Professional Documents

Culture Documents

Cleaning Guidelines for 30” Vibratory Sifter

Uploaded by

ananthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cleaning Guidelines for 30” Vibratory Sifter

Uploaded by

ananthCopyright:

Available Formats

VIBRATORY SIFTER (30)

1.0 SCOPE:

To provide guidelines to ensure effective line clearance of the area and equipment.

2.0 RESPONSIBILITY:

Operator, Production Officer.

3.0 PROCEDURE:

3.1 Ensure that the area is cleaned as per SOP: PRGN:xxxxx

3.2 Ensure that Vibratory Sifter (30) is cleaned as per the SOP: PRCLxxxx; Point No: 3.1 for

Batch change over/At the end of shift or is cleaned as per the SOP: PRCLxxxx; Point No: 3.2,

for Product change over/Expiry of use before date.

3.3 Ensure that all containers, documents and labels of previous product / batch are removed and

status board is updated.

3.4 Ensure that all the cervices and near by area is free from previous product.

3.5 Ensure that the sieves are cleaned, of correct product and check the integrity.

3.6 Ensure that all the gloves and accessories of previous product/batch are removed.

3.7 Ensure that gloves and accessories box is cleaned.

3.8 Check the Temperature, Relative Humidity and the Differential Pressure of the cubicle and

enter the same in the Batch Manufacturing Record.

3.9 Line clearance is given by Production Officer to start the next batch, after checking the

above-mentioned points, which is to be recorded in the Batch Manufacturing Record (BMR).

3.10 After checking all above points and the BMR, Final Line Clearance should be given by In

Process Quality Assurance Officer.

3.11 Record the observations in the format PRLC:xxxxx

4.0 ENCLOSURE:

4.1 Line Clearance Checklist for Vibratory Sifter, format PRLC:xxxxx

You might also like

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Standard Operating Procedure Department: ProductionDocument2 pagesStandard Operating Procedure Department: Productionasit_mNo ratings yet

- Good Distribution Practice A Complete Guide - 2020 EditionFrom EverandGood Distribution Practice A Complete Guide - 2020 EditionNo ratings yet

- SOP For Operation of Carton Coding MachineDocument3 pagesSOP For Operation of Carton Coding MachineJayant Kumar JhaNo ratings yet

- PV 01Document20 pagesPV 01Logan KandanNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- Capsule Process Validation ProtocolDocument28 pagesCapsule Process Validation ProtocolNavdeep ChaudharyNo ratings yet

- Defining Key Pharmaceutical TermsDocument18 pagesDefining Key Pharmaceutical TermsJavier Vich BerlangaNo ratings yet

- Operating Procedure for Pass BoxDocument2 pagesOperating Procedure for Pass BoxJai MurugeshNo ratings yet

- Leon Pharmaceuticals Raw Material SpecificationsDocument11 pagesLeon Pharmaceuticals Raw Material SpecificationsShagorShagor0% (1)

- Environmental MonitoringDocument19 pagesEnvironmental MonitoringHaroon RahimNo ratings yet

- Pharmaceutical Coating ProjectDocument27 pagesPharmaceutical Coating ProjectIbrahim BouzinaNo ratings yet

- GMP Trends-1Document177 pagesGMP Trends-1skvemulaNo ratings yet

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDocument77 pagesSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiNo ratings yet

- Xrex 50mg CapDocument20 pagesXrex 50mg Capziauddin bukhariNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- 3-Test Report of Amlodipine Besilate 3Document1 page3-Test Report of Amlodipine Besilate 3ShagorShagorNo ratings yet

- Annexure - II Product DevelopmentDocument50 pagesAnnexure - II Product DevelopmentLife PearlNo ratings yet

- Subject:: 1) Installation QualificationDocument2 pagesSubject:: 1) Installation QualificationDonig FermanianNo ratings yet

- GMP Facilities Set Up V2Document17 pagesGMP Facilities Set Up V2FakhriyahNur IbrahimNo ratings yet

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDocument4 pages2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniNo ratings yet

- Out of Specification Results InvestigationDocument91 pagesOut of Specification Results Investigationmunny000No ratings yet

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagorNo ratings yet

- Procedure for release of Drug Substance and ProductsDocument4 pagesProcedure for release of Drug Substance and Productsom shankar JhaNo ratings yet

- Visitors And Supervision Corridor Pharmaceutical Process AreasDocument1 pageVisitors And Supervision Corridor Pharmaceutical Process AreasBilal AbbasNo ratings yet

- Process Validation Protocol XXX 60 MG TabletsDocument33 pagesProcess Validation Protocol XXX 60 MG TabletsfarNo ratings yet

- Hold Time Study Ensures Clean Equipment QualityDocument11 pagesHold Time Study Ensures Clean Equipment QualityMarwa AhmedNo ratings yet

- Standard plant entry procedureDocument2 pagesStandard plant entry procedureBejoy KarimNo ratings yet

- Batch Manufacturing RecordsDocument4 pagesBatch Manufacturing RecordsDivyashree PatilNo ratings yet

- ASEAN TMHS GMP Training Chapter 9Document4 pagesASEAN TMHS GMP Training Chapter 9nsk79in@gmail.comNo ratings yet

- Batch Manufacturing Record - Capsule FinalDocument6 pagesBatch Manufacturing Record - Capsule FinalAkik Sasmal100% (1)

- Master Formula RecordDocument39 pagesMaster Formula RecordAbhijit kanavaje100% (1)

- 01 Disintegration Test For Tablets and CapsulesDocument30 pages01 Disintegration Test For Tablets and CapsulesmefroNo ratings yet

- 01 Cleaning Validation of Vibratory Sifter CLV 01Document2 pages01 Cleaning Validation of Vibratory Sifter CLV 01Ravi YadavNo ratings yet

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004No ratings yet

- 2-O&c of Paam Af 90 TDocument6 pages2-O&c of Paam Af 90 Tananth100% (1)

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarNo ratings yet

- Automatic Capsule Filling Machine Design QualificationDocument23 pagesAutomatic Capsule Filling Machine Design QualificationErum ManzoorNo ratings yet

- Operation & Cleaning Procedure for Octagonal BlenderDocument7 pagesOperation & Cleaning Procedure for Octagonal BlenderNgoc Sang HuynhNo ratings yet

- SOP For Handling of Market ComplaintDocument32 pagesSOP For Handling of Market Complaintsubbu_281No ratings yet

- SAMSHAMANIDocument7 pagesSAMSHAMANITrilochan AyurvedaNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- Urs PLMDocument17 pagesUrs PLMMohammadIsmailNo ratings yet

- QC Assay ValidationDocument102 pagesQC Assay Validation0921pyNo ratings yet

- WHO Certificate E120 2019Document4 pagesWHO Certificate E120 2019Risen ChemicalsNo ratings yet

- REVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSDocument8 pagesREVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSAndreas StathatosNo ratings yet

- Batch Manufacturing Record Requisition FormDocument1 pageBatch Manufacturing Record Requisition FormSolomon GamanuelNo ratings yet

- Sterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao FinalDocument54 pagesSterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao Finaltito1628100% (1)

- BPR - FP025-1 V-1Azinil 35ml PFSDocument17 pagesBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi YadavNo ratings yet

- Cleaning Validation ProcessDocument11 pagesCleaning Validation Processsamia khanNo ratings yet

- Facility Requirement SpecificationDocument3 pagesFacility Requirement SpecificationDarlenis RodriguezNo ratings yet

- Labaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalDocument33 pagesLabaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalgolamnobiNo ratings yet

- Guidance For Industry - PQR - 201312 PDFDocument9 pagesGuidance For Industry - PQR - 201312 PDFAshok LenkaNo ratings yet

- Actpro Al Drysyrup 3b001Document48 pagesActpro Al Drysyrup 3b001joerichladNo ratings yet

- URS Deviation ListDocument4 pagesURS Deviation ListjaiminNo ratings yet

- ASEAN Guideline Process OnDocument7 pagesASEAN Guideline Process OnVipin GuptaNo ratings yet

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- Sch. L1 Open LetterDocument4 pagesSch. L1 Open LetterananthNo ratings yet

- 43-O&C Strip Sealing MachineDocument6 pages43-O&C Strip Sealing MachineananthNo ratings yet

- 2-O&c of Paam Af 90 TDocument6 pages2-O&c of Paam Af 90 Tananth100% (1)

- FI MM SDintegration PDFDocument25 pagesFI MM SDintegration PDFGopa Kambagiri SwamyNo ratings yet

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- The NDAC (Gastroenterology & Hepatology) NewDocument4 pagesThe NDAC (Gastroenterology & Hepatology) NewananthNo ratings yet

- Certifying A Cleanroom To ISO 14644-1 Class 5Document3 pagesCertifying A Cleanroom To ISO 14644-1 Class 5Hassan HoudoudNo ratings yet

- 44-O&C Blister Packing MachineDocument7 pages44-O&C Blister Packing MachineananthNo ratings yet

- 57-Online Rejection Note, Material ReturnDocument3 pages57-Online Rejection Note, Material Returnananth100% (1)

- Specs RlamfiltersDocument4 pagesSpecs RlamfiltersananthNo ratings yet

- Ten Good Reasons To Learn Sas Software'S SQL Procedure: Sigurd W. Hermansen, Westat, Rockville, MDDocument5 pagesTen Good Reasons To Learn Sas Software'S SQL Procedure: Sigurd W. Hermansen, Westat, Rockville, MDashishkr3No ratings yet

- CR013 SOP Statistical Analysis PlanDocument4 pagesCR013 SOP Statistical Analysis PlanananthNo ratings yet

- Pratibha779 782Document4 pagesPratibha779 782BANDI N BHARADWAJNo ratings yet

- Pharma Licensing & Tech Transfer GuideDocument32 pagesPharma Licensing & Tech Transfer Guidevikram singh nitkNo ratings yet

- Heat SanitizationDocument2 pagesHeat SanitizationananthNo ratings yet

- Tips For Preparing For AuditDocument24 pagesTips For Preparing For Auditananth100% (1)

- Laminar Air Flow - For WebsiteDocument2 pagesLaminar Air Flow - For WebsiteananthNo ratings yet

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDocument7 pagesParticle Monitoring Requirements in Pharmaceutical CleanroomsananthNo ratings yet

- RHLlowresDocument4 pagesRHLlowresananthNo ratings yet

- Gamma Radiation Sterilization GuidanceDocument2 pagesGamma Radiation Sterilization Guidanceananth67% (3)

- Pharma Licensing & Tech Transfer GuideDocument32 pagesPharma Licensing & Tech Transfer Guidevikram singh nitkNo ratings yet

- CD09 - Iversen - Jorgen - 20130927 - Interpretation of The Output From The OpenCDISC ValidatorDocument23 pagesCD09 - Iversen - Jorgen - 20130927 - Interpretation of The Output From The OpenCDISC ValidatorananthNo ratings yet

- 1.3 Capsules and Effective Encapsulation - Shaikh ChandDocument62 pages1.3 Capsules and Effective Encapsulation - Shaikh Chandananth50% (2)

- Sterilization or Depyrogenation Validation - Non ProductDocument2 pagesSterilization or Depyrogenation Validation - Non ProductananthNo ratings yet

- Food Safety and Standards Rules 2011Document65 pagesFood Safety and Standards Rules 2011Anonymous EAineTizNo ratings yet

- Unplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing AreasDocument2 pagesUnplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing Areasananth100% (1)

- Repeal of The Enactment and Orders Hindi (15!11!2011)Document1 pageRepeal of The Enactment and Orders Hindi (15!11!2011)ananthNo ratings yet

- Presentation On Special Establishment Inspection by Sh. Venkateswaran VDocument21 pagesPresentation On Special Establishment Inspection by Sh. Venkateswaran VParikshit PrabhudesaiNo ratings yet

- The Tanzania Food, Drugs and Cosmetics Act, 2003Document89 pagesThe Tanzania Food, Drugs and Cosmetics Act, 2003ananthNo ratings yet

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Siren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetFrom EverandSiren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetRating: 5 out of 5 stars5/5 (3)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Cozy Minimalist Home: More Style, Less StuffFrom EverandCozy Minimalist Home: More Style, Less StuffRating: 4 out of 5 stars4/5 (154)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Modern Crochet…For the Beach Babe Goddess: Easy to Use StitchesFrom EverandModern Crochet…For the Beach Babe Goddess: Easy to Use StitchesRating: 3 out of 5 stars3/5 (2)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Layers of Meaning: Elements of Visual JournalingFrom EverandLayers of Meaning: Elements of Visual JournalingRating: 4 out of 5 stars4/5 (5)

- Fabric Manipulation: 150 Creative Sewing TechniquesFrom EverandFabric Manipulation: 150 Creative Sewing TechniquesRating: 4.5 out of 5 stars4.5/5 (13)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Crochet: Fun & Easy Patterns For BeginnersFrom EverandCrochet: Fun & Easy Patterns For BeginnersRating: 5 out of 5 stars5/5 (3)

- How to Dress: Secret styling tips from a fashion insiderFrom EverandHow to Dress: Secret styling tips from a fashion insiderRating: 4 out of 5 stars4/5 (1)

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsFrom EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsRating: 1.5 out of 5 stars1.5/5 (3)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsFrom EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsRating: 4.5 out of 5 stars4.5/5 (2)

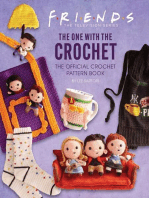

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsFrom EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsRating: 4 out of 5 stars4/5 (4)