Professional Documents

Culture Documents

Advanced Technology - Energy-Efficient Cladding Can Reduce Heating and Cooling Loads (2015 5 27)

Uploaded by

api-288292935Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Technology - Energy-Efficient Cladding Can Reduce Heating and Cooling Loads (2015 5 27)

Uploaded by

api-288292935Copyright:

Available Formats

Energy-Efficient Cladding Can Reduce Heating, Cooling

Loads

In general, there are two ways to reduce the heating and cooling loads in a

building: replace the HVAC systems with more energy efficient systems or

reduce the loads on the system. One way to reduce the loads is to install

energy-efficient cladding. Energy efficient cladding systems have a higher

thermal resistance and fewer thermal breaks than typical cladding

systems, so less energy is required to heat and cool the building.

Two of the most common energy efficient cladding systems in the market

today are exterior insulation and finish systems (EIFS) and insulated metal

wall panels. EIFS is a lightweight cladding that can imitate the appearance

of numerous building materials, including brick, stone, metal panels, siding

and stucco. It can also be used as a retrofit over existing claddings.

Compared to many of the systems that EIFS can imitate, it is a costeffective system in terms of both materials and installation costs.

Mechanical fasteners or adhesives to the substrate, a water-resistant base

coat applied to the top of the insulation, glass fibre or expanded metal

reinforcing mesh, and a finish coat. In the past, moisture problems have

occurred with EIFS throughout the United States. As a result, most EIFS

today include a water-resistant barrier installed behind the EIFS to provide

a drainage path for any incidental water that may enter the system.

Insulated metal wall panels consist of two prefabricated metal panels,

typically steel or aluminium, with a polyurethane and polyisocyanurate

foam core. The foam is applied in the form of liquid chemicals and expands

to fill the cavity and fuse with the metal skins. The insulated metal wall

panels attach directly to the supporting structure of the building. The

system relies on the permeability of the metal to prevent water from

entering the system.

Wide ranges of sizes, colours, textures and finishes are available for

insulated metal panels. The panels can also be oriented both vertically and

horizontally to create visually interesting structures. During a renovation,

the insulated metal panels can be easily removed and reinstalled or

installed on a different building. The metal content of the panels can be

recycled when the panels are no longer needed. The cost of materials is

generally higher for this system than standard wall systems; however, the

panels are lightweight and easy to install, which helps save on cost.

On the other hand, EIFS and insulated metal wall panels have the

insulation within the cladding system, which provides a continuous

insulated barrier around the exterior of the building. This barrier increases

the ability of the wall system to prevent heat transfer and reduces the

thermal energy load on the building. Typically, an EIFS system has a

thermal resistance of R-4 to R-24, depending on the thickness of the

insulation. This exterior layer is often used in conjunction with standard

cavity insulation. Insulated metal panel systems have a thermal resistance

of R-14 to R-30, depending on the insulating core used and its thickness.

Insulated metal panels are a preferred construction method for building

with refrigerated environments because they have up to 95 percent

thermal efficiency.

In a two-phase study, sponsored by the U.S. Department of Energy

through the Office of Energy Efficiency and Renewable Energys Building

Technologies Program and the EIFS Industry Members Association

(EIMA), different assemblies of EIFS were compared over a two-year period

with brick, stucco and cementations fibreboard siding. Testing included

energy efficiency, moisture intrusion, and temperature control. The results

showed that EIFS outperformed other systems, though the results were

dependent on the specific EIFS assembly, accuracy of installation and type

of water-resistive barrier used.

Considerations:

When planning to use energy-efficient cladding either in new construction

or during a retrofit, there are some considerations to keep in mind. The

most important item is to choose a qualified installer. Many of the water

infiltration problems associated with EIFS can be traced back to improper

installation of details at penetrations. Improper installation of the system

can also lead to thermal breaks and excess ventilation, which can reduce

system efficiency.

In new construction, look at the building as a whole. Proper details are

needed between the cladding system and the structural and glazing

systems to prevent failures. The mechanical equipment must take into

account the overall efficiency of the building, including contributions from

the cladding system, to be sized correctly. Oversized equipment is

expensive to install and operate.

Before completing a retrofit, perform an assessment of the building. Look

for deficiencies in the structural system and signs of water infiltration. Any

issues should be addressed properly before the new cladding system is

attached. Otherwise, the problem will continue to worsen beneath the new

cladding, which can lead to failures and loss of efficiency. Check for other

improvements that can be completed at the same time as the cladding

retrofit to improve the quality of the building and save on overall

construction costs.

Energy-efficient cladding systems still have standard maintenance that will

occur over the lifetime of the cladding. All joints and penetrations should

be inspected on a regular basis. Sealant joints and flashing should be

replaced as necessary. The systems should be cleaned on a regular basis

to prevent build-up of pollutants.

(http://www.facilitiesnet.com/hvac/article/Energy-Efficient-Cladding-CanReduce-Heating-Cooling-Loads-Facilities-Management-HVAC-Feature-11711#)

You might also like

- Personal Grooming PDFDocument8 pagesPersonal Grooming PDFayuNo ratings yet

- CB Insights - Fintech Report 2022 PDFDocument178 pagesCB Insights - Fintech Report 2022 PDFomafolabomiNo ratings yet

- IKO BUFR Design Guide Feb 2012Document40 pagesIKO BUFR Design Guide Feb 2012Deana WhiteNo ratings yet

- Considerationsforre Claddinghighrisepanelizedeifsbuildings DavidDocument16 pagesConsiderationsforre Claddinghighrisepanelizedeifsbuildings DavidYamir Collao HermosillaNo ratings yet

- Considerationsforre Claddinghighrisepanelizedeifsbuildings DavidDocument16 pagesConsiderationsforre Claddinghighrisepanelizedeifsbuildings DavidYamir Collao HermosillaNo ratings yet

- Facades and InterfacesDocument43 pagesFacades and Interfacesissamoune100% (2)

- Spancrete - CarbonCast - HP Insulated Wall PanelsDocument8 pagesSpancrete - CarbonCast - HP Insulated Wall PanelsMattSearsNo ratings yet

- Prefabricated Construction SystemDocument13 pagesPrefabricated Construction SystemHimani GaurNo ratings yet

- 26 Single Wythe Bearing WallsDocument15 pages26 Single Wythe Bearing WallsMuslimsNo ratings yet

- Questions and Answers About Non-Composite Topics Include:: THERMOMASS® Building Insulation SystemsDocument12 pagesQuestions and Answers About Non-Composite Topics Include:: THERMOMASS® Building Insulation Systemsaditarian .pNo ratings yet

- Air Tightness of Building Envelope Design SystemDocument7 pagesAir Tightness of Building Envelope Design SystemYolanda SelgaNo ratings yet

- Building Envelope Design PrinciplesDocument7 pagesBuilding Envelope Design PrinciplesDezyne EcoleNo ratings yet

- Construction and Performance of Curtain Wall Systems For Super Highrise BuildingsDocument20 pagesConstruction and Performance of Curtain Wall Systems For Super Highrise BuildingsAnonymous hk1fhAkwyNo ratings yet

- Cladding With Thermal InsulationDocument21 pagesCladding With Thermal InsulationRathinavel SubramanianNo ratings yet

- On Brick Construction: Technical NotesDocument11 pagesOn Brick Construction: Technical NotesniroNo ratings yet

- Waterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsDocument20 pagesWaterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsVaishamNo ratings yet

- Curtain WallsDocument34 pagesCurtain WallsKotesh ReddyNo ratings yet

- High Performance Precast Insulated Sandwich Wall PanelsDocument16 pagesHigh Performance Precast Insulated Sandwich Wall Panelstaz_taz3No ratings yet

- Construction Technology Ii Curtain Walling AssignmentDocument7 pagesConstruction Technology Ii Curtain Walling AssignmentTeddy MatiekaNo ratings yet

- Facades and InterfacesDocument22 pagesFacades and InterfaceshkatniwalaNo ratings yet

- Building Envelope SystemsDocument6 pagesBuilding Envelope SystemsBeau NorNo ratings yet

- Thermal Bridging March Insert PDFDocument16 pagesThermal Bridging March Insert PDFwal1547100% (1)

- BT5 - Wall Panel SystemsDocument5 pagesBT5 - Wall Panel SystemsJansen RosillaNo ratings yet

- Maintenance of Building ComponentsDocument4 pagesMaintenance of Building ComponentsIZIMBANo ratings yet

- Parapets ImportantDocument60 pagesParapets ImportantRafael Ramirez CasateNo ratings yet

- High Performance Precast Insulated Sandwich Wall PanelsDocument16 pagesHigh Performance Precast Insulated Sandwich Wall Panelsaditarian .pNo ratings yet

- Construction Technology - B: Project (A)Document40 pagesConstruction Technology - B: Project (A)Imran KalamNo ratings yet

- Materials For Walls Cast in Place WallDocument10 pagesMaterials For Walls Cast in Place WallEsya ImanNo ratings yet

- Construction Systems: Heavy and Lightweight SystemsDocument4 pagesConstruction Systems: Heavy and Lightweight SystemsyolcharnnguenNo ratings yet

- Open Prefabrication SystemsDocument17 pagesOpen Prefabrication SystemsRemya R. Kumar100% (2)

- Development of Chinese Light Steel Construction Residential BuildingsDocument5 pagesDevelopment of Chinese Light Steel Construction Residential BuildingsUday PratapNo ratings yet

- What Is Construction SystemDocument36 pagesWhat Is Construction SystemHiro KiritoNo ratings yet

- Curtain WallDocument3 pagesCurtain WalljitenderaNo ratings yet

- Insulating Solid WallsDocument25 pagesInsulating Solid WallsCristina VoicuNo ratings yet

- DocumentDocument38 pagesDocumentAlexandra Tracy OcampoNo ratings yet

- A Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are NonDocument23 pagesA Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are Nonbisrat meseretNo ratings yet

- T2.1 FacadesDocument13 pagesT2.1 FacadesPaula de la PeñaNo ratings yet

- Microsoft Power Point - 2011-05-17-Study of New Materials & Techniques For Building EnvelopeDocument24 pagesMicrosoft Power Point - 2011-05-17-Study of New Materials & Techniques For Building EnvelopeHari Om GuptaNo ratings yet

- Construction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceDocument13 pagesConstruction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceHeronijosh DgNo ratings yet

- Wall ConstructionDocument22 pagesWall ConstructionJohn Michael CastilloNo ratings yet

- Early Cavity WallsDocument23 pagesEarly Cavity WallsRevina SoniNo ratings yet

- MasonryDocument5 pagesMasonryk2v1n5No ratings yet

- Single Storey Steel Bings Steel Buildings in Europe 38Document1 pageSingle Storey Steel Bings Steel Buildings in Europe 38pawkomNo ratings yet

- Curtain WallDocument38 pagesCurtain Walledbern20005873100% (4)

- Curtain Wall NoAnswersDocument20 pagesCurtain Wall NoAnswersLuiz CarlosNo ratings yet

- Facade LectureDocument71 pagesFacade LectureYigezu YehombaworkNo ratings yet

- Cladding For BuildingsDocument8 pagesCladding For BuildingsCaryl Louise ObcianaNo ratings yet

- Facade ConstructionDocument16 pagesFacade ConstructionJaskirat100% (1)

- Green BuildingsDocument11 pagesGreen BuildingsRinaldyNo ratings yet

- Energy Efficient Homes: University of Engineering and TechnologylDocument36 pagesEnergy Efficient Homes: University of Engineering and TechnologylTariq QaisraniNo ratings yet

- Sto Design Considerations BrochureDocument60 pagesSto Design Considerations BrochureSam UriarteNo ratings yet

- Energy Efficient BuildingDocument14 pagesEnergy Efficient BuildingAnonymous ZVzA7msNo ratings yet

- Notes 8 For ENGI3731Document46 pagesNotes 8 For ENGI3731Sarbaz BanozaiNo ratings yet

- High Performance Precast Insulated Sandwich Wall PanelsDocument14 pagesHigh Performance Precast Insulated Sandwich Wall Panelsaditarian .pNo ratings yet

- Facade-cladding-.Research Team Erz 2013.22.10 Arch.2430Document29 pagesFacade-cladding-.Research Team Erz 2013.22.10 Arch.2430MusliminNo ratings yet

- Curtainwalls TextDocument18 pagesCurtainwalls TextLuciana MimiNo ratings yet

- Curtain Wall SystemsDocument28 pagesCurtain Wall SystemsKarvy Yadav90% (10)

- Roof DetailsDocument147 pagesRoof DetailsMartin FoxNo ratings yet

- LST I BurekDocument7 pagesLST I Burektroscian7No ratings yet

- CMHC2000-Rigid Air Barrier AssembliesDocument4 pagesCMHC2000-Rigid Air Barrier Assemblieskulov1592No ratings yet

- 7 Overroofing LPS BuildingsDocument59 pages7 Overroofing LPS BuildingsOliver SmithNo ratings yet

- Advanced Technology - Servo Types Summary 2015 10 19Document2 pagesAdvanced Technology - Servo Types Summary 2015 10 19api-288292935No ratings yet

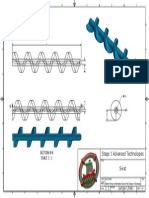

- Advanced Technology - Archimedean Screw Summary 2015 10 19Document4 pagesAdvanced Technology - Archimedean Screw Summary 2015 10 19api-288292935No ratings yet

- Advanced Technology - Water Pump Pipe Part Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Pipe Part Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 4 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 4 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump T Piece Part Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump T Piece Part Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Shaft Part Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Shaft Part Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Archimedes Screw Part Design 4 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Archimedes Screw Part Design 4 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 2 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 2 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Motor Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Motor Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 3 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 3 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 1 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 1 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Archimedes Screw Part Design 1 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Archimedes Screw Part Design 1 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Archimedes Screw Part Design 3 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Archimedes Screw Part Design 3 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Controlling A Servo Motor 2015 10 11Document2 pagesAdvanced Technology - Controlling A Servo Motor 2015 10 11api-288292935No ratings yet

- Advanced Technology - Water Flow Rate Prectical Report 2015 8 9Document3 pagesAdvanced Technology - Water Flow Rate Prectical Report 2015 8 9api-288292935No ratings yet

- Advanced Technology - Water Pump Archimedes Screw Part Design 2 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Archimedes Screw Part Design 2 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Archimedes Screw Research 4 2015 8 17Document2 pagesAdvanced Technology - Archimedes Screw Research 4 2015 8 17api-2882929350% (1)

- Advanced Technology - Archimedes Screw Research 3 2015 8 17Document1 pageAdvanced Technology - Archimedes Screw Research 3 2015 8 17api-288292935No ratings yet

- Advanced Technology - Types of Servo Motor 2015 10 11Document1 pageAdvanced Technology - Types of Servo Motor 2015 10 11api-288292935No ratings yet

- Advanced Technology - How Is The Servo Controlled 2015 10 11Document1 pageAdvanced Technology - How Is The Servo Controlled 2015 10 11api-288292935No ratings yet

- Advanced Technology - Archimedes Screw Research 1 2015 8 17Document2 pagesAdvanced Technology - Archimedes Screw Research 1 2015 8 17api-288292935No ratings yet

- Advanced Technology - Water Pump Shaft Part Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Shaft Part Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Pipe Part Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Pipe Part Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Archimedes Screw Part Design 4 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Archimedes Screw Part Design 4 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 2 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 2 Drawing 2015 8 5api-288292935No ratings yet

- Advanced Technology - Water Pump Assembly 1 Drawing 2015 8 5Document1 pageAdvanced Technology - Water Pump Assembly 1 Drawing 2015 8 5api-288292935No ratings yet

- Gregg Djs Dict OcrDocument424 pagesGregg Djs Dict OcrscribdNo ratings yet

- Vitamins and Minerals Lecture NotesDocument9 pagesVitamins and Minerals Lecture NotesJoymae Olivares Tamayo100% (1)

- (Morris, David Morris) Stereochemistry (Tutorial C (B-Ok - Xyz)Document179 pages(Morris, David Morris) Stereochemistry (Tutorial C (B-Ok - Xyz)anushka100% (2)

- Estimation of Measurement Uncertainty Printout 2016-2Document94 pagesEstimation of Measurement Uncertainty Printout 2016-2GustavoCaicutoNo ratings yet

- FS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoDocument7 pagesFS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoKatring O.No ratings yet

- Problems-Fluid Flow PhenomenaDocument2 pagesProblems-Fluid Flow PhenomenaRomel LeoNo ratings yet

- Chapter 7 - Divisions of Rashis - Ancient Vedic Texts !Document4 pagesChapter 7 - Divisions of Rashis - Ancient Vedic Texts !SN WijesinheNo ratings yet

- Pilot Learn English Now Eng0343Document18 pagesPilot Learn English Now Eng0343pedro.muneerNo ratings yet

- Review of Process Parameters For Biodiesel Production From Different FeedstocksDocument9 pagesReview of Process Parameters For Biodiesel Production From Different FeedstocksHow Heoy GeokNo ratings yet

- OCI Introduction: Presented By: Rahul MiglaniDocument21 pagesOCI Introduction: Presented By: Rahul Miglanisss pppNo ratings yet

- Kotak Mahindra Bank: Presented by Navya.CDocument29 pagesKotak Mahindra Bank: Presented by Navya.CmaheshfbNo ratings yet

- Cat-Eht Brake New PDFDocument4 pagesCat-Eht Brake New PDFLingaraj Suresh LingaianNo ratings yet

- Airbnb 2018 PDFDocument8 pagesAirbnb 2018 PDFyodhisaputraNo ratings yet

- Application Form Safety Program Pg1Document1 pageApplication Form Safety Program Pg1Mark Jayson GarciaNo ratings yet

- Critical Thinking and EBPDocument31 pagesCritical Thinking and EBPEni SukmawatiNo ratings yet

- Module 5 Advanced MechanicsDocument60 pagesModule 5 Advanced Mechanicsiknowvictoriassecret49No ratings yet

- WGS RXS - FTXS15 24lvjuDocument6 pagesWGS RXS - FTXS15 24lvjuRicky ViadorNo ratings yet

- DOH Breast Cancer Guidelines FinalDocument123 pagesDOH Breast Cancer Guidelines Finalsupratimbiswas073380No ratings yet

- Principles of Health EducationDocument3 pagesPrinciples of Health EducationJunah DayaganonNo ratings yet

- Kafka and NiFIDocument8 pagesKafka and NiFIabhimanyu thakurNo ratings yet

- Manual Usuario Hiki User-Manual-5392612Document174 pagesManual Usuario Hiki User-Manual-5392612Rafael MunueraNo ratings yet

- SPM Practice June 29Document7 pagesSPM Practice June 29Isabel GohNo ratings yet

- CS687 - Access Control 1 - Spring 2020Document41 pagesCS687 - Access Control 1 - Spring 2020Dawit GetchoNo ratings yet

- Roxas Claire B. Science Technology and Society 09 Activity 1Document1 pageRoxas Claire B. Science Technology and Society 09 Activity 1Eldrick Neil Reyes100% (1)

- FTL20.pdf Ultrasonic SondeDocument20 pagesFTL20.pdf Ultrasonic SondeJaroslav BiresNo ratings yet

- E38 Closed Circuit Current TestDocument4 pagesE38 Closed Circuit Current TestCezaryCezasNo ratings yet

- WPI PharmaceuticalsDocument23 pagesWPI PharmaceuticalsKyle Millar-CorlissNo ratings yet

- Vacancy For Ceo-Tanzania Association of Accountants-RevisedDocument2 pagesVacancy For Ceo-Tanzania Association of Accountants-RevisedOthman MichuziNo ratings yet