Professional Documents

Culture Documents

Technical Bid Volume 1 of 2

Uploaded by

doc4print0 ratings0% found this document useful (0 votes)

112 views285 pagesTechnical Bid Volume 1 of 2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTechnical Bid Volume 1 of 2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

112 views285 pagesTechnical Bid Volume 1 of 2

Uploaded by

doc4printTechnical Bid Volume 1 of 2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 285

[ TENDER DOCUMENT FOR

: CIVIL & STRUCTURAL

WORKS

| TENDER DOCUMENT

FOR

APARTMENTS - PHASE 2C

(BLOCK C1- C9)

PACKAGE 12B - CIVIL & STRUCTURAL WORKS

TO

PROPOSED “AQUALILY” RESIDENTIAL DEVELOPMENT

AT

MAHINDRA WORLD CITY, CHENNAI

FOR

M/S MAHINDRA RESIDENTIAL DEVELOPERS LTD.

VOLUME 1 OF 2

NOVEMBER 2012

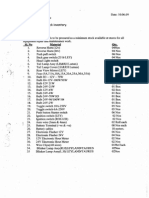

CONTENTS

CONTENTS,

DOCUMENT SCOPE PAGE No.

CONTENTS

VOLUME 1 OF 2

A ‘THE CONSULTANTS:

Employer and Consultants AM~AIM

B THE TENDER

1 Conditions of Tender BAM -BItI4

.2 Letter of Tender Brit — 8/212

c ‘THE CONTRACT

1 General can

2 Appendix to Tender Clan - ci2ie

.3 Particular Conditions crn = crsI9

D ‘SPECIFICATIONS

“1 GENERAL Dat - DINI2

‘2 TECHNICAL SPECIFICATIONS -CIVIL Page 1-84

3 TECHNICAL SPECIFICATION-ARCHITECTURAL Page 1-142

E THE PREAMBLES EAN ~ENN9

VOLUME 2 OF 2

F ‘THE BILLS OF QUANTITIES

-1 PRELIMINARIES & GENERAL FAM — FI1I26

-2 BASIC DETAILS Flan — Fi2i3

“3 SCHEDULE OF WORKS

6 ‘THE FINAL SUMMARY

Basic Tender cn

H ‘THE APPENDICES:

Appendix 1 ~ List of Drawings Ht

Appendix 2 - Performance Security - Demand

Guarantee Specimen

‘Appendix 3— Advance Payment Guarantee Specimen

Appendix 4 — Warranty Details

Appendix 6 ~ Mile stone Targets

Appendix 6 ~ List of Employer supplied Items

‘Appendix 7- Cement Coefficient

‘Appendix 8 Soil Investigation Report

‘Appendix 9~ UPVC Window ~Co-ordination Scope

DOCUMENT A

‘THE CONSULTANTS

DOCUMENT A

EMPLOYER & CONSULTANTS

EMPLOYER

PROJECT MANAGER

ARCHITECT

‘STRUCTURAL CONSULATANT

M& E ENGINEER

QUANTITY SURVEYOR

MAHINDRA RESIDENTIAL DEVELOPERS LTD

Canopy Unit I!

Mahingra World City,

Natham PO ( Sub )

Chengalpet

Chennai

CB RICHARD ELLIS SOUTH ASIA PVT LTD.

2C 82D GEE GEE Emerald

151 Vilage Road

Nungambakkam

Chennai ~ 600 034

Tel No 2621 4599

EDIFICE CONSULTANTS LTD

No 1 Saravanan Street

‘South Boag Road

T Nagar

Chennai - 600 017

Tel: 044-2434 4357 Fax: 2431 1067

VASTECH CONSULTANTS PVT LTD.,

Aimonte Building, Second Floor,

Kharadi, Pune ~ 411014.

Tel : 020-65103140

ENTASK CONSULTANCY SERVICES Pvt LTD

‘No 3/1 Chetana House 10” Cross

Kuppusamy Naidu Street

Vasanth Nagar

Bangalore ~ 560 052

‘KPK QUANTITY SURVEYORS (INDIA) PVT LTD

11. A 8B, Ega Trade Centre,

809, Poonamallee High Road,

Kilpauk,

Chennai ~ 600 010

Tet: 26480975 Fax: 26480952

DOCUMENT B

‘THE TENDER

DOCUMENT B

‘THE TENDER

10

20

3.0

40

Conditions of Tender

GENERAL

This Tender shall be submitted in compliance with the requirements of the following conditions and ail

requirements as specified in the Tender Documents.

The pricing of the tender including ali rates therein shall be in Indian Rupees.

‘The Tenderer shall bear the cost of preparing and complying with the requirements of the Tender and

‘such costs shall not be reimbursed by the Employer. The information contained in these Conditions of

‘Tender is for the instruction and guidance of tenderers.

SCOPE OF WORK

The Scope of works comprises Avartments - Phase 26 (Block C1 to CQ) - Package 128 — Civil &

‘Structural Works as shown described, alluded or inferred from the tender documents.

All ancillary and other works, whether separately or specifically mentioned or described in the above

documents, which are either indispensably necessary to carry out and bring to completion of the works

or which may contingently become necessary to overcome difficulties before completion and such shall

be deemed to be included in the offer.

‘The Tenderer shall visit and inspect the site and acquaint themselves with all the existing conditions in

land around the site during the tender period. Arrangements can be made through the Employer's

Representative.

The Tenderer shall liaise with all government authorities whom are having jurisdiction on the project.

‘The Contractor shall also rectify all defects for which he is liable under the conditions of contract during

the Defect Notification Period and without prejudice to his liabilities arising at law and arising after the

Defect Notification Period.

The general description of the works involved in this contract is provided for the guidance and

information of the Tenderer and shall not be considered as the final a definite description of the full

scope of works.

DOCUMENTS ISSUED

‘The tender documents comprises of ali documents as listed in the content page of this tender document

‘and the drawings as listed in the dacuments. ;

‘SUBMISSION OF TENDER

The Tender together with all necessary and stipulated information shall be duly completed and

submitted not tater than the time an date stipulated in the Letter of Invitations in a sealed envelope

clearly labeled with the name of the Project "TENDER FOR APARTMENTS — PHASE 2C (BLOCK Ci

to C9) - PACKAGE 128 — CIVIL & STRUCTURAL WORKS FOR THE PROPOSED “AQUALILY”

RESIDENTIAL DEVELOPMENT FOR MAHINDRA RESIDENTIAL DEVELOPERS PVT LTD” with the

name of the tenderer and addresses to the place stated in the Letter of Invitation,

‘Tenders delivered after this time and date shall not be considered,

Brit

40

50

60

7.0

DOCUMENT B

THE TENDER

Conditions of Tender

‘SUBMISSION OF TENDER ( Cont'd)

‘The tenderer shall include in the tender submission:-

1. The whole tender document duly completed, signed and stamped, including the Letter of

Tender with the tender sum. The tender sum, shown in the Letter of Tender must be the total

in the “Final Summary’ page.

2. Approgramme in a linked bar chart to show the intended construction sequence, including the

dates for appointment of nominated sub-contractors

3. site organization chart inctuding the CV of all personnel’s to be ful time on site.

4, Project Execution Pian

5. Other information requested in the tender documents

“The Tenderer shall submit with their Tenders such drawings, information and data as may be called for in

the Tender Documents, and shall complete the appendices as required. No Tender wil be considered

tnless the said items are submitted therewith,

“The tenderers have to submit the drawings issued along with tender.

When requested by the Employer, Authorised Person or Employers Representative, the Tenderer shall

submit any additional information, which may be considered necessary to clarify the Tender,

‘TENDER DEPOSIT

NOT APPLICABLE

VALIDITY OF TENDERS

‘Tenders shall remain valid for acceptance for ninety (90) days from the final date of submission of tenders

(notwithstanding any offers and counter offers thereafter) and no Tenderer shall be allowed to withdraw

his Tender within that period.

‘Should the Tender validity period lapse without Tenderers being notified of the results of the Tender, the

Tenderer may, within a period of ten (10) days from the date of expiry of the said period, give writen

notice to the Employer that his Tender is withdrawn, Should the Tenderer not withdraw his Tender as

aforesaid, the Tender shall remain valid for a further period of ninety (@0) days from the date of expiry of

the original period of validity.

NOTICES AND ADDENDA

Any notice to be given to a Tenderer shall be issued to the Tenderer’s address and such issuances shall

be deemed to be adequate service of such notice.

‘Any interpretation of, or change in the Tender Document prior to the spectied closing date, will be made

only by Addenda Issued by the Authorised Person or the Employers Representative to each Tenderer to

horn the Tender Documents have been issued and it shall form part of the Tender Documents.

Brie

DOCUMENT B

THE TENDER

80

9.0

10.0

11.0

120

13.0

Conditions of Tender

DISCREPANCIES IN TENDER DOCUMENTS

‘The Tenderer shall satisfy himself that adequate information has been given to enable him to determine

firm prices for preliminaries and temporary works, attendance, firm rates in the trade preambles,

percentage rates, taxes, off site overheads and profit and to prepare the linked bar chart

Tenderers shall raise any queries at least seven working days prior to submission of bids.

All queries raised by any tenderer shall be in writing addressed to the Authorised Person or tho

Employers Representative and the Authorised Person or the Employers Representative shell endeavor

to answer all queries. Replies, which were confirmed in writing to the enquirer, may be circulated to all

Tenderers.

‘The Tenderer is to check all pages and drawings of the Tender Documents as listed in the Content

Section that they are complete in number and satisfactory reproduced and shall refer to the Authorised

Person andlor Employers Representative for any missing drawings, pages, duplications or discrepancies,

If no communication is received by the Employers Representative and the Authorised Person prior to 7

days from the final date for submission of Tenders, it wil be deemed thet the Tender Documents are in

‘order and the Tenderer has fully understood the meaning and intent and no claim for extra payment will

be entertained

ALTERATIONS OR AMENDMENTS IN TENDER

No unauthorised alteration or amendments shall be made to the Tender Documents; otherwise the

‘Tender may be rejected.

ERRORS IN TENDER SUBMISSION BEFORE ACCEPTANCE OF TENDER

errors in the computation of the Tender Sum and errors in rates

‘Tenders shall be checked for arithmet

and prices.

‘Should arithmetical errors in the computation of the Tender Sum and errors in rates and prices be

discovered and the Tenderer elects to confirm his Tender in spite of the errors, all priced items

{excluding contingencies, prime cost and provisional sums) inserted by the Tenderer will be reduced or

increased in the same proportion as the corrected total of such priced items which exceeds or falls

short of the original total such that the original Tender Sum is not amended.

ACCEPTANCE OF TENDER

‘The Employer is not bound to accept the lowest or any tender nor is the Employer obliged to give any

reasons forthe rejection of any Tender.

COMPLIANCE BEFORE COMMENCEMENT OF WORK

‘The successful Tenderer shall be notified in wring that his Tender has been accepted within the period of

validity. The said Tenderer shall when called to do so execute the formal Contract.

In addition, he shall deposit the Performance Security equivalent to the same sum, as well as the

Workmen's Compensation Policy and the Contractors’ All Risks Policy and shal also produce for

inspection the recelpts of premiums paid, all as referred to in the Conditions of Contract

“The Tenderer's attention is drawn to the stipulation that the Performance Security shall be in accordance

with the specified format and effected with @ Bank to be approved by the Employer. All Insurance Policies

Under this formal Contract shall be obtained from an insurance company to be approved by the Employer.

COMMENCEMENT DATE OF THE CONTRACT

The Commencement Date of the Contract shall be the date of issuance of Letter of Acceptance or any

other date stipulated in the Letter of Acceptance.

‘The contractor shall note that the contract period includes all mobilization period required by the

contractor for the Works.

Bris

DOCUMENT B

THE TENDER

140

15.0

16.0

4170

18.0

Conditions of Tender

LETTER OF ACCEPTANCE

Until a formal Contract is prepared and executed, this Tender and approved amendments and

Glarfications together with the Lelter of Acceptance shall consttute a legal and binding contract between

the Employer and the successful Tenderer.

NON-COMPLIANCE WITH TENDER

Non-compliance with any or all of the above conditions in any respect shall render the Tender lable to

rejection and the Tender Deposit being forfeited.

CONFIDENTIALITY

Except with the consent in writing of the Employer, the Tenderer shall not disclose this Tender, or any

of it’s provisions, or any specifications, plans, drawings or information issued by the Employer,

Employers Representative, and/or Authorised Person.

OWNERSHIP OF TENDER DOCUMENTS

‘Al documents submitted by the Tenderer in response to the Iriitation to Tender shall become the

property of the Employer. However intellectual property in the information submitted by the Tenderer shall

remain vested in the Tenderer.

‘This clause is without prejudice to any provisions to the contrary in any subsequent contract betiveen the

Tenderer and the Employer.

‘TAXES IN TENDER SUM

The Tender Sum, including all rates and prices, submitted by the Contractor in his Tender shall be

inclusive of all taxes and duties. Tenderers to note that Project is being developed by the Co-

Developer in Non-Processing Zone of Mahindra World City SEZ. The unit rate to include VAT but

exclude Service Tax.

Bria

DOCUMENT B - TENDER

2. LETTER OF TENDER

DOCUMENT B

THE TENDER

Letter of Tender

TENDER FOR APARTMENTS ~ PHASE 2C (BLOCK C1 to C9) - PACKAGE 12B - CIVIL & STRUCTURAL

WORKS FOR THE PROPOSED RESIDENTIAL DEVELOPMENT ‘AQUALILY’ FOR MAHINDRA RESIDENTIAL

DEVELOPERS LTD

MAHINDRA RESIDENTIAL DEVELOPERS LTD.

2° Floor, Canopy,

Mahindra World City,

‘Chengalpet ( PO)

Chennai

Dear Sirs

4. We, the undersigned having read end examined the whole of the Tender Documents for the above-

mentioned Works and having visited the site, hereby tender and offer to execute, complete and maintain

the whole of the Works and to supply all labour and materials and everything of every kind respectively

named, shown, described and alluded to, in or to be inferred from, the Conditions of Contract for

Construction, the Specification, the Schedule of Works, the Drawings and all other documents herein

collectively referred to as the Tender Documents for the sum named below.

2. We accordingly offer to execute and complete the Works and remedy any defects therein, in conformity

with this Tender which includes all these documents and the enclosed proposal, for the fixed price of

(indtan-Rupees) Rs

Basic Tender (Based on Employer's stipulated Time for Completion of ) months -

INR,

(Rs, )

3. Inthe event of your acceptance of our Tender, we agree to:-

() execute @ formal contract in the form as. set out in the FIDIC Conditions of Contract for

Construction of Building and Engineering Works Designed By the Employer, 1st Exition, 1999

issued by Federation Internationale des Ingenieurs - Conseils (FIDIC) together with all

‘amendments and particular conditions as stated in the Tender Documents. Unti then, your written

Letter of Acceptance together with the documents listed as Contract Documents therein, shall

constitute a legal and binding contract between us;

{i) deposit with you the Insurance Policies for Workmen's Compensation, Contractor's All Risks

Insurance and to produce the receipts of premiums paid for inspection before the Date of

Possession of the Site

(il) deposit with you a sum in cash equivalent to ten (10) per cent of the Contract Sum or execute and

furnish you with a Performance Security in exact accordance with the format set out in the

‘Appendix of the Tender Document for a sum equivalent to ten (10) per cent of the Contract Sum

for the due performance of the Contract before the Date'of Possession of site

Brit

DOCUMENT B

THE TENDER

‘Letter of Tender

4. We agree that:-

() you reserve the right to accept or to refuse this Tender, whether it be lower or higher than any

‘other Tenders or of the same amount; and

(i) this Tender shall remain valid and shall not be withdrawn within Ninety (90) days from the final date

for submission of tenders (not withstanding any offers and counter offers thereafter) or for any

further period for which the Tender may become valid; and

(li), unt a formal Coniract Agreement is prepared and executed, this Tender together with your written

Letter of Acceptance shail constitute a legal and binding contract between us;

(v) where we awarded the tender, our tender price shall remain firm for phase wise execution of

works.

5. We further agree that should we become the successful Tenderer and in the event that the works (or any

Phase or Section of the Works) cannot be completed by the Completion date or Extended Completion

Date, the Employer shail be entitled to recover liquidated damages as stipulated in the Contract.

6 We confirm, after personal scrutiny, that the documents and drawings used by us in compiling the tender

are true copies of the documents and drawings included in the Tender Documents.

7. We further undertake to give you any further information, which you may require.

‘Authorised Signature of Tenderer

{To submit the Power of Attorney)

Company Name

Full Name of Signatory

Designation

‘Address of Tenderer

Fax Number

E-mail Adgross (ff any)

Date

Witness Signature

Full Name

Address

Date

B/2i2

DOCUMENT C

‘THE CONTRACT

DOCUMENT C ~ THE CONTRACT

4. GENERAL

DOCUMENT C

THE CONTRACT

General

The FIDIC Conditions of Contract for Construction of Building and Engineering Works Designed By the Employer,

1 Edition, 1999 issued by Federation Intemationale des Ingenieurs ~ Conseils (FIDIC) shall be the Contract used

but subject to the amendments and additions contained herein in the "Particular Conditions",

‘A copy of the FIDIC Conditions of Contract for Construction for Bui

Employer, 1* Ecition, 1999 may be obtained from

ing and Engineering Works designed by the

Federation Internationale des ingenieurs ~ Conseils (FIDIC)

World Trade Center It

P.O, Box 311

41215 GENEVA 15

‘Switzerland

TEL : 441227994905

FAX: 44122799 4901

EMAIL: fidic.pub@fidic.org

WWW : httpiiwwwfidie.org

cnn

DOCUMENT ¢ ~ THE CONTRACT

2. APPENDIX TO TENDER

DOCUMENT c

CONDITIONS OF CONTRACT

‘Appendix to Tender

Hom, SubGluse Data

Employers name and address 1122 MAHINORA RESIDENTIAL DEVELOPERS

uo

Canopy Unt Uaahinda World Cty,

Natham PO (Sub }, Chergalpat

‘Cheon

Engineer's name and address . 12d MAHINDRA RESIDENTIAL DEVELOPERS

Lo

Canopy Unit Mahindra World Clty,

Natham PO (Sub ), Changalpot

Chennai

Time for Complation of the Woks... 1433 To Refer Appendix 5

Defects Notification Period... 1437 1 Year 12 Months

Electronio transmission systems 13 Fascimillo / Email

Governing Law... sence India

Ruling language. 14 English

Language for communications. 14 English

Time for access to the Sito n-nonane AB stated in Letter of Accoptance

‘Amount of Performance Secu. 42 10% of Accepted Contract Amount

Normal working hours . 65. ‘As sipulated by loca authoties.

Delay damages forthe Works 4. 8.7 &14.16(0) 0.1% of Accepted Contract Amount

Maximum emount f delay damages. 87 10% of Accepted Contract Amount

{there are Provisional Sums :

Percentage for adjustment of

Provisional SUMS nnn 13.510) Not applicable

|f Sub-Clauso 13.8 applos: 138 Not Applicable

Total advance payment 142 10% of the Accepted Contract Sum

Number and Sing of instalment... 142 ‘One instalment

(Currencies and proportions. 142 sons thin Not Apical

1% in Not Appicable

Start repayment of advance payment 14.2(a)

When payments are 20% ofthe Accepted

Contract Amount

Repayment amortisation of advance

payment 1420) 18%

Initials of signatory of Tender

crn

DOCUMENT ¢

CONDITIONS OF CONTRACT

“Appendix to Tender

Item Da

Percentage of retention... 14.40) 40% of Work Done

Umit of Retenton Money 143. 10% of the Accepted Contract Sum

1 Sub-Ciause 14.5 applies:

Plant and Materials fr payment

‘when shipped en route tothe Sito 14.500) Not Applicable

Plant and Materials for payment Allrelovant plant and materia to

wen delivered to the Ste 14.5(0) be incorporated in the parmanent Works

Minimum amount of interim Payment

Certcates 148 Nu

1 payments are only tobe made in a currencyleurencies named cn the fst page ofthe Letir of Tender:

CCurrencylcurrencies of payment... 14.18

Indian Rupee

If some payments ere to be made ina curencycurrencies not named on the fst page of the Letter of Tender:

(Currencies of payment 14.18 Not Applicable

‘Currency Unk Percentage payable in he Rate of exchange : number

‘of Local per unt of Foreign

Loca! {name} 1.000

Foreign rama}

name}

Period for submission of insurance:

{a) Insuring Paty 184. Conredor

{b) evidence of insurance. 184 7 Days

(6) relevant pales. 184 21 Days

Maximum amount of decuetiles for

Insurance ofthe Employer righ... 10.260). NAL

Minimum amount ofthis party

ISUFANGE. nen 183. INR 10,000,000 for any one occurance

(unlined)

Date by which the DAB shal be appointed 202 WA.

“The DAB Shall BE ne OD reseninnne NAL

Appointment ifnot agreed) to be

cL 208. NA

Uthere are Sections: Not Applicable

Definitions of Sections:

Description Time for Completion Delay Damages:

(Sub-Clause 1.1.5.6) (Sub-Clause 1.13.30) (Sut-Ciause 8.7)

Inia of sgnstory of Tender

DOCUMENT C ~ THE CONTRACT

3. PARTICULAR CONDITIONS.

| CONDITIONS OF CONTRACT

3. Particular Conditions

“The Conditions of Contract comprise the “General Conditions” which form part of the "Conditions of Contract for

: Construction” First Editions 4889 published by the Federation Internationale des Ingeniers- Conseils (FIDIC),

and the following “Particular Conditions”, which include amendments and additions to such General Conditions.

CONTRACT CLAUSE Amendment and Additions to General Conditions

1 General Provisions

4.4.4. | The Contract

4.1.2 | Parties and Persons Delete Sub-Clause 1..1.2.9 in entiraty

1.1.3 | Base Date Delete the words “date 28 days prior to” and insert “date 7 days prior to”

1.1.5 | Works and Goods Delete sub clause 1.1.8.6 and Replace with “Section” means a part of

the works identified as such and more particularly described in the

specifications or schedule of works for which a date of completion is

stipulated in the appendix to tender

Delete sub clause 1.1.5.8 and replace with "Works" means the

permanent works and the temporary works or sithor of them as

appropriate. The works also include temporary flood protection

7 measures and maintenance of roads within the existing ROW during

construction period.

\ Insert the following new clause 1.1.5.9 “Section subject to excision”

means a section of the works the dotails of which are known but the

: implementation of which hes not been decided upon by the employer at

the time of tender and which shall only be implemented upon

subsequent decision of the employer followed by 2 waiten instruction

from the engineer.

In Sub-Clause (¢), insert the following after the words * a permanent

l 4.2 | Inlerpretation

: record”

mais and electronic submissions without signatures shall not be treated

a8 "Welton or in writing".

1.5 | Priontyof Documents | Delete the entire Sub-clause and REPLACE withthe folowing

The documents forming the Contract are to be taken as mutually

explanatory of one another. If any ambloully or discrepancy arises

\ between or among the documents, for the purpose of inferpretation, the

priority of documents shall bein accordance with the governing law and

In the event of any remaining unresolved ambiguity or dsorepancy the

\ Engineer shal issue any necessary ciarfcaton or instruction

418 | Contract Agreement _| REPLACE the words “28 days” In line 1 with “within 60 days"

( 1.45 | NewSub-Clause Insert the folowing new Sub-Clause

Private and Confidential Contract

The Contractor shall treat the contract as private and confidential,

: except to the extent necessary to carry out obligations under it or to

comply with applicable Laws. The Contract shall not publish, permit to

be published, or disclose any particulars of the Works in any trade or

technical paper or elsewhere without prior written agreement of the

Employer.

ors

CONDITIONS OF CONTRACT

3, Particular Conditions

“The Conditions of Contract comprise the “General Conditions” which form part of the “Conditions of Contract for

Construction” First Editions 1999 published by the Federation Internationale des Ingeniers- Consel's (FIDIC),

‘and the following “Particular Conditions”, which include amendments and additions to such General Conditions.

CONTRACT CLAUSE

Amendment and Additions to General Conditions

2.2

24

34

33

34

4a

The Employer

Permits, Licences or

Approvals

Employer's Financial

| Arrangements

‘The Engineer

Engineer's Duties and

Authority

Instruction of the Engineer

Replacement of the

Engineer

‘The Contractor

Contractor's General

Obligations.

REPLACE the following words in Paragraph 1 Line 1“ the Employer

shall“ with the words * The Employer may”

DELETE sub-paragraph (a)

RENAME sub-paragraph (b) as (a)

DELETE the entire sub-clause

Delete the entire paragraph 4" However..... deemed to have given

approval’ and replace with the following

‘The Engineer shall obtain prior permission from and specific approval of

the employer before taking any of the following actions

Consenting to the subcontracting to any part of the works under clause

4a

Ceriying any variations under clause 13

Ordering suspension of works under clause 8.8 and resumption of work

under clause 8.12 and determining an extension of time under clause

a4

‘Amend in sub-clause (¢) the words “two working days" to * fourteen

working days”

‘Amend “42 days" on the first line to "30 days”

‘Add the following after "(¢) prior... the Engineer" as a new paragraph

‘The Contractor shall engage independent checking engineers to check

and certify the contractors design of part of the permanent works 2s

stipulated in specication and drawings and al temporary works.

Without prejudice to other conditions stipulated in the contract, the

contractor shall submit contractor’s design drawings, specification,

calculation and other information as shall be necessary along with the

cerlificate issued by independent checking engineer to the engineer for

approval at least one month before the commencement of the relevant

‘works. Approval from the Independent checking engineer of any

contractor's design certified by Independent Checking Engineers shall

not relieve the contractors responsibilies for the sufficiency of the

contractors designed work

csi

CONDITIONS OF CONTRACT

‘3. Particular Conditions

‘The Conditions of Contract comprise the "General Conditions” which form part of the “Conditions of Contract for

Construction" First Editions 1999 published by the Federation Internationale des Ingeniers- Conseils (FIDIC),

and the following “Particular Conditions’, which include amendments and additions to such General Conditions,

CONTRACT CLAUSE Amendment and Additions to General Conditions

4 The Contractor

4.4 | Contractor's General _| Appointment of the Contractors Designer and Independent Checking

42

412

Obligations ( Cont'd)

Porformance Security

Unforeseeable Physical

Conditions.

Engineer ICE)

Within 14 days from the commencement date, the contractor shall

submit to the engineer the details of the personnel he proposes to

appoint as the Designers to carry out the design of the works and the

independent checking engineer to perform the contractors design

checking obligations. The submission shall include the details and

experience of the personnel and their terms and conditions

DELETE the entire sub-clause and REPLACE with the following

“Within 14 days from the date of the Letter of Acceptance, the

Contractor shall furnish the Employer with or performance bond

(hereafter referred to as the Performance Security) for an amount equal

fo ten (10) percent of the Accepted Contract Amount for the due

performance of the Contract. The Performance Security shall be in the

form as annexed hereto in the Appendix of the Document, and issued

by an international and reputable bank having office in India and

approved by the Employer. The Performance Security shall be valid

until the issuance of the Performance Certificate, The Sum secured by

the Performance Security shall in no way be altered or reduced by any

‘Taking Over of Pars of the Works and shall remain in ful effect until the

issuance of the Performance Certificate for the whole Works,

If the Contractor defaults in depositing the required cash amount or

submitting a conforming performance bond, the Employer reserves the

Tight to withhold from Interim Payment Certficates an amount or

‘amounts not exceeding ten percent of the Accepted Contract Amount.

If the default continues, the said amount withheld shall only be released

only after the issuance of the Performance Cettiicate for the whole

Works, Any price inserted in the Contract for fulfilling the obligations

under this Clause shall also be omitted.

If the Contractor submits @ conforming performance bond in lieu of a

cash deposit, evidence of payments for the performance bond in the

form of a stamped receipts must be presented to the Engineer, who on

receipt of such evidence will include the same amount in an Interim

Payment Cerificate. The balance, if any of the price included for the

provision of the Performance Seourity in the Contract will be paid

proportionately throughout the Time for Completion for the whole

weeks,

Delete sub-paragraph (b) of sub-clause 4.12 and substitute with

(b) the payment of such cost, thirty percent (30%) of which shall be

included in the Contract Price ( the balance percentage of the Cost

shall be borne by the Contractor)

crsia

CONDITIONS OF CONTRACT

‘. Parlicular Conditions

‘The Conditions of Contract comprise the “General Conditions" which form part of the “Conditions of Contract for

Construction’ First Editions 1999 published by the Federation Internationale des Ingeniers- Conseils (FIDIC),

‘and the following "Particular Conditions”, which include amendments and additions to such General Conditions.

CONTRACT CLAUSE

‘Amendment and Additions to General Conditions

4 ‘The Contractor

4.47 | Contractor's Equipment

4.25 | New Clause

4.26 | As Bullt Drawings

‘The following clause shall be added at the end of Sub-Clause 4.17

“Contractor's Equipment which is owned by the Contractor (either

directly or indirectly) shall be deemed to be the property of the

Employer with effect from it's arrival on site. The vesting of property

shail not:-

a)affect the responsibilty or liability of the Employer

b)prejudice the right of the Contractor to the sole use of the vested

Contractor's Equipment for the purpose of the Works, or

O)affect the contractor's responsibility to operate and maintain

Contractor's Equipment.

‘The property in each item shall be deemed to revest In the Contractor

when he is entitled either to remove it from the Site or to receive the

‘Taking Over Cerificate for the Works whichever occurs first

Insert the following new clause as "Working Drawings"

Working drawings for all epecified structures works based on general

layout drawing provided in the contract and design calculations and

fabrication drawings for all permanent and temporary works for these

structures, material ist for structural fabrication along with detailed

Grawing for anchorage and temporary support details, pre stressing

etails ete, Shall be prepared by the contractor at his own cost and

submitted in triplicate fo engineer at least four weeks prior to actual

constructional requirement.Tho engineer shall serutnise and return one

‘copy with amendments within 14 days. Such approval doesn't relieve

the contractor of any of his responsibilities in connection with temporary

‘works. The contractor shall submit four sets of approved drawings for

engineers use. The cost of preparation of such drawings is deemed to

be included in tender su.

Insert the following new clause as "As Built Drawings”

On the completion of works, the contractor shall arrange to finish to the

employer Six (6) bound set along with two sets of soft copies of all" As.

Built drawings® for each component of the works at his own cost. The

taking over certificate of the works shall be issued only upon submission

of as built drawings.

csi

CONDITIONS OF CONTRACT

3. Particular Conditions

The Conaitions of Contract comprise the "General Conditions" which form part of the "Conditions of Contract for

Construction” First Editions 1909 published by the Federation Internationale des ingeniers- Conseils (FIDIC),

and the following "Particular Conditions", which include amendments and additions to such General Conditions.

CONTRACT CLAUSE Amendment and Additions to General Conditions

7 Plant, Material and

Workmanship

74 | Testing Delete the paragraph This Sub-Clause shall apply to all test Completion

(if any) and replace with the following :-

The Sub-Clause shall apply to all test specified or required to confirm

the performance of the design, materials and workmanship proposed by

the Contractors, other than Tests after completion”

In Paragraph 4, on the first fine, amen the words “24 hours’ notice” to *

48 hours’ notice’.

8 ‘Commencement, Delays

and Suspension

84 | Extension of Time for _| in sub-clause (a), delete the words “or other substantial change in the

‘Completion quantity of an item included in the contract”.

Insert the following paragraph after the sub-clause (e):

“Any changes in quantities, in the Bills of Quantities, due to errors in the

measurement shall not be a cause for any extension of time.”

85 | Delays Caused by DELETE sub-clause 8.5 and insert the following

Authorities

The Contractor has diligently followed the procedures lald down by the

relevant legally constituted public authorities in the country and has

allowed a reasonable time in his programme to comply with the

requirements of such authorities.

isis

CONDITIONS OF CONTRACT

3. Particular Conditions

‘The Conditions of Contract comprise the “General Conditions” which form part of the “Conditions of Contract for

Construction” First Editions 1999 published by the Federation Internationale des Ingenlers- Conseils (FIDIC),

and the following “Particular Conditions", which include amendments and additions to such General Conditions.

CONTRACT CLAUSE ‘Amendment and Additions to General Conditions

11 | Defects Liability

11.4 _| Failure to remedy defects | In sub-clause (b), add the following words after "(Determinations)"

12

123

124

13

132

13.5

13.8

Measurement &

Evaluation

Evaluation

Omissions

Variation and

Adjustments

Value Engineering

Provisional Sums

Adjustments for changes

in cost

“Reasonable reduction shall mean either any saving in cost obtained by

the Contractor by failing to remedy the defect or damage or the reduced

value of the works to the Employer or the cost of rectifying,

reconstruction or replacement of the works by methods stipulated or

approved by the Engineer, whichever is the greatest.”

Delete the complete paragraph (a)

Clause (b) shail be renamed as (a)

DELETE the words “and/or (b)* on the third line of Paragraph 3

Delete the entire Sub-Ciause and Replace with the following

"Whenever the omissions of any work forms part (or all} of @ Variation,

the cost of the omitted work shall be evaluated in accordance with Sub-

Clause 12.3 ( Evaluation)

DELETE under sub-clause (c) the words "to agree or determine 2 fee,

which be included in the Contract Price. ‘This fee shall be half (50%) of

the difference between the following amounts :”

DELETE sub-clause (c) (i) and (i)

INSERT the following sentences at the beginning of the sub-clause

‘The term Provisional Sums also refers to the Prime Cost Sums or P.C.

‘Sums

DELETE the entire sub-clause

isis

CONDITIONS OF CONTRACT

3. Particular Conditions

‘The Conditions of Contract comprise the "General Conditions" which form pert of the “Conditions of Contract for

Construction” First Editions 1999 published by the Federation Intemationale des Ingeniers- Conseils (FIDIC),

‘and the following "Particular Conditions’, which include amendments and additions to such General Conditions,

142

144

146

147

148

149

14.1

CONTRACT CLAUSE Amendment and Additions to General Conditions

4 Contract Price and

| Payment

144 ‘The Contract Price DELETE the words

Advance Payment

‘Schedule of Payments

Issue of Interim Payment

Certticates

Payment

Delayed Payment

Payment of Retention

Money

‘Application for Final

Payment Certificate

“except as stated in sub-clause 13.7 (adjustments for changes in

legislation" in sub-ciause (b)

DELETE the following sentence in paragraph 2

“This guarantee shall be issued by an entity ...... Approved by

the Employer" and REPLACE with

“The Guarentee shall be in the form as annexed hereto in the

Appendix of the Contract Document and issued by an

intemational and reputable bank having a place of business in

India and approved by the Employer.”

DELETE the entire sub-clause

REPLACE the words “28 days” in Line 2 with "14 days"

REPLACE the words “66 days" in sub-paragraph (b) Line 1 with

"28 days"

DELETE the whole clause

DELETE the words “the latest of the expiry dates of the Defects

Notification Periods’ and INSERT ‘the issuance of the

Performance Certificate”

DELETE the sentence "If a Taking Over Certificate ...... Defects

Notification Period for the Section.”

In paragraph 3, DELETE the last sentence “Thereafter, if the

dispute is finally resolved under ......a Final Statement” and

REPLACE with the following

“Thereafter, if the dispute is finally resolved under Sub-Clause 20.5

[Amicable Settlement) or 20.6 (Arbiration), the Contractor shall

then prepare and submit to the Employer (with a copy to the

Engineer) 2 Final Statement.”

cir

CONDITIONS OF CONTRACT

3, Particular Conditions

‘The Conditions of Contract comprise the “General Conditions" which form part of the “Conditions of Contract for

Construction’ First Editions 1999 published by the Federation Internationale des Ingeniers- Conseils (FIDIC),

and the following “Particular Conditions”, which include amendments and additions to such General Conditions.

CONTRACT CLAUSE

Amendment and Additions to General Conditions

16

10.4

16.2

7

173

18

18.2

182

18.3

19

19.4

‘Suspension and

Termination by

Contractor

Contractor's Entitlement to

‘Suspend Works

Termination by Contractor

Risk & Responsibility

Employer's Risk

Insurance

Insurance of the Works

and Contractor's

equipment

Insurance of the Works

‘and Contractor's

‘equipment

Insurance against injury to

Persons and Damage to

Property

Force Majeure

Consequences of Force

Majeure

{In paragraph 1 lines 2 and 3, DELETE the words “or the Employer

fas to comply with Sub-clause 24 [Employer's Financial

Arrangements)’,

Delete sub-clause (a) and (e)

Delete sub-clauses (f )

DELETE the entire last paragraph

“if, more than one year ........for insurances)”

DELETE sub-clause (e)~ (ii) and (v)

DELETE sub-clause d (i)

DELETE the words “and/or incurs Cost" in paragraph 1 line 3

DELETE the entire sub-clause (b)

ADD a new paragraph

‘Neither party shall claim for payment of cost incurred or arising

from the consequences of Force Majeure against each other”

cris

CONDITIONS OF CONTRACT

3. Particular Conditions

‘The Conditions of Contract comprise the "General Conditions" which form part of the "Conditions of Contract for

Construction® First Editions 1999 published by the Federation Internationale des Ingeniers- Conseil

(FiDIC),

and the following "Particular Conditions”, which include amendments and additions to such General Conditions.

CONTRACT CLAUSE

Amendment and Additions to General Conditions

20

20.5

206

Claims, Disputes and

Arbitration

Amicable Settlement

Arbitration

ANNEXES

APPENDIX TO TENDER

Delete the entire sub-clauses 20.2, 20.3, 20.4, 20.7 and 20.8

DELETE the words "Where the notice of dissatisfaction has been

given under sub-clause 20.4 above, “paragraph 1 line 1 and

insert the following

"Where either party is dissatisfied with any agreement or

determination of the Engineer under Clause 3.5 that party shall

give notice of dissatisfaction to the other and.”

Under Sub-clause (a) , delete the words * the rules of arbitration

of international chamber of commerce” and inset " the Arbitration

and Conelliation Act 1996 and any amendments thereto. The

venue for the arbitration shall be Chennai.

‘The language of arbitration shall be in English.

DELETE Annex C, D, E, F and G

. ( Sub Clause) 8.7 ...

“Maximum amount of Delay...

‘of the Final Contract Price’

csi

DOCUMENT D

‘SPECIFICATIONS

DOCUMENT D - SPECIFICATIONS

4, GENERAL,

10

20

DOCUMENT D

SPECIFICATIONS

‘A. General

GENERAL,

This specification shall be read in conjunction with the other documents which together

shall form the Contract document. Notwithstanding the sub-division of the

Specification under different headings, every part of it shall be deemed supplementary to

‘and complementary to every other part, The specifications shall be deemed as

supplementary to the drawings and in the event of any discrepancy between the drawings

‘and the specifications, the drawings shall take precedence over the specifications. In

pricing the Bils of Quantities, the contractor shall be deemed to have studied the

requirements of the specifications and allowed for in his price/ unit rates.

‘All materials and workmanship shall be in accordance with the latest relevant india

Standards or the British Standards, whichever is applicable.

‘The standard specification set out the basic quality of material and workmanship required

by the Authorised Person in this Contract. Any statements pertaining to sequence and

procedures for the construction of the works herein specified shall be regarded only as a

uide to the Contractor.

1t shall be the contractual duly and responsibility of the Contractor to have his own

Professional Consultants to make in-depth stucies for the proper details, procedure, mode

‘of execution; use of relevant type, form, and size of machineries for the works; form and

extent of temporary works required; and to execute everything whether of a temporary or

permanent nature required in and for such construction; completion and maintenance, and

0 far as the necessity for providing the same is specified in or reasonably to be inferred

from the documents and drawings forming this Contract.

The Contractor shall perform the Contract works in proper manner and with due

‘competency for the satisfactory completion of same; and with all related precautionary

‘measures to safeguard against any possible damages to neighboring properties, for which

he shall have to rectify same solely and entirely at his own cost and expense.

INSTRUCTION ON PRICING

‘Specifications and Trade Preambles are description of materials and workmanship and

‘other matters relating {o items of work in the Bills of Quantities shall apply to the whole of

the work regardless of the trade/elements headings under which they have been described

‘or measured.

The rates for each item of work shall be held to include for all costs, expense, charges

and expenditure arising out of complying with the Specification and Trade Preambles.

‘The term "as described" as used in the description of items of measured work shall mean,

"as described in the Specification, Drawings and Preambles to All Trade". Where so

described, items of measured work shall be read in conjunction with the relevant items in

the Spectication and Trade Preamble.

The Contractor ie advised to study carefully the Drawings, Specification and Trade

Preambles before the acivel pricing ofthe documents and before submiting his tender, a

ro claim for exta payments on the ground of neglect to read the Specification and

Preambles can be entertained

DAN

DOCUMENT D

SPECIFICATIONS

‘A. General !

3.0 ABBREVIATION

‘Throughout these Contract Documents the following abbreviations have been used: }

m Linear meter

m2 = Square meter i

mn = Milimeter

mm = Square mitimeter f

No = Number

oz = Ounce (avoirdupcis)

b = Pound (avoirdupois)

' = Kilogram

t - Metric Ton

c = Degree Celsius

N = Newton

w - Watt

BS, = The latest "British Standard’ issued by the British

Standards Institution

ce. = The latest "British Standard Code of Practice” issued by the

Counoll for Codes of Practice of the British Standards Institution

“The letters B.S. refer to the British Standard as issued by the British Standards Institution,

British Standards House, London, The letters C.P. refer to the Code of Practice issued by

the Council of Codes of Practice (British) or the local Authorities. The latest amendment

is implied and applicable in each case.

4.0 APPROVED

‘The item "approved" shall mean approved by the Authorised Person.

DIAZ

DOCUMENT D - SPECIFICATIONS

.2 TECHNICAL SPECIFICATIONS-CIVIL

MAHINDRA RESIDENTIAL DEVELOPERS

The Canopy, Block ‘A’, Unit Il, 2nd Floor, 2ND Avenue, Mahindra World

Gity (P.O) Chengalpet Taluk, Kanchipuram Dist. 603 002 (T.N)

TENDER DOCUMENT FOR GENERAL CIVIL WORKS

FOR PROPOSED GATED COMMUNITY PROJECT AT

MAHINDRA WORLD CITY - AQUALILY

TECHNICAL BID:

‘SPECIFICATIONS

STRUCTURAL

EDIFICE CONSULTANTS PVT. LTD.

No.1, Saravanan Street,

T.Nagar, Chennai-600017.

‘TEL.: +91-44-24344357, Fax 491-44-24311607

‘TECHNICAL SPECIFICATION

AQUALILY

‘TECHNICAL SPECIFICATIONS

STRUCTURE

CONTENTS

Sr.No. Description Page no.

1.0 Preamble. 3

2.0 Inclusive Documents. 3

3.0 Order of Precedence, Clarifications and Interpretation. 3

40 ‘Measurement and Payments. 3

5.0 Unacceptable Work, 4

6.0 General Items of Execution 4

70 General Specification 4

8.0 General Specification of Materials and Workmanship 6

9.0 Tolerance 7

10.0 Earthwork in Excavation and Backfiing 10

11.0 Plain and Reinforced Cement Concrete 7

120 Structural Stee! Reinforcement 44

13.0 Formwork. 57

14.0 Waterproofing 61

15.0 Structural Steal Fabrication and Erection 69

16.0 Piling Works 84

[EDIFICE CONSULTANTS PUTLTD 2 IPE OA

TECHNICAL SPECIFICATION AQUALILY

10

20

3.0

40

PREAMBLE

‘These Specifications cover the items of work in structural and non- structural parts of

the works coming under Preview of this document. Ali work shall be carried out in

conformation with this. In general, provisions of Indian Standards, Indian Roads

Congress Codes and other national standards have been followed, These specifications

are not intended to cover the minute gvdetalls, The work shall be executed in

accordance with best modem practices. All codes and standards referred to in these

specifications shal be the fatest thereof,

INCLUSIVE DOCUMENTS:

‘The provision of Special Conditions of Contract, General Conditions of Contract, those

specified on the tender as well as execution drawings and notes or other specifications

issued in writing by the PMC / Architect shall from part of these specifications.

ORDER OF PRECEDENCE, CLARIFICATION AND INTERPRETATION

When the various specifications and codes referred to in preceding portion are at

variance with these specifications and each other the following order of precedence will

generally be accepted.

@) _ Notice Inviting Tender, Form of Tender & Appendix

b) General & Special Conditions of Contract & Articles of Agreement

© _ Bill of Quantities

d) Technical Specifications

©) Tender Drawings

f) Letter of acceptance of tender / award of work.

9) _ Relevant correspondence exchanged from receipt of tender to award of work.

‘The attention of the contractor is drawn to those clauses of IS codes which require

either specification by Architect/PMC or the mutual agreement between the supplier and

purchaser. In such cases it is the responsibility of the contractor to seek clarification on

any uncertainty and obtain previous approval of the Architect/PMC before taking up the

supply/ construction.

MEASUREMENT AND PAYMENTS.

The methods of measurement and payment shall be as described under various items

and in the bill of quantity. Where specific definitions are not given, the methods

described in IS 1200 will be followed, Should there be any detail of construction or

‘materials which has not been referred to in specification or In the bill of quantities and

drawings but the necessity for which may be implied or inferred wherefrom, or which

are usual or essential to the completion of the work in the tracles, the same shall be

deemed to be included in the rates and prices quoted by the contractor in the bill of

quantities,

‘EDIFICE CONSULTANTS PVT LTD 3 FOYPE/OA

‘TECHNICAL SPECIFICATION AQUALILY

5.0

6.0

5.

7.

70

1.0

2.0

3.0

40

UNACCEPTABLE WORK

[All defective works are liable to be demolished, rebuilt and defective materials replaced

by the contractor at his own cost. In the event of such works being accepted by carrying:

‘out repairs etc, as specified by the Architect/PMC the cost of repairs will be borne by the

contractor,

In the event of the work being accepted by giving "Design Concession’, arising out of but

not limited to undersizing, understrength, shift in location and alignment, etc, and

‘accepting design stresses in members which are higher than those provided for in the

‘original design or by accepting materials not fully meeting the specifications etc. the

‘contractor will be paid for the works actually carried out by him at the suitable reduced

rate of the tendered rates for the portion of the work thus accepted.

GENERAL ITEMS FOR EXECUTION

Excavation in all types of soils and! disposal of surplus earth.

‘Back-filing with approved material including compaction etc.

(a) Piain cement concrete.

(b) Reinforced cement concrete

Water proofing treatment in toilets, Under ground tank, Over head tank, Terrace.

Structural steel work

All the items to be executed as per the relevant IS specifications,

{All other works required to be carried out to complete the building as per drawing and

specifications & Bill of Quantity or Schedule of Quantity.

GENERAL SPECIFICATION

“These specifications are for work to be.cone, item to be supplied and materials to be used

in the works as shown and defined on the drawings and herein to the satisfaction of the

Owner) Architect.

‘The workmanship is to be the best possible and of a high standard. The contractor shall

take all steps immediately to make up deficiency if any noticed by the Owner / Architect.

Use must be made of special tradesmen in all aspects of the work and allowance must be

‘macie in the rates for the same,

‘The materials to be provided by the contractor shall be In accordance with the samples

already got approval from the Owner / Architect by the contractor and in conformity with

specification and approved is list of manufacture and brand, The contractor shall produce all

invoices, vouchers or receipts for any materials if called upon to do so by the Owner/

Architect.

‘A sample of all materials is to be submitted to the Owner/ Architects for their approval

before the contractor orders or delivers the material to the site, Samples together with their

packing are to be provided free of charge by the contractor and should any materials be

ejected they will be removed from the site at the contractor's expense. All samples will be

{EDIFICE CONSULTANTS PVT LTD 4 ‘FAYPEIORA

—

TECHNICAL SPECIFICATION AQUALILY

5.0

6.0

70

8.0

9.0

retained by the Owners / Architects for comparison with materials which will be delivered at

site, Also the contractor will be required to submit specimen finishes colours, Glass, ete., for

approval of the Owners / Architects before proceeding with the works.

‘The contractor shall be responsible for providing and maintaining temporary coverage

required for the protection of finished work, He is also to clean out all wood shavings, cut

ends and other waste from all parts of the works before covering of infilings are

constructed.

Contractor shall maintain uniform quality and consistency in workmanship throughout the

execution of the work.

‘The contractor shall provide: All materials, labour, maintenance, fixing, carrying, deaning,

making good, etc. temporary canvas, plastics and any other requisite protection of the

works, all the necessary equipments, labour and removal of the same at the completion of

the work. The Architect will be the sole judge in deciding as to the suitability of the tools or

plants that may be brought on the works by the contractors, for the proper execution of the

work,

‘The head masons and the supervisors on the works shall always carty with them a two feet

rule, a measuring tape ( 15 mts. ) a spirit level, 2 plumb bob and a square and shall chieck

that the work Is being done according to the drawings and specifications, The Architect or its

representative will use any OR all measuring instruments / tools belonging to the

Contractors in checking the works executed.

‘All measuring tapes shall be of steel and scaffolding and ladders that may be required for

taking measurements shall be supplied by the Contractors.

