Professional Documents

Culture Documents

ASME VIII Check List

Uploaded by

Ahmed RashiedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME VIII Check List

Uploaded by

Ahmed RashiedCopyright:

Available Formats

ASMEBOILER&PRESSUREVESSEL

ACCREDITATION

GUIDE

FOR

ASMEREVIEWTEAMS

FOR

REVIEWOFAPPLICANTS

FOR

ASMECERTIFICATESOFAUTHORIZATION

(A,M,PP,S,E,V,HV,H,HLW,H(CastIron),UD,UV,UV3,U,UM,U2,U3,RP,T,TD,TV)

A1.202/09(1/11)

TheAmericanSocietyofMechanicalEngineers

ThreeParkAvenue

NewYork,NY10016

INTRODUCTION

This Guide is prepared for the use of ASME Review Teams. It is not intended to replace or interpret the

requirementsoftheASMEBoilerandPressureVesselCode(B&PVC).

Inaddition,toassisttheASMEReviewTeam,thisGuidewillbeprovidedtoApplicantsforASMECertificates

ofAuthorizationfortheiruseincrossreferencingtheparagraphsintheirQualityControl(QC)Manualwith

theapplicablecontrolrequirementsoftheCode.

ThisGuideisbasedonSectionI,SectionIV,SectionsVIIIDivisions1,2and3,SectionX,andSectionXIIofthe

B&PVC. The Guide is subject to revision based on changes made in the aforementioned Sections in the

B&PVC.

A Review must cover a QC Manual and its implementation. It is recognized that the scope of work, QC

Manual, and Manual implementation will vary from Applicant to Applicant. Therefore, the ASME Review

TeamsareadvisedthatallaspectsofthisGuidemaynotapplyandthatthisGuidemaynotoutlineallpossible

aspectsofeachReview.TheManualneednotfollowtheformatofthisGuide.

Questions of possible need for Code interpretation raised by Review Teams shall be submitted to the ASME

Director,AccreditationandCertification.WhenarequestforaninterpretationistobesubmittedbyanApplicant,

theTeamLeadershalladvisetheApplicantthatallsuchinquiriesmustbesubmittedtotheSecretary,Boilerand

PressureVesselCommittee,andthatacopyoftheinquiryandreplyshouldbeprovidedbytheinquirertothe

ApplicantsAuthorizedInspectionAgencyandcognizantJurisdiction,ifappropriate.

SuggestionsforrevisionsorclarificationtothisGuideshouldbedirectedtotheASMEDirector,Accreditation

andCertification.

A1.202/09(2/11)

REVIEWDEMONSTRATION

ThepurposeoftheReviewDemonstrationistoevaluatetheApplicantsQualityControlSystem(QCS)andits

implementation.ForevaluationoftheQCS,theApplicantmustdemonstratetocurrentCoderulessufficient

administrative and fabrication functions of the QCS to show that they have the knowledge and ability to

producetheCodeitemscoveredbytheQCS.Fabricationfunctionsmaybedemonstratedusingcurrentwork,

amockup,oracombinationofthetwo.

WhiletheApplicantmustaddresseachelementoftheQCSintheCode,theApplicantneedonlydemonstrate

thoseelementswithintheintendedscopeofactivitiesthatapplytotheirprogram.

DemonstrationItem 1 :AnApplicant 2 forasingleCodeSymbolStampmustdemonstrateonanitemthatwill

befabricatedfortherequestedtypeofCodeSymbol.

For Applicants requesting multiple stamps, it is not necessary to have a demonstration item with design

calculationsforeachCodeSection.AnitemfabricatedtoanyoneoftherequestedCodeSymbolsmaybeused

as the demonstration item. However, if the demonstration item is not to the most stringent Code

requirements, the Applicant must provide additional calculations or another documentation package that

contains Code calculations to the most stringent Code requirements and administrative documentation to

sufficientlydemonstratecompliancewithallaspectsofthecompanysQCS.

For example, an Applicant for U & U2 Code Stamps could demonstrate their QCS on a Section VIII, Div. 1

pressurevesselincludingdesign.However,duetothenatureofSectionVIII,Div.2requirements,certification

ofadesignreportbyanEngineermeetingthecriteriaasdefinedinSectionVIIIDiv.2shallbeverified.

If computer calculations are to beused, the Applicant shall demonstrate that thecomputer program hasthe

capabilityofproducingacceptablecalculations.

IfthedemonstrationitemisbaseduponcurrentworkthatisbeingfabricatedtoapreviousCodeedition,the

ApplicantshalladdresschangesintheCodethatwouldrequiredifferentactionsinthedemonstrationstobein

compliancewiththecurrentCode.

1

2

ThedemonstrationitemshallbebasedonthelatestCodeEdition/Addendaineffectatthetimeofthereview.

ThisdoesnotapplytoanEngineeringContractorunderSectionI.ForanEngineeringContractorOrganizationunderSectionI,

withoutafabricatingfacility,aphysicaldemonstrationitemisnotrequired.However,adesignspecificationmustbeprovidedas

wellasadditionaladministrativefunctionstodemonstratecompliancewiththeorganizationsQCS.

A1.202/09(3/11)

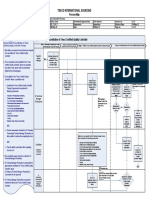

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

1.

QualityElementand

Subelements

GENERALQUALITYCONTROLSYSTEMREQUIREMENTS

(a) QCSystemisdocumentedindetailinaQCManualthataddressesallrequirements

oftheapplicableCodeSectionandincludes:

(1) acoversheetthatcontainsthecompanynameandphysicaladdressasitwill

appearontherequestedCertificateofAuthorization;

Note:ThecoversheetmayalsocontaintheeffectivedateoftheQCManual,mailing

address,phonenumberorotherinformationdesiredbytheCertificateHolderor

Applicant.

(2) abriefdescriptionoftheproductsbeingfabricatedand/orworkbeing

accomplishedundertheCodeincludingapplicabilityofQCSystemtoshop

activities,fieldactivitiesorboth;

(3) controlfeaturestodemonstrateCodecompliance;

(4) Manualrevisioncontrolsystem;

(5) provisionforreviewandapprovalofQCManualtomaintainitcurrent;

(6) provisionforsubmittalofQCManualrevisionstotheAuthorizedInspector

(AI)(ASMEDesigneeforH(CastIron),TClass3,orASMEDesignated

OrganizationforV,HVUD,UV,UV3,TDandTV)foracceptancepriorto

implementationincludingtimelyupdatingofallcopiestoreflectaccepted

revisions;

(7) provisionforthecustodyandcontroloftheCodeSymbolStampstoprevent

lossorunauthorizeduse;and

(b)

WhenthepurchaserrequestsanotherAIA(SecondaryAIA)toperforminspections

onitsprojectsorCodejobs,orwhenevertheAIAofRecordcannotprovidecoverage

forinspectionsataspecificfieldsite,thefollowingshallbeincludedintheQC

Manual:

(1)

DescriptionofhowdifferentAIAswillperformactivitiesundertheir

Certificate(s)ofAuthorization;

(2)

provisionsforassurancethattheCertificateHolderhasacontractor

agreementwiththeAIAperformingtheshop/fieldactivities;

(3)

provisionsforevidencethatthisprogramhasbeenacceptedbytheAIAof

Record.

Note: TheprovisionsfortheuseofanAIAotherthantheAIAofRecordisnotintendedfor

usebyashopworkingMultipleDuplicates.

A1.202/09(4/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

2.

3.

4.

QualityElementand

Subelements

(c)

InthecasewheretheQCManualexistsinmorethanonelanguage,atleastone

versionisinEnglishandidentifiedastheauthoritativeversion.

Note: Aglossaryoftermsisdesirablefromthestandpointofclarityifabbreviatedtitlesof

personnelandcontroldocumentsareusedthroughouttheQCManual.This,

however,isnotmandatory.

AUTHORITYANDRESPONSIBILITY

(a) TheauthorityandresponsibilityforQCbymanagementisdocumented.

Note: Inpractice,aStatementofPolicyandAuthoritymustbesignedbyaseniorcompany

officialresponsibleforCodeactivities(e.g.,President,VicePresident,PlantManager,

etc.).

(b) TheauthorityandresponsibilityofthoseinchargeoftheQCSystemareclearly

establishedanddocumented.

(c) PersonsperformingQCfunctionshavesufficientandwelldefinedresponsibility,the

authority,andtheorganizationalfreedomtoidentifyqualitycontrolproblemsandto

initiate,recommendandprovidesolutions.

ORGANIZATION

(a) Anorganizationchartshowingtherelationshipbetweenmanagementand

engineering,purchasing,manufacturing,production,fieldassembling,field

construction,inspectionandqualitycontrol,asapplicable,existsandreflectsthe

actualorganization.

Note: Thepurposeofthischartistoidentifyandassociatethevariousorganizationalgroups

withtheparticularfunctionforwhichtheyareresponsible.TheCodedoesnotintend

to encroach on the Certificate Holders right to establish and, from time to time, alter

whatever form of organization the Certificate Holder considers appropriate for their

Codework.

DRAWING,DESIGNCALCULATIONS,ANDSPECIFICATIONCONTROL

(a) Proceduresexistwhichassurethatthelatestapplicabledrawings,design

calculations,specificationsandinstructions,requiredbytheCode,aswellas

authorizedchanges,areusedformanufacture,assembly,examination,inspectionand

testing.Proceduresincludeprovisionfor

(1) reviewofcustomersupplieddocumentsforCodecompliance;

(2) thepreparation,review,approvalanddistributionofdrawings,calculations,

andspecifications:

A1.202/09(5/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

5.

QualityElementand

Subelements

(3)

[ApplicabletoU2andU3only]

useoftheusersCertifiedDesignSpecificationincludingauthorizedchanges;

(4)

[ApplicabletoU2andU3only]

providingtheManufacturersCertifiedDesignReportincludingauthorized

changes;

(5)

[ApplicabletoU2andU3only]

certificationofDesignSpecificationandDesignReportbyanengineermeeting

thecriteriadefinedinSectionVIIIDiv.2orDiv.3asapplicable;and

(6)

[ApplicabletoV,HV,UD,UV,UV3,TDandTVonly]

newcapacitycertificationtestsareconductedwhenchangesindesignare

madewhichaffectflowpath,liftorperformancecharacteristics.

(7) [ApplicabletoTClass3only],provisionsforDesignCertifiedEngineer.

MATERIALCONTROL

(a) Proceduresformaterialcontrolexisttoassurethatthematerialreceivedisproperly

identifiedandhasdocumentation,including,asapplicable,requiredmaterial

certificationsormaterialtestreports,tosatisfyCoderequirementsasordered.

(b) ThematerialcontrolsystemassuresthatonlytheintendedmaterialisusedinCode

construction.ForSectionXIIonly,materialshallsatisfytheapplicablemodel

appendicesrequirements.

(c) Ifsubstitutionofmaterialsisallowed,theapplicableproceduresforcontrolofthis

activityaredocumented,includingdesignationoftheindividualauthorizedto

approvesubstitutions.

(d) Thetitleoftheindividualresponsibleforidentifyingtheneedformaterialtest

reportsorcertificateofcomplianceisdesignated.

(e) ThetitleoftheindividualresponsibleforperformingareceivinginspectionofCode

materialsisdesignated.

(f)

Informationtobeprovidedtothereceivinginspectorconcerningthecharacteristicsto

becheckedisdocumented.

(g) Aprocedureexistsforhandlingmaterialsthatarefoundtobenonconformingat

receivinginspection.

(h) Iffurthermaterialtestingisrequiredtobeperformedatreceivinginspectionor

duringmanufacturingoperations,theapplicableproceduresforcontrolofthis

activityaredocumented.

A1.202/09(6/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

6.

QualityElementand

Subelements

(i)

Measuresareestablishedtoassurethepropermarking,handlingandstorageof

materials.

EXAMINATIONANDINSPECTIONPROGRAM

(a) Fabricationoperations,includingexaminationsandburstingtestprocedures(forH

CastIron)aredescribedinsufficientdetailtopermittheAI(ortheCertificateHolder

inthecaseofH(CastIron),V,HVUD,UV,UV3,TDandTV)todetermineatwhat

stagesspecificinspectionsaretobeperformed.Specifically:

(1)

Provisionsfortheuseofchecklists,processsheets,travelers,etc.,forlistingof

examinationsandteststobeperformedandfordesignationofinspection

points.

(2)

Suchchecklists,processsheets,travelers,etc,aremadeavailabletothe

Inspectorpriortothestartoffabrication.

(3)

[ApplicabletoRPOnly]

Abasicproductionflowdiagramexistsandincludesinplantinspectionand

checkoffpointsandmeansofrecordingthesame.

(b)

(c)

(d)

(e)

(f)

(g)

Materialtestreportsorcertificatesofcompliance,examinationreports,testrecords,

andotherfabricationrecordsareavailabletotheInspector.

Measuresprovidefortransferringmarkingstoassuretraceabilityismaintained.

(1)

Ifacodedmarkingsystemisused,itisdocumentedandacceptabletothe

Inspector.

MeasuresassurethattheInspectorisinformedofapproachinginspectionpoints.

[NotapplicabletoH(CastIron),TClass3,V,HV,UD,UV,UV3,TDandTV]

AIconcurrenceisobtainedforrepairstomaterial.

[NotapplicabletoH(CastIron),TClass3,V,HV,UD,UV,UV3,TDandTV]

Measuresareestablishedtoassurethatafinalinspectionisperformedtoassureall

specifiedrequirementshavebeenmetpriortoobtainingAIsconcurrencefor

applicationoftheCodeSymbolStamp.

[NotapplicabletoV,HV,UD,UVandUV3]

Measuresareestablishedtoprovideforthepreparation,certification,and

distributionoftheapplicableDataReports.

A1.202/09(7/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

7.

QualityElementand

Subelements

(h)

(i)

QCManual

References

Measuresareestablishedtocontrolfieldactivities,whenapplicable.

[ForoperationsunderUG90(c)(2),HG515.4(b)orTS200.7]

DocumentedproceduresexistandareacceptedbytheAuthorizedInspectionAgency

(AIA),JurisdictionalAuthority,andASMEDesignee.

Note:ProceduresshouldfullydescribeAIcoverageofASMECodeworkonallshifts.Also,

percentageofAItimespentinspectingvesselsorboilersthatmaynotqualifyfor

handlingunderUG90(c)(2),HG515.4(b)orTS200.7shouldbeaddressed.

(j)

[ApplicabletoH(CastIron)only]

Examinationandinspectionofeachboilerorboilerpartshallbeincompliancewith

Article2ofPartHC.

(k) [ApplicabletoH(CastIron)only]

HydrostatictestsareconductedasrequiredinHC410,andtherearemeansof

identifyingacceptableboilersectionsorparts.

(l)

[ApplicabletoRPonly]

(1) Resinmixingproceduresarespecified.

(2) Measuresareestablishedcoveringstorage,issuance,handling,anddisposalor

resins,catalysts,fillersandpigments.

(m) [ApplicabletoRPonly]

(1) Proceduresexistcovering

(i)assemblyandfitupofthepressurevesselandparts;and

(ii)adhesivebondingofcomponents.

(n) [ApplicabletoV,HV,UD,UV,UV3,TDandTVonly]

ProvisionsexistfortestingpressurereliefdevicesasdescribedinPG73.4,HG401.4

andUG136(d),UG137(d),KR340,TR210.4andTR310.5.

CORRECTIONOFNONCONFORMITIES

(a) Aprocedureexistsforthecorrectionofnonconformities.WhereAIinvolvementis

requiredbytheCode,theprocedureisagreeduponwiththeAI.Theprocedure

providesfor

(1) identifyingthoseresponsiblefortheresolutionofnonconformities;

A1.202/09(8/11)

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

8.

9.

QualityElementand

Subelements

(2) identifyingandcontrollingfurtherprocessingofnonconformingitemsuntil

finaldisposition;

(3) documentingthenonconformanceanditsdisposition;and

(4) [NotapplicabletoH(CastIron),TClass3,V,HV,UD,UV,UV3,TDandTV]

informingtheAIofnonconformingconditions.

Note: Anonconformityisanyconditionwhichdoesnotcomplywiththeapplicablerulesof

theCode,QCManualorotherspecifiedrequirements.Nonconformitiesmustbe

correctedbeforethecompletedcomponentcanbeconsideredtocomplywiththe

Code.

WELDING[NotapplicabletoH(CastIron)orRP]

(a) WeldingconformstorequirementsofSectionIXandotherSectionsoftheCode,as

applicabletothescopeofwork.

(b) ThoseresponsibleforcertifyingPQRsandWPQsareidentified.

(c) WPSsareavailabletothewelderintheworkarea.

(d) MeasuresassurecontinuedwelderqualificationinaccordancewithSectionIX.

(e) Thoseresponsibleforassuringthatonlyqualifiedweldersareassignedtoperform

Codeweldingareidentified.

(f)

Measuresprovideforthestorageandconditioning,asrequired,ofcovered

electrodes.

(g) Measuresareestablishedforthecontrol,issuanceandreturnofweldingmaterialto

assurepropermaterialsareused.

(h) Measuresareestablishedforremovingorinspectingtackwelds.

(i)

MeasuresprovidefortherightoftheAI[orASMEDesignatedOrganizationforV,

HV,UD,UV,UV3,TDandTV]torequirerequalificationofawelderorprocedurefor

cause.

(j)

Measuresprovideforasystemtoidentifyworkcompletedbyeachwelder.

NONDESTRUCTIVEEXAMINATION[NotapplicabletoH(CastIron)orRP]

(a) ProvisionsexistforidentifyingtheappropriateNDEproceduresapplicabletothe

scopeofCodework.Theseprovisionsassurethat:

A1.202/09(9/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

10.

11.

12.

QualityElementand

Subelements

(1)

NDEpersonnelarequalifiedinaccordancewiththeapplicableCodeSection

requirement;

(2)

NDE(UT,MTandPT)examinationsareperformedinaccordancewithwritten

procedureswhenrequired;

(3)

theAI[orarepresentativefromanASMEDesignatedOrganizationforV,HV,

UD,UV,UV3,TDandTV]canrequirerequalificationofanNDEexamination

orprocedureforcause;

(4)

UTreportsandRTfilms,asapplicable,areretainedinaccordancewiththe

applicableCoderequirement

(5) NDEequipmentiscalibrated.

HEATTREATMENT [NotapplicabletoH(CastIron)orRP]

(a) ControlsprovidedtoassurethatheattreatmentasrequiredbytheCodeforthescope

ofCodeworkisapplied.

(b) Measuresareestablishedtoassureproperplacementofthermocouplesanduseof

charts.

(c) Whenheattreatmentissubcontracted,measuresareestablishedtoassurethat

proceduresarefollowedandthatheattreatmentchartsareprovided.

(d) MeansareprovidedfortheAI[orarepresentativefromanASMEDesignated

OrganizationforV,HV,UD,UV,UV3,TDandTV]tosatisfythemthatCodeheat

treatmentrequirementsaremet,(e.g.,reviewoffurnacetimetemperaturerecordsor

othermethodsasappropriate).

CALIBRATIONOFMEASUREMENTANDTESTEQUIPMENT

(a) Aprocedureexistsforthecalibrationofexamination,measuringandtestequipment

usedinfulfillmentofapplicableCoderequirements.

(b) Measuresareestablishedthatassurecalibrationrecordsaremaintainedandthat

statusindicatorsareusedtoindicatethecurrentcalibrationstatusofequipment.

RECORDSRETENTION

(a) ProceduresexistforthemaintenanceofManufacturersDataReports,radiographs

andrecordsasrequiredbytheapplicableSectionoftheCode.

A1.202/09(10/11)

QCManual

References

QUALITYSYSTEMREVIEWCHECKLIST

Item

No.

QualityElementand

Subelements

13.

14.

15.

SAMPLEFORMS

(a) FormsusedtocontrolfunctionsrelativetoqualityareincludedwithintheQC

ManualandtheiruseexplainedinthetextoftheQCManual.

AUTHORIZEDINSPECTOR[NotapplicabletoH(CastIron),TClass3,V,HV,UD,UV,

UV3,TDandTV]

(a) AninspectionagreementisestablishedwithanASMEaccreditedAuthorized

InspectionAgency.

Note: ForSectionXIIClass2thiscouldbeaqualifiedinspector.

(b) AcontrolledcopyoftheQCManualisavailabletotheAIattheplantorconstruction

sitewhereCodeactivitiesarebeingcarriedout.

(c) TheAIhasaccesstoalldrawings,calculations,specifications,procedures,process

sheets,repairprocedures,records,testresults,andanyotherdocumentsasnecessary

fortheAItoperformtheirduties.

(d) ProvisionsexistforprovidingaliaisonbetweentheAIandthe

Manufacturer/Installer.

(e) ProvisionsexistforfreeaccessfortheAIandtheInspectionSupervisortoallareas

involvingCodeactivities.

(f)

ProvisionsexisttoassurethatallCoderequiredinspectionsbytheAIareperformed.

ASMEDESIGNEE[ApplicabletoH(CastIron),V,HV,UD,UV,UV3,TDandTVonly]

(a) AcontrolledcopyoftheQCManualisavailabletotheASMEDesigneeorASME

DesignatedOrganization,asapplicable.

(b) TheASMEDesigneeorrepresentativefromanASMEDesignatedOrganizationhas

accesstoalldrawings,calculations,specifications,procedures,processsheets,repair

procedures,records,testresults,andanyotherdocumentsasnecessaryfortheASME

DesigneetoperformthereviewinaccordancewiththeCode.

(c) [ApplicabletoV,HV,UD,UV,UV3,TDandTVonly]

ProvisionsexistfortheinspectionofpressurereliefvalvesasdescribedinPG73.3,

HG401.3,UG136(c),UG137(c),KR330,TR210.3andTR310.4.

A1.202/09(11/11)

QCManual

References

You might also like

- Redline Heavywall Data Sheet-12-16Document5 pagesRedline Heavywall Data Sheet-12-16Karthik AnandanNo ratings yet

- 350/M - FGP 450/M - FGP 550/M: Light-Oil Burners Two Stages Progressive or ModulatingDocument4 pages350/M - FGP 450/M - FGP 550/M: Light-Oil Burners Two Stages Progressive or ModulatingKarthik AnandanNo ratings yet

- Specification For Hot Water BoilersDocument6 pagesSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Quantometer For Secondary MeasurementsDocument4 pagesQuantometer For Secondary MeasurementsKarthik AnandanNo ratings yet

- Specification For Hot Water Boilers-9-10Document2 pagesSpecification For Hot Water Boilers-9-10Karthik AnandanNo ratings yet

- Specification For Hot Water BoilersDocument1 pageSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Self-Priming Liquid Ring Pumps: Installation and Use Performance RangeDocument4 pagesSelf-Priming Liquid Ring Pumps: Installation and Use Performance RangeKarthik AnandanNo ratings yet

- DWG Plate Coil AssyDocument2 pagesDWG Plate Coil AssyKarthik AnandanNo ratings yet

- Baltur Burner Page No 5Document1 pageBaltur Burner Page No 5Karthik AnandanNo ratings yet

- Guide 1Document9 pagesGuide 1Karthik AnandanNo ratings yet

- Parker Steam Boiler - Weekly Maintenance Report: WMR101-5Document2 pagesParker Steam Boiler - Weekly Maintenance Report: WMR101-5Karthik AnandanNo ratings yet

- DC 430Document66 pagesDC 430Karthik AnandanNo ratings yet

- Daily Boiler Blowdown Instructions 1.5-3 H.P. Parker Gas Fired BoilerDocument2 pagesDaily Boiler Blowdown Instructions 1.5-3 H.P. Parker Gas Fired BoilerKarthik AnandanNo ratings yet

- Materials Delivery Form: Supply of Water Level Controller (BD01/1) Supply of Water Level Controller (BD02/2)Document1 pageMaterials Delivery Form: Supply of Water Level Controller (BD01/1) Supply of Water Level Controller (BD02/2)Karthik AnandanNo ratings yet

- Weight of Inspection Door: 0.00 KG: MiscellaneousDocument11 pagesWeight of Inspection Door: 0.00 KG: MiscellaneousKarthik AnandanNo ratings yet

- 8.5 Welding ProcedureDocument47 pages8.5 Welding ProcedureKarthik Anandan100% (1)

- TEMA Data SheetDocument2 pagesTEMA Data SheetKarthik AnandanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Student/Proctor Agreement Form: Fill Out This Form and Return ToDocument1 pageStudent/Proctor Agreement Form: Fill Out This Form and Return ToRanayaNo ratings yet

- All HC Common Syllabus For Civil Judge ExamDocument3 pagesAll HC Common Syllabus For Civil Judge ExamMuhammad Sajid100% (4)

- Edre 146 R3Document2 pagesEdre 146 R3Mackenzie PatricioNo ratings yet

- Berkeley Review MCAT 1Document10 pagesBerkeley Review MCAT 1Ishita SharmaNo ratings yet

- Introduction and Overview For A Bar ChartDocument10 pagesIntroduction and Overview For A Bar ChartfarhanyazdaniNo ratings yet

- CL Accreditation of Tesco Certified QC Process and Note v1 PDFDocument11 pagesCL Accreditation of Tesco Certified QC Process and Note v1 PDFAbdullah Al HamimNo ratings yet

- StatisticsDocument8 pagesStatisticsHazel Grace BellenNo ratings yet

- The Rainbow Project PDFDocument30 pagesThe Rainbow Project PDFMalvika BabuNo ratings yet

- Updated NRSG 7050 Syllabus 2015 4Document7 pagesUpdated NRSG 7050 Syllabus 2015 4api-310557802No ratings yet

- Snippet of CIA Part 1 Test Bank Questions 2022Document239 pagesSnippet of CIA Part 1 Test Bank Questions 2022kinz787994% (17)

- Principles of Accounting I - Financial: Instructor: Wesley A. Tucker, CPADocument8 pagesPrinciples of Accounting I - Financial: Instructor: Wesley A. Tucker, CPAnurul000No ratings yet

- AWS Certified Solutions Architect Professional Exam GuideDocument3 pagesAWS Certified Solutions Architect Professional Exam GuideJhon HuamanchumoNo ratings yet

- SasDocument6 pagesSasసతీష్ పసులNo ratings yet

- ENGPROVDocument33 pagesENGPROVRyan SeolNo ratings yet

- Hero Motors Training & Development at Hero MotorsDocument76 pagesHero Motors Training & Development at Hero MotorsKashish AroraNo ratings yet

- Comm 220 Outline Summer 2012Document5 pagesComm 220 Outline Summer 2012Kevin GuérinNo ratings yet

- The Engineering Mathematics Self Learning Modules Independent Learning For Engineering FreshmenDocument8 pagesThe Engineering Mathematics Self Learning Modules Independent Learning For Engineering FreshmenkhairulazuadhusainNo ratings yet

- Dr. Emilio B. Espinosa, Sr. Memorial State College of Agriculture and Technology (Masbate State College) Cawayan CampusDocument3 pagesDr. Emilio B. Espinosa, Sr. Memorial State College of Agriculture and Technology (Masbate State College) Cawayan CampusRoger Yatan Ibañez Jr.No ratings yet

- Negaraku Versus Majulah SingapuraDocument6 pagesNegaraku Versus Majulah SingapuraBie_Tka_1459No ratings yet

- GMAT Official Score ReportDocument3 pagesGMAT Official Score ReportkanwarkahlonNo ratings yet

- Case Files Pharmacology, 3rd Edition (2017!07!18 02-28-27 UTC)Document375 pagesCase Files Pharmacology, 3rd Edition (2017!07!18 02-28-27 UTC)imperiouxx100% (2)

- Bilingual Articulation Phonology AssessmentDocument39 pagesBilingual Articulation Phonology AssessmentBarbara FernandesNo ratings yet

- Gold Seal Certification Program Expect ExcellenceDocument31 pagesGold Seal Certification Program Expect Excellencecanjobs2020No ratings yet

- NMCN CBT SensitizationDocument9 pagesNMCN CBT SensitizationchimelaciNo ratings yet

- Consolidated Advertisement No. 02/2016Document4 pagesConsolidated Advertisement No. 02/2016Ahsan KhanNo ratings yet

- Sbi Clerk Prelims 2021 Parallel Seating Arrangement QuestionsDocument11 pagesSbi Clerk Prelims 2021 Parallel Seating Arrangement QuestionsAkash SahuNo ratings yet

- MATH 324 Spring 2021 SuDocument2 pagesMATH 324 Spring 2021 SuHydeki RyugaNo ratings yet

- ME 610 - Data Acquisitions and Analysis: Kunal - Kate@louisville - EduDocument4 pagesME 610 - Data Acquisitions and Analysis: Kunal - Kate@louisville - Edubpierce12446No ratings yet

- MSE 52 Summer 2019 SyllabusDocument5 pagesMSE 52 Summer 2019 Syllabusglen_beckNo ratings yet

- Avid Site Team Plan 2015-2016Document7 pagesAvid Site Team Plan 2015-2016api-267445003No ratings yet