Professional Documents

Culture Documents

Design Guideline Separator Vessel

Design Guideline Separator Vessel

Uploaded by

cssdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Guideline Separator Vessel

Design Guideline Separator Vessel

Uploaded by

cssdCopyright:

Available Formats

LIDE

INDUSTRIES

P r o v i d i n g Q u a l i t y S t o r a g e Ta n k s S i n c e 1 9 7 6

Vertical Separator

Two & Three Phase / Low Pressure

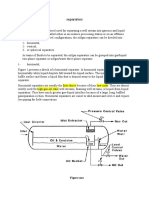

Application

Two phase separators are utilized to separate the gas from

the liquid in a wellstrem. This allows liquid free gas to be

diverted to gas sales and/or to be utilized as fuel. Relatively

gas free oil is then dumped to storage or to a treating system

for removal of water.

Two Phase- Low Pressure

The wellstream enters the separator and immediately

strikes the inlet deflector. This diverts the liquid and gas

around in a circular pattern which tends to throw the

heavier liquids to the shell of the separator where it travels

downward to the liquid section.

The gas expands and starts to travel upward at a low

velocity which allows more and more heavier liquids to fall

out. After adequate retention time, the gas goes through the

wire mesh mist extractor for final scrubbing of the gas.

The liquid section is sized to hold the liquid long enough for a

maximum portion of the gas in solution to break out and

travel up through the gas section.

As liquid builds up in the bottom section of the separator it

lifts a float which, through linkage, dumps the fluid by means

of a mechanical dump valve. A baffle protects the float and

reduces liquid turbulence.

Three Phase- Low Pressure Application

Operation is essentially the same as the two phase except

that the separator has an internal inlet flume which carries

the liquid down into the settling section. The three phase also

has a larger liquid section allowing more retention time for

the oil and water to separate.

At the oil/water interface there is a pneumatic

displacement type level control which actuates the water

dump valve. The oil which rises is then dumped by a

mechanical float operated oil dump valve.

The capacity is a function of the gravity difference in the oil

and water, and retention time. Oil and water must be present

as free liquids. The three phase separator will not break an

emulsified liquid stream.

Mexia, TX 254-562-0233

LIDE

INDUSTRIES

P r o v i d i n g Q u a l i t y S t o r a g e Ta n k s S i n c e 1 9 7 6

Vertical Separator

Two & Three Phase / Low Pressure

STANDARD ACCESSORIES:

STANDARD ACCESSORIES:

1-wire mesh mist extractor

1-inlet deflector

1-splash shield over float

1-2relief valve

1-2 back pressure valve

1-2 mechanical oil dump valve

1-8 float hub, trunnion, float and linkage

1-pressure gauge w/isolating valve

1-gauge glass assy.

1-concrete block

1-ladder

1-inlet flume

1-wire mesh mist extractor

1-2relief valve

1-2 back pressure valve

1-2 mechanical oil dump valve

1-8 float hub, trunnion, float and linkage (oil)

1-pneumatic interface llc (water)

1-instrument gas regulator

1-set tubing & fittings

1-pressure gauge w/isolating valve

2-gauge glass assy.

1-concrete block

1-ladder

Optional Items:

1-larger valves

1-pneumatic controls

1-coating

1-higher working pressures

Optional Items:

1-interior coatings

1-snap acting llc on oil an water

1-PD meters on liquid dumps

TWO PHASE

THREE PHASE

NOMINAL CAPACITIES

SIZE

S.S

INLET

& GAS

OUT

CONN

LIQUID

OUT

CONN

24 x 10

30 x 10

36 x 10

3

3

3

3

3

3

STD

GAS MMSCF/D

LIQUID

& GAS

LIQUID

50

100

VALVE SIZE

B/D

PSIG PSIG

2

2

2

600

1400

2700

2.3

4.2

6.1

3.1

5.7

8.2

NOMINAL CAPACITIES

SIZE

INLET

& GAS

OUT

CONN

LIQUID

OUT

CONN

24 x 10

30 x 10

36 x 10

3

3

3

2

2

2

STD

GAS MMSCF/D

LIQUID

APPX.

& GAS

LIQUID

50

100

WT.

VALVE SIZE

B/D

PSIG PSIG

LB.

2

2

2

700

1100

1800

1.9

3.8

5.0

2.8

5.3

7.1

850

1100

1300

Liquid capacities are based on 45 API liquid at 1 minute retention time 2 phase(3 minute retention -3 phase) with an even 24 hour flow

rate. Allowance must be made for slugging, gravity differences, and valves and lines sized for operating pressure differential.

You might also like

- Cpi O&m ManualDocument36 pagesCpi O&m Manualprasad336No ratings yet

- 10 1016@j Jngse 2016 01 016Document37 pages10 1016@j Jngse 2016 01 016saiful bahriNo ratings yet

- Two Phase SeparatorDocument67 pagesTwo Phase SeparatorRaden MasNo ratings yet

- ME 554 Problem Set-03 Nozzle Theory-Part-1Document1 pageME 554 Problem Set-03 Nozzle Theory-Part-1rahul prakash100% (1)

- There Phase Oil Water Gas SeparatorsDocument6 pagesThere Phase Oil Water Gas SeparatorsHAMZA GUERFI100% (1)

- 10.1.1.476.6482 Tesis de DR Carlos Oropeza VasquezDocument132 pages10.1.1.476.6482 Tesis de DR Carlos Oropeza VasquezAnonymous AtAGVssJNo ratings yet

- 2-Vertical Separator PDFDocument1 page2-Vertical Separator PDFSudarshan GopalNo ratings yet

- Flooding Capacity in Packed Towers: Database, Correlations, and AnalysisDocument12 pagesFlooding Capacity in Packed Towers: Database, Correlations, and Analysisaslam_bechemNo ratings yet

- Plate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFDocument12 pagesPlate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFFrandhoni UtomoNo ratings yet

- Optimal Design of Two and Three Phase Separators A Mathematical ProgrammingDocument16 pagesOptimal Design of Two and Three Phase Separators A Mathematical ProgrammingVimal Raj SNo ratings yet

- 1 s2.0 S0263876299718186 Main PDFDocument7 pages1 s2.0 S0263876299718186 Main PDFLeydi PatiñoNo ratings yet

- VGS Vane Separators Are Recommended ForDocument1 pageVGS Vane Separators Are Recommended ForSanthu PeelaNo ratings yet

- StichlmanirBravoFair General Model DP Packed ColumnDocument10 pagesStichlmanirBravoFair General Model DP Packed Columnmcusseglio3931No ratings yet

- CFD For Separator DesignDocument14 pagesCFD For Separator Designnwosu_dixonNo ratings yet

- Sizing Sheet of Vertical 2-Phase Separator As Per API 12JDocument5 pagesSizing Sheet of Vertical 2-Phase Separator As Per API 12JWickyNo ratings yet

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.WickyNo ratings yet

- Hydrocyclones DeoilingDocument2 pagesHydrocyclones DeoilingJ SlaterNo ratings yet

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsDocument4 pagesThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1 PDFDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1 PDFRaghulal SethumadhavanNo ratings yet

- Centrifugal PumpsDocument14 pagesCentrifugal PumpsAshishAgarwalNo ratings yet

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 pagesCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- ASPEN Design of Vap-Liq Separator EdtDocument6 pagesASPEN Design of Vap-Liq Separator EdtethanNo ratings yet

- PTIMS-OPS-DS-013 - Chemical Injection Pump Rev 3Document2 pagesPTIMS-OPS-DS-013 - Chemical Injection Pump Rev 3Hua Tien DungNo ratings yet

- Horizontal Three Phase SeparatorDocument1 pageHorizontal Three Phase SeparatorsandeepNo ratings yet

- Assignment Pump and Its PartsDocument19 pagesAssignment Pump and Its PartsSabyasachi PradhanNo ratings yet

- Optimizing A Large Vessel Separator DesignDocument9 pagesOptimizing A Large Vessel Separator DesignmctimlimNo ratings yet

- Presentationlu 180126221936 PDFDocument20 pagesPresentationlu 180126221936 PDFhaptoorNo ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocument7 pagesSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- Blower DSDocument2 pagesBlower DSpramod_tryNo ratings yet

- Savvy Separator - The Effect of Inlet Geometries On Flow DistributionDocument13 pagesSavvy Separator - The Effect of Inlet Geometries On Flow DistributionSHINo ratings yet

- Covnersion From KG/HR To SCMDDocument5 pagesCovnersion From KG/HR To SCMDsuNo ratings yet

- Gas Liquid Seperation by VesselsDocument2 pagesGas Liquid Seperation by VesselszapspazNo ratings yet

- Glycol Dehydration Unit English LetterDocument4 pagesGlycol Dehydration Unit English LetterRaulCamachoNo ratings yet

- Losses in Pipe BendsDocument5 pagesLosses in Pipe BendsLove KumarNo ratings yet

- C3 Recovery StudyDocument15 pagesC3 Recovery StudyengmohosmanNo ratings yet

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinNo ratings yet

- Gas/Liquid Separators: Quantifying Separation Performance - Part 1Document10 pagesGas/Liquid Separators: Quantifying Separation Performance - Part 1sara25dec689288No ratings yet

- Separator 1 Sizing Spread Sheets PDF FreeDocument21 pagesSeparator 1 Sizing Spread Sheets PDF FreeHenry WicaksanaNo ratings yet

- Three Phase Separator - Gas InternalsDocument9 pagesThree Phase Separator - Gas InternalsDeepak Raj100% (1)

- Preliminary Design of Sodium Carbonate Plant: Darft Assignment 2Document69 pagesPreliminary Design of Sodium Carbonate Plant: Darft Assignment 2Ardina Ayu WulandariNo ratings yet

- Api 2005Document2 pagesApi 2005Madeline DacianNo ratings yet

- Distillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsDocument11 pagesDistillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsJohan Sebastian Moreno LaraNo ratings yet

- Random PackingDocument4 pagesRandom PackingAadam AryanNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different StandardsAMRUTA PATILNo ratings yet

- LP Cold Vent & Closed Drain)Document1 pageLP Cold Vent & Closed Drain)Shibu ThomasNo ratings yet

- 1055 Crude Stailization Systems-SperoidsDocument0 pages1055 Crude Stailization Systems-SperoidsgshdavidNo ratings yet

- Design Calculation For Gaseous SystemsDocument16 pagesDesign Calculation For Gaseous Systemsshashi ranjanNo ratings yet

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocument18 pagesPrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6No ratings yet

- Gas Blowby - An Overview - ScienceDirect TopicsDocument15 pagesGas Blowby - An Overview - ScienceDirect TopicsWin Thi HaNo ratings yet

- Instrucalc ManualDocument18 pagesInstrucalc ManualRangga Taufiqurahman100% (1)

- Design Shell TubeDocument3 pagesDesign Shell TubeAKSHEYMEHTANo ratings yet

- Three Phase SeparatorDocument9 pagesThree Phase SeparatorboringNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallDocument10 pagesPrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehNo ratings yet

- What Are Oil and Gas SeparatorsDocument15 pagesWhat Are Oil and Gas SeparatorsFriday IjokgwungNo ratings yet

- Oil and Gas Separation System and Process: Unit-4Document18 pagesOil and Gas Separation System and Process: Unit-4Rinkesh GuptaNo ratings yet

- Separators: Figure OneDocument8 pagesSeparators: Figure OneMohamed Moder100% (1)

- Separators: Advantages DisadvantagesDocument46 pagesSeparators: Advantages DisadvantagesMahmoud Ahmed Ali Abdelrazik100% (1)

- 5.1 ASME Sec II Part C Ed 2015Document1 page5.1 ASME Sec II Part C Ed 2015Anbarasan PerumalNo ratings yet

- Translate 2.6.3 - Determination of Z-FactorDocument2 pagesTranslate 2.6.3 - Determination of Z-FactorelaNo ratings yet

- Modification of Hall-Yarborough Equation of State For Predicting Gas Compressibility FactorsDocument11 pagesModification of Hall-Yarborough Equation of State For Predicting Gas Compressibility FactorsNicolas CastañoNo ratings yet

- Calculation of Back Pressure of Silencer: Item # Silencer Name of Item # Silencer Name of Model Model Model ModelDocument1 pageCalculation of Back Pressure of Silencer: Item # Silencer Name of Item # Silencer Name of Model Model Model Modeluntung_susiloNo ratings yet

- 525-358 KMB18&28 Soft Goods Overhaul Kit With SUperflow 350 RegulatorDocument2 pages525-358 KMB18&28 Soft Goods Overhaul Kit With SUperflow 350 RegulatorMuhaimin MuhammadNo ratings yet

- CBerto El Tordillo FieldDocument68 pagesCBerto El Tordillo Fieldner68No ratings yet

- The Fires and Explosion at BP Oil Grangemouth Refinery LTD PDFDocument48 pagesThe Fires and Explosion at BP Oil Grangemouth Refinery LTD PDFBurgosg ValeryNo ratings yet

- Gas Conditioning & Processing - GLOMACSDocument5 pagesGas Conditioning & Processing - GLOMACSCHO ACHIRI HUMPHREYNo ratings yet

- 3 Hydrocarbon Phase BehaviourDocument45 pages3 Hydrocarbon Phase BehaviourMD. ASIF ALL AZADNo ratings yet

- Parts and Maintenence Labconco Vacio BombaDocument20 pagesParts and Maintenence Labconco Vacio BombaMartin Fco EncinasNo ratings yet

- TM31 ServicemanualDocument48 pagesTM31 ServicemanualAnonymous 9xvU1FNo ratings yet

- Kompendium Power Bolland PDFDocument168 pagesKompendium Power Bolland PDFHillmiAdiWijaya100% (1)

- Natural Gas Dehydration in Offshore RigsDocument6 pagesNatural Gas Dehydration in Offshore RigsEllen DawitriNo ratings yet

- PsycrometryDocument24 pagesPsycrometryFaisal Ahmmed FahimNo ratings yet

- Training ManualDocument49 pagesTraining ManualMahaveer ChaudhariNo ratings yet

- Chapter 2 PensyarahDocument75 pagesChapter 2 PensyarahAdi BaddNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Pedro Caminos BolanosNo ratings yet

- Nfpa 58: Liquefied Petroleum Gas CodeDocument14 pagesNfpa 58: Liquefied Petroleum Gas CodeRickey L. SantiagoNo ratings yet

- Boiler Aalborg Aq-2 OvimuDocument193 pagesBoiler Aalborg Aq-2 Ovimunguyenvanhai1903198175% (4)

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- Analisa Teknik I - Dewandono BAyu Seto - S952002003Document6 pagesAnalisa Teknik I - Dewandono BAyu Seto - S952002003DewaNo ratings yet

- Bank ProposalDocument19 pagesBank ProposalAhmad Murad bin Md AliNo ratings yet

- Fluid Theraphy Branula:: GreenDocument4 pagesFluid Theraphy Branula:: Greenkuku93No ratings yet

- FR Goldschmied - Integrated Hull Design Boundary Layer ControlDocument10 pagesFR Goldschmied - Integrated Hull Design Boundary Layer ControlVictor PadillaNo ratings yet

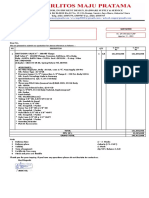

- Penawaraan CMPDocument1 pagePenawaraan CMPCV Carlitos Maju PratamaNo ratings yet

- SRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFDocument26 pagesSRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFRiyesh KpNo ratings yet

- Maquina de Anestesia - ADSIIDocument2 pagesMaquina de Anestesia - ADSIIalexanderNo ratings yet

- Boiler With Mountings and AccessoriesDocument67 pagesBoiler With Mountings and AccessoriesYashvir Singh100% (1)

- Piusi Air Operated P60 1 InstructionsDocument2 pagesPiusi Air Operated P60 1 Instructions673348300 Producto CartesNo ratings yet