Professional Documents

Culture Documents

Cement Feeding

Uploaded by

doc4print0 ratings0% found this document useful (0 votes)

7 views40 pagesCement Feeding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCement Feeding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views40 pagesCement Feeding

Uploaded by

doc4printCement Feeding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

O00003009

a

oO

oO

Acme Air Equipments Co. Pvt Lad.

Plot No. 57/344+8, Phase-1, G.LDB.

Vatva, Ahmedabad-382 445,

ir Equipments Company

OPERATION & MAINTENANCE

INSTRUCTION MANUAL

Gretta tye llare ey Cu : )

: TCP. -3

OMIM 03

oe

Plot No. 87/3+445, Phase.

Vatva, Ahmedabad.382 445,

‘Operation & Maintenance Instruction

Mi

cal

CEMENT FEEDING | 8°? 0f30

Air Equipments Company SYSTEMATICS

Cement Feeding System -TCP-3

Machine ‘System Number {03040 / 145

Year of Manufacture:- 4010-11

Customer Purchase Order No.:- ceD/ayy/po/ 20101) (Purl

1505/4

Purchase Order Date: 09-09~ 20/0

Order Acknowledgement No.:-

- Cha

Customer: Gannen Duarentey a eo bs Cl

C/o: ONGC prengalere Pepa herr Is C4

suvatal, plengeloe :

. of ake 5 7-

Manufacturer & Supplier “~~7”"

AIR EQUIPMENTS COMPANY

UNIT- II ,PLOT NO. 57/3,4,5, Acme Air Equipments Co, Pvt, Lad.

PHASE-lI, G.I.D.C. VATVA, Plot No. 57/344+8, Phase-1, GDC,

AHMEDABAD-382 445— INDIA Yat, Ahmedabad.382 445.

Tel No.: +91-79-22747527

+91-79-22730646/666

E-mail: info@airequipments.com ;

URL: www.airequipments.com ; www.airequipments.co.in;

www.airequipments.in

‘Operation & Maintenance Instruction

‘CEMENT FEEDING Page 3 0f 30

5 Air Equipments Company SYSTEM TCP-3

FOREWORD

Dear Customer,

We take this opportunity to thank you very much for purchasing the

A.E.C. Cement Feeding System

We have prepared this elaborate user manual for your detailed

information.

Since the beginning, Air Equipments Company has adopted a

policy of technical improvements & quality enhancement. In some

cases, you might receive equipment that does not exactly match

this manual. This variance may be due to some minor modification

in the system and hence should be ignored.

We once again thank you for your decision to purchase our above

equipment and hope that you are fully satisfied with the same.

Thank you

Sincerely Yours,

For : AIR EQUIPMENTS COMPANY

OO”0

4Z5 air Equipments Company

‘Operation & Maintenance Instruction

anual

‘CEMENT FEEDING

SYSTEM TCP-3

Page 4 of 30

a ATTENTION !

Employers and supervisors should ensure that this instruction

Manual or its contents are communicated or made available, to all

personnel who operate, clean, maintain or work in the vicinity of

this system.

a WARNING !

Before commencing installation, cleaning or maintenance work,

the electrical supply to the machine MUST _BE DISCONNECTED.

VOUIVGS

425 Air Equipments Company

‘Operation & Maintenance Instruction

fanual

CEMENT FEEDING

SYSTEM TCP-3

Page 5 of 30

INTRODUCTION:-

Principle

The principle of the Cement Feeding System (TCP-3) is to push

forward the Cement through barrel and compacting it through

screw flights. In the mixing chamber air flow helps fluidizing the

Cement, which is conveyed through the pipe further.

The System is equipped with an option for unloading bulker

(which has integrated piping) to Silo.

u

‘Operation & Malatenance Tasiraction

Air Equipments Company | CEMENT FEEDING

Page 6 of 30

GENERAL DESCRIPTION

What you should know about this manual

This manual will save your valuable time and may also prevent

possible injury. To help you find what you need to know all the

information and instructions about a task, such as operation or

maintenance, are located in a single section. In some cases,

however, specific details on some parts of your customized TCP-3

may be located in the appendices.

This manual tells you :-

* How to assemble, install and set-up your TCP-3 for the most

efficient operation.

+ How to operate your TCP-3.

* How to maintain and clean your machine , locate the sources of

trouble and make necessary adjustments or corrections or

replacements.

+ Drawings and special illustrations as well as electrical details.

The information and drawings in this manual apply specifically to

the TCP-3 that is identified by the serial number on the title of this

manual.

‘Operation & Maintenance Tastruction

| CEMENT FEEDING

SYSTEM TCP-3

Page 7 of 30

Air Equipments Company

The NOTES , CAUTIONS AND WARNINGS in this manual are

used to indicate alternative actions, abnormal conditions that may

occur in your work environment, or possible consequences of

inappropriate action.

W nore:

Is used to emphasize information that is useful but not directly part

of the instructional step of the data being described. For example,

note may tell you what to do if a task you are performing does not

exactly fit the description in an instruction.

Is used before a step or action in which there is a possibility that

Production will be adversely affected or that machinery or

Production materials may be damaged.

ZS warns:

Is similar to caution, except that personal injury may also

result if procedures as indicated are not followed.

‘Operation & Malatenance Tastruction

Mana!

Page 8 of 30

ZS Air Equipments Company ENE

GENERAL DESCRIPTION

Superior Quality

The Air Equipments Company make Cement Feeding System is

built to the highest standards of quality and every minute detail has

been taken care of. The equipment is finished to the international

standards.

High Relial

The A.E.C. Cement Feeding System is built with standard

components and the design features make it one of the most

reliable equipment. The components used are standard and the

equipment has been thoroughly inspected before shipment.

Controls

User friendly Controls have been employed to give the operator

the ease of use and control over the total process. All functions of

the equipment can be easily controlled by the control panel.

oO

‘Operation & Maintenance Tasiraction

M

1 Equipments Company | CEMENT FEEDING

Page 9 of 30

Safety is everybody’s JOB!

a WARNING !

SERIOUS INJURIES MAY RESULT IF

SAFETY REGULATIONS ARE IGNORED

Safety features

Due care has been taken to ensure the safety of the operating

personnel while operating the machine.

Enclosed moving parts

All the moving parts of the machine are totally enclosed thereby

eliminating accidental contact with them.

Cable Termination

The machine is supplied dully fitted with the electrical and wired

wherever possible. Both Electric Motors are connected through

Junction Box. The Electric Cable in Junction Box are connected to

Control Panel. The other end of these cables are numbered and

ate to be connected in panel number wise, wherever the panel is

fixed. The control panel is supplied separately in a box. The

corresponding incoming cabling has to be provided by customer at

site.

‘Operation & Maintenance Tasiraction

Manual

; ‘CEMENT FEEDING eee

; ir Equipments Company aa

} eee

ae Major Components of the Equipment

) The major components of TCP-3 are:

Base Frame

Feed Hopper

Screw Pump with Drive

Roots Blower with Drive

Pressure Relief Valve

Differential Pressure Switch

.

* Non Return Valve

« Butterfly Valves

* Suction Filter

* Suction Silencer

* Control Panel

‘Operation & Maintenance Instruction

‘CEMENT FEEDING

43 Air Equipments Company SvETeMTCES)

Base Fram

It is fabricated heavy duty Mild Steel Structure. It is sturdy and free

from vibration. It serves as a base frame to install all major parts

and works as a platform to operate the Cement Feeding System.

Feed Hopper:

It is specially designed to facilitate dumping of Cement bags

manually. The grating prevents entry of undesirable foreign

material like plastic Sacks; large lumps etc. into the Screw feeder.

Roots Blower:-

The rugged and precisely manufactured Roots Blower is mounted

on the Base Frame. The accessories are provided to ensure noise

free & vibration free running of the Blower .Detailed Specification

and Operation & maintenance instruction for Blower is elaborated

in separate documents appended as Appendix I.

Screw Pump:

This consists of screw with hollow core. The Shaft is separate and

is supported by bearings on the drive side. It includes fluidizing

and mixing chambers.

Pressure Switch & Pressure Relief Valve: -

These are provided to prevent over pressure and thus safeguard

the screw and Blower.

Maesal Page 11 of 30

OO <

5 Air Equipments Company SiaTRL TCR

‘Operation & Maintenance Tastraction

(CEMENT FEEDING

Starting the System

. Check Oil level in Roots Blower. Make up the level with

specified Oil.

Ld

Check Suction filter of Blower. Clean or replace if it is found

clogged.

o

. Check V-Belt drive of Screw Pump and Roots Blower and

ensure proper tension and alignment.

4. Carry out thorough cleaning of Blower, Screw Pump and

discharge pipe. Ensure that these are all free from

Cement /materials.

a

. Check Hopper. Ensure it is free from Cement bags, strings,

lumps of cements and such foreign materials.

6. Check Mixing Chamber, and ensure it is free from foreign

material.

7. Ensure Grease in Plummer Block Bearing of Screw Shaft.

8. Switch on Power Supply. Put control in “Manual” mode.

i) Check & ensure Motor Rotation direction for Screw Pump and

Blower as per Arrow Mark.

ii) Check other parameters like Voltage, Current etc.

9. Start M/c. Push Button.

Page 12 of 30

‘Operation & Maintenance Instruction

Manca

CEMENT FEEDING Page 16 of 30

y= en

45 Air Equipments Company SYSIEMLICESS

FILTER:

Clean the Suction Filter or replace at regular interval of 6 to 8

hours.

LN actentio

Filter elements should be cleaned by Blowing Compressed air.

Do not use Diesel/Kerosene /Thinner etc.

> ACME AIR EQUIPMENTS CO. PVT. LTD. REV. _00

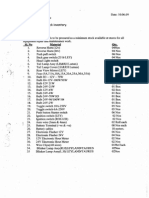

‘ SPARE PARTS LIST FOR CEMENT FEEDING SYSTEM TCP. PAGENO. 17 OF

o |SPL-TCP-3 “ASSLY DRG. NO. : SP-003 & SP-003-C}

[er.No,Pant Cove no} PARTS NAME POS. MATERIALSTO] UNIT [ary

wa) aomoonray PASE TRAIT WAU os Te Arrgonar at ws [no [ot

) 1-0 Nak Recor fuse [vo Le

| amon oy” RASEFRANE (WRAY Fad) eo

Kiar Reciever sf oms No [or

) ease Frame wan Te) eo

ca | asos010100. fire Resor sms no or

d [Cii) Adjustable Suppor 01. MS. No. | or

TE TTEA SRNO™“61 OR tz OR 09 VLL BE USED AG PER CUSTOUERS REGUREVENT

ca] 0000000300 oon ZO us pe

) os] 000920020 iN CHAMBER of ms p-no [or

6 | oe0s010-00” Jeanne sno or

) or ‘09030400-00 [FEED HOPPER 05 MS. No. | 01

5 co | 0002050000” FEED HOPPER GAIL oe | ws no os

“ 09 09033600-00 [HOPPER TOP COVER 068 MS. NO. | oF

) 10] 00s1800:00” [SRE a

11 | e20sr00000 [screw SaAeT 7 | enze [no os

) 42 09031200-00 _[(i) WEAR SLEEVE o7A | ALLOY STEEL | NO. | OF

5) 13] 090900030 SEALING LATE ce [us | No [ 01

£9053600-09 SEALING ARRANGEMENT = ser | 01

) 05050700:0" [1 SEALING ING (-HOLES) Sno fo

5 va [letameonan [PRESSING RNG | es ose

08020900-00 _|{ ii) GLAND BUSH 7 BRASS: No. | o1

. 42705099-00v) TEFLONE RING terion [no | ot

801600000 |(v) GLAND ROPE sto reer ot

) 75] s0s2600:09PADeSTaL BLOOK GUARD wp ws | no Pos

75] BOSNGSIT a0 PADESTAL LOOK (heh ATE TL st | wos: | 2

) 7] Asos2100-00 WPULLEY FOR SCREW, 2] so | wo or

; To] Asos2000.00 [PULLEY FoR 30 HP MOTOR re ae OC

72] Aansee00.00 JV PULLEY FOR AEG 2 BLOWER [ws [0-01

e 20 A9032500-00 _[V-PULLEY FOR 50 HP MOTOR, 18 MS. No. | 01

: 217] As0s190000_po He WOTOR 1475 REM FOR SOREW si] en costamal| Enos

, 22 "A9032400-00 [50 HP MOTOR / 1475 RPM FOR BLOWER a7 STD. set | 01

Z| azere00000 [ROOTS BLOWER [ost [sero

. 24 "903220000 |V-BELTS FOR SCREW & 30 HP MOTOR 19 ‘RUBBER

) FE | LAoz10.00 _[WBELTS FOR BLOWER & SO} MOTOR 20_[ RUBBER

Ze] AsC3250000 [BELT GUARO FOR SCREW 8 OHP HOTOR af ms

ST Asene600.00” [-6ELT GUAPO FOR BLWR & ScHPOTOR | us.

| 28 A9030300-00 [SUCTION SILENCER: ~ 23 MS.

25] epr0nn0000~ fr SAFETY VaWvE 2a | CAST IRON

30 ‘A019S050-09 [NON RETURN VALVE 23 MS.

S17] Asenes00.00” er BUTTER FLY VALVE [FOR ISOLATION UNE) aco aaasr0

aa | A0090500-00 [55a T-CONNECTION (INE FOR BULKER UNLOADIN = fms

53] Aes 200.00 FRENBLE HOSE PPE ze [Ruse

| 3 "A9030700-00 [5° FLEXIBLE JOINT | Rubber Beliow } a RUBE:

36 | a8033600 00 | REALISE COUPLING WIH'S'THO FING

| _A9037700-00 [5° MATING FLANGE -

en jae [Ess sesso

ze | A00s00000 JDISCHARIWE SUENCER ae [is

[Co aoana-do pa so FOUNDATION BOTT ciecostl amas

a] asez0e00-007 [av Fao 3 [ube

| a 99031600-00. [TYRE SET 36 MS/RUBBER

Tae TEM SRNO. 41 OR 42 WILL BE USED AS PER CUSTOMERS REQUIREMENT ~

ACME AIR EQUIPMENTS CO. PVT.LTD. Rev 0

s SPARE PARTS LIST FOR CEMENT FEEDING SYSTEM TOPS PREENO.: 18 OF 39

[SRNO PART CODE NO. PARTS NAME FOS, MMATERIALISTO] UNIT [GTY.

) “_|_-Asstauna0 [PRESSURE SATOH a7] so _[ no [a

2 [ crane 0 [PRESSURE GAUGE ec

) 6 Assi00-09 fa PURGING FX PENG [us [reer] os

: G6 | noczete-00_JORY aAG FILTER Denes ound) pus no Por

'09031700-00 [TOP COVER ( For Flap Type N.R.V. Assiy. ) MS. [ser [or

) cone 0) RAP us| wo a

1909160-00 (a) BRACKET Saure Pee) ms [ve [a

) «7 | esesnoo co [i TORSIONAL SPRING a [Daest— [no ot

5 99210600 [PIN us [v0 [a

08e20000 0) MIG LOORING BOLT us [ve [a

D 003230-00 [(n PI us [Nef

: GE_| 312227010 |SPHERIGRL ROLLER BEARING esto [ser |

) 6 | cw800 0 [ADAPTOR SLEEVE-ARRST? ase serp a

) | _ewsiona0 [SPLASH GUARO fms sera

| nean000-00~ > BALL VALVE oe

y 52 A9031000-00 [THREADED NON RETURN VALVE a7 ‘STO. NO. | a1

; 33_[ Asa 14000 [SEALING GASKET (Bek) we [S10 pure [os

) Se] amino HOSE PPE RORPTOR a

D

.

9

.

yy

gd

‘Operation & Maintenance Instruction

‘Manual

+ a ‘CEMENT FEEDING

ir Equipments Company SYSTEM TCR-3

Page 19 of 30

DEX—ELECTRICALS

Ones

OMAN AOA w

DETAILS OF SYMBOLS

PANEL CUT OUT

- DETAILS — PANEL CUTOUT AND CABLE ENTRY PORTS

- POWER CIRCUIT FOR BLOWER MOTOR -— 50 HP

- POWER CURCUIT FOR SCREW MOTOR — 30 HP

CONTROL CIRCUIT FOR 3—MODES

CONTROL CIRCUIT FOR BLOWER MOTOR — 50 HP

CONTROL CIRCUIT FOR SCREW MOTOR — 30 HP

CONNECTION OF TERMINAL STRIP

PAGE NO. : 20 OF 30

| o' bec

oa) ena)a(

A I

i 5.49) i

i

aN ele

neal ' 5 So | ate

PART LIST REF. : SPL-TCP-3

y= oy AIR EQUIPMENTS CO. PVT. LTD,

STAT mea AAMEDSEAD. NOI

D0 NOT SCALE ORANG ca: 1:1 [oRD.O. SP-003-C ar owe [Ree av. 0

PRETO = ero | Pravin [osu zona OR Sa

tis SCREW PUMP MoDEL :rc°-3| *f

aaa Ho. th 00 0 re «

ea APPS. lnp08 7005)" GENERAL ARRANGEMENTORG.| @

r x i t i

VVVVVVOL UL,

YIU VVOY

DOOD D

oO

r

PAGE NO. 21 OF 30

NRV_ELAP &

ING

REW_FITT

PART LIST REF. : SPL-TCP-3

| 4-g ACME AIR EQUIPMENTS CO. PVT. LTDJ:

a RS sauepaso, ‘naa

00 NOT SCALE DRANNG sour - 117 [ORGNO.SP-003-C Sen [owe Pee fe

— | Pa fey up none Tora |S

e} ee. PaO eset o

© zea Tessa Genera. arzancement ons, |

x x i i

SPORE —Poqopauny ‘ORDA “O'OTD

I-Hd ‘S®¥'E/LS "ON ld

GL (4) (09 SINGNdINda SIV ANOV BF

Fig VTS

fathoees a NT,

‘Wivid ONTINNON se" we

De Fee

oe

Te

oT

Teer

we

We

eal

Semotioneaara STIVLUd SLYOd AMLNA WIV ¥ LNOLAD TANVd

RARR AAR ARR Ae

PAGE N 23 OF 30

DETAILS OF SYMBOL

SR.NO. PARTS DETAIL SYMBOL

1 M.C.B. 4

2 INDICATION LAMP @

3 OVERLOAD RELAY ¥

4 CONTACTOR NO”

5 CONTACTOR ‘NC’

6 PRESSURE SWITCH 'NO’

7 PRESSURE SWITCH 'NC’ )

8 TIMER STAR ‘NO’ An

9 TIMER DELTA ‘NO’ an

10 RELAY 'NO' i

1 RELAY "NC" q

12 PUSH BUTTON 'NO’ &

13 PUSH BUTTON 'NC’ 5

14 CONTECTOR COIL @

15 FAIRULE NO aD

16 |. -EARTHING |

17 CT. “|

4 ACME AIR EQUIPMENTS CO. (P) LTD

Plot No. 57/3,4&5, PH-i,

G.L..C., Vatve, Ahrnedabad~ 380445,

VVIOFG OSCE

OOO

o

POO enone)

)

POWER CIRCUIT FOR BLOWER MOTOR 40/50HP

PAGE NO.

|

24 OF

@) @@)

L

RI RI

¥1 ¥1

a BI

v | 8 & %)mce | ip lo

¢ es ar |

fa

vss

1004 |]

R_|R2 MCCB spp

|__.

gt 2 u 21 SPP

N 8 B2 R3| Ne

Y3|

B3}

ce-] | |c-al |b e-al

R4| |

|_|

at_|

F-41125 A | 6

| M.C.C.B, 7

| af £ [one

ane eee 8He

NR Y 423 cf

©) @ @™ — (@) (9) (19)

TO SOH.P. BLOWER MOTOR

MG ACME AIR EQUIPMENTS CO. (P) LTD

Plot No. 57/3,4&5, PH-!

GALO.C., Votva, Anmedabod-380445

TO

PG.NO.-26

Rt

) MCB

=

oO

POWER CIRCUIT FOR SCREW MOTOR 30HP

634 MCB

TO 30H.P. SCREW MOTOR

49 ACME AIR E

Plot No. 57/3,

G.L.D.C., Vatva,

PAGE NO. : 25 OF 30

‘SerOBE—poaopewuy “onen “OOTD

Ha “SPV'E/LS “ON 0%

LT (d) (09 SINANdINDa YIV SNOV By |.

No. 430

HOLON xO10n

NaHS =. AaMOTE

uo wos ae avigy dHOf aHos

anaes Penny 23M, GVOIND yaisy “NYA GR “SRL No

aN av130 a3 spnne “non olny 7/0 7/0 wINO |

NI Nj Ny] NI NI N Ny ~

9 ona ofa offs

ri

‘oN'od>— or? Pe BP

woud ec of ve |

aw

I

i ai y ise] saan) [a

lc fio oe” ow fee

o9| Iss es

is %,

30k:

Sros| ony on Hy

iH y ul 30

axis $8 oun

oe les oy.

is g¥0

ON ON, at oT

tad iz nav BB). Lon

on

7S e-5 oe ee

on. lve

pal ON, (

oa hy:

9z foinw a a

oN'od ses

Rous 32 z z 3z eZ tz

ocFsolecERonl=ova] SHCON=€ HOT LIMON TOXINOD

OXOONNANAOONWOANeOwrOowC Aeececcce:sc

PAGE NO. : 27 OF 30

CONTROL CIRCUIT FOR BLOWER MOTOR 40/50HP

To.

34 57 y PS

FROM NO.

PC.NO=24 28

10

38 38 38

— PG.

a4 062} FROM NO.

: ee soup On 28

0/500] rAR

stor E-pojsae Sil No

Soke ee AUTO.

Mat FUNCTION | 50

6:

ea BLK.RL_ 162

TEST,

KEY(8)

25

START ee hae

SOHP+ Jc 10/504

MAN PB.

26

To

PONO 26 26 26 Pe 26 ,

1 T1 NO

Jer Ic3 wor la

26 28 30

7 Jo2 es 0

PG.

29 31 N fo.

/ 24

u| [el fer [cs c2

ud

NI Int M Nt Nt

orate To

ROM _ y PS

N2—BE.NO- 04 fi N MOTOR SN nod |

RUN 28 1]

AA ACME AIR EQUIPMENTS CO. (P) LTD

Plot No. 57/3485, PH-I;

G.LD.C., Votva, Anmedabad-380445. _|

> OVVOVOVOVDVIE

DO09

CONTROL CIRCUIT FOR SCREW MOTOR SOHP

P/S No

41(20)

57

RO!

PG.NO.-27

> \ 38

FROM __c2 i

PG.NO.-27 NO stop

—J FIXED witH

SOHP STOP STOP

ACT

PB MANUAL

30HP ACT

aa)

Heys NC

40(19)

SE NO. : 28 OF 30

AUTO-RL

Na Sl LE START oe MANUAL

0 Ol rest] BOHP. AC

43 43.43 KEMS)| 43 43

1B

C4 cé |

No INS gs] NO

|} 7

Jes

44.

46

12 | [e+ 6

FROM \.4) 5

eG Nat IN2 IN2

4 ACME AIR EQUIPMENTS CO. (P) LTD

t No. 57/3,4&5, PH

C..D.C., Votva, Ahmedabad- 380445.

‘GyPORE-poqopauy “ONIOA “JaTO

‘IcHa SPP'E/LS ON ld

GLI (d) 00 SLNANdINOG UV SHOV Br

Younus, 40}OUs UO “OU ZI 7% ‘OL OSI “ou GE % { SbUDYOLEWU! 9509/0 UoriDeUIP sesoNss UL UNs sOYON MOIS 4) (A)

JOUIUUD 4JOUN UO “OU g 7% % OSID “OU E *% | aBUOYDIA\U! asDaI¢ UoNoDIP aS1ORDI UI UNA JOY JOKE H (D)

voH}SaUUOD DYap UI UN JOOW UdyR UO.

o

= AIR EQUIPMENTS COMPAN

1.0 ORGANISATION INTRODUCTION

Air Equipments Company is incorporated in 1990 with an ambitious objective to

Manufacture Top Quality Twin Lobe Rotary Compressors / Exhausters complete with

accessories and instrumentations,

‘The Company is run by Technocrats with a rich Industrial Experience of more than three

decades,

In pursuit of the goal to achieve excellence, the firm has also acquired

1SO 9001-2000 Quality Assurance Certification in year 2002.

The Steady Growth achieved in last several years endorses Company's Customer Friendly

‘Approach focusing on total solution, backed up by prompt service.

Numerous applications covering a large spectrum of Industries are evolved, employing

these Blowers/Exhausters to their optimum level in India and abroad.

The product range consisting of 13 Air Cooled and 7 Water Cooled models covering

Capacity from 20 MY/Hr. to 14,000 M’/Hr. with pressure up to 1 Kg/CM? (Max.) in single

stage.

The other products/Packages manufactured include Tri-Lobe series of

Blowers, Mechanical Vacuum Boosters, Vacuum Systems, Vacuum Pumps,

Pneumatic Conveying Systems, De-watering Systems, Catalyst Unloading

System Centralized Vacuum Cleaning System etc.

(3)

== AIR EQUIPMENTS COMPANY

2.0 PRODUCT INTRODUCTION

2.1 DESCRIPTION & WORKING PRINCIPLE ( Drg. No. AS-3566, 3567 & 3568)

It is like a gear pump. The profile of Rotor is such that a minimum clearance is always

maintained between two Rotors and rotor & casing. Losses are kept low.

‘Two Rotors (006 & 007) or (11.306 & 11.307) rotate in casing(001) or (11.301). They are

driven through timing Gears (029 & 030) or (11.329 & 11.330).

The product offered against this Purchase Order is “Twin Lobe Type Rotary Blower /

Exhauster.” This is a positive displacement type, low pressure, high volume compressor

Jexhauster working on constant Volume characteristic.

The model offered is an air cooled machine with both side bearings and timing Gears Oil

lubricated by splash.

2.2 SPECIFICATION WITH SCOPE OF SUPPLY :

Twin Lobe type Rotary Exhauster Model AEC * 2.4 Complete with accessories

Machine Sr.No.

ACCESSORIES :

3), Base Frame Common for {Lr Prossure/Vacylim Gauge

Machine and Electric Motor

with Slide Rails for Motor

alignment.

Suction Silencer ‘Uatii) Non Return Valve

ili) Discharge Silencer xiv) Tee-Congfection

‘Uy Pressure/Vacyum Safety Valve UF By bag suction filter

v) Coarse filter ji) Cougling

+L) V Pulley for Machine ii) Coupling/Guara

(wP V Pulley for Electric Motor iv) Anti-Vibray6n Pads

‘Util V Betts vy) Rubpertetic cae in

iy) V Belt Guard

Ww vi) Mating Flange

vii) Foundgfion Bolts

@

Acme Air Equipments Co. Pvt. Lis

Plot No. $7/3+448, Phase-1, G.LD4

Vuiva, Ahexedabad-382 445.

2.3. TECHNICAL DETAILS :

1) Flow Medium

ii) Direction of Flow

ili). Direction of Rotation

(Viewed from drive shaft end.)

iv) Capacity

v) Pressure/Vacftim

vi) Machine Speed

vii) Shaft Power

vili) Electric Motor( Recommended)

(Custfner /AEC Scope)

ix) Motor Details

a) Make

b) Frame Size

©) Sr.No.

x) Material of Construction :

For Machine from AEC-9 to AEC-22 L-—~

a) Casing, Covers & Lobes

b) Rotor with Shaft

¢) Timing Gears

For Machine from AEC-26 to AEC-70

a) Casing, Covers & Lobes

b) Shaft

¢) Timing Gears

(5)

= AIR EQUIPMENTS COMPANY

AirlGfs

Vergfcal / Horizontal

Clockwise / Anti-clokwise

50 wir.

1000 wmwe

JERE REM

PLE KW

Bt «wi 744QReM

COL

ND-225S

_ LIAM 2430

Cast Iron as per |S 210 Grade FG-260

SG Iron Grade 400/15

20 MnCr5. Hardened & Ground

—NA-

: “Cast Iron as per IS 210 Grade FG-260

EN-8

20 MnCr5. Hardened & Ground

2 AIR EQUIPMENTS COMPANY

xi) Dimensions Gb eee dn v7 : Beroshuth we J

Length (L) =

Width (W) > 400

Height (4) 540

xii) Weight

Not wight Kg ' 359 bye.

(Machine + Accesories +Mqfor)

OPERATIONAL DATA :

ii) Oil Filling :

Drive Side max. {10Q cc Min. 5° cc

Non Drive Side Max. 2600 cc min. 1200 cc

ii) Oil Specification :

Commercial Grade motor Oil with a viscosity between 10° and 18°E at 50° C (Servo System

320 manufacture by Indian Oil Corporation or it's equivalent) from standard Company anda

thermal stability at 120° C in continuous operation.

A CAUTION

Using oil others than that specified above or reprocessed, local or unbranded oil or oil having

inferior characteristics will lead to serious damage to the machine. The warranty in such

case shall become null and void.

aA WARNING

© Oil filling Aop-up should not be done while Machine is running It must be done when

Machineis at standstill. :

© Don't smoke and don't approach flames during interventions for oil addition or change.

© Never perform welding operations near the machine when the oil in the system is full.

(6)

3

5 AIR EQUIPMENTS COMPANY

SO)

25

Drive Details:

a) Machine Pulley size (MM): ROO PCD x 45PB _ 49)

b) Motor Pulley Size (MM) . 212 Pod +4 ASPO _. C80)

) V Belts - 8PB- 2360 CO4ANos)

INPUT ENERGY :

Electric Power Loyos, Ot 577 Hz; 3 Phase , AC

4 WARNING / CAUTION :

‘Showing the possible damages to the machine or equipment, if instructions are not strictly

followed, Showing the risks of accident, if instructions are not followed

Warning : Do work, but with precautions.

Caution : Don't do.

ww NOTE: It gives useful information.

Before starting with operation of the machine and before any lubrication or maintenance

intervention, itis absolutely necessary that the OPERATOR has read and understoodall the

CAUTION and WARNING notes specified in the manual.

Besides, the machine is provided also with tags for the identification of specific risks, which

may cause damages both to the operator and the machine if not duly taken into account

We recommend to keep always the Handbook within Operator's reach, and to preserve it in

its integral form.

”

AIR EQUIPMENTS COMPANY

3.0 INSTALLATION :

Every consideration should be given to the proper installation of the

*) machine. The arrangement of the accessories, the pipe work, any noise dampening

measures, etc. that may be required during the plant operation shouldbe done.

)

5 Om

> WARNING / CAUTION :

) DO NOT OPEN SUCITON / DELIVERY PORTS UNTIL THE MACHINE IS INSTALLED.

» PROTECT MACHINE AGAINST DUST, MOISTURE AND MECHANICAL DAMAGE; TILL.

5 ITISINSTALLED AND COMMISSIONED.

34 Machine and Electric Motor :

) The following recommendations concerning installation to be observed when the machine

is supplied without a drive unit. I however, the machine and drive motor, including coupling

or belt drive, are supplied ready-to-install and mounted on a base plate (or foundation

frame),we advise clients to carry out corresponding checks to establish whether damage

has been sustained during transport or storage.

a) Machine directly coupled to the Electric Motor :

The machine & motor must be horizontal leveled on all sides. Their axes to be aligned in both

vertical and horizontal directions. The spacing between two halves of coupling to be strictly

maintained

B) V-Belt Drive:

‘The motor to be placed on slide rails. The machine and motor must be horizontal and their

shafts aligned parallel. The belts must be running perpendicular to the motor /machine axes.

Over tightening of V-belts should be avoided. Pulley to be fixed with lock washers

After assembling motor and machine on base frame place the assembly on foundation &

bolt properly. After this, verify that Rotors are rotating by hand with least effort. Fix safety

guard.

3.2 If machine is supplied complete with Drive : “

Ifmachine including complete drive is supplied ready to install and mounted on base frame,

customer must check for transit damage before laying the uniton foundation

(8)

AIR EQUIPMENTS COMPANY

) 3.3 PIPING:

Ifthe machine is not supplied as compact unit (i.e. duly connected with discharge silencer

and electric motor etc.) then piping on suction and delivery side should be so connected that

the machine does not get the direct load like bending, twisting, tension compression and

also shear. The pipe should be thicker and must be properly supported.

é A CAUTION :

ALL THE PIPELINES MUST BE CLEAR. PRESENCE OF ANY TYPE OF FOREIGN

i MATTER MAY CAUSE DAMAGE TOTHE MACHINE.

3.4 Accessories ::

> Following accessories are recommended in majority of cases.

3.4.1 Silencer ;- For suction and discharge. It brings down the noise level

3.4.2 Non Return Valve : It isolates machine from vacuum line, when m/c. is switched off.

Thus preventing its reverse turn

3.4.3 Suction Air Filter : Prevents entry of foreign material, dirt, dust into working chamber

This is bag type filter box and is an optional supply.

3.4.4 Grob Filter : This is coarse filter fixed on suction side

3.4.5 Safety Valve : It protects machine against excessive Pressure/Vacuum for Exhauster

this valve is fixed on the suction side and for Blower it is fixed on discharged side.

Monitoring Device :

The pressure gauge/ vacuumfjauge connected before or after the silencer is adequate to

monitor machine operation. The pressure gauge is isolated by a valve. Always shut the valve

off as soonas pressure is checked.

& (9)

AIR EQUIPMENTS COMPANY

att

4.0 COMMISSIONING :

5.0

5.1

5.2

Following checks are mandatory before commissioning.

a) Ensure Electrical Data are in line with suppliers operation manual, i.e.

‘Speed, Frequency, Voltage, Power Input, Heating etc.

b) Ensure that suction line is clear.

c) Ensure that machine is not loaded by piping.

d) Ensure that machine rotates freely by hand.

©) Ensure that pulleys are properly /coupling aligned.

f) Ensure Belt tension in accordance with the recommendation.

9) Fill up, Correct Quality & Quantity of oil in m/c on both the sides.

w NOTE : machine is not supplied with oil.

Operation & Maintenance :

Weekly Checks :

Frequency : Once per week after maxi. 50 operation hours.

a) Oillevel to be checked in stand-still condition of machine. In no case it should go below

min-mark of the sight glass.

5) Check the gaskets and seals : especially shaft oil seal and ensure that there is no

leakage of oil

©) Drain condensate through drain plug.

4) Observe machine during running. If abnormal sound is heard, the machine should be

stopped immediately, If machine continues to run in this condition, it may lead to, major

break down /damage to the machine.

Monthly Checks :

a) Ensure that safety valve functions properly.

») Clean Suction Filter Depending on quality of inlet air and mesh size; the filter may have

tobe cleaned more frequently.

©) Ensure proper V-Belt tension.

d) Fill up oil in both chambers as per recommended level in stand still condition,

(10)

AIR EQUIPMENTS COMPANY

CONTROL SHEET

sR.NO.: LO3040 _ DATE:

we.TyPE: AEC. 22°

m.o./s.fo.no.: 220U10- 14

CLIENT : 2? Ganain Dunkerly 4 Co. Lhe.

20

2 “20

Ss D

2 20

£20

ROTOR TO ROTOR ROTOR TO CASING

CLEARANCE CLEARANCE

ROTOR PAIR NO. : 1 AD

ROTOR TO ROTOR CLEARANCE, _. fol. 15 NOTE : S - Suction

ROTOR TO CASING CLEARANCE__-2£0 D - Discharge

GEAR PAIR NO. : T-Top

BACKLASH OF GEAR: __. azhoy B - Bottom

‘S’CLEARANCE A-I 35 All__+30

B+ -18) Bi_.25

as)

ments Co, Pvt, Little

Plot No, 57/32445, Phuse-L, Gul.Dal

Vatva, Ahmedabad-382 443,

TEST SHEET OF MACHINE TYPE. CO

CuENT ewe Cccapaane

DIFFERENTIAL PRESSUI IN KG / Cm?

oreo Pg OF

4-& AIR EQUIPMENTS COMPANY

wcume no: LOZ04O

capacity BE wab ihe

Drive Dirfot/V Belt

cis)

RECOMMENED MOTOR: _5'O_

ORDER NO ATE

r TEST AS PER :B5.-1571 PARTI

nozzteoia:__ 24a"

= . | wozaeconstk: 20.516

BAROMETRIC PRESS Pb,-_Z5" cm oF Ha

ya Detals of Reading us [1 ]fe2]s]«ls]el7

H_| Reading taken a Tous

Y_ | Dierentat Pressure lam Horan

V_[ vacuum atin rom of Hg

Pb_| Pressure of free air (Barometric Pr) mm Hg.

1 | Préssure drop scrose nozzle rim. of Wg

m__[ Depression afer nozzle eae

P2_| Absolute pressure after nozzle {Po - si] mm. of Hg,

tt | Temp. of tee ai c :

t Temp. of air after nozzle °C

1 [ Absolute omp of res air °« :

T_[ Absolute temp. of air after nozzle “x

Speed ofthe machine APM

W | oitage Vos |

A | oureen ‘Amps — 15,

TW Power inp to ho maton we,

Efficiency of the motor % | 4a _|

Efficiency of Drive 7.

Kwm | shait power of the machine kw [or 54

KxvT xvnxV Pyx36

FAD | Q= fe MB / be

Corrected Capacity a PM@IE3G} _ we/he_ [e-o7| tla

r Penns or Saeco HE

wae . 7 Insel oy

ide s9 SI

RPM

Amps:

Motor No. : —

For, Air Equipments Co,

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Amc TermsDocument1 pageAmc Termsdoc4printNo ratings yet

- Model - Design Od Drip For 1ha-A3Document1 pageModel - Design Od Drip For 1ha-A3doc4printNo ratings yet

- Technical Bid Volume 2 of 2Document381 pagesTechnical Bid Volume 2 of 2doc4printNo ratings yet

- Bar Cutting & Bending MachineDocument2 pagesBar Cutting & Bending Machinedoc4printNo ratings yet

- Consumable Spares PDFDocument22 pagesConsumable Spares PDFdoc4printNo ratings yet

- Technical Bid Volume 1 of 2Document285 pagesTechnical Bid Volume 1 of 2doc4printNo ratings yet

- 5s House KeepingDocument40 pages5s House Keepingdoc4printNo ratings yet

- GeneralTechnical BridgeDeckDocument11 pagesGeneralTechnical BridgeDeckdoc4printNo ratings yet

- 5s House KeepingDocument40 pages5s House Keepingdoc4printNo ratings yet

- Bracing For Wall FormworkDocument4 pagesBracing For Wall FormworkKrm ChariNo ratings yet

- 2010 10 18 Windlasten An Klettersystemen Langfassung enDocument19 pages2010 10 18 Windlasten An Klettersystemen Langfassung endoc4printNo ratings yet

- Types of FormworkDocument2 pagesTypes of Formworkdoc4printNo ratings yet

- GeneralTechnical BridgeDeckDocument11 pagesGeneralTechnical BridgeDeckdoc4printNo ratings yet

- Isarc2006-00111 200608141302Document6 pagesIsarc2006-00111 200608141302doc4printNo ratings yet

- © 1997 by Glenn Ballard. All RightsDocument14 pages© 1997 by Glenn Ballard. All Rightscolbert_ig2308No ratings yet

- Planning and Scheduling Consideration and Constraints in Automated Construction EnvironmentDocument8 pagesPlanning and Scheduling Consideration and Constraints in Automated Construction Environmentdoc4printNo ratings yet

- WBSDocument30 pagesWBSHoustonRiosNo ratings yet

- MHergunsel Thesis BIMDocument95 pagesMHergunsel Thesis BIMEfetobor Otomewo Joe100% (1)

- Pep Has Ew Bs DictionaryDocument13 pagesPep Has Ew Bs Dictionarydoc4printNo ratings yet

- WBSDocument30 pagesWBSHoustonRiosNo ratings yet

- Planning and Scheduling Consideration and Constraints in Automated Construction EnvironmentDocument8 pagesPlanning and Scheduling Consideration and Constraints in Automated Construction Environmentdoc4printNo ratings yet

- 1 FloorDesignGuideDocument18 pages1 FloorDesignGuidesayedwafiullahNo ratings yet

- Code of Practice For Formwork-AussieDocument37 pagesCode of Practice For Formwork-AussiePedro SousaNo ratings yet

- 011Document11 pages011doc4printNo ratings yet