0% found this document useful (0 votes)

1K views1 pageRoughness Conversion Table

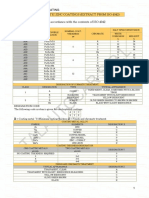

- This document contains a roughness conversion table with various roughness measurement scales including Ra, Rz, Rt, Ry, and AA.

- It provides roughness levels ranging from very smooth superfinishing to raw material surfaces.

- Roughness is measured as the series of micro-geometrical errors on a machined surface, with the most common measurement being the mean arithmetical value Ra in micrometers measured transversally to the main grooves.

Uploaded by

dreamingscientist3393Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views1 pageRoughness Conversion Table

- This document contains a roughness conversion table with various roughness measurement scales including Ra, Rz, Rt, Ry, and AA.

- It provides roughness levels ranging from very smooth superfinishing to raw material surfaces.

- Roughness is measured as the series of micro-geometrical errors on a machined surface, with the most common measurement being the mean arithmetical value Ra in micrometers measured transversally to the main grooves.

Uploaded by

dreamingscientist3393Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd