Professional Documents

Culture Documents

Manual Bv20m

Uploaded by

ifmatosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Bv20m

Uploaded by

ifmatosCopyright:

Available Formats

BV20M

Light Duty

Engineering Lathe

User Manual

AXMINSTER

W H I T E

Axminster Devon EX13 5PH UK

01297 33656

(International Dialling +44 1297 33656)

w w w. a x m i n s t e r. c o . u k

BV20M

BV 2 0 M

Light Duty

Engineering Lathe

AXMINSTER

W H I T E

2002

Order No: BV20M

Index of Contents

Notes

Page No

Declaration of Conformity................................................................2

Whats in the Box...............................................................................................3

General Instruction for 230v BV20M Lathe..................................................................................................... 3

Assembly Instructions...................................................................................................................................... 4

Machine Specification/Definitions.........................................................................................5

Identification and Description of the parts of the BV20M Lathe.......................................................6

Machine Illustration and parts Description/Fig 1.........................................................................................7

Identification and Description of the parts of the BV20M Lathe.................................................................. 8

Machine Illustration and parts Description/Fig 2..................................................................................... 9

Identification and Description of the parts of the BV20M Lathe................................................................ 10

Machine Illustration and parts Description/Fig 3...........................................................................................11

Identification and Description of the parts of the BV20M Lathe...................................................................12

Machine Illustration and parts Description/Fig 4/Fig 5.................................................................................13

Identification and Description of the parts of the BV20M Lathe/Fig 6/Fig 7................................................14

Machine Illustration and parts Description/Fig 8/Fig 9/Fig 10/Fig 11........................................................ 15

BV20M Light Duty Lathe Maintenance.......................................................................................................16

BV20M Light Duty Lathe Maintenance (Oil lubrication points) Fig 12..........................................................17

Coupling Gear Table.......................................................................................................................................18

Notes....................................................... 19

Declaration of Conformity

The undersigned, CanTin authorised

by Bengbu City Domestic Machine Tool General Plant North

of Huai River Bridge, Bengbu City Anhui prov. 233020

P.R. China

declares that this product:

BV20B/BV20B-L

manufactured by Bengbu City Domestic Machine Tool

General Plant is in compliance with the following standards

or standardisation documents

EN 55014-1/1993A1/1997 EN 61000-3-2/1995A13/1997

EN 55014-2/1997 EN 61000-3-3/1995

in accordance with Council Directives

02

19

Coupling Gear Tables

Whats in the Box?

CHANGE GEAR

G1=DRIVER

G1

G3

G2

G4

G4=DRIVEN

Metric Thread Pitch

PITCH

0.25

0.3

0.35

0.4

0.45

0.5

0.6

0.7

0.75

0.8

1.0

1.25

1.5

1.75

2.0

2.5

3.0

18

G1

30

45

21

30

45

30

45

63

45

60

45

45

63

63

63

45

63

G2

50

35

80

65

50

80

60

45

65

55

80

80

42

60

65

40

40

G3 G4

80

100

40

50

60 80

40

50

60

40

50

30

24

60 40

24

21

100 30

100 35

Leadscrew

Gearbox Ratio

BV20M 0.666

Quantity

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

1 No.

(N.B. Please note that some of these gears are already fitted to your lathe)

Imperial Thread T.P.I.

T.P.I.

48

40

32

28

26

24

22

20

19

18

16

14

12

11

10

9

8

G1

50

60

60

60

50

50

50

40

60

50

50

50

50

50

60

40

60

G2

55

50

63

63

65

63

55

80

63

63

80

42

60

55

42

45

42

G3 G4

63

63

50 40

50 35

80 42

80 40

80 42

21

80 38

80 30

21

80 35

80 21

80 21

80 30

100 21

100 30

www.axminster.co.uk

Item

Model Number

Light Duty Engineering Lathe

BV20B-L

4 Diameter 3 jaw self centering chuck with internal and external jaws

Headstock Dead centre (1*No3 Morse Taper)

Tailstock Dead centre (1* No.2 Morse taper)

Single ended spanner 10mm

Single ended spanner 14mm

Double ended spanner 17-19mm

Allen Key 4mm

Allen Key 5mm

Allen Key 6mm

8mm T socket wrench for tool post

Set of Change Gears comprising:Gear 21,24,30,35,38,40,42,45,50,55,60,63,65,80,100 + 18T

18 Tooth Tumbler Reverse Gear

General Instructions for 230v BV20M Lathe

Good Working Practices/Safety

The following suggestions will enable you to observe good working practices, keep yourself and fellow

workers safe and maintain your tools and equipment in good working order.

WARNING!! KEEP TOOLS AND EQUIPMENT OUT OF THE REACH OF YOUNG CHILDREN

Mains Powered Tools

Primary Precautions

These machines are supplied with a moulded 13 Amp. Plug and 3 core power cable. Before using the

machine inspect the cable and the plug to make sure that neither are damaged. If any damage is visible

have the machine inspected/repaired by a suitably qualified person. If it is necessary to replace the plug, it

is preferable to use an unbreakable type that will resist damage. Only use a 13 Amp plug fuse at 13 Amp. If

extension leads are to be used, carry out the same safety checks on them, and ensure that they are

correctly rated to safely supply the current that is required for your machine. Ideally, your lathe should be

installed close to a correctly rated power supply, in a warm dry environment, well ventilated and illuminated

by bright clear natural light, with adequate access all around the machine, and sufficient adjacent storage

space for your tools, accessories and material.

CAN WE DREAM A LITTLE?

03

BV20M Light Duty Lathe Maintenance ( Oil Lubrication Points)

Assembly Instructions

F

Oil

Please read the Instruction Manual prior to using your new machine; as well as the installation procedure,

there are daily and periodic maintenance recommendations to help you keep your machine on top line and

prolong its life. Keep this Instruction Manual readily accessible for any others who may also be required to

use the machine.

The BV20M requires to be mounted on a rigid bed, this is to ensure stability of the machine and to

attenuate any vibration that is generated when the machine is running, (especially with eccentric work

mounted in the chuck).

The bed should be flat and set level in both planes, and at a height that enables comfortable operation of

the machine. It is not necessary to anchor the bed through to the floor, but it must be stable enough to

remain immovable during any normal forceful operations (especially tightening) carried out whilst operating

your lathe.

If you are preparing your own bed for the machine, it should be at least 870mm long by 320mm wide; you

will need to drill two 14mm holes to allow for bolt fixing. Set out the centres of the holes as follows:-(sizes

are minimum excepting distance between centres).

From the left side of the bed (Headstock side) 170mm,150mm from the front edge of the bed.

Distance between centres 650mm; second hole again 150mm from front edge.

Bolt the lathe to the bed using M12 nuts, bolts and washers.

Once the lathe is mounted, remove the headstock cover plate and fill the headstock with SAE20 oil to a level

slightly above the sight glass. Do Not Overfill. The gearbox does not have oil sealed bearings fitted

throughout, and if you overfill oil will leak out.

The machine was fully greased and oiled before leaving the factory, but it would certainly be prudent for you

to check and re-oil all the lubrication points and lube all the beds/slides etc., before start up. Refer to the

lubrication chart later in this manual.

Check the tension of the drive belt. If the belt is too slack, tighten by adjusting the motor mounting plate,

ensuring that you maintain co-linearity of the two pulleys.

Although the machine has been thoroughly tested at the factory, it is recommended that you carry out a

running in procedure to check for correct gear meshing, vibration, etc. Ensure the lathe is running

forward (i.e. the spindle is turning towards you). Select the lowest spindle speed i.e. 170 rpm, and run for

approximately 20 minutes, check for vibration, excessive noise, etc. After the 20min period, increase the

speed one step at a time and run for approximately 5 minutes in each gear. Stop the machine before

changing gear. If everything appears satisfactory, reduce the speed to one of the lower registers; manually

drive the saddle back towards the tailstock, check the saddle feed engages and disengages positively;

engage the saddle feed and drive the saddle towards the headstock, checking for smoothness of

movement, etc. Engage and disengage the saddle several times during its travel and check that its travel

pick up is smooth. If everything appears to be satisfactory, move the saddle to a position about mid travel,

MAKE SURE THE SPINDLE IS STOPPED, switch the machine into reverse and check the machine functions

equally well whilst running in reverse.

Fig 12

Having unpacked your machine and its accessories, please check the contents against the equipment list

Whats in the box, if there are any discrepancies, please contact Axminster Power Tool Centre using the

procedures laid down in the catalogue. Please dispose of the packaging responsibly, much of the material is

bio-degradable. The machine and its accessories will arrive coated with heavy corrosion preventative

grease. This will need to be cleaned from the machine, its components and accessories prior to it being set

up and commissioned. Use coal oil, paraffin or a proprietary degreaser to remove the barrier grease. Be

warned, it will stain if you splash it on clothing etc., wear overalls, coverall et al., rubber gloves are also a

good idea, as is eye protection if your cleaning process tends to be a little bit enthusiastic. After cleaning,

lightly coat the machine with a thin layer of light machine oil. N.B If you used paraffin/kerosene make sure

you apply this thin film sooner rather than later.

04

17

BV20M Light Duty Lathe Maintenance

Your BV20M light bench lathe is a precision tool. In order to maintain this precision and prolong

its useful life, it is advised that you follow the recommended daily and periodic maintenance

tables printed below.

Installation/commissioning Oil Changing

1st oil change. Drain the gear box and renew the oil after 35 hrs.running.

2nd oil change. Drain the gearbox and renew after 110 hrs. running.

Thereafter. Drain the gearbox and renew oil after every 350hrs. running.

Daily and Periodic Maintenance

Daily Pre-use

1. Using an oil can with a narrow nozzle, oil all the oil points on the machine, incl.

A) Saddle (4), B) tailstock (2), C) traverse slide (1), D) compound slide (2), E) leadscrew gearbox

(2), and F) leadscrew end bearing (1).

2. Move the traverse and compound slides to give access to their drive shaft threads and

lightly coat with oil, work the oil up the threads to lubricate the thread followers.

3. Spray-oil the slides and the lathe bed, exercise the saddle and the slides to spread the oil

to all surfaces, both hidden and visible.

4. Spray up under the rack cover to lubricate the rack. (G)

5. Apply oil to the change gears and their axle mountings. (H)

Daily after-use

1. Clean all swarf and chips away from the machine bed, slide surfaces, and the tool post.

2. Exercise the slides and ensure no swarf etc., is lodged in the drive shaft tunnels.

3. If you have been using suds make sure the machine is throughly dried off. Clear the suds

tray of all swarf and chips, especially around the drain.

4. Check the tool, ensure it is usable the next time, if not re-sharpen or replace the tool tip.

5. Lightly oil spray all the machine beds and surfaces, and the tailstock barrel.

6. Clean and lightly oil any tools you may have been using (centres, drill chucks, spanners

chuck keys etc, and put them away.

7. Switch off the power supply. Disconnect the plug.

8. Cover the machine over with a dust cloth.

Weekly

Machine Specifications

Axminster No:

Motor

Maximum swing over the bed

Maximum distance between centres

Spindle Speeds Forward and Backward

Reversing Method

Clear Bore in Headstock Mandrel

Possible metric Thread pitches

Possible imperial tpis

Number of possible feed speeds

Maximum longitudinal travel of compound rest

Maximum tranverse travel of compound rest

Maximum turning angle of compound rest

Maximum extension of tailstock barrel

Leadscrew Gearbox ratio

Weight

Overall size (lathe only)

BV20M

230V a.c. 375W (1/2 H.P.)

110mm

350mm

170, 312, 450, 736, 1354, 1950

Electrical

20mm

17

17

5

70mm

115mm

+ or - 45 degrees

50mm

6:1

140 Kgs

Width 650 x Length 915 x Height 560mm

Definitions

Main Axis This is the axis established through the spindle of the headstock. It is horizontal

to and parallel with the lathe bed along its length.

Work Axis This is the axis established by the work piece, it is horizontal to but not necessarily

parallel with, the lathe bed, along its length.

Traverse This is the axis described by the traverse slide when it is being moved independently

Axis

of the saddle. It is perpendicular to the main axis in the horizontal plane.

Compound

Axis.

This is the axis described by the compound slide when it is being operated

independently of the traverse slide and the saddle.

a) Check the belt tension.

b) Check the oil level in the gearbox.

c) Check the tautness of the slides.

d) Check the level of the suds reservoir. (if you are using suds).

Accessories

May we recommend the following products for use with your BV20M

Gearbox Oil - The recommended oil we suggest is 15/40w non synthetic (such as GTX White).

