Professional Documents

Culture Documents

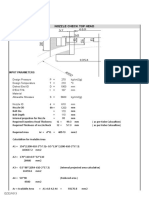

Thickness Calculation of Cylindrical Shell and Tube

Uploaded by

tasingenieriaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thickness Calculation of Cylindrical Shell and Tube

Uploaded by

tasingenieriaCopyright:

Available Formats

Item No.

Part

Material

SA-516-70

Shape

Cylindrical shell

Thickness calculation of cylindrical shell and tube

Code

ASME Section VIII Division 1; UG-27,UG-28

Design data

Symbols

Pi

Pe

Temp

Ci

Ce

E

Di

Tnom

Tol

L

Descriptions

Internal design pressure ,Bar

External design pressure ,Bar

Design temperature ,Degree C

Corrosion allowance at inside surface,mm

Corrosion allowance at outside surface,mm

Joint efficiency

Shell inside diameter in uncorroded condition ,mm

Shell nominal thickness ,mm

Permissible variation under specified thickness ,mm

Design length of shell ,mm

Values

12

1

100

1.5

1.5

0.85

1900

16

0.25

2500

Calculations

Under internal pressure

Maximum allowable stress value ,S

120.66

MPa

Required thickness ,Treq

0.05*Pi*(Di+2*Ci)

S*E-0.06*Pi

11.21

mm

Design thickness ,Tdes

Treq+Ci+Ce

14.21

mm < Tnom

Required thickness ,Treq

13.00

Shell outside diameter in corroded ,Doc

Di+2*(Tnom-Ce)

L/Doc

1.30

Doc/Treq

148.38

Factor determined from Fig.G ,A

0.0005611

Factor determined from Fig.CS-2 ,B

56.131

40*B

3*(Doc/Treq)

Yield strength ,Y

Se

MIN(2*S,0.9*Y)

Pa1

Pa2

Maximum allowable external pressure

Under external pressure

mm

= 1929.00 mm

>=

10

MPa

If Doc/Treq >= 10

Maximum allowable external pressure

5.04

2. 167

0. 0833 ]* 10 * B

Doc / Treq

20 * Se

1

*[1

]

Doc / Treq

Doc / Treq

MIN(Pa1,Pa2)

Bar > Pe

If Doc/Treq < 10

Satisfactory

You might also like

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- Nozzle Calculations: Understanding Asme Code Calculations-Pressure VesselsDocument28 pagesNozzle Calculations: Understanding Asme Code Calculations-Pressure VesselsRamakrishnan SrinivasanNo ratings yet

- Keys To The Ultimate Freedom PDFDocument245 pagesKeys To The Ultimate Freedom PDFdebtru100% (2)

- Pipe Thickness CalculationDocument1 pagePipe Thickness Calculationananyo_senguptaNo ratings yet

- Nozzle & FlangeDocument14 pagesNozzle & FlangeRaghNo ratings yet

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Design and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016Document13 pagesDesign and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016renu rani100% (1)

- Chapter 3 (PERFORMANCE MANAGEMENT AND STRATEGIC PLANNING)Document18 pagesChapter 3 (PERFORMANCE MANAGEMENT AND STRATEGIC PLANNING)shakeelakousar24100% (2)

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- ASME - Wake Frequency CalculationDocument7 pagesASME - Wake Frequency CalculationpsaayoNo ratings yet

- Mobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Document50 pagesMobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Neha Kumar100% (1)

- AIV and LOFDocument2 pagesAIV and LOFaw_aeNo ratings yet

- 4-10 Vacuum Stress in Pipe PDFDocument11 pages4-10 Vacuum Stress in Pipe PDFChristopher BrownNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- 39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01Document2 pages39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01masaminathanNo ratings yet

- 5 Dollar Trading PlanDocument3 pages5 Dollar Trading PlanTafadzwa Mangoma92% (25)

- Pipe Wall Thickness CalASME B31Document8 pagesPipe Wall Thickness CalASME B31Ton PhichitNo ratings yet

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Design Calculations For Pressure VesselsDocument28 pagesDesign Calculations For Pressure VesselsUmair AwanNo ratings yet

- Ancor Flanges Asme ViiiDocument3 pagesAncor Flanges Asme ViiiAnjani PrabhakarNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatNo ratings yet

- Module 5 Developing Mission, Vision, and ValuesDocument25 pagesModule 5 Developing Mission, Vision, and ValuesMatthew ScarellaNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Basis of Design - Pig Reciever 16 Design 2014Document27 pagesBasis of Design - Pig Reciever 16 Design 2014Andreas SchlagerNo ratings yet

- Surge CalculationsDocument7 pagesSurge CalculationsSameer MinhajNo ratings yet

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- ASME Air Tank DesignDocument2 pagesASME Air Tank Designchethan100% (1)

- Expansion Loop 1Document3 pagesExpansion Loop 1reach_arindomNo ratings yet

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- SLR Strainer Data SheetDocument7 pagesSLR Strainer Data SheetKailas NimbalkarNo ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Expansion LoopDocument54 pagesExpansion Loopsteepa22No ratings yet

- Pipe Wall Thickness Calculation According ASME B31 3Document93 pagesPipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- Alexander Galloway Laruelle Against The DigitalDocument321 pagesAlexander Galloway Laruelle Against The DigitaljacquesfatalistNo ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Pipe Size Flange Rating Operating Condition: E F SFDocument4 pagesPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- Wake Frequency Calculation: Customer: Tag No: Reference: DateDocument1 pageWake Frequency Calculation: Customer: Tag No: Reference: DateShakeel AhmedNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- PDIL-Stress Analysis Design Basis PDFDocument13 pagesPDIL-Stress Analysis Design Basis PDFDarshan Panchal100% (1)

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- Doshi Ion Exchange & Chemical Ind. LTD.: Material DataDocument7 pagesDoshi Ion Exchange & Chemical Ind. LTD.: Material DataMakrand Sakpal100% (5)

- Cross Country Piping Stress AnalysisDocument8 pagesCross Country Piping Stress Analysisprabu2001No ratings yet

- Ug-45 Nozzle Neck Thickness: Plus The Thickness Added For AllowancesDocument2 pagesUg-45 Nozzle Neck Thickness: Plus The Thickness Added For AllowancesLcm TnlNo ratings yet

- Type of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadDocument1 pageType of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadwhngomjNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- 117 Excerpts 2004Document7 pages117 Excerpts 2004Anonymous DJrec2No ratings yet

- BEM Code of Ethics - Ir. Yim Hon WaDocument53 pagesBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2No ratings yet

- Circulating Fluidized Bed Boiler Development Situation and ProspectsDocument4 pagesCirculating Fluidized Bed Boiler Development Situation and ProspectsAnonymous DJrec2No ratings yet

- External Friction Angle On The Geotechnical Information WebsiteDocument2 pagesExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- BEM Code of EthicsDocument11 pagesBEM Code of EthicsAbdul Hakim AbdullahNo ratings yet

- Industrial LowbayDocument8 pagesIndustrial LowbayAnonymous DJrec2No ratings yet

- Power Amps Efficiency PFDocument5 pagesPower Amps Efficiency PFAnonymous DJrec2No ratings yet

- Third Quarter 2016 Investment Outlook: Asset Class SectorDocument6 pagesThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2No ratings yet

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocument22 pagesDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2No ratings yet

- Sportage SL Pen-010112 PDFDocument1 pageSportage SL Pen-010112 PDFAnonymous DJrec2No ratings yet

- CiMB Research Report On REITDocument6 pagesCiMB Research Report On REITAnonymous DJrec2No ratings yet

- Zoning Plan Model1Document1 pageZoning Plan Model1Anonymous DJrec2No ratings yet

- Vol3 No2 Art1Document13 pagesVol3 No2 Art1Hariadi IrwansyahNo ratings yet

- Moncat Fatty Acid BookDocument10 pagesMoncat Fatty Acid BookAnonymous DJrec2No ratings yet

