagesVAM System DesigngenipankajNo ratings yet

- Vacuum Drying TheoryDocument5 pagesVacuum Drying TheoryShishir Koyare100% (1)

- Air Generation and DistributionDocument55 pagesAir Generation and DistributionJespher Adam AndalNo ratings yet

- Kaeser Kompressoren 2000 1Document35 pagesKaeser Kompressoren 2000 1paulo josé sá patachoNo ratings yet

- 2.8 Pressurization of Pneumatics System (Compressors) : by Tadele LibayDocument15 pages2.8 Pressurization of Pneumatics System (Compressors) : by Tadele LibayMc AxNo ratings yet

- Secondary RefrigerantsDocument15 pagesSecondary Refrigerantse4erkNo ratings yet

- Woods Silencer Catalogue and Technical DataDocument12 pagesWoods Silencer Catalogue and Technical DataJagatjeet MaanNo ratings yet

- Dorner 3200 Vacuum ConveyorDocument8 pagesDorner 3200 Vacuum ConveyorBobKatNo ratings yet

- Slug CatcherDocument3 pagesSlug Catcherwkhan_55No ratings yet

- Thermodynamics Tutorial 6 Air Compressors: © D.J.Dunn 1Document26 pagesThermodynamics Tutorial 6 Air Compressors: © D.J.Dunn 1Eddie SantillánNo ratings yet

- Automatic Water Flow ControlDocument18 pagesAutomatic Water Flow ControlssgjmlimNo ratings yet

- ScrollDocument8 pagesScrolltrung2iNo ratings yet

- BlowersDocument58 pagesBlowersmahmad61100% (1)

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- 39TC Installation and Maintenance Manual PDFDocument35 pages39TC Installation and Maintenance Manual PDFAngga HardiyantomoNo ratings yet

- Whrs ManualDocument41 pagesWhrs ManualAKHLESH JHALLARENo ratings yet

- Manuals Control ValveDocument257 pagesManuals Control Valvetreetree100% (1)

- Spec For Rim Seal Fire Protection SystemDocument5 pagesSpec For Rim Seal Fire Protection Systemshashi ranjanNo ratings yet

- Prince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaDocument2 pagesPrince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaShaho Abdulqader MohamedaliNo ratings yet

- Smoke Extraction Fans - 20100830174123Document10 pagesSmoke Extraction Fans - 20100830174123Kristaps PuļķisNo ratings yet

- Operating Manual: FOR Commpressed Air SystemDocument11 pagesOperating Manual: FOR Commpressed Air Systemthach pha thienNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Standard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticeDocument9 pagesStandard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticejrodNo ratings yet

- ChillerDocument12 pagesChillerMard ApikNo ratings yet

- Steam Ejector Pumps and Ejectors Theory PDFDocument5 pagesSteam Ejector Pumps and Ejectors Theory PDFmahaveenNo ratings yet

- Compressor Surge!!: Muhammad Fadzlee Samsuba HADocument12 pagesCompressor Surge!!: Muhammad Fadzlee Samsuba HAMuhd Fadzlee ZNo ratings yet

- LPG Pump IOM LGL2 LGL3 PDFDocument12 pagesLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- Induced Draft Cooling Towers PDFDocument78 pagesInduced Draft Cooling Towers PDFHamid ArizNo ratings yet

- Instrumentation and Contrrol PPT LessonDocument41 pagesInstrumentation and Contrrol PPT LessonFRANCK DAMSSSNo ratings yet

- Pump ADocument172 pagesPump AAdithya VKNo ratings yet

- Air CompressorsDocument59 pagesAir Compressorsommech2020No ratings yet

- Self Study Material ON Screw Air Compressor: Adhunik Metaliks LTDDocument17 pagesSelf Study Material ON Screw Air Compressor: Adhunik Metaliks LTDNesaralamNo ratings yet

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control SystemfinalneoNo ratings yet

- Lectro-Dryer PDFDocument45 pagesLectro-Dryer PDFHenry NimbomaNo ratings yet

- Model 5 Operating and Maintenance Manual - Low Water VolumeDocument120 pagesModel 5 Operating and Maintenance Manual - Low Water VolumeJuan C FrancoNo ratings yet

- Hydraulic PumpsDocument6 pagesHydraulic PumpsSriram SastryNo ratings yet

- PDH CompressorsDocument90 pagesPDH CompressorsLawren Ignatius100% (2)

- Compressed Air Systems, PDH Course M146Document91 pagesCompressed Air Systems, PDH Course M146cramerps2084No ratings yet

- Plant Air SystemDocument7 pagesPlant Air SystemAnuj ShahiNo ratings yet

- How To Size and Select An Air CompressorDocument2 pagesHow To Size and Select An Air CompressornelsonNo ratings yet

- PR 859991559370 enDocument2 pagesPR 859991559370 enprevrtljivacNo ratings yet

- WWW - Whirlpool.eu/register: User ManualDocument14 pagesWWW - Whirlpool.eu/register: User ManualprevrtljivacNo ratings yet

- 198 199Document2 pages198 199prevrtljivacNo ratings yet

- Users Guide 48601Document4 pagesUsers Guide 48601prevrtljivacNo ratings yet

- Press Brake BendingDocument6 pagesPress Brake Bendingkumarjs19No ratings yet

- Voe Main2Document4 pagesVoe Main2prevrtljivacNo ratings yet

- DC or AC DrivesDocument12 pagesDC or AC DrivesNeelima MishraNo ratings yet

- Today:: Internal Effects in Beams Continued - Deformation Signs Continued - FramesDocument28 pagesToday:: Internal Effects in Beams Continued - Deformation Signs Continued - FramesprevrtljivacNo ratings yet

- Technical Specification of Asta Cooling Duct CTCDocument2 pagesTechnical Specification of Asta Cooling Duct CTCprevrtljivacNo ratings yet

- 7.2 Complex Arithmetic: C Pearson Education LTD 2000Document2 pages7.2 Complex Arithmetic: C Pearson Education LTD 2000prevrtljivacNo ratings yet

- Hany Et AlDocument13 pagesHany Et AlprevrtljivacNo ratings yet

- 7.5 The form: r (cos θ + j sin θ)Document2 pages7.5 The form: r (cos θ + j sin θ)prevrtljivacNo ratings yet

- 7.4 The Polar Form: B Z A + BJ (A, B) RDocument2 pages7.4 The Polar Form: B Z A + BJ (A, B) RprevrtljivacNo ratings yet

- 7.3 The Argand Diagram: Imaginary AxisDocument1 page7.3 The Argand Diagram: Imaginary AxisprevrtljivacNo ratings yet

- Complex Theory2Document8 pagesComplex Theory2prevrtljivacNo ratings yet

- Mitsubishi AC 20 HPDocument3 pagesMitsubishi AC 20 HPAry TubagusNo ratings yet

- Shellmax Boiler Design Calculation PDFDocument2 pagesShellmax Boiler Design Calculation PDFApolo Fumbuja0% (1)

- Floating Study PaperDocument6 pagesFloating Study Papervishalbhavar1100% (1)

- Fuel System Pressure - TestDocument7 pagesFuel System Pressure - TestHamilton MirandaNo ratings yet

- Nfpa 25 - 2008 Edition: Inspection, Testing, and Maintenance of Water-Based Fire Protection SystemsDocument2 pagesNfpa 25 - 2008 Edition: Inspection, Testing, and Maintenance of Water-Based Fire Protection Systemsjar100% (1)

- Table DickyDocument7 pagesTable DickyRestianingNo ratings yet

- Mini Water Service StationDocument46 pagesMini Water Service StationAakash DindigulNo ratings yet

- HP/WA: 0812-6178-6886 (Tsel), Supplier Panel MCCDocument2 pagesHP/WA: 0812-6178-6886 (Tsel), Supplier Panel MCCDistributor Panel ListrikNo ratings yet

- F75201-Pressure Test ReportDocument1 pageF75201-Pressure Test Reportsarsan nedumkuzhiNo ratings yet

- ET420 ET 420 Ice Stores in RefrigerationDocument2 pagesET420 ET 420 Ice Stores in RefrigerationMijhael Anatholi Romero MamaniNo ratings yet

- Turbine Engine StartingDocument4 pagesTurbine Engine Startingmamaadam02No ratings yet

- Steam Turbine Cycle and PerformanceDocument43 pagesSteam Turbine Cycle and PerformanceDivyank Arya100% (1)

- Rancang Bangun Turbin Uap Pada Maket Pembangkit Listrik Tenaga UapDocument4 pagesRancang Bangun Turbin Uap Pada Maket Pembangkit Listrik Tenaga UapMaulana DigoNo ratings yet

- Lm6000 PF Plus Fact SheetDocument2 pagesLm6000 PF Plus Fact SheetNivaldo GarciaNo ratings yet

- Fast Pyrolysis and Bio Oil Upgrading Presentation)Document46 pagesFast Pyrolysis and Bio Oil Upgrading Presentation)api-3799861100% (3)

- Ansaldo Thomassen - Gas Turbine Remanufacturing (2014)Document4 pagesAnsaldo Thomassen - Gas Turbine Remanufacturing (2014)guerrez100% (1)

- G.S.S.S. Banur Distt. PATIALA State PUNJABDocument7 pagesG.S.S.S. Banur Distt. PATIALA State PUNJABapi-3731257No ratings yet

- X2000 Service Guide: 1. Power Supply SystemDocument5 pagesX2000 Service Guide: 1. Power Supply SystemвладNo ratings yet

- N Series: Initial Pressure Up To 13 Bar - Final Pressure Up To 45 Bar Air Delivery 0.28 - 18 M /minDocument5 pagesN Series: Initial Pressure Up To 13 Bar - Final Pressure Up To 45 Bar Air Delivery 0.28 - 18 M /mineugent tereziuNo ratings yet

- 9340-1131 Turbine Water Induction Protection - TWIPDocument2 pages9340-1131 Turbine Water Induction Protection - TWIPMKOZERDEM100% (1)

- 2012 York Tech Guide - VA AirDocument36 pages2012 York Tech Guide - VA AirAndrea LemusNo ratings yet

- Reactor Physics Review + Thermal Parameters: - Fall 2010 Problem Set 2Document2 pagesReactor Physics Review + Thermal Parameters: - Fall 2010 Problem Set 2pstgouveiaNo ratings yet

- Solar Inverter - Wikipedia, The Free EncyclopediaDocument6 pagesSolar Inverter - Wikipedia, The Free EncyclopediaronniedakingpouNo ratings yet

- Thermoelectric EffectsDocument43 pagesThermoelectric EffectsLIAKMANNo ratings yet

- Vapor Compression Refrigeration System LabDocument7 pagesVapor Compression Refrigeration System LabKurtNo ratings yet

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- H11 Espl Comm Rev01Document4 pagesH11 Espl Comm Rev01Norberto NorbertoNo ratings yet

- Pelleting ProcessDocument59 pagesPelleting ProcessMinh PhamNo ratings yet

- HRSG Overview PDFDocument36 pagesHRSG Overview PDF55312714100% (6)

- New Nuclear Power Plant To Interface With The GridDocument39 pagesNew Nuclear Power Plant To Interface With The Grid210zhoqueNo ratings yet