Grease

- Rocol Saphire 2 (Code: ROC 52041).

Lubricant

- Rocol Slideway lubricant spray (Code: ROC 52041).

Cutting Fluid - Rocol Multisol cutting fluid Code: (ROC 3521L).

There are numerous accessories listed for the machine listed in the Axminster catalogue

in section 1

16

05

Identification and Description of the parts of the BV20M Lathe

Machine Illustration and parts Description

Fig 8

Please take some time to identify the various parts of your machine so that you are familiar with

the terminology we will use to enable you to set up and operate your Lathe safely and correctly.

Headstock

The engine block of the lathe, supports the motor, the spindle, contains the

gearbox for the spindle speed selection, mounts the change gears and the

driven end of the lead screw.

Rack (unseen)

The rack is fixed on the underside of the front rail of the lathe bed, it is

permanently engaged with the saddle control wheel pinion.

Tailstock

Large casting that mounts the tailstock barrel, it is moved on and clamped to

the lathe bed to allow the tailstock barrel to be moved to the proximity of the

workpiece. It can be offset from the central axis of the lathe to allow for taper

turning between centres.

Leadscrew/Rack A formed metal plate that covers and protects the leadscrew and the

guard

rack.

Tool Post

A four sided tool post. Each tool position has 3 securing bolts to clamp the

tool in place. The tool post is located on a central pivot mounted on the top of

the compound slide. It has a four position click locator, that locates it to its

major axis, but it can be held at any angle by the tool post locking clamp.

Leadscrew

(unseen)

The leadscrew, through the various gear trains available, rotates at a selected

ratio to the spindle to enable the various screw threads to be cut, or to

provide a feed rate for the saddle when auto feed is selected.

Chuck

safety cover

A clear acetate cover mounted on a pivot bar on the rear top front face of the

headstock, It can be tipped out of the way to access the chuck when it is

stationary, and repositioned over the chuck during operation.

Tool post cover

Fitted to compound slide it is there to provide protection from flying swarf

whilst turning between centres.

Headstock

cover plate

Fig 9

Typ. 4 no. cap head bolts

Oil sight glass

Oil drain plug

Door for change

gear compartment

18T reversing

tumbler gear

Change gears

Fig 10

Fig 11

Door microswitch

06

15

Identification and Description of the parts of the BV20M Lathe

Door for

change gear

compartment

Protective cover, enclosing the motor pulley, the drive pulley and drive belt

and the change gears. The change gear cover operates an interlock

microswitch that will prevent the motor being started if the cover is not

closed.

Oil drain plug

The oil drain plug is a hex head bolt with a sealing washer located low down

at the rear of the headstock gear box,- when refitting the oil drain plug ensure

that the mating faces of the headstock and the sealing washer are clean.

Headstock

cover plate

The headstock cover plate is a flat metal plate secured to the top of the

headstock gearbox by four cap head bolts. Unscrew the bolts and remove the

cover to inspect the gearbox or replace or top up the oil. There is no gasket

beneath the cover plate, so ensure the mating surfaces are clean before

replacing the cover.

18T reversing

The 18T reverse tumbler gear, when fitted, enables the rotation of the

leadscrew to be reversed. (For left hand threads (as Fig 6) or in the case of an

asymmetric change gear selection to allow the leadscrew to maintain its

correct rotation (as Fig 7).

Fig 11 shows the reverse tumbler gear fitted in the gear train.

Oil sight glass

The oil level sight glass enables you to check the amount of oil you have

in your lathe.

Machine Illustration and parts Description

Fig 1

Chuck

safety

cover

Chuck

Headstock

Tool post cover

Tailstock

18T reversing gear

(left hand thread)

Fig 6

Fig 7

Rack

(unseen)

Leadscrew/rack

guard

Leadscrew

(unseen)

Cabinet

AXMINSTER

W H I T E

14

07

Identification and Description of the parts of the BV20M Lathe

Machine Illustration and parts Description

(For clarity the guard has been removed form the machine)

Motor

Single phase 230V 50Hz motor. 1H.P.

Chuck

mounting

flange

The chuck mounting flange is integral with the spindle and mounts all the

material carriers, (chucks, faceplate etc.), it is bored with a No.3 morse taper

to accept the headstock centre. The boring is then carried through the

complete length of the spindle (20mm clear) to allow long lengths of round

bar to be machined. Because of the limited space between the headstock and

the chuck mounting flange a shortened allan key has been supplied to allow

tightening of the chuck securing bolts.

Tailstock barrel

lock

Small swing lever that locks the barrel in place once it has been moved into

the required position.

Tailstock drive

handle

This engineers wheel and handle controls the movement of the tailstock

barrel, backwards and forwards. It has a graduated ring (thimble) mounted on

the neck of the handle so that the amount of movement can be monitored.

Tailstock barrel

Steel barrel bored with No. 2 morse taper to mount various tooling, centres,

drill chuck, reamers etc. The barrel has a travel of 50mm, this travel allows

the mounted tool or centre to be brought into controlled contact with the

workpiece.

Mounting feet

Shaped in the casting of the lathe bed, the two feet have 14mm slots cut into

them to enable the fitting of two 12mm bolts to effect the rigid fastening of the

lathe onto its stand? a work bench?

Lathe bed

Vee rail and flat rail bed, precision machined to provide an accurate mounting

for the headstock and a precision guide for the movement of the saddle. It

also mounts the tailstock in an accurate relationship to the main axis of the

lathe.

Saddle

Main casting that is precision machined to marry with the lathe bed. It moves

parallel to the main axis. It mounts the traverse slide. It also mounts its control

handle and the autofeed or thread cutting engaging lever.

Tailstock

barrel

Fig 4

Tailstock barrel lock

Tailstock drive handle

Tailstock clamp

Tailstock

offset screws

Fig 5

Off/on

switches

Chuck safety

cover

Gear change

levers

(B)

(A)

Reversing switch

(under cover)

Spindle speed

change chart

08

Feed speed and thread

cutting gear change

chart

13

Machine Illustration and parts Description

Identification and Description of the parts of the BV20M Lathe

Tailstock barrel lock

Chuck

mounting

flange

Tailstock clamp

A nut and bolt fitted through the tailstock and the clamping dog.

Tightening the nut pulls the clamping dog up against the underside of the bed

and clamps the tailstock in position. Conversely, loosening the nut releases

the bolt and the clamp allowing the tailstock to slide freely on the bed.

Tailstock

offset screws

The tailstock is keyed into a large support base, and is able to be driven

backwards and forward across this base about the central axis of the lathe.

There are two opposing screws set in the base that control the movement of

tailstock , the screws have to be adjusted sequentially, i.e. loosen, tighten,

loosen, tighten etc., to move the tailstock.

Gear change

levers

Two levers marked A and B which, in their various settings select the

different spindle speeds of the lathe. Refer to the Speedchange chart to select

the required speed.

Chuck

safety cover

A clear acetate cover mounted on a pivot bar on the rear top front face of the

headstock, It can be tipped out of the way to access the chuck when it is

stationary, and repositioned over the chuck during operation.

On and Off

switches

Green push button switch marked I to start the motor, Red push button

switch marked O to switch the motor off.

Feed speed

and thread

cutting gear

change chart

This chart indicates the necessary gears and their positions to enable the

wide range of metric, imperial, module and diametral threads to be cut

and the different feed rates to be achieved. The feed speed is quoted

as a linear distance along the Main Axis per revolution of the leadscrew.

Reversing

Switch

Rocker switch set under a protective cover, (to prevent inadvertent

operation), changing the position of the switch will reverse the direction

of the motor. MAKE SURE THE SPINDLE IS STOPPED BEFORE

OPERATING THIS SWITCH.

Spindle Speed

change chart

This chart indicates the position of the levers to select the various spindle

speeds.

Chuck

Fig 2

Tailstock barrel

Tailstock

drive

handle

Compound

slide

Lathe bed

Cabinet

Mounting feet

Traverse slide

Motor

Saddle

AXMINSTER

W H I T E

12

09

Identification and Description of the parts of the BV20M Lathe

Saddle control

Autofeed lever

Machine Illustration and parts Description

This engineers wheel/control handle is mounted on a shaft that goes through

the apron of the saddle; there is a pinion mounted on the end of the shaft that

is permanently engaged with the fixed rack on the lathe bed. This enables the

saddle to be moved back and forth along the lathe bed. N.B. Remember

this handle is PERMANENTLY engaged to the rack and during thread cutting

or autofeeding will turn with the movement of the saddle.

This lever engages the saddle to the leadscrew to enable the autofeed or the

thread cutting function of the lathe. Move the lever down to engage the feed.

As there is no synchronising dial indicator fitted for thread cutting - to ensure

correct pick-up during thread cutting, leave the auto feed lever engaged.

Disengage the tool clear of the work. Stop the spindle, electrically reverse the

drive system and drive tool back clear of the work piece - stop the spindle:

switch back to normal - and set the new cutting depth and restart the

machine; repeat this procedure until the thread is cut.

Traverse Slide

Mounted on a Vee machined slide on the saddle. The accuracy of the fit of

the Vee slide is maintained by the gybe strips set in the offside of the

traverse slide.

Traverse slide

control

handle

A U handle, mounted on a shaft that is anchored into a housing cast at the

front of the traverse slide, the shaft is threaded and is engaged in a fixed

thread follower on the slide, enabling the traverse slide to be driven back

and forth across the saddle perpendicular to the main axis. There is a

graduated ring (thimble) on the neck of the handle to allow the movement of

the slide to be measured.

Compound

slide

Fig 3

Compound

slide control

Tool post locking handle

Compound slide The compound slide is mounted on a machined vee slide with a circular

base, that is then mounted and located on the top of the traverse slide by a

central pivot. Through the circular block, near the edge, are two diametrically

opposed nuts and bolts; the bolt shanks extend through two concentric slots

machined in the traverse slide that allow the compound slide mount to turn

about the central pivot. The nuts on the ends of the bolts (in machined

recesses under the front and back edge of the slide) also lock the compound

slide along its selected axis (+ or 45 degrees from the main axis).

The compound slide fits over this vee slide mount; the accuracy of the fit is

maintained by the gybe strips set in the front edge of the compound slide.

There is a scale set on the front of the circular base to enable the angle set

on the compound slide to be measured.

Compound slide A U handle, mounted on a shaft that is anchored into a housing cast at the

control handle

Control Handle end of the slide; the shaft is threaded and is engaged in a

fixed thread follower on the circular mounting plate, enabling the slide to be

driven backward and forward along its axis. There is a graduated ring

(thimble) on the neck of the handle to allow the movement of the slide to be

measured.

Autofeed lever

Traverse slide

Saddle Control

Tool post

locking

handle

10

The central locating pivot for the tool post has a threaded end which passes

through the tool post, and is fitted with a threaded boss lever handle.

Tightening down on the handle clamps the tool post firmly in position.

Traverse slide

control handle

11

You might also like

- Bridgeport J-Head Series I RebuildDocument69 pagesBridgeport J-Head Series I RebuildBasil Hwang100% (1)

- Lathes and Lathe Machining OperationsDocument18 pagesLathes and Lathe Machining Operationssarasrisam100% (1)

- Jdsw51a Usb Mach3 (Blue) - 5aixsDocument36 pagesJdsw51a Usb Mach3 (Blue) - 5aixsabelmil123No ratings yet

- Unit-2 - 03 Aug 2015Document98 pagesUnit-2 - 03 Aug 2015Prasad AurangabadkarNo ratings yet

- PowerTIG 250EX 2016Document32 pagesPowerTIG 250EX 2016Bob john100% (1)

- Mini Mill Users GuideDocument28 pagesMini Mill Users Guidechriswood_gmailNo ratings yet

- NC Mill SFTWR ManualDocument100 pagesNC Mill SFTWR ManualPham LongNo ratings yet

- Gs 3 MDocument316 pagesGs 3 MNazielNo ratings yet

- Planetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignDocument44 pagesPlanetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignAmal TharakaNo ratings yet

- Manual TornoDocument60 pagesManual Tornojulie2420140% (1)

- Capstan & Turret LatheDocument27 pagesCapstan & Turret LatheMuraliNo ratings yet

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- Bearcat 71014Document21 pagesBearcat 71014forwirelessNo ratings yet

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- AVHC Quick StartDocument58 pagesAVHC Quick StartAndres Jose Amato TorresNo ratings yet

- Machine Shop ManualDocument6 pagesMachine Shop ManualManoj KumarNo ratings yet

- smhs 7727 Special Instruction-проверка установки гильз 3400Document5 pagessmhs 7727 Special Instruction-проверка установки гильз 3400Евгений АбрамовNo ratings yet

- Biax 7EL Assembly - RepairDocument6 pagesBiax 7EL Assembly - RepairKarsten BergNo ratings yet

- Elliott Tool English CatalogDocument220 pagesElliott Tool English Catalogmaruti nandgadkarNo ratings yet

- Shaper MachineDocument81 pagesShaper Machinesam clastineNo ratings yet

- Fordson Major PartsDocument2 pagesFordson Major Partssbj1946No ratings yet

- Bridgeport Rebuid 1Document15 pagesBridgeport Rebuid 1wolviak100% (1)

- Delta Model 31-080 1" Belt Sander ManualDocument12 pagesDelta Model 31-080 1" Belt Sander ManualRobert Steven Ciaccio0% (1)

- HMT Mandrel Bending 101Document80 pagesHMT Mandrel Bending 101zaiofracassadoNo ratings yet

- Rebuild ManualDocument55 pagesRebuild Manualaccujack0% (1)

- Fresadora #12Document15 pagesFresadora #12jmtortu100% (1)

- Cold Setting The Valves On A 1953 Dodge M37 Power WagonDocument2 pagesCold Setting The Valves On A 1953 Dodge M37 Power Wagoncriag100% (1)

- 1962-Burgmaster - Bench Model Turret Drilling and Tapping MachineDocument17 pages1962-Burgmaster - Bench Model Turret Drilling and Tapping Machinesalulai100% (3)

- Th23 Th26 Th34 Kawasaki Service Repair ManualDocument41 pagesTh23 Th26 Th34 Kawasaki Service Repair ManualRanieri BenčićNo ratings yet

- Ford Old TimersDocument25 pagesFord Old TimersJan-Erik Kaald HusbyNo ratings yet

- Lathes and Lathe Machining OperationsDocument11 pagesLathes and Lathe Machining OperationsJunayed HasanNo ratings yet

- Bridgeport Series I ManualDocument134 pagesBridgeport Series I ManualMANUEL VICTOR100% (1)

- Linkoln Ranger 300 DLXDocument56 pagesLinkoln Ranger 300 DLXkarimNo ratings yet

- Manual 000004336Document19 pagesManual 000004336ridho_kresnaNo ratings yet

- Longworth Chuck PDFDocument6 pagesLongworth Chuck PDFBen Gerez100% (2)

- CE3458 Parts ManualDocument84 pagesCE3458 Parts ManualMrbigg10No ratings yet

- SouthBend Lathe ManualDocument144 pagesSouthBend Lathe ManualJoel TurnerNo ratings yet

- LeBlond's Dual Drive Lathe SmallDocument28 pagesLeBlond's Dual Drive Lathe Small4U6ogj8b9snylkslkn3nNo ratings yet

- Special Electric Motors: High-Speed Machining MotorsDocument68 pagesSpecial Electric Motors: High-Speed Machining MotorsAbed samadsureyft7vewyrNo ratings yet

- Metal LatheDocument25 pagesMetal Lathebogesz68No ratings yet

- CDS PB 840, 844D #6800253Document324 pagesCDS PB 840, 844D #6800253Hai Van100% (1)

- 2016 Machine Shop Manual PDFDocument95 pages2016 Machine Shop Manual PDFShravan Shetty100% (1)

- Lathe Schaublin 102n 9982Document1 pageLathe Schaublin 102n 9982FranciscoNo ratings yet

- 12 Machinery Ebook PDFDocument135 pages12 Machinery Ebook PDFTeuku Andy Nur IsaNo ratings yet

- Shaper Used As Surface GrinderDocument1 pageShaper Used As Surface Grinderradio-chaserNo ratings yet

- MI-1220 XL Manual 2008Document115 pagesMI-1220 XL Manual 2008James BanksNo ratings yet

- Conquest Lathe ManualDocument47 pagesConquest Lathe Manualkennkki67% (3)

- Manual PDFDocument100 pagesManual PDFAnonymous hPxR0SNo ratings yet

- Accessories and Attachments of Lathe MachineDocument6 pagesAccessories and Attachments of Lathe MachinejadeNo ratings yet

- Cigweldaeb Transtig 220acdc, 300acdc (S) 0-5292 - AbDocument104 pagesCigweldaeb Transtig 220acdc, 300acdc (S) 0-5292 - AbRobert Case0% (1)

- Suzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveDocument1 pageSuzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveAymzNo ratings yet

- Modification and Development of Work Holding Device - Steady-RestDocument6 pagesModification and Development of Work Holding Device - Steady-RestInternational Journal of Innovative Science and Research Technology100% (1)

- Online HDM690Document20 pagesOnline HDM690Kyle SchwulstNo ratings yet

- BT20 Setting ToolDocument12 pagesBT20 Setting Toolanthony silvaNo ratings yet

- VW 8103 12 InstructionsDocument17 pagesVW 8103 12 InstructionsLilibeth Martinez PenaNo ratings yet

- Powermatic 58480438-Millrite-Mvn-Manual PDFDocument54 pagesPowermatic 58480438-Millrite-Mvn-Manual PDFJason Willis75% (4)

- Workshop Manual Winget 200tm MixersDocument149 pagesWorkshop Manual Winget 200tm MixersSRG BTPNo ratings yet

- Automatic Drawbar ManualDocument24 pagesAutomatic Drawbar Manualjason mossNo ratings yet

- Lambda - Designing LED Optical Components DatasheetDocument2 pagesLambda - Designing LED Optical Components DatasheetifmatosNo ratings yet

- Ac20 30BDocument13 pagesAc20 30BifmatosNo ratings yet

- Hi VAWT Brief (New Version)Document80 pagesHi VAWT Brief (New Version)ifmatosNo ratings yet

- c503b Ras Ran Aas Aan Rbs RBN Abs Abn Rcs RCN Acs Acn 1079Document13 pagesc503b Ras Ran Aas Aan Rbs RBN Abs Abn Rcs RCN Acs Acn 1079ifmatosNo ratings yet

- 920 4304A Manual 4 23 15Document38 pages920 4304A Manual 4 23 15ifmatosNo ratings yet

- Trabajo 2Document18 pagesTrabajo 2ing_pemNo ratings yet

- Light Energy: Solar Cell Based On Artificial PhotosynthesisDocument21 pagesLight Energy: Solar Cell Based On Artificial PhotosynthesisifmatosNo ratings yet

- LED DriversDocument16 pagesLED DriversifmatosNo ratings yet

- Light Energy: Solar Cell Based On Artificial PhotosynthesisDocument21 pagesLight Energy: Solar Cell Based On Artificial PhotosynthesisifmatosNo ratings yet

- Bta12 600BW3 DDocument6 pagesBta12 600BW3 DWilliam JPNo ratings yet

- ACS712 DatasheetDocument15 pagesACS712 DatasheetwirawansatriaNo ratings yet

- OPTO817Document6 pagesOPTO817ifmatosNo ratings yet

- BC546 / BC547 / BC548 / BC549 / BC550 NPN Epitaxial Silicon TransistorDocument6 pagesBC546 / BC547 / BC548 / BC549 / BC550 NPN Epitaxial Silicon TransistorIsrael MendozaNo ratings yet

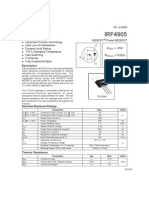

- Irf 4905Document9 pagesIrf 4905plamenvp21No ratings yet

- BC 635Document4 pagesBC 635Floricica Victor VasileNo ratings yet

- CCS ManualDocument257 pagesCCS ManualJuan Fco Rocha ParedesNo ratings yet

- Media Movel Teclado Pelo A-DDocument14 pagesMedia Movel Teclado Pelo A-DifmatosNo ratings yet

- Solid State Circuit Breaker PDFDocument7 pagesSolid State Circuit Breaker PDFifmatosNo ratings yet

- Aoc Service Manual-Hp l1740 Nt68663mefg TPV Power A02 1947Document60 pagesAoc Service Manual-Hp l1740 Nt68663mefg TPV Power A02 1947ifmatosNo ratings yet

- Walker 99Document6 pagesWalker 99ifmatosNo ratings yet

- Arquitetura 12F509Document21 pagesArquitetura 12F509ifmatosNo ratings yet