Professional Documents

Culture Documents

VISI Modelling

VISI Modelling

Uploaded by

Val ArtCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VISI Modelling

VISI Modelling

Uploaded by

Val ArtCopyright:

Available Formats

cad

Easy to learn

intuitive interface

Extensive CAD

interfaces

: visi modelling

true hybrid modelling

Industry standard

Parasolid kernel

Combined wireframe, solid &

surface modelling

Solid, surface, wireframe &

mesh geometry deformation

Solid & surface

boolean operations

VISI Modelling is the foundation of all VISI products and

provides a robust and powerful solid and surface modelling

system based around the industry standard Parasolid

kernel. Combined with Veros surface technology, model

analysis and 2D design, VISI Modelling offers complete

flexibility to construct, edit, deform or repair the most

complex 3D data.

Extensive range of CAD interfaces

VISI can work directly with Parasolid,

IGES, CATIA v4 & v5, Pro-E, UG,

STEP, Solid Works, Solid Edge, ACIS,

DXF, DWG, STL and VDA files. The

extensive range of translators ensures

that users can work with data from

almost any supplier. The ability to skip

corrupt records during the import

process provides a platform from

where the most inconsistent data can

be managed. Very large files can be

handled with ease and companies

working with complex designs will

benefit from the simplicity with which

their customers CAD data can be

manipulated.

True hybrid modelling

VISI provides a dynamic structure

from where it is possible to work

with either solid, surface, wireframe

or a combination of all three without

any restrictions. Solid modelling has

become a fundamental cornerstone of

design but is often limited to prismatic

or basic geometry. Solid modelling

commands include boolean technology

such as unite, subtract, extrude,

revolve, sweep, cavity, intersect and

hollow. Surfacing technology however

provides a different set of tools and

techniques for more organic, free-form

geometry creation. Surface modelling

functions include ruled, lofted, drive,

sweep, n-sided patch, drape, tangent,

draft, revolved and piped surfaces.

These modelling commands combined

with advanced surface editing make

it easy to heal imported geometry or

construct the most complex 3D data.

Surface repair and editing

Small gaps between surfaces on

imported models can be automatically

healed preventing the time consuming

process of rebuilding very small surface

patches. Where surfaces are corrupt

or missing VISI will automatically create

the edge curve geometry making it

easy to rebuild new faces using the

comprehensive surfacing suite. To

ensure the new surfaces are within

tolerance, the new and the old surfaces

can be compared to check for min/

max distance and curvature deviation.

Closing a surface model to produce

a solid body eliminates construction

problems later in the design process

and immediately brings the benefits

of solid modelling to the user. The

ability to seamlessly switch between

solid and surface technology provides

unlimited freedom, ensuring the user

can work with difficult CAD data.

Surface repair

& analysis

Edge tolerance

manipulation

Powerful

blending

Mechanical curve

construction

Associative tool

detailing

Automatic B.O.M.

creation

cad

Keeping the model within the same product environment throughout the

entire project, from design to manufacture will guarantee data consistency

and significantly smooth the design process.

Geometry deformation

Solid, surface, wireframe and mesh

data can be easily adapted using

a number of mechanically driven

deformation tools including stretch,

twist, bend and target driven

deformation. These tools are ideal

for product modifications, applying

sheet metal over-bending and allowing

designers to try different design

variants without the need of additional

complex modelling operations.

Powerful blending

Constant radius, variable radius, disc,

hyperbolic and elliptical blends can

be constructed directly onto a solid

model. Blends can be propagated

along tangent edges to quickly sweep

across a component. For very complex

blending conditions or when working

with inconsistent data, blend faces

can be constructed as surfaces in

an untrimmed state providing greater

flexibility. Trimming is easy using either

wireframe curves, edge geometry or

existing faces.

Full range of 3D curves

Create a theoretical split line curve or

construct 3D curves including isoparametric, cross section, helix, ellipse,

spiral, hyperbolic and other mechanical

curves. Advanced curve editing

provides the ability to force tangency

or periodicity, move control points, join

Vero Software Limited

Hadley House

Bayshill Road

Cheltenham

Gloucestershire

GL50 3AW

United Kingdom

or extend curves. Combined curve

reprocessing allows multiple command

combinations to greatly simplify the

process of creating high quality curves.

Ease of use

Simple menu and icon commands

with context sensitive on line help

make it quick and easy to start using

VISI. Dynamic rotation, zoom and pan,

together with programmable function

keys and mouse buttons help speed

up the operation of the software.

Unlimited undo and redo operations

with user definable bookmarks enable

the designer to move backwards

and forwards throughout the design

process. Multi layer and multi origin

control with user definable colour

pallets and line styles makes it easy

to review, create and work with very

complex designs. All information is

stored in a single file providing easy

access and reducing the burden of

data management. Managing one

session of the software with all the

components available for editing at

the same time provides much greater

flexibility. Super fast rendering, texture

mapping and dynamic sectioning make

it easy to visualise CAD files and large

assemblies.

tel. +44 (0) 1189 22 66 99

email. info@verosoftware.com

web. www.visicadcam.com

Automatic creation of 2D views

A complete set of 2D detailed drawings

can be generated directly from the

3D model. This includes fully editable

2D and isometric section views,

automatic dimensioning and hole type

and position tables. Individual details

can be created from any component

in the assembly and displayed as

a mixture of 3D rendered and 2D

drawings. Any standard catalogue

component will have the correct detail

representation within a section view. A

change in the 3D model will result in a

modification to the 2D view along with

any fully associative dimensions. Parts

list table items and their respective

balloon references can be added to

the drawing using dedicated assembly

management tools.

Manufacturing modules

All the VISI applications run in one easy

to use environment with knowledge

based modules available for mould tool

and progressive die design. Once the

tool design is complete, machining of

plates can be completed using feature

recognition; drilled hole features and

apertures are automatically selected

with the correct drilling cycles and 2D

milling routines applied. For 3D forms,

VISI Machining will create the toolpaths

directly on the model incorporating

conventional, high speed and 5 axis

toolpaths.

You might also like

- VISI Progress 2016Document8 pagesVISI Progress 2016Gilson ChristoNo ratings yet

- Visi BlankDocument1 pageVisi Blankชัยรัตน์ ตันตืไพบูลย์วุฒิNo ratings yet

- Visi AnalysisDocument40 pagesVisi Analysiseestradabarbosa1447No ratings yet

- Intro To NXOpen For CAEDocument11 pagesIntro To NXOpen For CAEALDAIR ALVES BUENONo ratings yet

- Visi Cad ManualDocument4 pagesVisi Cad ManualserdarNo ratings yet

- Edgecam Getting StartedDocument51 pagesEdgecam Getting StartedPet UrNo ratings yet

- Chapter 10Document21 pagesChapter 10kent russel lauriquezNo ratings yet

- Pyramid of Balls Calculator - Tetrahedron and Square PyramidDocument2 pagesPyramid of Balls Calculator - Tetrahedron and Square PyramidAditya Gupta67% (3)

- Visi MouldDocument2 pagesVisi MouldSreedhar PugalendhiNo ratings yet

- VISI ProgressDocument4 pagesVISI Progressชัยรัตน์ ตันตืไพบูลย์วุฒิNo ratings yet

- Vero Software - Sheet Metal SolutionsDocument16 pagesVero Software - Sheet Metal Solutionsmarc5135No ratings yet

- Vero Software - Plastic Tooling SolutionsDocument16 pagesVero Software - Plastic Tooling Solutionsmarc5135100% (1)

- Siemens PLM NX CAD CAM Turning Foundation Fs Tcm1023 118147Document4 pagesSiemens PLM NX CAD CAM Turning Foundation Fs Tcm1023 118147rasgeetsinghNo ratings yet

- PostProcessor 17Document30 pagesPostProcessor 17alexespiNo ratings yet

- VISI Machining-2016-LOW PDFDocument8 pagesVISI Machining-2016-LOW PDFBenedict JoNo ratings yet

- Introducing简介: 3DquickpressDocument46 pagesIntroducing简介: 3DquickpressxevniNo ratings yet

- WNC Brochure WebDocument10 pagesWNC Brochure WebAkshay RaskarNo ratings yet

- Alphacam For Wood Datasheet-240212Document2 pagesAlphacam For Wood Datasheet-240212Cristina CardosoNo ratings yet

- 01 Exercise CrossmemberDocument54 pages01 Exercise CrossmemberSebastian OrdoñezNo ratings yet

- 3DQuickPress V5.0.1 Training Manual PDFDocument219 pages3DQuickPress V5.0.1 Training Manual PDFNguyen Tan TaiNo ratings yet

- 01 NX CAM High Productivity Part Manufacturing EngDocument20 pages01 NX CAM High Productivity Part Manufacturing Enguday kumarNo ratings yet

- SolidCAM 2013 Training Course-iMachining 2D+3DDocument146 pagesSolidCAM 2013 Training Course-iMachining 2D+3DvekacoricNo ratings yet

- SolidWorks Tutorial 5 For Prepatory and Advanced Vocational TrainingDocument33 pagesSolidWorks Tutorial 5 For Prepatory and Advanced Vocational TrainingagingagentNo ratings yet

- S.Balamurugan: Asst - Prof (SR.G) Departement of Mechanical Engineering SRM UniversityDocument38 pagesS.Balamurugan: Asst - Prof (SR.G) Departement of Mechanical Engineering SRM UniversityPradeepvenugopalNo ratings yet

- c01 nx8.5 EvalDocument20 pagesc01 nx8.5 EvalSeshi ReddyNo ratings yet

- Designing and Manufacturing Ruled Surface Blades: Peter Klein, CAM Software Director, Concepts NRECDocument6 pagesDesigning and Manufacturing Ruled Surface Blades: Peter Klein, CAM Software Director, Concepts NRECCésarNo ratings yet

- DMU Fitting Simulation PDFDocument9 pagesDMU Fitting Simulation PDFtest1No ratings yet

- Nigraphics: Student Guide September 2002 MT11015 - Unigraphics NXDocument226 pagesNigraphics: Student Guide September 2002 MT11015 - Unigraphics NXวิษณุ บุตรแววNo ratings yet

- 5XCAMDocument10 pages5XCAMTrường GiangNo ratings yet

- NX NF TipsUndTricksDocument12 pagesNX NF TipsUndTricksThilo Breitsprecher100% (1)

- C16 NX11 PDFDocument82 pagesC16 NX11 PDFVignesh WaranNo ratings yet

- Basic To Advanced CAD Using NX 12 Sample PDFDocument29 pagesBasic To Advanced CAD Using NX 12 Sample PDFYaseen JamilNo ratings yet

- Manual Unigraphics NX - 13 SketchingDocument108 pagesManual Unigraphics NX - 13 SketchingWagner AndradeNo ratings yet

- Merged RubberDocument16 pagesMerged RubberngejooNo ratings yet

- Instruction Design With Studio ShapeDocument124 pagesInstruction Design With Studio ShapenghiaNo ratings yet

- Siemens NX 6 Surface-Modeling (Tutorial 2 - Mouse)Document49 pagesSiemens NX 6 Surface-Modeling (Tutorial 2 - Mouse)goliatt1609No ratings yet

- PowerMill 2019 Feature Comparison MatrixDocument2 pagesPowerMill 2019 Feature Comparison MatrixBojan RadovanovicNo ratings yet

- 3d Modeling Fea CATIA v5Document25 pages3d Modeling Fea CATIA v5Jasime IhocuNo ratings yet

- From Solid To Shell: Extracting The Middle Skin GeometryDocument72 pagesFrom Solid To Shell: Extracting The Middle Skin GeometryHuy TrầnNo ratings yet

- Immerge Reference GuideDocument39 pagesImmerge Reference Guidecmm5477No ratings yet

- Basic: Cad-Based For Greater PowerDocument2 pagesBasic: Cad-Based For Greater PowerraduvascautiNo ratings yet

- Catia v5-6r2016 What S NewDocument72 pagesCatia v5-6r2016 What S NewD-No CteNo ratings yet

- Siemens NX CAM Turning Add On Fs Tcm1023 118093Document2 pagesSiemens NX CAM Turning Add On Fs Tcm1023 118093rasgeetsinghNo ratings yet

- Scan FABDocument2 pagesScan FABqlx4No ratings yet

- NX7 For Engineers and DesignersDocument1 pageNX7 For Engineers and DesignersDreamtech Press100% (1)

- Bro Hypermill 2019 2 en PDFDocument12 pagesBro Hypermill 2019 2 en PDFvw manNo ratings yet

- Mechanical Freeform Modeling: Student Guide October 2012 MT10035-S - NX 8.5Document369 pagesMechanical Freeform Modeling: Student Guide October 2012 MT10035-S - NX 8.5Isaque SilvaNo ratings yet

- Wireframe and Surface Design: CATIA TrainingDocument55 pagesWireframe and Surface Design: CATIA Trainingkishore99939No ratings yet

- NX Electrode Design AysDocument2 pagesNX Electrode Design Aysbadboys123No ratings yet

- Generative Design Essentials of Convergent Modeling Topology OptimizationDocument10 pagesGenerative Design Essentials of Convergent Modeling Topology Optimizationcad cadNo ratings yet

- Catia v5 Basic Training English Cax 2012Document104 pagesCatia v5 Basic Training English Cax 2012Cristian DogaruNo ratings yet

- HyperCAD S enDocument16 pagesHyperCAD S enPaul VeramendiNo ratings yet

- BRO Millturn HypermillDocument4 pagesBRO Millturn HypermillPaul VeramendiNo ratings yet

- Catia: Promotional Content External Links Neutral Point of ViewDocument12 pagesCatia: Promotional Content External Links Neutral Point of ViewIhsan1991 YusoffNo ratings yet

- Indian Institute of Technology, Delhi: Department of Mechanical EnggDocument0 pagesIndian Institute of Technology, Delhi: Department of Mechanical EnggGeorge KaridisNo ratings yet

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)From EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Rating: 4.5 out of 5 stars4.5/5 (5)

- Autodesk 3ds Max 2024 for Beginners: A Tutorial Approach, 24th EditionFrom EverandAutodesk 3ds Max 2024 for Beginners: A Tutorial Approach, 24th EditionNo ratings yet

- AutoCAD 2014 Essentials: Autodesk Official PressFrom EverandAutoCAD 2014 Essentials: Autodesk Official PressRating: 4 out of 5 stars4/5 (1)

- Sheet Metal Solutions OptimisedDocument16 pagesSheet Metal Solutions Optimisedrolo6945100% (1)

- 2.1 Plane and Spherical Trigo - Without SolutionDocument54 pages2.1 Plane and Spherical Trigo - Without SolutionNala A.No ratings yet

- CUHK MATH1510 Chapter - 12 NotesDocument39 pagesCUHK MATH1510 Chapter - 12 NotesJames LiNo ratings yet

- Topologia y CoreografiaDocument3 pagesTopologia y CoreografiaJavierNo ratings yet

- An Example of Cauchy: Donald Trump and Mike PenceDocument10 pagesAn Example of Cauchy: Donald Trump and Mike PencekjdsflkjdslkfjlksNo ratings yet

- Sheet 2Document2 pagesSheet 2Hassan MolhamNo ratings yet

- 10 Years Question Paper of CBSE Class 10 MATHS 2015Document7 pages10 Years Question Paper of CBSE Class 10 MATHS 2015Debdeep BhuniaNo ratings yet

- 1 William Wallace's Proof of The Butterfly Theorem PDFDocument3 pages1 William Wallace's Proof of The Butterfly Theorem PDFneiljain421No ratings yet

- 3 5-+Inscribed+Angles+PPTDocument11 pages3 5-+Inscribed+Angles+PPTDANIEL FRANCO GOMEZNo ratings yet

- Properties of 2D Shapes and 3D Objects: Terms Illustrations DefinitionsDocument11 pagesProperties of 2D Shapes and 3D Objects: Terms Illustrations DefinitionsChoukri SaoudiNo ratings yet

- Components or Resolved ForcesDocument16 pagesComponents or Resolved ForcesNagarajSitaramNo ratings yet

- Denavit Hartenberg Parameters: June 17, 2009Document4 pagesDenavit Hartenberg Parameters: June 17, 2009AshokNo ratings yet

- PM Shri KV Gachibowli Maths Class X 11 Sample Papers For PracticeDocument68 pagesPM Shri KV Gachibowli Maths Class X 11 Sample Papers For Practiceopom1050No ratings yet

- Wormhole TheoryDocument3 pagesWormhole TheoryNUR LIYANA ZAKARIANo ratings yet

- Locus and Constructions: Edexcel GCSEDocument14 pagesLocus and Constructions: Edexcel GCSEAli Ahmad AliNo ratings yet

- Engineering Graphics Question BankDocument8 pagesEngineering Graphics Question BankSriram JNo ratings yet

- Conic Sections WorksheetDocument2 pagesConic Sections WorksheetbhartNo ratings yet

- Gordon McCabe - Possible Physical UniversesDocument16 pagesGordon McCabe - Possible Physical UniversesDex30KMNo ratings yet

- Towards an ω-groupoid model of Type Theory: Based on joint work with Ondrej RypacekDocument33 pagesTowards an ω-groupoid model of Type Theory: Based on joint work with Ondrej RypacekΓιάννης ΣτεργίουNo ratings yet

- Plane Survey Notes 2021Document92 pagesPlane Survey Notes 2021Mike mikeNo ratings yet

- 17 Ex 5A Review of Tangent and NormalDocument6 pages17 Ex 5A Review of Tangent and NormalRalph Rezin MooreNo ratings yet

- CAT1000P: Program To Create A GEOPAK Part Program With The Help of CAD DataDocument39 pagesCAT1000P: Program To Create A GEOPAK Part Program With The Help of CAD DataYnomata RusamellNo ratings yet

- 小學五年級 Primary 5: 120 120 試題 Question PaperDocument8 pages小學五年級 Primary 5: 120 120 試題 Question PaperMartin Lewis KoaNo ratings yet

- 30 3 2 Maths StandardDocument11 pages30 3 2 Maths StandardThe MoviesNo ratings yet

- CH 13Document56 pagesCH 13bp9243798No ratings yet

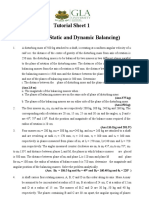

- Tutorial Sheet 1Document3 pagesTutorial Sheet 1Shashank SrivastavaNo ratings yet

- Cyclic GroupsDocument26 pagesCyclic GroupsMatthew NdetoNo ratings yet

- Platonic SolidDocument12 pagesPlatonic SoliddavparanNo ratings yet

- Ch8 Quadrilaterals Chapter NotesDocument5 pagesCh8 Quadrilaterals Chapter NotesMohanNayakNo ratings yet