- Most Underrated Skills That'll Make You A Rockstar in The Staffing Agency IndustryDocument2 pagesMost Underrated Skills That'll Make You A Rockstar in The Staffing Agency Industrygalairae40100% (1)

- NOAH STANTON - 3.1.3 and 3.1.4 Creating Graphs and Finding SolutionsDocument7 pagesNOAH STANTON - 3.1.3 and 3.1.4 Creating Graphs and Finding SolutionsSora PhantomhiveNo ratings yet

- 5070 s10 QP 41Document30 pages5070 s10 QP 41G M Ali KawsarNo ratings yet

- Activity 1 CONDUCTING AN INTERVIEW WITH AN OFWDocument5 pagesActivity 1 CONDUCTING AN INTERVIEW WITH AN OFWSammuel De BelenNo ratings yet

- L A Level Physics A MS Jun 2008 Old g481Document69 pagesL A Level Physics A MS Jun 2008 Old g481dasha962No ratings yet

- FMI Longitudinal PonudaDocument6 pagesFMI Longitudinal PonudaD Kao DraganNo ratings yet

- Good Practice Guide No. 120: Avoidance of Corrosion in Plumbing SystemsDocument16 pagesGood Practice Guide No. 120: Avoidance of Corrosion in Plumbing SystemsMochamad Irvan MaulanaNo ratings yet

- 9ER1 Question BookletDocument16 pages9ER1 Question BookletCSC TylerNo ratings yet

- Relationship With Josephine BrackenDocument9 pagesRelationship With Josephine BrackenNothingNo ratings yet

- Waking Up Gasping For Air Anxiety, Falling Asleep, Acid RefluxDocument1 pageWaking Up Gasping For Air Anxiety, Falling Asleep, Acid RefluxAstra CardinalNo ratings yet

- Ryan PrintDocument24 pagesRyan PrintALJHON SABINONo ratings yet

- 100 Golden Rules of English Grammar For Error Detection and Sentence ImprovementDocument8 pages100 Golden Rules of English Grammar For Error Detection and Sentence ImprovementHajra bibiNo ratings yet

- Introducing The True Ekklesia of Jesus ChristDocument5 pagesIntroducing The True Ekklesia of Jesus ChristRamil Moreno SumangilNo ratings yet

- VungleDocument14 pagesVunglegaurdevNo ratings yet

- Air Quality Report - SWDocument43 pagesAir Quality Report - SWromesh 96No ratings yet

- Datasheet Ls 7222Document4 pagesDatasheet Ls 7222Martín NestaNo ratings yet

- Consider The Rape of The Lock As A Social SatireDocument3 pagesConsider The Rape of The Lock As A Social SatireElena AiylaNo ratings yet

- CEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsDocument26 pagesCEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsMAHESH CHANDNo ratings yet

- kPI Dashboard Excel Template Free Download - Hkwr8Y7WQTb4BZ5Document16 pageskPI Dashboard Excel Template Free Download - Hkwr8Y7WQTb4BZ5arjanimpexhoNo ratings yet

- Updated Nca PDFDocument914 pagesUpdated Nca PDFRio Corral100% (1)

- Unit Plan Lesson 1 - 3Document16 pagesUnit Plan Lesson 1 - 3api-547362187No ratings yet

- The Dynamics of Hate Speech and Counter Speech in The Social Media - English 1Document16 pagesThe Dynamics of Hate Speech and Counter Speech in The Social Media - English 1A MNo ratings yet

- The Use of Salicylaldehyde Phenylhydrazone As An Indicator For The Titration of Organometallic ReagentsDocument2 pagesThe Use of Salicylaldehyde Phenylhydrazone As An Indicator For The Titration of Organometallic ReagentsLuca PeregoNo ratings yet

- mathematicsproficiencyattitudeandperformanceofgrade9studentsinprivatehighschoolsinBukidnonPhilippines PDFDocument15 pagesmathematicsproficiencyattitudeandperformanceofgrade9studentsinprivatehighschoolsinBukidnonPhilippines PDFNacivah BasherNo ratings yet