Professional Documents

Culture Documents

Welding QC 17 - Heat Treatment

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding QC 17 - Heat Treatment

Uploaded by

Exsan OthmanCopyright:

Available Formats

T\MI

v[ot

THE \}ELDTNC SISTITUTE

S E C T ION1 7

TWI

wflt

THE WE1511.,15

INSTTTUTE

HEAT TREATMENT

Many metals must be given heat treatmentbeforeand after welding. The

inspecto/s functionis to ensurethat the treatmentis given and given cofrectly,

to the detailssuoolied.

Below are the types of heat treatmentavailable. The temperaturesmentioned

are for steels.

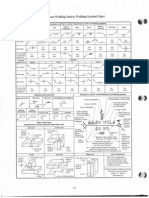

Process

Temperature

Cooling

Rbsult

N.B.

Annealing:

920'C

hold, furnacecool improvesductility

decreasestoughness

makes bending,etc

easier

lowersyield stress

Normalising:

920"C

hold, ajr cool

relievesinternalstress

imDrovesmechanical

properties

increasestouahness

Quench, harden: 920"C

hold, quenchcool hardenscarbon steels

oreventscarbide

precipitationin

austeniticsteels

preventstemper

brittlenesswhen

coolingafter tempering

oreoaresmetal for

tempenng

Temper:

550-700'C

hold, air cool

Stress relief:

550-700"C

hold. air cool

Preheatfor

50-250"C

welding:

This may be overallor local.

WELDING TECHNOLOGY

lssue 0191

increasestoughnessof

quenchedsteels

relievesresiduar

stresses

improvesstability

duringmachining

-^),

,^^^

l,,)-.

reouces

nyorogen

levels

preventsstress

corrosioncrackinq

hold during welding,

exceptionallyhigher

V.1

TWI

W'

THE WET.r]INCNSTITUTE

The inspector,in general,shouldensurethat:

a) Equipmentis as specified

b) Equipmentis in good condition,i.e. temperaturecontrol

c) Proceduresas specifiedis beingused

e.g. Methodof application

Rate of heating and cooling

MaximumtemDerature

'Soaktime'

Temperaturemeasurement(and calibration)

DOCUMENTATIONAND RECORDS.

17..2

WELDING TECHNOLOGY

Issue 0191

:

T\vI

7O[f

--

THE WEI.DING INSTITU-TE

OUESTIONS

HEAT TREATMENTOF WELDMENTS

01

whichmaybe appliedto

Givethe namesof four (4) heattreatmentrs

steelweldments.

Q2

usedwhenheattreating

Statethe maximumtemperatures

weldments.

03

What temoeratureis used for temoerinoweldments?

Q4

Whatis the obiectiveof NORMALISING?

Q5

Whichheattreatmentis usedwhen maximumtouohnessis reouired?

os17

You might also like

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Alloy Steels 8620: Chemistry DataDocument6 pagesAlloy Steels 8620: Chemistry DataVijay PalNo ratings yet

- HT ManualDocument17 pagesHT ManualAkhilesh KumarNo ratings yet

- ToolSteel AISIH13Document2 pagesToolSteel AISIH13Hirmanto SuibNo ratings yet

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDocument4 pagesAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno WijayaNo ratings yet

- 3 - Heat Treatment & Engineering ApplicationDocument24 pages3 - Heat Treatment & Engineering ApplicationHussein SaeedNo ratings yet

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienNo ratings yet

- Heat Treatment AnnealingDocument7 pagesHeat Treatment AnnealingEngr Arfan Ali DhamrahoNo ratings yet

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentAshish BoraNo ratings yet

- Acero para BarcosDocument39 pagesAcero para BarcosviyfNo ratings yet

- EN26Document3 pagesEN26Moldoveanu TeodorNo ratings yet

- Over View Heat Treatment Processes: by MadhubalanDocument61 pagesOver View Heat Treatment Processes: by Madhubalanjohn powerNo ratings yet

- Caracteristicas Do Aço 40CrMnMo7Document2 pagesCaracteristicas Do Aço 40CrMnMo7Gabriel GonçalvesNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyDocument9 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyOnur AltuntaşNo ratings yet

- Heat Treatment of SteelsDocument6 pagesHeat Treatment of SteelsSrinivas LaishettyNo ratings yet

- Cswip - Section 20-Heat TreatmentDocument9 pagesCswip - Section 20-Heat TreatmentNsidibe Michael Etim100% (1)

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- Perlakuan Panas Logam: (TTT & CCT Diagram, Annealing, Hardening)Document46 pagesPerlakuan Panas Logam: (TTT & CCT Diagram, Annealing, Hardening)Iqbal DebbyNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- Deepesh Heat TreatmentDocument26 pagesDeepesh Heat TreatmentVaidNo ratings yet

- Heat Treatment of Steel: As-Rolled, Hot Roller and Hot FinishedDocument8 pagesHeat Treatment of Steel: As-Rolled, Hot Roller and Hot FinishedManoj KumarNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- Invar 36Document3 pagesInvar 36TrentStewartLaCourNo ratings yet

- Unit 2 Heat TreatmentDocument59 pagesUnit 2 Heat TreatmentAmutha PSGRKCWNo ratings yet

- API RP 571 Damag 10Document12 pagesAPI RP 571 Damag 10JithuJohn100% (2)

- Heat Treatment ProcessesDocument61 pagesHeat Treatment ProcessesMadhubalan100% (1)

- Hardening Is Usually Done To: Heat Treatment of AlloysDocument8 pagesHardening Is Usually Done To: Heat Treatment of AlloysMadhavanIceNo ratings yet

- En 19 TDocument3 pagesEn 19 TchaitanyaNo ratings yet

- Presentation On PWHT & Stress RelievingDocument23 pagesPresentation On PWHT & Stress Relievingedu_canete88% (16)

- Heat Treatment: Dr. Mohamed Abd Elmonem DahaDocument23 pagesHeat Treatment: Dr. Mohamed Abd Elmonem DahashoroukNo ratings yet

- What Is Heat TreatmentDocument5 pagesWhat Is Heat TreatmentAbdulbar kelilNo ratings yet

- Alloy SteelDocument4 pagesAlloy SteelDalibor CetojevicNo ratings yet

- Spring SteelDocument2 pagesSpring Steelvaishu1502No ratings yet

- CHAPTER - Heat Treatment 3rd Sem ManufacturingDocument11 pagesCHAPTER - Heat Treatment 3rd Sem Manufacturingkaranragav12No ratings yet

- 8620 Case Hardening SteelDocument3 pages8620 Case Hardening Steelkumarsathish2009No ratings yet

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- Age HardeningDocument5 pagesAge Hardeninganum_nNo ratings yet

- 1.8550 - 34CRAlNi7sdfDocument2 pages1.8550 - 34CRAlNi7sdfAdrian FinichiuNo ratings yet

- Fti Vhssm50 InglesDocument2 pagesFti Vhssm50 InglesAntonio Melgaço da SilvaNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- As Rolled, Hot Rolled, Hot Finished: Applied ToDocument8 pagesAs Rolled, Hot Rolled, Hot Finished: Applied ToAlaaNo ratings yet

- S7 Tool Steel: What Is ?Document3 pagesS7 Tool Steel: What Is ?Sama UmateNo ratings yet

- FinDocument3 pagesFinTVP_contechNo ratings yet

- Fiche z38cdv5Document1 pageFiche z38cdv5Emmanuel LAIZETNo ratings yet

- X20 CR Mo 13 KGDocument2 pagesX20 CR Mo 13 KGBonthala BadriNo ratings yet

- 410 Ss PDFDocument2 pages410 Ss PDFRiza KhanNo ratings yet

- Heat Treatment of Welded JointsDocument4 pagesHeat Treatment of Welded JointskingstonNo ratings yet

- Heat Treatment of SteelDocument59 pagesHeat Treatment of SteelNaman ShethNo ratings yet

- Types of Steel & Their TreatmentsDocument15 pagesTypes of Steel & Their Treatmentsrizwan_ali264No ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFdiego.peinado8856No ratings yet

- Carpenter Stainless Custom 630 PDFDocument9 pagesCarpenter Stainless Custom 630 PDFGrafton MontgomeryNo ratings yet

- eNERGY cONSUMPTIONDocument8 pageseNERGY cONSUMPTIONRefky FNo ratings yet

- Valbruna Grade Steel TypeDocument3 pagesValbruna Grade Steel TypeLebasNo ratings yet

- Cold Work Steels: Available Product ShapesDocument6 pagesCold Work Steels: Available Product ShapesSangHak LeeNo ratings yet

- A-Health Advance-I Premium RatesDocument2 pagesA-Health Advance-I Premium RatesExsan OthmanNo ratings yet

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- Tube Inspection GuidebookDocument28 pagesTube Inspection GuidebookAkhileshNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Chat For Organization of CodeDocument1 pageChat For Organization of CodeExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- Material CharacteristicsDocument4 pagesMaterial CharacteristicsExsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Nozzle Repad Design SpreadsheetsDocument2 pagesNozzle Repad Design SpreadsheetsArt G. EnziNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet