Professional Documents

Culture Documents

Rotary Valves

Rotary Valves

Uploaded by

jps27Copyright:

Available Formats

You might also like

- Honda CVT ManualDocument142 pagesHonda CVT ManualHussein Mohamed95% (38)

- Screen OneDocument2 pagesScreen OneMtyghm Tymmt100% (1)

- Design Procedure of A Pyramid Shaped HopperDocument4 pagesDesign Procedure of A Pyramid Shaped HopperOkayNo ratings yet

- Calculation of AirslidesDocument6 pagesCalculation of AirslidesSelvakumar PonramNo ratings yet

- Bucket Elevator CatalogDocument20 pagesBucket Elevator CatalogLeonardo De la CruzNo ratings yet

- CFD Analysis of Pressure Coefficient For NACA 4412Document3 pagesCFD Analysis of Pressure Coefficient For NACA 4412seventhsensegroupNo ratings yet

- Structural Tanks and ComponentsDocument19 pagesStructural Tanks and ComponentsRodolfo Olate G.100% (1)

- AS350 Manual-HydraulicsDocument34 pagesAS350 Manual-HydraulicsJudd100% (2)

- Catalogo Apache Rtr180 PDF 2012Document48 pagesCatalogo Apache Rtr180 PDF 2012Edgar Sorto63% (8)

- Dyna PoreDocument12 pagesDyna PoreaminNo ratings yet

- Rotary Valves Feeders and AirlocksDocument7 pagesRotary Valves Feeders and Airlocksmarvin17100% (1)

- Perhitungan Rotary DryerDocument4 pagesPerhitungan Rotary DryerDella Ayu MeitasariNo ratings yet

- Most Mikro ACM® - Air Classifying Mill SystemsDocument12 pagesMost Mikro ACM® - Air Classifying Mill SystemsCesar EnochNo ratings yet

- Donaldson UK Manual TDS PDFDocument19 pagesDonaldson UK Manual TDS PDFPatricio TamayoNo ratings yet

- DFZC 7985 1 91 en - GB 1211Document4 pagesDFZC 7985 1 91 en - GB 1211RogerioNo ratings yet

- Data Sheet For Rotary Valve VRT-301 Rev.1Document1 pageData Sheet For Rotary Valve VRT-301 Rev.1Long Ellery Pham0% (1)

- Cascade Air Separator KVT enDocument6 pagesCascade Air Separator KVT enkamjulajayNo ratings yet

- Continuous Disc Dryer: Use and FunctionDocument4 pagesContinuous Disc Dryer: Use and FunctionDouglas TondelloNo ratings yet

- GA-150027-1 (003) Ffetbigbore1750 PDFDocument1 pageGA-150027-1 (003) Ffetbigbore1750 PDFriinNo ratings yet

- A554 y 730 HV DWG Hva 300Document1 pageA554 y 730 HV DWG Hva 300josephNo ratings yet

- MBL Volkmann Che Mag IsDocument47 pagesMBL Volkmann Che Mag IsarizakarolNo ratings yet

- Rotary ValveDocument2 pagesRotary Valvechem_taNo ratings yet

- Power Powders: The inDocument6 pagesPower Powders: The insalkan_rahmanovic810No ratings yet

- Chain Appron Conveyor R1a01-BushingDocument1 pageChain Appron Conveyor R1a01-Bushinger_winwibowoNo ratings yet

- Dosing Solutions - Rotary Airlock Feeder Blow Through - Palamatic ProcessDocument4 pagesDosing Solutions - Rotary Airlock Feeder Blow Through - Palamatic Processxxx0% (1)

- Flap Valve Angular: Machine Manual En-11091.011-FDocument20 pagesFlap Valve Angular: Machine Manual En-11091.011-FRahmat HidayatNo ratings yet

- Modelling of Rotary KilnsDocument123 pagesModelling of Rotary KilnsLuis Gabriel L. CatalanNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Linear Screen SizingDocument4 pagesLinear Screen SizingHARIPRASADNo ratings yet

- Belt Tension CalculatorDocument1 pageBelt Tension Calculatortnchsg100% (1)

- Comex Air ClassifierDocument8 pagesComex Air ClassifierFiroj AlamNo ratings yet

- 07 Elevators Deep Buckets DIN 15234 02Document1 page07 Elevators Deep Buckets DIN 15234 02mkiani2No ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- GKN Filter Technology Sika-R Is As enDocument16 pagesGKN Filter Technology Sika-R Is As encaapromoNo ratings yet

- TR521 Tier 4i - 1112 - WebDocument6 pagesTR521 Tier 4i - 1112 - WebBrunoNo ratings yet

- Ash CoolerDocument8 pagesAsh CoolerthiyagarajankNo ratings yet

- Should I Replace My Electrostatic Precipitator (ESP) With A Fabric Filter (FF) ?Document19 pagesShould I Replace My Electrostatic Precipitator (ESP) With A Fabric Filter (FF) ?Anonymous yF1z4oNo ratings yet

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Document2 pagesNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131No ratings yet

- PROK Product CatalogueDocument32 pagesPROK Product CatalogueDiego AndradeNo ratings yet

- Technical Manual Bag FilterDocument14 pagesTechnical Manual Bag Filterjp nayak100% (1)

- Installation Equipment: Sanitary Fittings and ValvesDocument89 pagesInstallation Equipment: Sanitary Fittings and ValvesSebassde0% (1)

- Westrup BrochureDocument36 pagesWestrup BrochureADS ADSNo ratings yet

- Ball Mill Capacity Dimensions PAUL O ABBEDocument2 pagesBall Mill Capacity Dimensions PAUL O ABBEaghilifNo ratings yet

- SchuF Valve Guide v6Document57 pagesSchuF Valve Guide v6Adam Chapin100% (1)

- Geho ZPM TZPM Series Spec SheetDocument1 pageGeho ZPM TZPM Series Spec SheetSandy ZhangNo ratings yet

- 11-2756-b Elevator Boot Assy 28SIDocument1 page11-2756-b Elevator Boot Assy 28SIBoanerges BritoNo ratings yet

- AVE Ribbon Blenders 2020Document4 pagesAVE Ribbon Blenders 2020Hitesh DesaiNo ratings yet

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocument1 pageDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89No ratings yet

- Line Sizing Tool Hydrogen LineDocument31 pagesLine Sizing Tool Hydrogen LineAhmed HassanNo ratings yet

- Hangers Hanger BearingsDocument10 pagesHangers Hanger BearingsDouglas BatistellaNo ratings yet

- Rbs PerformancesDocument28 pagesRbs PerformancesMarcos Carvalho100% (1)

- Baghouse Filter Modular Pulse Jet Type: Operation and ApplicationDocument5 pagesBaghouse Filter Modular Pulse Jet Type: Operation and ApplicationBudy AndikaNo ratings yet

- 185-170-5-300-M44-0055 RevBDocument1 page185-170-5-300-M44-0055 RevBVashish RamrechaNo ratings yet

- Crack Propogation in KILNDocument9 pagesCrack Propogation in KILNSiddharth DeshmukhNo ratings yet

- Catalogo Filtros de Aire DanthermDocument158 pagesCatalogo Filtros de Aire Danthermipla_mecanico359No ratings yet

- Conveyor Cross Section at Each Typical Segment r0 - c3Document1 pageConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNo ratings yet

- TS 1600-140 - Datenblatt - V3Document2 pagesTS 1600-140 - Datenblatt - V3Ulfah Fauziyyah0% (1)

- Block 10 Module 3Document14 pagesBlock 10 Module 3Sandra FerrellNo ratings yet

- A406 - Manuale Cappa e BruciatoriDocument478 pagesA406 - Manuale Cappa e BruciatoriLuis Cruz100% (1)

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Rotolok UK Rotary Valves AirlocksDocument6 pagesRotolok UK Rotary Valves AirlocksAngel AlvarezNo ratings yet

- Alborz Industrial Air CoDocument4 pagesAlborz Industrial Air CoaminNo ratings yet

- 8C Throttle Trip ValvesDocument4 pages8C Throttle Trip Valvesjr110livecom100% (1)

- MH - 3 Instruction Manual (Operation Manual 1)Document71 pagesMH - 3 Instruction Manual (Operation Manual 1)alin_popovici_12No ratings yet

- Sub-Water Demand Cal (27062010)Document59 pagesSub-Water Demand Cal (27062010)Tiffany CombsNo ratings yet

- QX140191-LD75-160-H RepsnetDocument68 pagesQX140191-LD75-160-H Repsnetabdur rohmanNo ratings yet

- Piston Valve KVN-15-50: Material of ConstructionDocument3 pagesPiston Valve KVN-15-50: Material of Constructionjcojedar2009No ratings yet

- Si - Guidelines For The Supply of Water To Fire Sprinkler Systems 09-2004 PDFDocument10 pagesSi - Guidelines For The Supply of Water To Fire Sprinkler Systems 09-2004 PDFcarolyne smithNo ratings yet

- WINNER-Poppet Solenid Operated Valves PDFDocument85 pagesWINNER-Poppet Solenid Operated Valves PDFВладиславМасарскийNo ratings yet

- 40 MT Tyre MountedDocument5 pages40 MT Tyre MountedramyaNo ratings yet

- A6V10218252 - Rotary Actuators GDB..9E GLB..9E - enDocument6 pagesA6V10218252 - Rotary Actuators GDB..9E GLB..9E - enSAINo ratings yet

- Sporlan Thermostatic Expansion ValvesDocument19 pagesSporlan Thermostatic Expansion ValvesevrimkNo ratings yet

- 77-9075 DD5Document72 pages77-9075 DD5Imad AghilaNo ratings yet

- WallMountedS30 36AHP ServiceManualDocument75 pagesWallMountedS30 36AHP ServiceManualSonia Alejandra LopezNo ratings yet

- STAUFF Catalogue 7 STAUFF Test EnglishDocument84 pagesSTAUFF Catalogue 7 STAUFF Test EnglishKartalNo ratings yet

- T700 TutorialDocument95 pagesT700 TutorialEnzo Rubinace100% (3)

- Sistema Hidraulico CAT 966FDocument24 pagesSistema Hidraulico CAT 966FNicolas AvocNo ratings yet

- JCM 415 Type 2 Installation Instruction 0306Document2 pagesJCM 415 Type 2 Installation Instruction 0306Hoang Bao HaNo ratings yet

- Material Requisition (MR) : 1.: CascadeDocument7 pagesMaterial Requisition (MR) : 1.: CascadesubudhiprasannaNo ratings yet

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaNo ratings yet

- Bop Hoist InstallationDocument20 pagesBop Hoist InstallationShag ShaggyNo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Super 8 50 (4T) - KL10SA (RO) - 2009.10.15.Document98 pagesSuper 8 50 (4T) - KL10SA (RO) - 2009.10.15.Costinel CTNNo ratings yet

- Model FCDocument23 pagesModel FCLeandroNo ratings yet

- Honeywell ml7420 User ManualDocument8 pagesHoneywell ml7420 User ManualLaurensius ArdiNo ratings yet

- Chalwyn Product Selection Guide LowResDocument16 pagesChalwyn Product Selection Guide LowResElsad HuseynovNo ratings yet

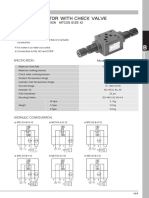

- MTC 03 W Throttle Check ValveDocument4 pagesMTC 03 W Throttle Check Valve박준용No ratings yet

- WFT101353 Weatherford Valves - CatalogoDocument13 pagesWFT101353 Weatherford Valves - Catalogoandres peraltaNo ratings yet

- Explosivo PartesDocument2 pagesExplosivo PartesJOSE INESNo ratings yet

- Documentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS RomaniaDocument80 pagesDocumentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS Romaniajoko setiawanNo ratings yet

Rotary Valves

Rotary Valves

Uploaded by

jps27Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotary Valves

Rotary Valves

Uploaded by

jps27Copyright:

Available Formats

ROTARY VALVES & AIRLOCKS

everything under control...

ROTARY VALVES & AIRLOCKS

INTRODUCTION

STANDARD FEATURES

The prime function of a rotary valve is to regulate

the flow from one chamber to another while

maintaining a good airlock condition. The product

is mainly in dry powder or granular form.

Maximum number of blades in contact with

In the dust filtration field good airlocks are

essential on cyclone and bag filter applications

in order that the manufacturers quoted high dust

collection efficiencies can be maintained.

Airlocks are also important in the pneumatic

conveying industry, where product is regulated

into a high pressure conveying line while

minimising air leakage.

With Rotolok there are no double standards, all

our standard valves are precision machined for

close tolerances and minimal eccentricities.

Pressure differentials to 20psi and temperatures

to 750 F.

We have made specials to handle temperatures

covering 2200 F and pressures to 350psi.

body at one time without affecting

throughput.

Good throat opening at valve entry allowing

high pocket filling efficiency.

Minimum clearance at rotor tips and sides

with body.

Robust body adequately stiffened to prevent

distortion.

Heavy shaft diameters minimising

deflection.

Outboard bearings for non-contamination.

Packing gland type seals.

Maximising valve speed to 25 rpm prolonging life, ensuring good throughput.

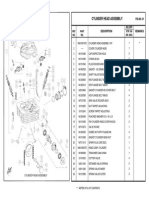

Square Rotary Valve

OPTIONS

Quick Release Rotors

Precision machining of components.

Direct Coupled Drives

All add up to Rotolok standards.

Air Purge Glands

Body Vents

Vent Boxes

SPECIFICATION

Dropout Boxes

Bodies - Cast Iron, Stainless Steel or Aluminum precision bored.

V.S. Drives

End Covers - Cast Iron, Stainless Steel or Aluminum spigot located in body for concentricity.

Speed Switches

Rotor - Fabricated Mild or Stainless Steel.

Flameproof Motors

Bearings - Sealed-for -life-ball type rigged outboard or high temperature above 475 F.

Shaft Seal - Gland type with PTFE packing.

Shear Plate Deflectors

Electroless Nickel Plating

Drive - TEFC geared motor unit side wall mounted to valve body and complete with taper

lock sprockets chain drive all in an enclosed guard.

Hard Chrome Internals etc.

Air Purge

Gland

Round Rotary Valve

Quick Release Rotor Detail

Body Vent

ROTARY VALVES & AIRLOCKS

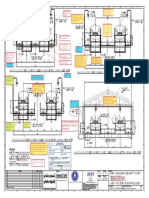

SQUARE INLET

PLANNING-IN DETAIL

FOR GENERAL GUIDANCE ONLY

(TO COVER SAFETY ASPECTS

ASK FOR OUR SAFETY LEAFLETS)

Drillings are Rotolok standards. Variations can be made.

VALVE SIZE

SQUARE ROTARY VALVES

SIZE

A1

B1

8 7/8

8 7/8

1/2

3 7/8

7 3/4

7 7/8

6 1/4

9 1/8

16

8 5/8

28

4 5/8

9/16

9 7/8

9 7/8

1/2

5 1/2

11

7 1/8

6 7/8

9 3/4

16

9 1/4 7 3/4

28

4 5/16

12

1/2

2 3/4

2 3/4

1/2

11 7/8 11 7/8

5/8

6 1/2

13

6 1/8

7 7/8 10 3/4

16

10 1/4

8 5/8

28

5 5/8

12

1/2

3 9/16

3 9/16

1/2

10

10

10

13 1/4 13 1/4

5/8

7 1/2

15

7 7/8

12 3/4 18 7/8 11 1/2 9 7/8

35

6 5/16

12

9/16

10

12

12

12

15 3/4 15 3/4

1/2

9 1/16 18 1/8 6 3/4 10 1/4 13 7/8 18 7/8 12 5/8

11

35

7 11/16

12

1/2

10

4 11/16

4 11/16

14

14

14

18 1/2 18 1/2

3/4

10 1/8 20 1/4 6 3/8

11 3/8

35

8 11/16

12

1/2

10

5 1/2

5 1/2

16

16

16

21 5/8 21 5/8 3/4

11 7/8 22 7/8 4 1/2

13

16 3/4 24 5/8 15 7/8 13 7/8

50

9 1/4

12

11/16

14

6 1/2

6 1/2

1 1/2

18

18

18

3/4

12 5/8 24 7/8 3 3/8

14

17 3/4 24 5/8 16 7/8 14 7/8

50

11 1/4

12

11/16

14

7 3/8

7 3/8

20

20

20

25 5/8 25 5/8

3/4

13 3/8 26 3/8

15

18 3/4 27 1/2 17 7./8 15 7/8

50

11 3/8

16

11/16

14

5 13/16

5 13/16

24

24

24

29 1/2 29 1/2

3/4

17

20 3/4 27 1/2 19 3/4 17 3/4

50

13 3/16

16

11/16

14

6 13/16

6 13/16

29 1/2 29 1/2 39 3/8 39 3/8

19 5/8 39 3/8

19 3/4 25 1/4 35 3/4 23 7/8 20 1/2

70 17 11/16

24

11/16

20

12

5 7/8

5 7/8

23 5/8 47 1/4

-1

23 7/8 29 1/2 39 3/8 27 7/8 24 5/8

70

24

7/8

20

12

6 7/8

6 7/8

30

36

36

36

24

24

45 7/8 45 7/8

15

29 1/2 4 1/2

10 5/8 14 3/8 20 1/8

13

All dimensions in inches.

21 1/4

ON APPLICATION

H.P.

1/2

ROTARY VALVES & AIRLOCKS

CIRCULAR INLET

PLANNING-IN DETAIL

FOR GENERAL GUIDANCE ONLY

(TO COVER SAFETY ASPECTS

ASK FOR OUR SAFETY LEAFLETS)

Rotolok manufactures and

casts other valve sizes with

rectangular & other nonstandard inlets. If you are

looking for something

considered special it may be

in our library of valves.

Drillings are Rotolok standards. Variations can be made.

ROUND ROTARY VALVES

3/8

2 3/8 4 3/4

H.P

*DETAILS ON APPLICATION

*DETAILS ON APPLICATION

3 1/2 3 3/8

VALVE SIZE

7 1/2

3/8

3 1/8 6 1/4

9 1/2

1/2

4 1/4

11 1/4

1/2

12 1/2

10

10

12

8 1/2

4 5/8

7 3/4

6 1/4

SIZE A

9 1/8

16

8 5/8

5 1/2 10 5/8 7 1/8

6 7/8 9 3/4

16

1/2

6 1/4 12 1/4 6 1/8

7 7/8 10 3/4

16

14 1/2

5/8

7 7/8

28

5 5/8

11/16

7 7/8

1/2

9 1/4 7 5/8

28

5 5/8

7/8

9 1/2

1/2

10 1/4 8 5/8

28

5 5/8

11/16

11

1/2

12 3/4 18 7/8 11 3/8 9 3/4

35

6 1/8

11/16 12 5/8

10

12

17 3/8

3/4

9 1/2 18 3/8 6 3/4 10 1/4 13 7/8 18 7/8 12 5/8

35 7 11/16

12

7/8

15 1/2

10

14

14

21

3/4

10 5/8 20 1/2 6 3/8

11 3/8

35

8 11/16

12

7/8

17 1/2

10

16

16

21 1/4

3/4

11 7/8 22 7/8 4 3/8

13

16 3/4 24 5/8 15 7/8 13 7/8

50

9 1/4

12

7/8

19 1/2

14

1 1/2

18

18

25

3/4

12 5/8 24 5/8

14

17 3/4 24 5/8 16 1/2 14 7/8

50

11 1/4

16

1 1/4

22 3/4

14

20

20

27 1/2

3/4

13 3/8 26 3/8

15

18 3/4 27 1/2 17 7/8 15 7/8

50

11 3/8

20

1 1/4

25

14

24

24

32

3/4

15 1/8

17

20 3/4 27 1/2 19 3/4 17 7/8

50

13 3/16

20

1 3/8

29 1/2

14

30

30

38 3/4

70 17 11/16

28

1 3/8

36

20

12

15

30

19 5/8 39 3/8

10 5/8 14 3/8 20 1/4

13

11

19 3/4 25 1/2 35 7/8 23 7/8 20 1/2

All dimensions in inches.

ROTARY VALVES & AIRLOCKS

STANDARD ROTORS

Rotolok basically manufactures four types of rotor

as outlined, but to give the plant engineer

flexibility many variations can be accommodated,

e.g. closed/tipped, reduced volume, staggered

blades etc. We will make a rotor to suit your

application - not our production.

VALVE SELECTION

Closed rotor

Suitable for general use on filters, cyclones, silos,

screw conveyors and on low pressure conveying

systems. Sealing by means of packing gland.

Open adjustable bladed rotor

Suitable for most products and pressure differentials

to 20 psi. Blades are adjustable, reversible and

replaceable and can be supplied in mild steel, PVC rigid,

PTFE, stainless steel etc. to suit particular product. Can

be adapted to suit highly abrasive materials.

Open fixed bladed rotor

Suitable for general range of products and particularly

suitable on conveying systems to pressure of 15 psi.

Sealing is by packing gland type with standard packing

being fluolion or equal.

Scalloped rotor

Particularly suitable for sticky materials and discharge

can be further aided by the application of PTFE coating,

generally used in food processes where no product buildup can be tolerated. Pressures to 15 psi are applicable.

The chart below gives theoretical and estimated

throughputs on the basis of rotor speed.

The theoretical figure is determined by the swept

volume of the valve and is calculated on a pocket

fillage of 100%.

In practice this is seldom achieved as density,

product characteristics, pressure differential,

feeding methods, all affect the valve throughput

efficiency.

On these considerations the estimated figures

are assessed and are more acceptable for

selecting the correct valve. e.g. Select a valve

to handle 7 tons/hour of flour at 35 lb/cu. ft.

Volume required = 7.0 x 2000 35 = 400 cu.

ft/hr.

Capacity Chart in Cubic Feet/Hr

36

30

24

20

From the chart, two valves economically

cover this:

1. 10 Valve at 26 rpm.

2. 12 Valve at 12 rpm.

18

With flour being sluggish and the 10 unit on its

uppermost speed, the selection is limited to the

12 unit.

12

Factors other than throughput can sometimes

determine valve selection. This is particularly

true on cyclone and filter applications where the

valve inlet size to prevent bridging can become

the governing factor, always with the proviso that

the potential valve discharge rate exceeds the

collecting rate.

16

14

10

8

6

5

3.5

2

1158

1158

681

681

356

356

205

205

149

149

104

104

65.2

65.2

45.4

45.4

25.6

25.6

12.7

12.7

5.0

5.0

2.8

2.8

.96

.96

.228

.228

5792

5792

3405

3405

1780

1780

1024

1024

743

743

519

519

326

326

227

227

128

128

63

63

25

25

14

14

4.8

4.8

1.1

1.1

9266 11583 13900 16216 18533 20849 23166 25483

8803 10425 12232 13946 15568 16888 18069 18857

5448 6809 8171 9533 10895 12257 13619 14981

5176 6128 7190 8198 9152 9928 10623 11086

2848 3560 4272 4984 5696 6408 7120 7832

2706 3204 3759 4286 4785 5190 5554 5796

1639 2048 2458 2868 3277 3687 4097 4506

1557 1843 2163 2466 2753 2986 3196 3334

1189 1487 1784 2082 2379 2676 2974 3271

1130 1338 1570 1791 1998 2168 2320 2421

830 1037 1245 1452 1660 1867 2075 2282

789

933 1096 1249 1394 1512 1618 1689

521

652 782 912 1043 1173 1303 1434

495

587 688 784 876 950 1016 1061

363

454 545 636 727 818 908 999

354

409 480 547 611 663 708 739

205

256 307 359 410 461 512 564

195

230 270 309 344 373 399 417

101

127 152 177 203 228 253 279

96

114 134 152 171 185 197 206

40

50

60

71

81

91

101 111

38

45

53

61

68

74

79

82

23

28

34

39

45

51

56

62

22

25

30

34

38

41

44

46

7.7

9.6 11.5 13.4 15.4 17.3 19.2 21.1

7.3

8.6 10.1 11.5 12.9 14

15

15.6

1.8

2.3 2.7

3.2

3.6 4.1

4.6

5.0

1.7

2.1

2.4

2.7

3

3.3

3.6

3.7

10

12 14 16 18 20

Rotor Speed RPM

22

27799

19737

16343

11604

8544

6066

4916

3490

3568

2533

2490

1768

1564

1110

1090

774

615

437

304

216

121

86

68

48

23

16.3

5.5

3.9

30116

20479

17704

12039

9255

6293

5326

3622

3866

2629

2697

1834

1694

1152

1181

803

666

453

329

224

131

89

73

50

25

17

5.9

4

24

26

100%

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

Practical

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

100%

Practical

NOTES

Throughput

Certain products when fluidised can greatly

exceed the conservative rating and on

application, e.g. cement, 100% pocket fillage

has been known to occur - similarly light

products up to 15lb/cu. ft. the opposite effect

can happen.

Temperature

Note: On any application above ambient (70F)

it is important to specify operating

temperatures so rotor compensation for

expansion can be adjusted as necessary.

Conversions

Divide cubic metres/hr by 0.0283 to obtain

cubic feet/hr.

Theoretical capacity 100% pocket fillage

efficiency.

Conservative estimated throughout.

OTHER ROTOLOK PRODUCTS

Rotary Airlocks

Conveying Diverters

Double Dumps

Blowing Seals

Fabricated Slides

Slim Slides

Rotoslides

Rotoflex Valves

Slimflex Valves

Butterfly Dampers

Weigh Valves

Plug Diverters

Screw Conveyors

Gravity Diverters

Rotospeed Switch

Level Lok

Pipe Couplings

Ni Hard Bends

Special Designs

SPECIAL ROTARY VALVES

Rotolok manufactures other valve sizes with rectangular and other non

standard inlets. We have also made specials to handle temperatures of

2200F and pressures of 350 p.s.i. If you are looking for something special

please ask for our ODDBALL Brochure.

Rotolok Valves Inc

Industrial Ventures II, 2711 Gray Fox Road

Monroe, North Carolina, 28110

Tel: (704) 282-4444 Fax: (704) 282-4242

e-mail: sales@rotolok.com

website: www.rotolok.com

You might also like

- Honda CVT ManualDocument142 pagesHonda CVT ManualHussein Mohamed95% (38)

- Screen OneDocument2 pagesScreen OneMtyghm Tymmt100% (1)

- Design Procedure of A Pyramid Shaped HopperDocument4 pagesDesign Procedure of A Pyramid Shaped HopperOkayNo ratings yet

- Calculation of AirslidesDocument6 pagesCalculation of AirslidesSelvakumar PonramNo ratings yet

- Bucket Elevator CatalogDocument20 pagesBucket Elevator CatalogLeonardo De la CruzNo ratings yet

- CFD Analysis of Pressure Coefficient For NACA 4412Document3 pagesCFD Analysis of Pressure Coefficient For NACA 4412seventhsensegroupNo ratings yet

- Structural Tanks and ComponentsDocument19 pagesStructural Tanks and ComponentsRodolfo Olate G.100% (1)

- AS350 Manual-HydraulicsDocument34 pagesAS350 Manual-HydraulicsJudd100% (2)

- Catalogo Apache Rtr180 PDF 2012Document48 pagesCatalogo Apache Rtr180 PDF 2012Edgar Sorto63% (8)

- Dyna PoreDocument12 pagesDyna PoreaminNo ratings yet

- Rotary Valves Feeders and AirlocksDocument7 pagesRotary Valves Feeders and Airlocksmarvin17100% (1)

- Perhitungan Rotary DryerDocument4 pagesPerhitungan Rotary DryerDella Ayu MeitasariNo ratings yet

- Most Mikro ACM® - Air Classifying Mill SystemsDocument12 pagesMost Mikro ACM® - Air Classifying Mill SystemsCesar EnochNo ratings yet

- Donaldson UK Manual TDS PDFDocument19 pagesDonaldson UK Manual TDS PDFPatricio TamayoNo ratings yet

- DFZC 7985 1 91 en - GB 1211Document4 pagesDFZC 7985 1 91 en - GB 1211RogerioNo ratings yet

- Data Sheet For Rotary Valve VRT-301 Rev.1Document1 pageData Sheet For Rotary Valve VRT-301 Rev.1Long Ellery Pham0% (1)

- Cascade Air Separator KVT enDocument6 pagesCascade Air Separator KVT enkamjulajayNo ratings yet

- Continuous Disc Dryer: Use and FunctionDocument4 pagesContinuous Disc Dryer: Use and FunctionDouglas TondelloNo ratings yet

- GA-150027-1 (003) Ffetbigbore1750 PDFDocument1 pageGA-150027-1 (003) Ffetbigbore1750 PDFriinNo ratings yet

- A554 y 730 HV DWG Hva 300Document1 pageA554 y 730 HV DWG Hva 300josephNo ratings yet

- MBL Volkmann Che Mag IsDocument47 pagesMBL Volkmann Che Mag IsarizakarolNo ratings yet

- Rotary ValveDocument2 pagesRotary Valvechem_taNo ratings yet

- Power Powders: The inDocument6 pagesPower Powders: The insalkan_rahmanovic810No ratings yet

- Chain Appron Conveyor R1a01-BushingDocument1 pageChain Appron Conveyor R1a01-Bushinger_winwibowoNo ratings yet

- Dosing Solutions - Rotary Airlock Feeder Blow Through - Palamatic ProcessDocument4 pagesDosing Solutions - Rotary Airlock Feeder Blow Through - Palamatic Processxxx0% (1)

- Flap Valve Angular: Machine Manual En-11091.011-FDocument20 pagesFlap Valve Angular: Machine Manual En-11091.011-FRahmat HidayatNo ratings yet

- Modelling of Rotary KilnsDocument123 pagesModelling of Rotary KilnsLuis Gabriel L. CatalanNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Linear Screen SizingDocument4 pagesLinear Screen SizingHARIPRASADNo ratings yet

- Belt Tension CalculatorDocument1 pageBelt Tension Calculatortnchsg100% (1)

- Comex Air ClassifierDocument8 pagesComex Air ClassifierFiroj AlamNo ratings yet

- 07 Elevators Deep Buckets DIN 15234 02Document1 page07 Elevators Deep Buckets DIN 15234 02mkiani2No ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- GKN Filter Technology Sika-R Is As enDocument16 pagesGKN Filter Technology Sika-R Is As encaapromoNo ratings yet

- TR521 Tier 4i - 1112 - WebDocument6 pagesTR521 Tier 4i - 1112 - WebBrunoNo ratings yet

- Ash CoolerDocument8 pagesAsh CoolerthiyagarajankNo ratings yet

- Should I Replace My Electrostatic Precipitator (ESP) With A Fabric Filter (FF) ?Document19 pagesShould I Replace My Electrostatic Precipitator (ESP) With A Fabric Filter (FF) ?Anonymous yF1z4oNo ratings yet

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Document2 pagesNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131No ratings yet

- PROK Product CatalogueDocument32 pagesPROK Product CatalogueDiego AndradeNo ratings yet

- Technical Manual Bag FilterDocument14 pagesTechnical Manual Bag Filterjp nayak100% (1)

- Installation Equipment: Sanitary Fittings and ValvesDocument89 pagesInstallation Equipment: Sanitary Fittings and ValvesSebassde0% (1)

- Westrup BrochureDocument36 pagesWestrup BrochureADS ADSNo ratings yet

- Ball Mill Capacity Dimensions PAUL O ABBEDocument2 pagesBall Mill Capacity Dimensions PAUL O ABBEaghilifNo ratings yet

- SchuF Valve Guide v6Document57 pagesSchuF Valve Guide v6Adam Chapin100% (1)

- Geho ZPM TZPM Series Spec SheetDocument1 pageGeho ZPM TZPM Series Spec SheetSandy ZhangNo ratings yet

- 11-2756-b Elevator Boot Assy 28SIDocument1 page11-2756-b Elevator Boot Assy 28SIBoanerges BritoNo ratings yet

- AVE Ribbon Blenders 2020Document4 pagesAVE Ribbon Blenders 2020Hitesh DesaiNo ratings yet

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocument1 pageDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89No ratings yet

- Line Sizing Tool Hydrogen LineDocument31 pagesLine Sizing Tool Hydrogen LineAhmed HassanNo ratings yet

- Hangers Hanger BearingsDocument10 pagesHangers Hanger BearingsDouglas BatistellaNo ratings yet

- Rbs PerformancesDocument28 pagesRbs PerformancesMarcos Carvalho100% (1)

- Baghouse Filter Modular Pulse Jet Type: Operation and ApplicationDocument5 pagesBaghouse Filter Modular Pulse Jet Type: Operation and ApplicationBudy AndikaNo ratings yet

- 185-170-5-300-M44-0055 RevBDocument1 page185-170-5-300-M44-0055 RevBVashish RamrechaNo ratings yet

- Crack Propogation in KILNDocument9 pagesCrack Propogation in KILNSiddharth DeshmukhNo ratings yet

- Catalogo Filtros de Aire DanthermDocument158 pagesCatalogo Filtros de Aire Danthermipla_mecanico359No ratings yet

- Conveyor Cross Section at Each Typical Segment r0 - c3Document1 pageConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNo ratings yet

- TS 1600-140 - Datenblatt - V3Document2 pagesTS 1600-140 - Datenblatt - V3Ulfah Fauziyyah0% (1)

- Block 10 Module 3Document14 pagesBlock 10 Module 3Sandra FerrellNo ratings yet

- A406 - Manuale Cappa e BruciatoriDocument478 pagesA406 - Manuale Cappa e BruciatoriLuis Cruz100% (1)

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Rotolok UK Rotary Valves AirlocksDocument6 pagesRotolok UK Rotary Valves AirlocksAngel AlvarezNo ratings yet

- Alborz Industrial Air CoDocument4 pagesAlborz Industrial Air CoaminNo ratings yet

- 8C Throttle Trip ValvesDocument4 pages8C Throttle Trip Valvesjr110livecom100% (1)

- MH - 3 Instruction Manual (Operation Manual 1)Document71 pagesMH - 3 Instruction Manual (Operation Manual 1)alin_popovici_12No ratings yet

- Sub-Water Demand Cal (27062010)Document59 pagesSub-Water Demand Cal (27062010)Tiffany CombsNo ratings yet

- QX140191-LD75-160-H RepsnetDocument68 pagesQX140191-LD75-160-H Repsnetabdur rohmanNo ratings yet

- Piston Valve KVN-15-50: Material of ConstructionDocument3 pagesPiston Valve KVN-15-50: Material of Constructionjcojedar2009No ratings yet

- Si - Guidelines For The Supply of Water To Fire Sprinkler Systems 09-2004 PDFDocument10 pagesSi - Guidelines For The Supply of Water To Fire Sprinkler Systems 09-2004 PDFcarolyne smithNo ratings yet

- WINNER-Poppet Solenid Operated Valves PDFDocument85 pagesWINNER-Poppet Solenid Operated Valves PDFВладиславМасарскийNo ratings yet

- 40 MT Tyre MountedDocument5 pages40 MT Tyre MountedramyaNo ratings yet

- A6V10218252 - Rotary Actuators GDB..9E GLB..9E - enDocument6 pagesA6V10218252 - Rotary Actuators GDB..9E GLB..9E - enSAINo ratings yet

- Sporlan Thermostatic Expansion ValvesDocument19 pagesSporlan Thermostatic Expansion ValvesevrimkNo ratings yet

- 77-9075 DD5Document72 pages77-9075 DD5Imad AghilaNo ratings yet

- WallMountedS30 36AHP ServiceManualDocument75 pagesWallMountedS30 36AHP ServiceManualSonia Alejandra LopezNo ratings yet

- STAUFF Catalogue 7 STAUFF Test EnglishDocument84 pagesSTAUFF Catalogue 7 STAUFF Test EnglishKartalNo ratings yet

- T700 TutorialDocument95 pagesT700 TutorialEnzo Rubinace100% (3)

- Sistema Hidraulico CAT 966FDocument24 pagesSistema Hidraulico CAT 966FNicolas AvocNo ratings yet

- JCM 415 Type 2 Installation Instruction 0306Document2 pagesJCM 415 Type 2 Installation Instruction 0306Hoang Bao HaNo ratings yet

- Material Requisition (MR) : 1.: CascadeDocument7 pagesMaterial Requisition (MR) : 1.: CascadesubudhiprasannaNo ratings yet

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaNo ratings yet

- Bop Hoist InstallationDocument20 pagesBop Hoist InstallationShag ShaggyNo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Super 8 50 (4T) - KL10SA (RO) - 2009.10.15.Document98 pagesSuper 8 50 (4T) - KL10SA (RO) - 2009.10.15.Costinel CTNNo ratings yet

- Model FCDocument23 pagesModel FCLeandroNo ratings yet

- Honeywell ml7420 User ManualDocument8 pagesHoneywell ml7420 User ManualLaurensius ArdiNo ratings yet

- Chalwyn Product Selection Guide LowResDocument16 pagesChalwyn Product Selection Guide LowResElsad HuseynovNo ratings yet

- MTC 03 W Throttle Check ValveDocument4 pagesMTC 03 W Throttle Check Valve박준용No ratings yet

- WFT101353 Weatherford Valves - CatalogoDocument13 pagesWFT101353 Weatherford Valves - Catalogoandres peraltaNo ratings yet

- Explosivo PartesDocument2 pagesExplosivo PartesJOSE INESNo ratings yet

- Documentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS RomaniaDocument80 pagesDocumentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS Romaniajoko setiawanNo ratings yet