10.0 The Contractor shall place at the disposal of the Employer and the Architect and the

advice of himself and his firm, and their staff or Foreman of trades or other skilled

person employed by him or them for the conduct of the works comprised in the

Contract.

11.0 The Contractors are to take care in loading and unloading materials for the works, so

that the roads and footpaths are not obstructed, damaged or the traffic impeded, and

they must conform with the Police Regulations for carrying, loading and unloading all

materials, plant, earth, debris, etc. to and from the buildings.

12.0 The Architect shall have full powers and authority to issue such instructions as to the

order of proceeding with or carrying out the work as he may deem necessary for the

guidance of the Contractor and contractor shall be bound by such Instructions of the

Architect or any person authorized by the Architect to give such instructions,

13.0 The levels and measurements of the existing site, as shown in the drawings, are

believed to be correct, but the Contractor should verify them for himself before

proceeding the work .No claim or allowance whatsoever will be entertained hereafter on

account of any errors or omission in the description of the site turning out different from

‘what was expected or shown in the drawings,

14.0 All floors, paving, staircase, etc. are to be scrubbed, all glasses to be cleaned on both

sides of windows/curtain wall including its members, screens, doors, sky-lights, roof

lights, etc, all gulley, gutters, pipe heads, etc. to be Cleaned out and the premises left

clean, perfect and water tight upon completion. However, a proper care needs to be

taken during such deaning works that the original finishing such as polishing, painting,

anodizing, powder coating etc. are not scratched/damaged. In case of any such

EDIFICE CONSULTANTS PVT LTD 5 FHUPERWA

LEAS

CT)

tS

XY ¥

‘TECHNICAL SPECIFICATION AQuALILY [

damage, the contractor shall have to reinstaté the same as original as per the

instructions of Employer/Architects, without any cost to Employer.

15.0 The Contractor shall work in co-ordination with all electrical, Air-Conditioning/HVAC, Fire

Fighting/Detection, Security System , Plumbing and santitary and any other contractors |

working for other works involved in the project and provide all necessary assistance to

them for successful completion of the project.

16,0 Any loss or damage caused due to fault or negligence on the part of Contractors labours,

staff etc. during working in the premises will be made good by the contractor at no extra

cost or the damage and repair cost will be deducted from the contractor RA bills If the

‘owner/PMC engage other contractors for the same,

17.0 The contractor shall be responsible to provide and maintain temporary coverage

required for the protection of finished work. He is also required to clean out all wood

shavings, cut ends and other waste from all parts of the works before covering of

Inflings are constructed,

18,0 The contractor shall be responsible for providing and maintaining any boxing or other

temporary coverage’s required for the protection of dresses or finished work if left

unprotected. He is also to clean out all shavings, cut ends and other waste from all parts

‘of the work before coverings or in-filings are constructed.

19,0 Templates, boxes and moulds shall be accurately set out and rigidly constructed so as to

remain accurate during the time they are in use,

20,0 All unexposed surfaces of timber e.g, backing fillets, backs of door frames, cupboard

framing, grounds, etc., are to be treated with two coats of approved timber preservative

before fixing or covering.

21.0 All the contractors should consider the below mentioned points before quoting for the

Job.

+All vitrified tiles/aranite/marble samples to be approved prior to fix the same wherever

‘mentioned,

«The expenses for paying Municipal Taxes for dumping materials on/off site, etc. to be

borne by the contractor.

+ Expenses of bearing ward officer's sanction, etc. To be borne by the contractor.

Contractor should be responsible for the security of the materials on site.

+ Contractor should be responsible for lifting of the material to the respective floors and

‘expenses of the same should be borne by him.

8.0 General Specifications for Material & Workmanship

1.0 All materials brought on the site of works and meant to be used for the said project site,

shall be as per the approved makes mentioned & shall be deposited with architect before

the order for the materials Is placed with the suppliers / manufacturers and should be prior

approved from the Architect before execution.

2.0 The workmanship is to be the best available and of a high standard, use must be made of a

special tradesman in all aspects of the work and allowances must be made in the rates for

s0 doing.

"EDIFICE CONSULTANTS PUT LTD 6 ‘FHYPEPDA

‘TECHNICAL SPECIFICATION AAQUALILY

3.0 Workmanship: All works shall be to true line, level, plumb and square comers, edges and

arises in all cases shail be unbroken and finished neat, Only first class workmanship will be

accepted. Contractor shall maintain uniform quality and consistency in workmanship

throughout the execution of the work,

40 Skilled head masons / tradesman for the respective trades shall be employed by the

contractors to check the work in progress and to instruct and extract the right kind of

workmanship from the men employed on the works, Instructions given to such Head

‘masons by the Architect or his Representative shall be carried out with a view to get the

work executed in a neat and workman like manner, according to the specifications.

5.0 The Architect may order for the inspection of any finished work as he chooses and in a

manner he decides, and the contractors shall bear all expenses in.this connection, If the

results of such inspection prove that the material used and/or workmanship is not of the

standard required, the work will be rejected and removed forthwith and be replaced by

‘works of the accepted standard of quality and material without any extra cost,

6.0 The contractor shall produce ail invoices vouchers or receipts for any materials if called upon

to do so by the Employer /PMC/architects,

7.0 Samples together with their packing are to be provided free of charge by the Contractor and

should any materials be rejected, they will be removed from the site at the Contractor's

expense. All samples will be retained by the Employer/Architects for comparison with

materials, which will be required to submit specimen finishes of colours, fabrics, etc,, for the

approval of the Architects before proceeding with the work,

9.0 TOLERANCES:

S| tem Tolerance

No.

at Variation from piumb in the lines and surface of columns, piers, walls

and arrises.

In any 3.05 mt height. 6mm

)_Maximum for total building height of approx, 50m. 38mm.

2 Variation in plumb for exposed corner columns. Control joint groves

and other conspicuous lines.

a) In any 6.10 mt height. 6mm

b)_ Maximum for total building height of approx. 50m, 19 mm

3 Variation in level of slab soffits, celing, beam soffits and in arrirers,

measured before removal of supporting shores,

a) In any 3.05 mt height, + 6mm

b) In any bag or in any 6.40m length, £10 mm

)_Maximum for total length of the structure £19 mm,

a Variation in level of exposed lintels, sills, parapets, horizontal grooves

and other conspicuous lines,

a) In any bag or in any 6.10m length, + 6mm

b) Maximum for total length of the structure £13 mm,

3 Variation in level of elevation control points for slabs on grade.

a) In any bag or in any 6.10m tength. #10 mm

b)_Maximum for total lenath of the structure. £19mm,

6 Variation In tinear bullding lines from the basic dimension in plan and

related position of columns, walls, beams and partitions,

a) Inany bay

b) In bay 6.10m £13 mm

¢)_Maximum for the structure £13 mm

[EDIFICE CONSULTANTS PVT LTD 7 PHYPEDA

‘TECHNICAL SPECIFICATION

AQuaLILY

£25 mm

Z Varlation in size of sleeves; floor openings, and wall opening. = 6mm

8 Variation in location of centre lines of sleeves, floor opening and wall

‘opening. £13 mm

9 Variation in cross sectional dimension of colunins, beams, walls and

slab thickness

a) Upto 3.05 mm +10 mm

- 6mm

b) More than 3,05mm +13 mm

= 10 mm

10 | Variation in horizontal dimension of footings with formed excavation. [+ 51 mm

= 13 mm

Ti] Variation in horizontal dimension of footing with unformed excavation. | + 76 mm

=n

12 | Variation in misplacement or eccentricity of footing

Positive and Negative tolerance

Lesser of Simm or 2% of footing dimension in the direction of

misplacement.

73 | Variation in cross sectional thickness of footing. + no timits

= 5%

T4 | Variation in alignment of footing to receive masonry construction:

a) 113.05 m length

b) Maximum for 15.24 m fength + 6mm

£13 mm

5 | Variation in level of footing to receive masonry construction

a) In 3.05 mlength = 6mm

b)_Maximum for 15.24 m length £13 mm

J | Variation in dimension of an individual step of a stairway.

a) Riser 4 3mm

b)_Treed + 6mm

77 | Variation in dimension of an extra fight of a stairway.

a) Rise + 3mm

b) Run = 6mm

8 | Variation in finished slab surface determined as depressions in floors

between high spots using 2 3.05 m long aluminium straight edge over

five consecutive measurements per day. &mm

79 | Variation from specified gradient in longitudinal direction of pavements

‘as measured with a 3,05 m long aluminium straight edge.

