Professional Documents

Culture Documents

CHE Ron Bracing in Low-Rise Buildings: Steel Wise

CHE Ron Bracing in Low-Rise Buildings: Steel Wise

Uploaded by

Efrainz TorresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHE Ron Bracing in Low-Rise Buildings: Steel Wise

CHE Ron Bracing in Low-Rise Buildings: Steel Wise

Uploaded by

Efrainz TorresCopyright:

Available Formats

Steel Wise

CHE

RON BRACING

IN LOW-RISE BUILDINGS

Roberta Marstellar, Keith Mueller, Jason Ericksen and Christopher Hewitt

Estimating member sizes for

chevron bracing in low-rise

steel-framed construction is

easier than ever with this

handy design aid.

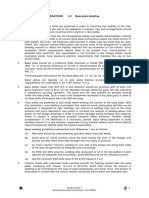

Schematic of typical chevron brace configurations. The details circled are highlighted in

later figures in this article.

hevron braces are a common configuration for

providing lateral-load resistance in steel-framed

buildings. This handy

chart will help you quickly estimate the

brace size and connection material required for a given force in chevron

bracing designed to resist lateral forces

due to gravity, wind and low-seismic

loads.1 These rules of thumb dont

cover all situations, but they will provide a reasonable starting point for the

preliminary brace and connection design or cost estimating.

Estimated brace sizes, gusset plate

thicknesses, and required number of

bolts or size and length of the welds are

tabulated for a practical range of unfac-

`Modern Steel Construction April 2002

tored brace forces (tensile and compressive). The bolts and welds indicated

are for the connection of the brace to

the gusset plate. A 3 center-to-center

bolt spacing and a 11/2 edge distance

were assumed in the connection design. Suggested details for the various

connections involved in chevron bracing are also included for each of the

bracing types: HSS, W-shapes, WTshapes and double angles.

The connection(s) of the gusset plate

to the beam and/or column are not addressed in the table. Also, drift control

issues must be considered separately.

The minimum length of the welds

for the connection of the HSS to the

gusset is 1.3 times the diameter of the

round HSS or 1.3 times the side of the

square HSS. Rectangular HSS are not

included. This minimum length allows

the welds to be designed with a shear

lag coefficient U = 1 in the HSS.2 A

smaller weld length may be acceptable,

provided the effects of shear lag are

considered.

Thanks to Victor Shneur, P.E., of

Lejeune Steel Company in Minneapolis, MN, for laying the groundwork for

this feature.

Roberta (Bobbi) Marstellar is Director,

Steel Solutions Center, Keith Mueller is Senior Engineer, Steel Solutions Center, and

Jason Ericksen is Solutions Center Advisor.

Christopher Hewitt is Staff Engineer

Structures in AISCs Engineering and Research department. Email the Steel Solutions Center at solutions@aisc.org, or visit

them at the AISC web site, www.aisc.org.

Chevron Bracing in Low-Rise Buildings

30

50

75

100

150

200

Gusset Plate

ASTM A36

PL

3/8"

PL

3/8"

PL

1/2"

PL

1/2"

PL

3/4"

PL

3/4"

2L5x5x5/16

(21 lb/ft)

2L6x6x3/8

(30 lb/ft)

2L6x6x3/8

(30 lb/ft)

2L6x6x1/2

(39 lb/ft)

2L8x8x1/2

(53 lb/ft)

2L8x8x1/2

(53 lb/ft)

3/4" Bolts / row

ASTM A325

7/8" Bolts / row

ASTM A325

No. of Rows

Round HSS

ASTM A500, Gr. B

HSS

5.000x0.375

(18.5 lb/ft)

HSS

6.000x0.312

(19.0 lb/ft)

HSS

6.000x0.500

(29.4 lb/ft)

HSS

6.875x0.500

(34.1 lb/ft)

HSS

8.625x0.500

(43.4 lb/ft)

HSS

9.625x0.500

(48.8 lb/ft)

Square HSS

ASTM A500, Gr. B

HSS5x5x1/4

(16 lb/ft)

HSS6x6x1/4

(19 lb/ft)

HSS6x6x1/4

(19 lb/ft)

HSS7x7x1/4

(22 lb/ft)

HSS8x8x5/16

(32 lb/ft)

HSS8x8x3/8

(38 lb/ft)

"a" (in)

[See Details]

3/16

3/16

1/4

1/4

5/16

5/16

"b" (in) **

[See Details]

9 (Round)

10 (Square)

12 (Round)

11 (Square)

13 (Round)

11 (Square)

W6x20

W8x28

W8x31

W8x35

W8x48

W10x49

Web Plates

ASTM A36

(2)

PL 3/8"

(2)

PL 3/8"

(2)

PL 3/8"

(2)

PL 3/8"

(2)

PL 3/8"

(2)

PL 3/8"

3/4" or 7/8"

ASTM A325 Bolts

4 - Gusset

4 - Web

4 - Gusset

4 - Web

4 - Gusset

4 - Web

4 - Gusset

4 - Web

4 - Gusset

4 - Web

4 - Gusset

4 - Web

Angles

ASTM A36

4 L4x4x5/16

4 L4x4x5/16

4 L4x4x5/16

4 L4x4x5/16

4 L4x4x5/16

4 L4x4x5/16

3/4" or 7/8"

ASTM A325 Bolts

4 - Gusset

8 - Flange

4 - Gusset

8 - Flange

4 - Gusset

8 - Flange

4 - Gusset

8 - Flange

6 - Gusset

12 - Flange

8 - Gusset

16 - Flange

WT6x13

WT6x25

WT6x43.5

WT7x45

WT8x38.5

WT13.5x73

3/4" Bolts

ASTM A325

7/8" Bolts

ASTM A325

Bolts

Double Angles

ASTM A36

Weld

HSS

Double Angles

Unfactored Loads

(Kips)

Web

WT-Shape

ASTM A992

Bolts

WT-Shape

(Flange Connection)

Flange

W-Shape

W-Shape

ASTM A992

** Weld lengths are based on 1.3H , where H is the outside diameter of a round HSS or leg dimension of a square HSS.

REFERENCES

1. Low-seismic loads are those for applications in which the seismic response modification factor R is

taken equal to or less than 3. Structural elements and connections in

such applications are designed to

meet the requirements in the AISC

Load and Resistance Factor Design

(LRFD) Specification with no special

seismic detailing.

2. Kulak, Geoffrey L., and J. J. Roger

Cheng, 2000, Gusset Plate Connection to Round HSS Tension Members. Engineering Journal Vol. 37

No. 4 (Fourth Quarter): 133-139.

Turn page for typical details

April 2002 Modern Steel Construction

Steel Wise

SUGGESTED DETAILS FOR CHEVRON BRACING

`Modern Steel Construction April 2002

SUGGESTED DETAILS FOR CHEVRON BRACING

April 2002 Modern Steel Construction

You might also like

- Guidelines: BracingDocument28 pagesGuidelines: BracingkjdaraNo ratings yet

- Thumb Rules BuildingsDocument6 pagesThumb Rules Buildingsapi-3697897100% (3)

- REDBOOK Full Download 01c5Document252 pagesREDBOOK Full Download 01c5Kyle LockwoodNo ratings yet

- Australian Steel StrengthDocument5 pagesAustralian Steel StrengthDonald HamiltonNo ratings yet

- Avanta MezzanineDocument4 pagesAvanta MezzanineRanjit MarimuthuNo ratings yet

- BEARING CAPASITY OFSOIL FinalDocument41 pagesBEARING CAPASITY OFSOIL FinalAysha RasheedNo ratings yet

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNo ratings yet

- 22a - Simply Supported Crawl BeamDocument22 pages22a - Simply Supported Crawl BeamMbalekelwa MpembeNo ratings yet

- Bs-Id Technical Drawing GuideDocument16 pagesBs-Id Technical Drawing GuideJudea CaballeroNo ratings yet

- Bolts - LRFDDocument6 pagesBolts - LRFDalexortiz83No ratings yet

- 17-185 Salary-Guide Engineering AustraliaDocument4 pages17-185 Salary-Guide Engineering AustraliaAndi Priyo JatmikoNo ratings yet

- Lesson Plan in AccountingDocument7 pagesLesson Plan in AccountingRoz Ada0% (1)

- Temporary StructuresDocument65 pagesTemporary StructuresnisfibolahenkNo ratings yet

- BORAL PlywoodDocument36 pagesBORAL PlywoodKeri Martinez100% (1)

- CIA Z11 Presentation 2022Document14 pagesCIA Z11 Presentation 2022John Van RooyenNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- CSA S16-09 CSA S16 09: Design of Steel StructuresDocument20 pagesCSA S16-09 CSA S16 09: Design of Steel StructuresArnold GonzalesNo ratings yet

- Computation: Reinforced Concrete Slab DesignDocument4 pagesComputation: Reinforced Concrete Slab DesignARSENo ratings yet

- Anchor Bolt Shock CalculationDocument1 pageAnchor Bolt Shock Calculationvikramjain66No ratings yet

- Engineering Structures: SciencedirectDocument8 pagesEngineering Structures: SciencedirectFeleki AttilaNo ratings yet

- Doc9 5 4 PDFDocument5 pagesDoc9 5 4 PDFAnonymous dSFbLxc90% (1)

- Alternative Solution Fire Compliance: Timber StructuresDocument24 pagesAlternative Solution Fire Compliance: Timber StructuresThomas ChaiNo ratings yet

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjNo ratings yet

- Beam Design Notes Nzs 3404Document24 pagesBeam Design Notes Nzs 3404sdewss100% (3)

- An Introduction To Strategic CommunicationDocument9 pagesAn Introduction To Strategic Communicationscrane@100% (1)

- Axon Bracing Technical SupplementDocument1 pageAxon Bracing Technical SupplementRajeev SharanNo ratings yet

- NZS 3404-1997 Example 003 PDFDocument6 pagesNZS 3404-1997 Example 003 PDFIhab El AghouryNo ratings yet

- Perry Rhodan 009 The Wasp Men AttackDocument70 pagesPerry Rhodan 009 The Wasp Men AttackHeavycavalryNo ratings yet

- Beams AS3600 v1Document3 pagesBeams AS3600 v1Nicky198No ratings yet

- Pryda Builders Guide WebDocument80 pagesPryda Builders Guide WebRafid Yuda Setiawan0% (1)

- Math 2nd Quarter CoDocument6 pagesMath 2nd Quarter CoNerissa HalilNo ratings yet

- BIA - Steel Lintel DesignDocument7 pagesBIA - Steel Lintel Designgpax42No ratings yet

- Bobcat S150 Series - Operation Maintenance Parts ManualDocument545 pagesBobcat S150 Series - Operation Maintenance Parts ManualMarco Aurélio100% (2)

- Amendment No. 5 To AS/NZS 1170.2:2011 Structural Design Actions Part 2: Wind ActionsDocument2 pagesAmendment No. 5 To AS/NZS 1170.2:2011 Structural Design Actions Part 2: Wind ActionsPratik KaleNo ratings yet

- BHP Hot Rolled SectionsDocument30 pagesBHP Hot Rolled SectionsDaGoose81100% (1)

- Pile Analysis (As2159) in Accordance With Australian Standard: Piling-Design and Installation Per AS 2159-2009Document3 pagesPile Analysis (As2159) in Accordance With Australian Standard: Piling-Design and Installation Per AS 2159-2009PhranckNo ratings yet

- Business Analyst SampleDocument2 pagesBusiness Analyst SampleAbha SaxenaNo ratings yet

- AIJ GuideDocument80 pagesAIJ GuidedamindaNo ratings yet

- Keil Undercut AnchorsDocument16 pagesKeil Undercut AnchorsTracyval CadaNo ratings yet

- Tesla Sales DataDocument1,504 pagesTesla Sales DataZorawar ZedNo ratings yet

- CE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemDocument17 pagesCE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemwinminthetgeoNo ratings yet

- STP624-EB.28676-1 Nondestructive Testing Standards... 1977Document355 pagesSTP624-EB.28676-1 Nondestructive Testing Standards... 1977Marcos Silva100% (2)

- Acrowskaf: Boral Formwork & ScaffoldingDocument24 pagesAcrowskaf: Boral Formwork & ScaffoldingScooby DooNo ratings yet

- Con 1303Document8 pagesCon 1303chef100% (1)

- DD Env 1991 1 1996Document67 pagesDD Env 1991 1 1996Vishwakarma VishwakarmaNo ratings yet

- ABM Work Immersion Plan For 2nd Quarter 2Document3 pagesABM Work Immersion Plan For 2nd Quarter 2Geosippi San Antonio Layman100% (1)

- Weldlok Balltube HandrailDocument12 pagesWeldlok Balltube HandrailnovadistributorsNo ratings yet

- Holes and Slots, Standard SizesDocument3 pagesHoles and Slots, Standard SizesStephen KokoNo ratings yet

- Detailing Considerations Design Guide 7 - bk745 PDFDocument5 pagesDetailing Considerations Design Guide 7 - bk745 PDFFunkNo ratings yet

- Ancon QwikFoot and QwikFix Threaded Inserts Design GuideDocument36 pagesAncon QwikFoot and QwikFix Threaded Inserts Design GuideDan MoldoveanuNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Civil Design Help - Foundation For Rotating Equipment PDFDocument31 pagesCivil Design Help - Foundation For Rotating Equipment PDFoluomo1No ratings yet

- Steel Top Hats Battens Capacitytables Product Technical ManualDocument16 pagesSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaNo ratings yet

- Civil Equaltion PDFDocument2 pagesCivil Equaltion PDFBalaji_Rajaman_2280No ratings yet

- Formulationforfree Standingstaircase PDFDocument8 pagesFormulationforfree Standingstaircase PDFjames112522100% (1)

- TN008 - Welding Consumables and Design of Welds in As 4100-1998 With Amendment 1, 2012Document6 pagesTN008 - Welding Consumables and Design of Welds in As 4100-1998 With Amendment 1, 2012Andy AcousticNo ratings yet

- Introduction Nash HB RLRSFDocument8 pagesIntroduction Nash HB RLRSFDenise2512No ratings yet

- Build 141 Bracing SupplementDocument36 pagesBuild 141 Bracing SupplementRajeev SharanNo ratings yet

- Guidance On Structural Connections For SAEDocument7 pagesGuidance On Structural Connections For SAEGaruda GarudaNo ratings yet

- bALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFDocument8 pagesbALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFSudharsana PrayogaNo ratings yet

- L T Formwork Component List PDFDocument54 pagesL T Formwork Component List PDFanbumaniNo ratings yet

- Manual 9T Edge Lifter 2017 V1.0Document8 pagesManual 9T Edge Lifter 2017 V1.0darren dmuscat1hotmail.comNo ratings yet

- As 1576 2 ScaffoldingDocument36 pagesAs 1576 2 ScaffoldingmceregxNo ratings yet

- Bolt and Weld Capacity - Red Book 1999 PDFDocument2 pagesBolt and Weld Capacity - Red Book 1999 PDFWhite_rabbit2885764No ratings yet

- Mitek 12kN Pile FixingDocument2 pagesMitek 12kN Pile FixingTuroyNo ratings yet

- Civil Engineering ProjectDocument25 pagesCivil Engineering ProjectFadi BoustanyNo ratings yet

- CIVL311 - CIVL911 - 2020 - Week1 - Student - 1 SlideDocument72 pagesCIVL311 - CIVL911 - 2020 - Week1 - Student - 1 SlideMohammad Touhidul HaqueNo ratings yet

- HSS - American Institute of Steel ConstructionDocument4 pagesHSS - American Institute of Steel ConstructionJagatheesh RadhakrishnanNo ratings yet

- UL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ADocument1 pageUL FM OS&Y Gate Valves, AWWA C515 - Water Works - Fire Protection - Model 2030 Series ASiles LimberdsNo ratings yet

- Watson Metal Products - Threaded Rods To Grade 5Document5 pagesWatson Metal Products - Threaded Rods To Grade 5ameensderajNo ratings yet

- Seismic Brace DesignDocument19 pagesSeismic Brace Designapi-3697897100% (6)

- Beam Column Base Plate DesignDocument10 pagesBeam Column Base Plate DesignSPUD1100% (3)

- Sivagamiyin Sabatham Part1Document125 pagesSivagamiyin Sabatham Part1api-19854516No ratings yet

- TACO Faurecia Design Center Private Limited (TFDC)Document55 pagesTACO Faurecia Design Center Private Limited (TFDC)Subash SathyanathanNo ratings yet

- Synthesis and Characterization of Selenium Doped Zinc Oxide (Zno-Se) NanoparticlesDocument6 pagesSynthesis and Characterization of Selenium Doped Zinc Oxide (Zno-Se) NanoparticlesKrishna DontarajuNo ratings yet

- I. Tell Whether The Given Is An EXPRESSION or A SENTENCE. If It Is A Sentence, Identify Whether It Is A True or False SentenceDocument4 pagesI. Tell Whether The Given Is An EXPRESSION or A SENTENCE. If It Is A Sentence, Identify Whether It Is A True or False SentenceMykristie Jho B. MendezNo ratings yet

- Batch No 14Document62 pagesBatch No 14Santhosh ReddyNo ratings yet

- 6N137 Datasheet en 20190610 PDFDocument8 pages6N137 Datasheet en 20190610 PDFwilltorNo ratings yet

- Hole FinderDocument1 pageHole FinderSLK SPVNo ratings yet

- CheatDocument1 pageCheatPenda JoseNo ratings yet

- Letter of Intimation - STUDENT SECTIONDocument1 pageLetter of Intimation - STUDENT SECTIONHims GovaniNo ratings yet

- MIS210 ProgrammssssDocument55 pagesMIS210 ProgrammssssSk. Shahriar RahmanNo ratings yet

- SSPL - Payroll - Leading Practices - v2019Q3Document11 pagesSSPL - Payroll - Leading Practices - v2019Q3Priya MNo ratings yet

- Namibia's Language Policy Is 'Poisoning' Its ChildrenDocument4 pagesNamibia's Language Policy Is 'Poisoning' Its ChildrenMustafa khatibNo ratings yet

- Mohammad Saifuddin Khaled Profile Without PhotoDocument1 pageMohammad Saifuddin Khaled Profile Without Photoapi-19968318No ratings yet

- METTL - Logical Building 1 - 2 and 3 LinksDocument2 pagesMETTL - Logical Building 1 - 2 and 3 Linksvtu17998No ratings yet

- Test Bank For Clinical Calculations 8th Edition Joyce Lefever Kee Sally M MarshallDocument24 pagesTest Bank For Clinical Calculations 8th Edition Joyce Lefever Kee Sally M MarshallMichaelThomasyqdi100% (44)

- Rest API SlidesDocument34 pagesRest API SlidesFRANCISCO JAVIER Sampedro nuñezNo ratings yet

- Pharma PresentationDocument79 pagesPharma Presentationakkimakki2No ratings yet

- Patricia EvangelistaDocument7 pagesPatricia Evangelistaaccidently gave a little hope to my selfNo ratings yet

- Preface: The 9th International Conference On Global Resource Conservation (ICGRC) and AJI From Ritsumeikan UniversityDocument2 pagesPreface: The 9th International Conference On Global Resource Conservation (ICGRC) and AJI From Ritsumeikan UniversityAdriani HasyimNo ratings yet

- Sales Proposal: 3 HP Submersible Pump With Ac/Dc ControllerDocument3 pagesSales Proposal: 3 HP Submersible Pump With Ac/Dc ControllerRyan RequiñaNo ratings yet

- IndexDocument14 pagesIndexJane Maica VicoyNo ratings yet

- Module 2Document5 pagesModule 2Emmarie LlantinoNo ratings yet