Professional Documents

Culture Documents

F&D Head Design Tool: Pressure Vessel Engineering LTD

F&D Head Design Tool: Pressure Vessel Engineering LTD

Uploaded by

Exsan Othman0 ratings0% found this document useful (0 votes)

22 views1 pagehd

Original Title

F_D Head

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthd

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views1 pageF&D Head Design Tool: Pressure Vessel Engineering LTD

F&D Head Design Tool: Pressure Vessel Engineering LTD

Uploaded by

Exsan Othmanhd

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

1

Pressure Vessel Engineering Ltd.

Finite Element Analysis ASME Code Calculations

Canadian Vessel Registration Vessel Modeling and Drafting

3

4

5

6

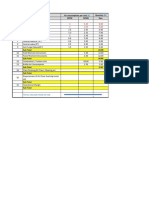

F&D Head Design Tool ver E4.01

8

9

10

11

12

13

14

15

16

17

18

Dimensions:

24.000

24.000

1.440

0.188

0.159

0.010

2.000

Do [in] - outside diameter of head

L [in] - inside crown radius (note 1)

IKR [in] - inside knuckle radius (note 2)

tb [in] - thickness before forming

tf [in] - thickness after forming (note 3)

Corr [in] - corrosion allowance

Skirt [in] - straight skirt length

Material and Conditions:

SA-240 304 Material

20,000 S [psi] - allowable stress

0.85 E - head longitudinal efficiency

50.0 P [psi] - interior pressure

19

20

21

Calculated Properties:

24

note 1:Suggested radius L per UG-32(j)

note 2:Suggested radius IKR per UG-32(j)

note 3:Suggested thickness after forming

25

Variables:

22

23

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

Page 1 of 1

F&D Head Description

nt [in] =

D [in] =

L/r =

M=

Ro [in] =

24.00

1.440

0.1555

Approx. head weight based on steel, lbs =

Approx. head volume including skirt, cuft =

tf-Corr ~~ thickness with corrosion allowance removed

Do-2*nt ~~ ID with corrosion allowance removed

L/IKR

0.25*(3+sqrt(L/IKR))

L+tb

0.159-0.01 =

24-2*0.149 =

24/1.44 =

0.25*(3+SQRT(24/1.44)) =

24+0.188 =

38.53

1.12

0.149

23.701

16.667

1.771

24.188

Required Thickness: App. 1-4(a), App. 1-4(d)

App1-4(f) = tf/L

0.159/24 = 0.007

App1-4(f)Calc = if(AND(0.0005=<App1-4(f),App1-4(f)<0.002),"Calculation Required","Calculation not requi

App. 1-4(f) Calculation Not Required

Treq [in] = (P*L*M)/(2*S*E-0.2*P)+Corr ~~ required minimum thickness

(50*24*1.771)/(2*20000*0.85-0.2*50)+0.01 = 0.073

CheckTreq = Treq<=tf

0.073<=0.159 = Acceptable

Maximum Pressure: App. 1-4(a), App. 1-4(d)

Pmax [psi] = (2*S*E*nt)/(L*M+0.2*nt) ~~ maximum allowed design pressure

(2*20000*0.85*0.149)/(24*1.771+0.2*0.149) = 119.4

CheckPMax = Pmax >= P

119.4 >= 50 = Acceptable

App. 1-4(f) calculation is not included on this sheet

Nozzles may be subject to a smaller required thickness depending on location in the head.

Only the knuckle required thickness is calculated on this sheet

Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UG-37(a)(1)

The UG-16(b) minimum thickness requirement has not been taken into consideration here.

This sheet cannot be used to check for allowable exterior pressure loads.

Use the Weld Efficiency program to calculate E

This sheet is for educational use only - use at your own risk.

Pressure Vessel Engineering Ltd.

120 Randall Drive, Suite B

Waterloo, Ontario, Canada, N2V 1C6

www.pveng.com (519) 880-9808

You might also like

- Pv-Elite He 101 - Rev 7Document118 pagesPv-Elite He 101 - Rev 7Dwi Putra100% (1)

- Heat Load CalculationsDocument6 pagesHeat Load CalculationsHoney Tiwari0% (1)

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Separator CalcsDocument20 pagesSeparator CalcsHoney Tiwari100% (3)

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- API Sizing Calculations WebSiteDocument11 pagesAPI Sizing Calculations WebSiteJunaid MateenNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- External PressureDocument22 pagesExternal PressureAbhijeet SahuNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh PatelNo ratings yet

- Coulson& Richardson - Cap.10 Gas-Liquid Separation PDFDocument6 pagesCoulson& Richardson - Cap.10 Gas-Liquid Separation PDFHoney TiwariNo ratings yet

- Dish HeadsDocument1 pageDish HeadsDarshan PanchalNo ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- Bunded Steel Fuel Tanks - SmallDocument1 pageBunded Steel Fuel Tanks - SmallNAHASALI11No ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000100% (2)

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolMohammad Kamal HabbabaNo ratings yet

- Stack SpecDocument10 pagesStack SpecHoney TiwariNo ratings yet

- Mechanical Design of ColumnDocument12 pagesMechanical Design of ColumnfarahanisiliasNo ratings yet

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013No ratings yet

- Rules of Thumb PDFDocument2 pagesRules of Thumb PDFHoney Tiwari100% (1)

- 299 Elliptical Head Design Tool Ver E4 01Document1 page299 Elliptical Head Design Tool Ver E4 01Noman Abu-FarhaNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Pressure Vessel DesignDocument21 pagesPressure Vessel DesignAbdullah AlgwhriNo ratings yet

- Flat Ends With A Hub For Uniform Thickness ShellDocument5 pagesFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- Flat Ends Welded Directly To The ShellDocument9 pagesFlat Ends Welded Directly To The ShellEng-CalculationsNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- Compressor Capacity CalculationDocument4 pagesCompressor Capacity CalculationHoney Tiwari100% (1)

- Elliptical Head DesignDocument1 pageElliptical Head Designrodriguez.gaytanNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajNo ratings yet

- Air Cooled Condenser ACC PDFDocument3 pagesAir Cooled Condenser ACC PDFHoney TiwariNo ratings yet

- Design Check List Viii-1 Rev1Document2 pagesDesign Check List Viii-1 Rev1nirmalNo ratings yet

- Pipe Shell Design ToolDocument1 pagePipe Shell Design Toolep_alfiNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- B16 Case 12Document2 pagesB16 Case 12InaamNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- 7 PDFDocument26 pages7 PDFargaNo ratings yet

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNo ratings yet

- Tailing Lifting Lug Design 57 V 202 r2Document10 pagesTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarNo ratings yet

- Page No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressDocument93 pagesPage No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressSiva baalanNo ratings yet

- How To Use Code Case in PV EliteDocument2 pagesHow To Use Code Case in PV EliteMukeshChopraNo ratings yet

- Filter Vessel Calculations Per As Me Viii 1Document40 pagesFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2No ratings yet

- Working Principle of Shell and Tube Heat ExchangerDocument8 pagesWorking Principle of Shell and Tube Heat ExchangersanjayNo ratings yet

- Hemispherical HeadDocument5 pagesHemispherical HeadPuRuiSen HelathchemicalNo ratings yet

- Application For The Static Equipment Design EngineerDocument3 pagesApplication For The Static Equipment Design EngineerTejas ShahNo ratings yet

- Diseño de Cabeza ElípticaDocument1 pageDiseño de Cabeza ElípticapedroluischoqueNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01BAHADIRNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01mohamed faragNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolbai tap hoa vo coNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design Toolnaveen_86No ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- PPP Prospectus 8 12 19 1Document18 pagesPPP Prospectus 8 12 19 1Honey Tiwari100% (1)

- PRESS RELEASE Round3 RFQ PDFDocument2 pagesPRESS RELEASE Round3 RFQ PDFHoney TiwariNo ratings yet

- As On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresDocument2 pagesAs On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresHoney TiwariNo ratings yet

- Air Cooled HX Data SheetDocument1 pageAir Cooled HX Data SheetHoney TiwariNo ratings yet

- Fluor Daniel India Private LimitedDocument1 pageFluor Daniel India Private LimitedHoney Tiwari100% (1)

- Ventilation Calculation For Inverter RoomDocument1 pageVentilation Calculation For Inverter RoomHoney Tiwari100% (1)

- Seal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BDocument1 pageSeal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BHoney TiwariNo ratings yet

- CPCB DG Set Noise Emission NormsDocument6 pagesCPCB DG Set Noise Emission NormsRSNo ratings yet

- Emission Standards Diesel Engin Upto 800 PDFDocument4 pagesEmission Standards Diesel Engin Upto 800 PDFHoney TiwariNo ratings yet

- Pressure Drop AND HEADDocument2 pagesPressure Drop AND HEADHoney TiwariNo ratings yet

- Title of Proposal in Initial Capital Letters: Times New Roman (18 Point Boldface)Document8 pagesTitle of Proposal in Initial Capital Letters: Times New Roman (18 Point Boldface)AidaAkieNo ratings yet

- Elite Cranes - Hoists Catalogue PDFDocument2 pagesElite Cranes - Hoists Catalogue PDFHoney TiwariNo ratings yet

- Curve of MD Fire Main PumpDocument1 pageCurve of MD Fire Main PumpHoney TiwariNo ratings yet

- Selecting A Cooling Fan: Device CharacteristicsDocument4 pagesSelecting A Cooling Fan: Device CharacteristicsGary KerrNo ratings yet