Professional Documents

Culture Documents

Seamless AMT Offers Efficient Alternative To CVT

Seamless AMT Offers Efficient Alternative To CVT

Uploaded by

SarthakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seamless AMT Offers Efficient Alternative To CVT

Seamless AMT Offers Efficient Alternative To CVT

Uploaded by

SarthakCopyright:

Available Formats

20075013

314-20075013

Seamless AMT offers efficient alternative to CVT*

R P G HEATH

Zeroshift technology allows a manual transmission to change gear in zero time. The Zeroshift automated manual

transmission (AMT) is easy to manufacture and is an alternative to the CVT. Zeroshift offers potential fuel economy

improvements from driveline efficiency and the best possible vehicle acceleration. Compared to an existing AMT,

Zeroshift offers an uninterrupted torque path from the engine to vehicle which allows for a seamless gearshift.

Keywords: transmission, synchronizer system, seamless shift, automated manual transmission

1. INTRODUCTION

The world is dominated by two forms of transmission, the

manual transmission (MT) and the Automatic

Transmission (AT). In Japan, there is also a third option

as the Continuously Variable Transmission (CVT) is

gaining in popularity.

The MT is the most efficient transmission available. This

lends itself to providing good fuel economy for the

vehicles it is employed in. The efficiency of the MT is

dependent on the load applied. Over a representative

drive cycle its overall efficiency can approach 97% [1].

economy, performance and shift quality.

The

combination of these has not previously been seen in

any other transmission.

2. ZEROSHIFT CONCEPT

The

Zeroshift

concept

replaces

synchromesh

components within a manual transmission with Zeroshift

rings, Figure 1. Synchronisation is aided externally with

the assistance of torque intervention performed by the

engine control unit and an automated single plate dry

clutch (standard equipment in an AMT).

The AT and CVT main advantage is their ease of driving.

Drivers are willing to pay a premium for this type of

transmission even though performance and fuel

economy are inferior to the MT. A reduced performance

and fuel economy is apparent because of the lower

efficiency of the transmission.

Over the same

representative drive cycle the efficiency is seen to be

less than the MT, Table 1.

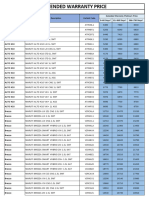

Transmission type

Efficiency

Manual

97%

Automatic

86%

CVT belt

88%

CVT toroidal

93%

Table 1. Efficiencies of various transmissions over a

drive cycle.

If a transmission could have the efficiency of an MT and

drive like an AT or CVT, this would introduce a fourth

option to segment the market. Traditionally, the AMT

has matched or improved on the MT for fuel economy

but has suffered from inferior performance (compared to

the MT) and bad shift quality. Zeroshift corrects these

latter two issues allowing simultaneously good fuel

*

1

Figure 1. Exploded view showing pair of Zeroshift rings

between two gears.

The Zeroshift rings act as a pair with each ring being

similar to those found in dog engagement transmissions.

The unacceptable backlash found in dog engagement

transmissions is eliminated by splitting the dog into two

halves. One Zeroshift ring is engaged to take up drive

whilst the other Zeroshift ring is brought in afterwards to

take up the backlash.

Each ring is double-sided where one side can only drive

in one direction and the opposite side in the other

direction. When paired back-to-back they present either

a direct-drive or a ramp face depending on the vehicle

drive direction.

Presented at 2007 JSAE Annual Congress.

Zeroshift, Davy Avenue, Milton Keynes, MK5 8PB, United Kingdom.

When initiating a shift from the neutral position, one drive

ring is engaged with the dog faces on the gear and the

other ring provides drive in the opposite direction to

oppose engine overrun and, more importantly, eliminate

perceivable backlash. As this unloaded ring will make

the next shift, compared to a synchroniser, it requires up

to 25 times less shift force.

st

Figure 4. 1 gear engaged.

st

To perform a Zeroshift gearshift, whilst still driving in 1

gear on the blue ring, the unloaded red ring may be

nd

moved to the 2 gear (bottom of diagram), Figure 5.

Figure 2. Neutral position.

Each pair of rings has three pairs of bullets. It is easier

to see the actions of these rings if we look at an

exploded view, Figure 2. Here we see just one pair of

bullets without the ring for clarity. On one side of the

bullet is a retention angle to take up the drive whilst on

the opposite side is a ramp face to disengage drive.

nd

st

Figure 5. 2 gear overruns 1 gear.

nd

st

As 2 gear is rotating faster, it overruns 1 gear and

takes up drive on the red ring allowing the engine torque

to be handed over. At no time is the engine torque

interrupted from being transferred to the vehicles

wheels.

st

The gearshift is complete when the original blue ring is

st

no longer loaded on 1 gear and is able to be actuated

nd

over to 2 gear to take up backlash, Figure 6.

Figure 3. Actuate first ring to take up drive in 1 gear.

The unique feature of Zeroshift is that it is able to change

gear in zero time, just like a digital switch. We can see in

Figure 3 how by shifting the blue ring and its bullets with

st

a shift fork, drive is taken up on the 1 gear (top of

diagram). Backlash is taken up by shifting the red ring,

Figure 4.

The instantaneous shift is by definition a torque handover from one gear to another. This creates a torque or

energy impulse in the driveline which is managed

through a combination of engine, transmission and clutch

control. The result is a continual delivery of torque and

unaffected vehicle stability. Such a concept has wide

application not only because of improved acceleration

performance but also fuel economy and shift quality.

performance benefit as the vehicle is never coasting in

neutral. Each gearshift which would normally take a test

driver approximately 0.5 seconds to complete is

performed in 0 seconds with Zeroshift technology,

Figure 7. For most (non-test) drivers, the gearshift would

be greater than 1 second.

120

Zeroshift

Synchromesh

100

80

Road

speed

(mph)

60

40

20

nd

Figure 6. 2 gear engaged.

1st

2n

3rd

4th

3. ZEROSHIFT BENEFITS

fuel economy

performance

shift quality

3.1. FUEL ECONOMY

To date, the MT has provided better fuel economy than

the AT and CVT [2].

A technology that has

demonstrated on occasions, even better fuel economy

than the MT is the AMT. This fuel economy is not due to

the in gear efficiency of the transmission as it is no more

efficient than the MT but due to the gear shift schedule.

On a drive cycle an AMT is able to shift to a taller gear

earlier whilst the MT is constrained to follow a mandatory

gear schedule. In real driving with the AMT in automated

mode, an improvement in fuel economy over the MT can

be achieved for the same reason. It is unlikely that the

driver will always be in the best gear for all situations. At

highway cruise the standard AMT will be no better than

the MT. It may be slightly worse if parasitic losses are

present to operate the power pack for clutch and

gearshift actuation.

Zeroshift is an AMT which has no significant parasitic

losses when in gear. Only a small amount of power is

required during the gear shifting and clutch operation

compared to an AMT. There is no hydraulic actuation so

there are no parasitic losses to operate a hydraulic

pump. Both the gear actuation and clutch control can be

electrically operated from the standard 12V vehicle

electrical system.

3.2. PERFORMANCE

Compared to an MT the Zeroshift concept allows gear

shifts to take place in zero time. This has an immediate

12

6th

14

16

18

20

Time (s)

Figure 7. Zeroshift compared to manual gear shift.

For the average automobile equipped with a MT it is

necessary to perform one gear shift during a 0 100 kph

st

nd

acceleration starting in 1 gear and ending in 2 gear.

The Zeroshift technology enables the acceleration to be

completed approximately 0.5 seconds quicker than a MT

driven by a test driver.

Compared to the MT the fuel economy and acceleration

performance (0 100 kph) of various transmissions are

shown in Figure 8. The traditional 4 to 5 speed AT has

been superseded with the 6 to 7 speed AT. This

transmission is now able to compete directly with the

CVT in terms of fuel economy, performance and

manufacturing costs [2, 3].

Fuel Economy (%)

The main benefits of Zeroshift are:

5th

10

Zeroshift

-15

-10

0MT

0

-5

AT67

-5

10

DCT

CVT

AT45

-10

-15

Acceleration Performance (%)

Figure 8. Fuel economy and acceleration performance of

various transmissions as compared to MT.

It is necessary for CVT manufacturers to improve their

product in order to retain market share. Even the MT is

under threat from the Dual Clutch Transmission (DCT).

Zeroshift is able to exceed all these current transmission

technologies by offering the best fuel economy and

acceleration performance.

3.3. SHIFT QUALITY

Zeroshift

1-2 gearshift at 2500rpm

Ford Mustang 4.0L

Manual gearbox

1-2 gearshift at 2500rpm

Ford Mustang 4.0L

1.1

Shift start

(clutch disengaged)

3500

0.3

3000

0.1

-0.1

2500

4000

0.5

3500

1.3s

0.3

3000

0.1

2500

7.5

8.5

-0.3

9.5

10

5.5

-0.3

6.5

2000

1500

-0.5

1000

Time (s)

Figure 10. Zeroshift transmission with no torque

interrupt.

The Zeroshift transmission has been demonstrated and

has the following benefits:

Improved fuel economy compared with torque

converter automatic transmission and CVT

Improved acceleration performance compared

with manual transmission

Improved shift quality compared with manual

transmission

10.5

2000

1500

-0.5

4.5

4. CONCLUSIONS

Engine Speed (RPM)

Longitudinal Acceleration (G)

4000

0.1

0.5

4500

Shift end

(clutch re-engaged)

0.7

4500

0.7

5000

Long_Acc(G)

Engine_Speed(rpm)

0.9

-0.1

5000

Long_Acc(G)

POT_B

(V)

Fork_B

Fork_A (V)

Engine_Speed(rpm)

0.9

Engine Speed (RPM)

Objectively, a vehicle may be instrumented to measure

longitudinal acceleration which will show the deceleration

and acceleration experienced during a gear shift. It can

be seen from Figure 9 that during a standard upshift in a

MT there is a torque interrupt to the wheels. This is

shown in the figure by the reduction in longitudinal

acceleration during the shift.

1.1

Longitudinal Acceleration (G), Fork Position

(V)

Transmission shift quality is measured in many ways,

some objectively and others subjectively. We consider

here the longitudinal acceleration of a vehicle which can

be measured both objectively and subjectively.

1000

Time (s)

Figure 9. Manual transmission with torque interrupt.

Subjectively, this is experienced by the vehicles

occupants not only by observing the pitching of the front

of the vehicle but also by what is known as head nod. In

its mildest form this is merely a discomfort to the

occupants. In its severest form this can lead to instability

of the car, especially during cornering.

It can be seen from Figure 10 that during a standard

upshift in a vehicle fitted with Zeroshift there is no torque

interrupt to the wheels. This is shown in the figure by the

consistently flat longitudinal acceleration during the shift.

Subjectively, the shift is unobserved by the vehicles

occupants as there is no pitching of the vehicle and

stability is maintained.

5. REFERENCES

[1]

Kluger, M and Long, D. An Overview of Current

Automatic, Manual and Continuously Variable

Transmission Efficiencies and Their Projected

Future Improvements. SAE 1999-01-1259.

[2]

Knibb Gormezano & Partners. Transmission

Trends Including Hybrids in Passenger Cars

& Light Commercial Vehicles in Europe 20062016. 2006.

[3]

Heath, R P G and Child, A J. Zeroshift. A

seamless Automated Manual Transmission

(AMT) with no torque interrupt. SAE 2007-011307.

You might also like

- LS Swaps: How to Swap GM LS Engines into Almost AnythingFrom EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingRating: 3.5 out of 5 stars3.5/5 (2)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- Group 2 FerrariDocument22 pagesGroup 2 FerrariMahekNo ratings yet

- Continuous Variable TransmissionDocument18 pagesContinuous Variable TransmissionMamesh100% (1)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- ZF Vt1f MiniDocument31 pagesZF Vt1f Minibaccara180% (5)

- CVT DiagnosticsDocument6 pagesCVT Diagnosticscherokewag100% (2)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Continuous Variable TransmissionDocument30 pagesContinuous Variable TransmissionAkash KhokharNo ratings yet

- Unit IV Automatic TransmissionDocument10 pagesUnit IV Automatic TransmissionPadmanabhanNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Audi 01J Multitronic CVTDocument99 pagesAudi 01J Multitronic CVTenes_br95% (21)

- Sandeep CVTDocument18 pagesSandeep CVTŽan PjerNo ratings yet

- SSP 228 - Part1 - Variable Automatic Gearbox Multitronic R 01JDocument12 pagesSSP 228 - Part1 - Variable Automatic Gearbox Multitronic R 01JfibelenitoNo ratings yet

- Continuously Variable Transmission: Presentation by Sixth Semester (2012) Under The Guidance ofDocument30 pagesContinuously Variable Transmission: Presentation by Sixth Semester (2012) Under The Guidance ofAbhishek GhoshNo ratings yet

- Manual Transmissions: Transmission Motor Vehicle Clutch Torque Engine Gear SelectorDocument10 pagesManual Transmissions: Transmission Motor Vehicle Clutch Torque Engine Gear SelectorJayvee PoliranNo ratings yet

- Multitronic 01JDocument100 pagesMultitronic 01JAlex Dosoftei100% (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Analysis, Design and Application of Continuously Variable Transmission (CVT)Document7 pagesAnalysis, Design and Application of Continuously Variable Transmission (CVT)ChiragNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- HW19710 Transmission System Repair ManualDocument78 pagesHW19710 Transmission System Repair Manualsample name80% (5)

- Automatic Gear Transmission SystemDocument8 pagesAutomatic Gear Transmission SystemCooldude RishabNo ratings yet

- Gas CompressorsDocument55 pagesGas CompressorsBilal Ahmed75% (4)

- Road & Track Iconic Cars: CamaroFrom EverandRoad & Track Iconic Cars: CamaroLarry WebsterNo ratings yet

- F1 2010 The Guide - in FullDocument43 pagesF1 2010 The Guide - in FullFurkan YalçınkayaNo ratings yet

- MB C107Document106 pagesMB C107mnbvqwertNo ratings yet

- Zeroshift atDocument8 pagesZeroshift atItalo AdottiNo ratings yet

- UrbanDocument24 pagesUrbanWahyunal YuriswanNo ratings yet

- SSANGYONG KORANDO SERVICE MANUAL Body Exterior Korando 2012Document72 pagesSSANGYONG KORANDO SERVICE MANUAL Body Exterior Korando 2012moraesj760967% (3)

- Zeroshift Automated Manual Transmission SAE2007!26!061Document4 pagesZeroshift Automated Manual Transmission SAE2007!26!061José Antonio GutiérrezNo ratings yet

- Working of Gear TransmissionDocument6 pagesWorking of Gear TransmissionTechmate TechnologiesNo ratings yet

- Types of TransmissionDocument12 pagesTypes of TransmissionMPENDULO MABILANo ratings yet

- Continuously Variable Transmissions (CVT) :: The Holy Grail of Automotive Transmission Systems?Document26 pagesContinuously Variable Transmissions (CVT) :: The Holy Grail of Automotive Transmission Systems?Mohit RajNo ratings yet

- 36 Ranbir SinghDocument5 pages36 Ranbir SinghBbaPbaNo ratings yet

- CVT VS TIPTRONIC (Engines Comparisons)Document7 pagesCVT VS TIPTRONIC (Engines Comparisons)zohairahmedNo ratings yet

- Comparitive Study Between Manual and Automatic Transmission in AutomobilesDocument5 pagesComparitive Study Between Manual and Automatic Transmission in AutomobilesHarish PadmanabanNo ratings yet

- CVT Simulation On The Dynamic Engine Test BedDocument3 pagesCVT Simulation On The Dynamic Engine Test BedCiprian SerdinNo ratings yet

- Automatic Gear BoxDocument19 pagesAutomatic Gear BoxInquiry XEEPLNo ratings yet

- Semi Automatic Transmission ReportDocument52 pagesSemi Automatic Transmission ReportPranav EkhandeNo ratings yet

- Technical Report 1Document15 pagesTechnical Report 1Santosh Raj0% (2)

- Power Assisted Gear ShiftingDocument25 pagesPower Assisted Gear ShiftingPramodPradhanNo ratings yet

- Continuously Variable TransmissionDocument11 pagesContinuously Variable Transmissionsonirocks0% (1)

- Tim 7-Sistem Transmisi OtomatisDocument31 pagesTim 7-Sistem Transmisi Otomatismisbahul arifinNo ratings yet

- Jatco cvt8 - DrivetrainDocument5 pagesJatco cvt8 - Drivetrainomid yadegariNo ratings yet

- Second ReportDocument14 pagesSecond ReportMy ProNo ratings yet

- Gear Shifting Control For Pure Electric Vehicle With Inverse-AMTDocument5 pagesGear Shifting Control For Pure Electric Vehicle With Inverse-AMTThơm PhùngNo ratings yet

- Final ReportDocument37 pagesFinal ReportAliNo ratings yet

- CVTDocument18 pagesCVTRon Farm100% (1)

- Howo TransmisionDocument81 pagesHowo TransmisionMantenimiento Mecanico BiddleNo ratings yet

- Transmission System: Windmills Horse Steam Engines Pumping Milling HoistingDocument9 pagesTransmission System: Windmills Horse Steam Engines Pumping Milling Hoistingajay mauryaNo ratings yet

- AT6501 QBDocument8 pagesAT6501 QBSahayaraj GabrielNo ratings yet

- Continuously Variable TransmissionDocument12 pagesContinuously Variable TransmissionMuhammad HossamNo ratings yet

- Challenges and Opportunities in Automotive Transmission ControlDocument6 pagesChallenges and Opportunities in Automotive Transmission ControlArnabGhoshNo ratings yet

- Continuously Variable Transmission - Wikipedia, The Free EncyclopediaDocument14 pagesContinuously Variable Transmission - Wikipedia, The Free EncyclopediaprashantNo ratings yet

- Continuously Variable Transmissions2Document29 pagesContinuously Variable Transmissions2Faris AbdullahNo ratings yet

- A Review of Robotics in Onshore Oil-Gas Industry PDFDocument8 pagesA Review of Robotics in Onshore Oil-Gas Industry PDFAmit ShuklaNo ratings yet

- Peshwa Bajirao I and Maratha ExpansionDocument258 pagesPeshwa Bajirao I and Maratha ExpansionAmit ShuklaNo ratings yet

- Seekur JRDocument2 pagesSeekur JRAmit ShuklaNo ratings yet

- Sheet 2: Topic: Motion Models and Robot OdometryDocument6 pagesSheet 2: Topic: Motion Models and Robot OdometryAmit ShuklaNo ratings yet

- Vaisnava CalendarDocument48 pagesVaisnava CalendarAmit ShuklaNo ratings yet

- MMEG 221 - Section 1 Matlab Project 5: Student Name Student IDDocument1 pageMMEG 221 - Section 1 Matlab Project 5: Student Name Student IDAmit ShuklaNo ratings yet

- MMEG 221 - Section 1 Matlab Project 4: Student Name Student IDDocument1 pageMMEG 221 - Section 1 Matlab Project 4: Student Name Student IDAmit ShuklaNo ratings yet

- MMEG 221 - Section 1 Matlab Project 3: 10N 0.2kg / MDocument1 pageMMEG 221 - Section 1 Matlab Project 3: 10N 0.2kg / MAmit ShuklaNo ratings yet

- Course ID MEEG221 Course Name Engineering MATLAB Instructor Dr. Amit Shukla Section 01Document1 pageCourse ID MEEG221 Course Name Engineering MATLAB Instructor Dr. Amit Shukla Section 01Amit ShuklaNo ratings yet

- MMEG 221 - Section 1 Matlab Project 2: Student Name Student IDDocument1 pageMMEG 221 - Section 1 Matlab Project 2: Student Name Student IDAmit ShuklaNo ratings yet

- Problem 2: Script FileDocument3 pagesProblem 2: Script FileAmit ShuklaNo ratings yet

- Safe Operation With Fork Lift Trucks: SAC Doc 165/10/EDocument27 pagesSafe Operation With Fork Lift Trucks: SAC Doc 165/10/Ecosmicbabe_2000No ratings yet

- Company Profile PT - Guteg Harindo 2013Document16 pagesCompany Profile PT - Guteg Harindo 2013EricDumasNo ratings yet

- Flakiness and Elongation TestDocument6 pagesFlakiness and Elongation TestnoorshafiqNo ratings yet

- TES LetterDocument9 pagesTES LetterJason KoeblerNo ratings yet

- Exploring The Taxi and Uber Demand in New York City: An Empirical Analysis and Spatial ModelingDocument20 pagesExploring The Taxi and Uber Demand in New York City: An Empirical Analysis and Spatial ModelingHenry TranNo ratings yet

- Smarter Traffic Management With Evidence-Based Decision Support SystemDocument20 pagesSmarter Traffic Management With Evidence-Based Decision Support SystemJerome UapsaNo ratings yet

- Sustainable Transport Mass Transit Options PDFDocument36 pagesSustainable Transport Mass Transit Options PDFWisnu AjiNo ratings yet

- Sand PatchDocument4 pagesSand PatchJebat FooNo ratings yet

- Technical Report 1 (Castillo&Doriano)Document13 pagesTechnical Report 1 (Castillo&Doriano)Baron Geoff CastilloNo ratings yet

- Dimensions: Standard Configuration: Arti Boom, 2,1 ArmDocument2 pagesDimensions: Standard Configuration: Arti Boom, 2,1 ArmCopemaq CopemaqNo ratings yet

- Irctc Sample Ticket FormatDocument1 pageIrctc Sample Ticket FormatMOHIT YADAVNo ratings yet

- Highways Department: Name of WorkDocument29 pagesHighways Department: Name of WorkThangavel RajNo ratings yet

- Request For Binder Course Asphalt Concrete Mix DesignDocument2 pagesRequest For Binder Course Asphalt Concrete Mix DesignAdyam YonasNo ratings yet

- Renault Sandero Katalog RPADocument24 pagesRenault Sandero Katalog RPARobert S.No ratings yet

- Ts Scope of Work and SupplyDocument12 pagesTs Scope of Work and Supplykbpatel123No ratings yet

- Marine Insurance Final ITL & PSMDocument31 pagesMarine Insurance Final ITL & PSMaeeeNo ratings yet

- PlatinumDocument6 pagesPlatinumkinjalamitgulatiNo ratings yet

- Riopel Full CatalougeDocument4 pagesRiopel Full CatalougedtoxidNo ratings yet

- Lecture Te 2Document34 pagesLecture Te 2SRUTHI PNo ratings yet

- DTDCDocument1 pageDTDCYuvraj SinghNo ratings yet

- Mexico FatalityDocument3 pagesMexico FatalityjohangomezruizNo ratings yet

- Conversion PamphletDocument1 pageConversion Pamphletpanashemanyere2No ratings yet

- Prices Effective Dated August 01 2023Document9 pagesPrices Effective Dated August 01 2023Faheem AbbasNo ratings yet

- 9 - Pavement Quality ControlDocument85 pages9 - Pavement Quality ControlgeoffreyNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)