3mm

20 | Variation from specified gradient in turnover direction of pavements as

‘measured with a 3.05 m long aluminium straight edge.

6mm

Zi] Variation from specified gradient of ramps and intersection as

‘measured with a 3,05 m long aluminium straight edge. 6mm,

22 | Variation from specified focation of dowels. #25 mm,

73____[ Variation in alignment of 450mm long dowels. = 6mm

24 | Variation in length of precast non-prestressed elements,

a) Per 3.05 m of length + 3mm

b)_Maximum for entire length. £19 mm

25 | Variation in cross sectional dimensions of precast non-pre-stressed

elements.

a) Sections upto and including 152 mm & 3mm

b) Sections between 153mm and 456mm & 5mm

©) Sections between 457mm and 913mm + 6mm

)_Sections above and including 914mm £10 mm,

"EDIFICE CONSULTANTS PVT LTD 8 FOPEFORA

‘TECHNICAL SPECIFICATION AQUALILY

26 _| Variation from straight line of precast non pre-stressed elements

a) In any 3.05m of length * 3mm

b)_Maximum for entire length £19 mm

27 | Variation from specified camber of precast non-pre-stressed elements

a) Per 3.05 m of span

b) Maximum for entire width + 3mm

#13 mm

28 | Differential in camber between adjacent units In erected position of

precast, non pre-stressed elements.

a) Per 3,05m of span + 3mm

b) Maximum for entire length £13 mm

{EDIFICE CONSULTANTS PVT LTD 3 PHUPEo3A

‘TECHNICAL SPECIFICATION ‘AQUALILY

40.0 EARTHWORK IN EXCAVATION & BACK FILLING

10.1.0 General

Contractor shall be deemed to have visited the site prior to submitting his Bid and made all

necessary inspection and investigations and to have decided for himself the means of access and

working space, the nature of the ground and subsoil, if any, level of water table, extent of rock

demolitions, alterations, support of neighbouring properties, etc.

10.2.0 Related work

a) Clearing, grubbing and removing all vegetation from the site.

b) Excavation including getting out, and necessary dressing to make surface ready to receive

binding,

‘c) Filling and back filing and compaction of fills

d) Removal and disposal of surplus material.

€) Stone soling to roads and paving.

‘The Contractor shall provide all labour, equipment, materials and any incidentals necessary to

complete all aspects of work included in the drawings and specifications.

10.3.0 Applicable Standards:

‘The following standards shail be followed:

a). IS: 3764-1966 Safety Code for Excavation Work.

). IS: 1498-1970 Classification and identification of soils for general engineering purposes.

©). British Standard 1377-Methods of test for Soils for Civil Engineering Purposes.

4). British Standard 5930- Code of Practice for Site Investigations.

©). SP27 Handbook of method of measurement of building works.

£). Local Building Regulations and Statutory Regulations.

10.4.0 Definitions

Clear: The removal of trees, scrub and artificial obstructions including fences, concrete slabs,

kerb and channel, remains of old buildings and the like.

Grub; The removal of tree stumps and roots.

‘Top soil: Topsoil is all surface soils, which have sufficient humus to support plant growth without.

resort to artificial fertilization.

Cut: A general term for ‘in place’ material removed by digging from the ground. The term

‘excavation’ or derivatives thereof may be used interchangeably.

Fill: A general term for material spread and compacted over the ground to make up finished

levels or levels to sub-grade, The term ‘Embankment’ or derivatives thereof may be used

interchangeably.

Sub-Grade: The finished, trimmed and prepared surface of the earth works after completion of

all cut and fils operations. The term “formation level’ or derivatives thereof may be used

interchangeably.

‘Sub-Base: A selected filling layer spread and compacted over the sub-grade to make up levels to

the underside of the base course or floor slab.

[EDIFICE CONSULTANTS PT LTD 10 AIYPERIA

‘TECHNICAL SPECIFICATION AQUALILY

Base course: A selected filling layer spread and compacted to levels immediately below road

‘wearing course.

Spoil: Excess cut material remaining at the end of filing operations.

Bulk Earthworks: Earthworks to create, by excavation and/or filling and compacting, building

platforms, road formations, parking areas, reservoir, embankments, drainage canals or any other

formation where the unimpeded use of large earthmoving equipment is possible, This is distinct

from backfill of trenches, foundations or other earthworks immediately adjacent to completed or

partially completed structures.

10.5.0 Site Preparation

10.5.1 Site Inspection ~ Preamble

Any Site details or site information included in the Contract documents or Drawings are provided

for the Contractor's guidance only. The information provided may not be a complete or accurate

description of conditions existing below the surface of the ground. ‘The correctness of the

information is not guaranteed and the Contractor shall be responsible to make its own

interpretation of sub-surface conditions,

‘The Contractor shail visit the site, examine the boreholes, and decide for himself the nature of

the ground and the subsoil to be excavated. No claim for extra payment will be entertained

because of any misunderstanding, incorrect information, assumptions, or ignorance of existing

conditions,

10.5.2 Site Quality Control

‘The Contractor shall provide in his quality assurance program information to show that a system

will be used to ensure that all works carried out under this section (including any done by sub -

Contractor) will comply with all the requirements of this section,

10.6.0 Antiquities

‘Any ancient carvings, relics, coins or other curiosities discovered during the excavation or other

‘work shall remain the property of the owner and shall be handed over to the owner as required

under the General Conditions of Contract.

10.7.0 Setting Out and Clearing of the Site - Rates to Include,

‘The Contractor shall set out the centre line of the building or other involved works after

Clearing the site and get the same approved from PMC/ Architect. It shall be the responsibilty of

the Contractor to install substantial reference marks, bench marks etc and maintain them as long

as required by the PMC/ Architect. The Contractor shail assume full responsibility for proper

setting out, alignment, elevation and dimension of each and all parts of the work.

7.1 Benchmarks and Setting Out

‘The Contractor shall engage @ qualified surveyor to establish permanent benchmarks in sultable

locations around the site. ‘These benchmarks shall enable the Contractor to set out the location

of all buildings, paths, roads, utility lines, storm water drains and all other portions of the

Contract work.

If an error in setting out causes some portion of the work to be constructed in the wrong

location, or to the wrong dimensions, the Contractor shall make good the incorrect work at his

‘own expense to the satisfaction of the PMC/ Architect. ‘The Contractor shall be liable for any

consequential loss experienced by the Cifent,

{EDIFICE CONSULTANTS PVT LTD rr

‘TECHNICAL SPECIFICATION AQUALILY

10.8.0 Excavation Classification

a). Excavate foundation from existing ground Jevel to the formation levels shown in drawing.

). Excavation to pit working level.

©). Earthworks outside property line.

4). Excavation, compaction and backfill to plinth and service trenches.

10.8.1. Related Works

a. Site clearance, layout and preparation

b. Dewatering, shoring and strutting.

cc. Cast-in-Situ Concrete

10.8.2 Controlled Blasting /Excavation in Hard Rock

‘a. When blasting operations are considered necessary, the Contractors shall

Intimate about the same and shall obtain license from District/Public authorities

for carrying out blasting work as well as for obtaining, transporting and storing

‘explosives as per ‘Explosive Rules 1940" or as amended. The Contractor shall

responsible for safe custody and accounting of explosives.

b. Blasting operations shall be carried out under the supervision of a responsible

licensed operator of the Contractor during certain specified hours preferably

during lunch break on approval in writing.’ The operator shall be conversant with

the rules of blasting. The operator should have the valid blasting license.

c. All proper precautions for safety shall be taken. All persons shall be moved to a

distance not less than 200. All entries to the blasting zone shall be sealed and

red flags displayed at prominent places.

d. The Contractor shall be responsible for any accident / death to these working on

the site, to the public or to the property due to blasting operations, and that the

Contractor shall keep the Client fully indemnified against such accidents / death.

The PMC/ Architect shall be informed about all misfires, their causes and the

temedial steps taken,

The Contractor shall obtain license from District Authorities for undertaking

blasting work and explosive storing as per Explosives Rules. 1940, and as

updated Explosives shall only be procured from an authorised dealer. He shall be

responsible for the safe custody and proper accounting of explosives. The PMC/

Architect shall have access to the store,

10.8.3 Classification of Soll / Rocks: