Professional Documents

Culture Documents

Condensate Pumps

Uploaded by

tricky110 ratings0% found this document useful (0 votes)

96 views1 pageCONDENSATE PUMPS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCONDENSATE PUMPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views1 pageCondensate Pumps

Uploaded by

tricky11CONDENSATE PUMPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

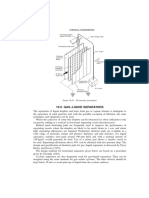

steam

steam

supply

supply

flash tank

LAH

self-regulating area

(automatic without any

level control)

LAL

min.

NPSH A

min.

flash tank

max.

HZ max.

max.

condensate tank

is

standard solution

no pit ed

ir

requ

BungartZ solution

Bungartz

CONDENSATE PUMPS

IN POWER PLANTS.

The condensates collected in tanks always have high

turbulences in gas & steam power plants processes and

are usually at boiling point. As they are not in balance

with the atmospheric pressure in the vessel, steam is

generated. For conventional pumps a condensate tank

is required in order to store almost steam-free condensates. Only an additional levelling control ensures

that the level is higher than the NPSH value of the pump

(NPSHA > NPSHR + 0.5m).

The entire installation requires a constructional intake

height which, as a rule, is only achieved by an additional

pit. However, the situation is different with the selfregulating pump VKS-AN. The trouble-shooter pump is

equipped with a pressure balance device. As a result

the pump has an NPSH value (R) close to zero and can

deliver directly from the flash tank.

CONiP / 13_e

The supply level (Hz) in the tank is self-adjusting without

any level control depending on the actual feed rate. Even

in the case of gas bubbles in the condensate, the flow

will not stall. Any steam generated will be returned via

the balance line. If there are atmospheric pressure

conditions in the flash tank, a dry-running gland packing

is sufficient as a shaft seal for the pump.

ADVANTAGES.

no NPSH problems

automatic adaptation to variable supplies

no condensate collecting vessel required

no control technology necessary

safe to run dry

no pressure impacts due to discontinuous operation

reduction of plant costs

robust construction with an extremely long service life

high operational reliability

You might also like

- Centrifugal Pump FundamentalsDocument9 pagesCentrifugal Pump FundamentalsGauravNo ratings yet

- Esp Calculation Exhaust Air-TaDocument4 pagesEsp Calculation Exhaust Air-TaAshiq NishmaNo ratings yet

- Hand PumpsDocument224 pagesHand PumpsKarin AndersonNo ratings yet

- 1/2Document3 pages1/2konainglincho001No ratings yet

- Thermocompressors Improve Paper Machine Dryer DrainageDocument8 pagesThermocompressors Improve Paper Machine Dryer DrainageclintoncNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Calculating Minimum Pump Submersion to Avoid Vortex FormationDocument3 pagesCalculating Minimum Pump Submersion to Avoid Vortex FormationsksghNo ratings yet

- Flow Formulas PDFDocument4 pagesFlow Formulas PDFkronafNo ratings yet

- 20tips Purchasing Bio ReactorDocument8 pages20tips Purchasing Bio Reactorglq223No ratings yet

- Unesco - Eolss Sample Chapters: Vacuum Creating EquipmentDocument7 pagesUnesco - Eolss Sample Chapters: Vacuum Creating Equipmentahmed nawazNo ratings yet

- 05 - 3 Piston Cartridge PumpsDocument2 pages05 - 3 Piston Cartridge PumpsJose FernandezNo ratings yet

- Pump problem set solutions and calculationsDocument10 pagesPump problem set solutions and calculationsJames Nevin GoNo ratings yet

- Veturi Design ProcedureDocument2 pagesVeturi Design Procedureshivanandr2481No ratings yet

- Blower and Compressor Selection for Membrane AerationDocument42 pagesBlower and Compressor Selection for Membrane AerationSuryaprakashNo ratings yet

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiNo ratings yet

- Air VelocityDocument10 pagesAir VelocityMorkechoNo ratings yet

- 750-326 Blowdown Separator 11 2015Document10 pages750-326 Blowdown Separator 11 2015osamaNo ratings yet

- Plate Type Wet ScrubberDocument6 pagesPlate Type Wet ScrubberRoger IsidoreNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Calculation Vapour Line DiameterDocument2 pagesCalculation Vapour Line DiameterAbdul BasitNo ratings yet

- Line Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsDocument2 pagesLine Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsRawlinson TolentinoNo ratings yet

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88No ratings yet

- How VFD Speed Affects Centrifugal Pump HydraulicsDocument6 pagesHow VFD Speed Affects Centrifugal Pump HydraulicsAudrey Patrick KallaNo ratings yet

- Compresses Air TableDocument13 pagesCompresses Air TableAnonymous BJ9omONo ratings yet

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveeNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592No ratings yet

- Estimation For Instrument Air Consumption of Pneumatic InstrumentDocument2 pagesEstimation For Instrument Air Consumption of Pneumatic Instrumentmyself_ritesh100% (1)

- Suction DesignDocument23 pagesSuction Designalexmuchmure2158No ratings yet

- Mollie ChartDocument15 pagesMollie ChartKriz EarnestNo ratings yet

- Pumps PresentationDocument44 pagesPumps Presentationoida_adNo ratings yet

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Airlift PumpDocument18 pagesAirlift Pumptushar patelNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNo ratings yet

- Mixer SizingDocument0 pagesMixer SizingIlija RunjajicNo ratings yet

- Design and Operation of Conventional BioreactorDocument25 pagesDesign and Operation of Conventional BioreactorMahesh RamNo ratings yet

- Tappt Method T211Document5 pagesTappt Method T211HeerHeerNo ratings yet

- HEAT EXCHANGER PERFORMANCE ANALYSISDocument6 pagesHEAT EXCHANGER PERFORMANCE ANALYSISJM Flores De SilvaNo ratings yet

- Compact Heatless Air DryersDocument1 pageCompact Heatless Air DryersBossman Instruments TechnologyNo ratings yet

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Document5 pagesCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNo ratings yet

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Flowrate Calculation For A Draining TankDocument2 pagesFlowrate Calculation For A Draining TankAnonymous bHh1L1No ratings yet

- Impeller DesignDocument6 pagesImpeller Design19MECH052 SYED YOUNUS100% (1)

- Effulent Treatment Plant: A Presentation By-Nishith Shekhar TripathiDocument16 pagesEffulent Treatment Plant: A Presentation By-Nishith Shekhar TripathianadinathNo ratings yet

- B A S Ket Strainer Pressure Drop-LiquidsDocument4 pagesB A S Ket Strainer Pressure Drop-LiquidsguillemaraNo ratings yet

- Pump Suction Pipe Design Considerations PDFDocument8 pagesPump Suction Pipe Design Considerations PDFhogsp1No ratings yet

- Orifice SizingDocument2 pagesOrifice SizingXheikhKaleemNo ratings yet

- Pump Sizing Formulas and Calculations GuideDocument3 pagesPump Sizing Formulas and Calculations GuideKehinde AdebayoNo ratings yet

- Condensate Pumping: High Temperatures and Danger of Impeller Cavitation Is The Major Challenge of Condensate PumpingDocument2 pagesCondensate Pumping: High Temperatures and Danger of Impeller Cavitation Is The Major Challenge of Condensate PumpingcordobaluisfNo ratings yet

- Net Positive Suction Head (NPSH) theory and cavitation preventionDocument3 pagesNet Positive Suction Head (NPSH) theory and cavitation preventionOstwald GarciaNo ratings yet

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- NPSH Is An: Acronym Hydraulic Vapor PressureDocument5 pagesNPSH Is An: Acronym Hydraulic Vapor PressureSantosh Yellappa SulebhavikarNo ratings yet

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- NPSHDocument1 pageNPSHssabih75No ratings yet

- HP-LP Bypass System Quickly Starts TurbinesDocument13 pagesHP-LP Bypass System Quickly Starts Turbinesshashank das100% (1)

- ReportplDocument27 pagesReportplMirek SzumowskiNo ratings yet

- Industrial Trainning File Contents 1Document7 pagesIndustrial Trainning File Contents 1mohasan ali50% (2)

- Ee6711 Pss Lab MaualDocument23 pagesEe6711 Pss Lab MaualJaya ShreeNo ratings yet

- AKSML 230 - 33 KV - Sheet1Document2 pagesAKSML 230 - 33 KV - Sheet1Arif HossenNo ratings yet

- Busway Short Ciruit Testing ProceduresDocument3 pagesBusway Short Ciruit Testing ProceduresJAIRO EDUARDO RAMIREZ ACERO100% (1)

- List of TestsDocument1 pageList of TestsTarun BhatejaNo ratings yet

- Electrical Wiring DigramDocument15 pagesElectrical Wiring DigramSunilMurkikarNo ratings yet

- Charger ManualDocument34 pagesCharger Manualanil peralaNo ratings yet

- HVDC Transmission Cable SystemsDocument46 pagesHVDC Transmission Cable Systemsmajid madadiiNo ratings yet

- Compact 18kW Power System for Telecom ApplicationsDocument2 pagesCompact 18kW Power System for Telecom Applicationseddywidjaya9No ratings yet

- EATON ARMS DetailsDocument20 pagesEATON ARMS DetailsSumit SharmaNo ratings yet

- JFY Off-Grid Solar Power SystemDocument18 pagesJFY Off-Grid Solar Power SystemstupynetsbNo ratings yet

- Mach3 Breakout Board Relay Spindle ControlDocument5 pagesMach3 Breakout Board Relay Spindle ControlAntochi CiprianNo ratings yet

- Project Proposal: AC to DC Converter CircuitDocument10 pagesProject Proposal: AC to DC Converter Circuitsayed237100% (1)

- Sgre 2013070517301019 PDFDocument12 pagesSgre 2013070517301019 PDFAbdelkader Faklani DouNo ratings yet

- JK48V100 LiFePO4 Battery SpecificationDocument1 pageJK48V100 LiFePO4 Battery SpecificationMaxime TerrettazNo ratings yet

- Thesis Paper - Synchronous Generator Controllers For Micro Hydro Power Plants ELC ModelDocument8 pagesThesis Paper - Synchronous Generator Controllers For Micro Hydro Power Plants ELC ModelDayvd MagandaNo ratings yet

- Chapter 3 Generator Circuit Breaker (GCB)Document15 pagesChapter 3 Generator Circuit Breaker (GCB)Anonymous nwByj9LNo ratings yet

- Power System Planning & OperationDocument31 pagesPower System Planning & OperationBelayneh TadesseNo ratings yet

- Annual Report 2021-22 ElectricityDocument238 pagesAnnual Report 2021-22 ElectricityManishPandeyNo ratings yet

- Gas Insulated Substations: An IntroductionDocument30 pagesGas Insulated Substations: An IntroductionSiD mailNo ratings yet

- Industrial Training - 2010 Bharat Heavy Electricals Ltd. JhansiDocument20 pagesIndustrial Training - 2010 Bharat Heavy Electricals Ltd. JhansiRoop SinghNo ratings yet

- Comparative Study Between DGVCL (Dakshin Gujarat Vij Company Limited) and Torrent Power LTDDocument109 pagesComparative Study Between DGVCL (Dakshin Gujarat Vij Company Limited) and Torrent Power LTDBhagat LakhaniNo ratings yet

- DOL StarterDocument4 pagesDOL Starterdramsree1No ratings yet

- Barfg1370 00 R1Document28 pagesBarfg1370 00 R1Anonymous axyNzhNo ratings yet

- Annexure-I: NTPC Ltd. Badarpur Thermal Power Station / Non Pit HeadDocument10 pagesAnnexure-I: NTPC Ltd. Badarpur Thermal Power Station / Non Pit HeadYogeshNo ratings yet

- Remote control switches, relays, contactors and soft-starting devices overviewDocument12 pagesRemote control switches, relays, contactors and soft-starting devices overvieweujeffNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sf-6 Pad-Mounted SwitchgearHaleem Ur Rashid BangashNo ratings yet

- Load Flow Studies - Lecture Notes 2Document29 pagesLoad Flow Studies - Lecture Notes 2Snr Berel Shepherd100% (1)

- 337 Units: Mansoor Ali DamaniDocument2 pages337 Units: Mansoor Ali DamaniSaadArshadNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)