Professional Documents

Culture Documents

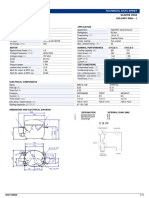

Preheater - Spec Sheet

Uploaded by

KAMINIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preheater - Spec Sheet

Uploaded by

KAMINICopyright:

Available Formats

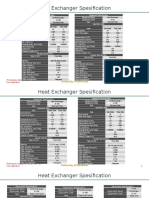

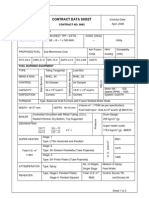

HEAT EXCHANGER SPECIFICATION

SHEET

MEK PRODUCTION PLANT

Equipment Number: HE 105

Description: Shell and Tube

GENERAL DETAILS

Size (mm)

Connected: Series |

Parallel

Heat Transfer Area (m2)

279.4-1830

TEMA Type

BEU

Orientation

Horizontal

PERFORMANCE OF UNIT

Fluid Allocation

Fluid Name

Flowrate, Total (kg/hr)

SHELL SIDE

Process Stream

1532

Vapour (kg/hr)

Liquid (kg/hr)

Non-condensable (kg/hr)

Density (kg/m3)

Vapour/Liquid

Viscosity Fluid (mPa.s)

Specific Heat (kJ/kg.K)

Thermal Conductivity

(W/m.K)

Temperature (C)

Latent Heat (kJ/kg)

Operating Pressure (bar)

Velocity (m/s)

Pressure Drop (bar)

Fouling Resistance

(m2.K/W)

Heat Exchanged (kW)

Allow.

TUBE SIDE

Steam

500

IN

0

1532

-

OUT

1142

390

-

IN

500

-

OUT

199

301

-

/788.54

2.65/737.11

2.55 /

2.54/ 861.3

/0.4008

0.0086/0.2453

0.0145 /

/2.147

1.637/2.338

1.914 /

/0.1412

0.0163/0.1301

0.0292 /

37

446.6

1.1

82.6

446.63

1.04908

152

2107.9

5

15.02

0.22408

Calc.

0.05092

Allow.

0.00018

180.5

Overall Clean (W/m2.K)

Overall Heat Transfer Coefficient

(W/m2.K)

1287

0.0145/

0.1773

1.913/ 53.009

0.0292/

0.6851

151.71

2108.6

4.97

10.17

0.25855 Calc.

0.028

0.0002

MTD Corrected (C)

Overall Fouled

(W/m2.K)

72.58

823.8

354.5

MECHANICAL DESIGN

Design Pressure (bar)

Design Temperature (K)

Number Of Passes

Corrosion Allowance (mm)

Material Of Construction

Tubes

Shell

No.

31Us

ID

(mm)

280

Baffles

Head Type

Weight (kg)

SHELL SIDE

5.51

470

1

3.18

Carbon Steel

OD(mm

Thickne

19.05

2.11

)

ss (mm)

Tube Pattern

90 Square

OD

Thickne

296.76

8.38

(mm)

ss (mm)

Type

Single Segmental

Spacing (mm)

120

Torispherical

Shell

360.3

TUBE SIDE

5.51

470

2

3.18

Carbon Steel

Length

Pitch

1830

25.4

(mm)

(mm)

Tube Type

Plain

Cut (%)

Position

L/D Ratio

Filled With Water

26.19

Horizontal

6.5

464.2

NB. Dimensions is

mm

SCHEMATIC OF SBA/MEK

You might also like

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- Specification Sheet Shell and Tube ExchangerDocument1 pageSpecification Sheet Shell and Tube ExchangerDanang PrakosaNo ratings yet

- Heat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriDocument1 pageHeat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriTrần Quang ThắngNo ratings yet

- Manual Service - TadiranDocument39 pagesManual Service - TadiranPaul Paulista100% (1)

- Htri Trial PDFDocument39 pagesHtri Trial PDFcroprobosNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Shell Tube Heat Exchanger CalculationDocument20 pagesShell Tube Heat Exchanger CalculationĐoàn TrangNo ratings yet

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Heat Exchanger Rating Data Sheet Dumai UnitsDocument1 pageHeat Exchanger Rating Data Sheet Dumai UnitsagusnnnNo ratings yet

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamNo ratings yet

- HTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFDocument14 pagesHTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFSivi NallamothuNo ratings yet

- HP Boiler Blowdown Hex - OPERATINGDocument1 pageHP Boiler Blowdown Hex - OPERATINGMuthuKumar ArunachalamNo ratings yet

- Output Summary: See Runtime Message Report For Warning MessagesDocument3 pagesOutput Summary: See Runtime Message Report For Warning MessagesSimranjeet SinghNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMuthuKumar ArunachalamNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- HEATEX Select PAU LZ1,2 PDFDocument1 pageHEATEX Select PAU LZ1,2 PDFTrần Khắc ĐộNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument2 pagesHeat Exchanger Specification Sheet SI UnitssalamrefighNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SidehaosfNo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument4 pagesAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNo ratings yet

- E 0211Document23 pagesE 0211Thinh ViproNo ratings yet

- Heat Exchanger Specification Sheet: MM M M Performance of One UnitDocument1 pageHeat Exchanger Specification Sheet: MM M M Performance of One UnitLucia D'AmbrosioNo ratings yet

- GL90TBDocument3 pagesGL90TBaaaNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Duct TypesDocument11 pagesDuct TypesJohn Vincent PajigarNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument2 pagesHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SidehaosfNo ratings yet

- Chillers HeatgggDocument43 pagesChillers HeatgggArif MohammedNo ratings yet

- Heat Exchanger Spec SheetDocument1 pageHeat Exchanger Spec SheetAnnabellee ChuaNo ratings yet

- Assignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueDocument27 pagesAssignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueAravind NaiduNo ratings yet

- HolDocument52 pagesHolDavidLagosNo ratings yet

- Databook Quhz-W40vha Aug2016Document72 pagesDatabook Quhz-W40vha Aug2016Vishal KhiroyaNo ratings yet

- Shell-And-Tube Heat Exchanger: Performance of One UnitDocument4 pagesShell-And-Tube Heat Exchanger: Performance of One UnitGio Ibarra MolinaNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument2 pagesHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideBruno CredidioNo ratings yet

- Tema SheetDocument2 pagesTema SheetMurad ALiNo ratings yet

- Assg 3 He Valve PnidDocument7 pagesAssg 3 He Valve PnidpangiastikaNo ratings yet

- TANK Module: Sample PrintoutDocument17 pagesTANK Module: Sample PrintoutAnonymous J1vjrU2No ratings yet

- Technical Dairy: 1-Boiler and Auxillaries Main BoilerDocument59 pagesTechnical Dairy: 1-Boiler and Auxillaries Main Boilersuleman247No ratings yet

- Flat Work IronerDocument33 pagesFlat Work IronerAbid HussainNo ratings yet

- (SX SP) Swimming PoolDocument2 pages(SX SP) Swimming PoolFadi EidNo ratings yet

- Tranter PHE GCD-09 X 43Document4 pagesTranter PHE GCD-09 X 43alokNo ratings yet

- Spesifikasi AlatDocument5 pagesSpesifikasi AlatLisna RohmawatiNo ratings yet

- Datasheet of Equipment - ANNAMDocument8 pagesDatasheet of Equipment - ANNAMhuyly34No ratings yet

- Cooling TowerDocument14 pagesCooling TowerAbdulla DoskiNo ratings yet

- Características Evaporador ECO Mod. CTE125L8Document4 pagesCaracterísticas Evaporador ECO Mod. CTE125L8RodolfoNo ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Mini Chillers InventorDocument2 pagesMini Chillers Inventormmihmmih2003No ratings yet

- Rcug - 120ahyz1Document1 pageRcug - 120ahyz1Tran Anh TuanNo ratings yet

- Kelvion HEXDocument2 pagesKelvion HEXHakkı YılmazNo ratings yet

- Spek UAL MalaysiaDocument1 pageSpek UAL MalaysiaRiski SuhardinataNo ratings yet

- GL80AADocument2 pagesGL80AAdrissdragon7No ratings yet

- Parameter 500 MWDocument3 pagesParameter 500 MWBalraj Padmashali100% (1)

- Aspen 1 PDFDocument6 pagesAspen 1 PDFQamar AbbasNo ratings yet

- Basic Data Sheet - FormatDocument18 pagesBasic Data Sheet - FormatAkaash JainNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet