Professional Documents

Culture Documents

Hazardous Area Equipment

Hazardous Area Equipment

Uploaded by

Shah JayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazardous Area Equipment

Hazardous Area Equipment

Uploaded by

Shah JayCopyright:

Available Formats

HAZARDOUS AREA EQUIPMENT

Zone Classification

Definition

The classification of a Zone is a complex problem with the main factors to consider:

The probability of the presence of Gas or Vapour or Dust

The quantity and duration of hazardous environment

The amount of ventilation

The nature of Gas being lighter or heavier than Air

The division of the plants or parts into Zones is generally undertaken by the supervisory

authority in that industry with process engineers / chemists at the design and / or construction

stage.

Zone 0

Continuously Hazardous ( Protection Technique Allowed)

Ex ia Intrinsically Safe

Ex ma Encapsulation

Zone 1

Frequently Hazardous (Protection Technique Allowed)

Ex ib Intrinsic Safety

Ex d Flameproof

Ex e Increased Safety

Ex p Pressurized or Purged

Ex s Special Protection

Zone 2

Infrequently Hazardous (Protection Technique Allowed)

Ex n Non-sparking

Typical Example of Zone

HAZARDOUS AREA EQUIPMENT

Classification of Hazardous Areas

Definition

Explosive gas vapours atmospheres

Combustible Dust

Specific occupancies

Group Classification

Hazardous area equipment is specified in terms of the types of gases present or where dust

is present.

Group I Underground mining applications

Group II Industries other than mining

Group III Industries having dust or fibres

Group I :

Equipment has a representative gas of Methane and all equipment used in underground mining

applications fall into this category.

Group II:

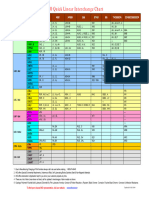

As shown in the below table this Group II is segmented into three different representative gas

groups, IIA, IIB and IIC.

Group III:

Equipment is segmented concerning the thickness of the dust Practice A and B regarding

maximum surface temperatures relating to the ignition temperatures of the material. The Group

III dusts are segmented into three different representative dusts IIIA, IIIB and IIIC, with the

worst case being IIIC for conductive dusts.

Group Classification and Representative Gas Data Table

Group Classification

Representative Gas

I

Methane

IIA

Propane

IIB

Ethylene

IIC

Hydrogen, Acetylene

Equipment Protection Levels EPLs

The introduction of Equipment Protection Levels ( EPLs ) is provided to give further segregation

of products and protection techniques for hazardous areas. The EPLs consider assessment of the

risk involved with an installation and the suitable equipment protection techniques. These EPLs

are generally in line with Zones, however on risk assessment a higher EPL may be used to

provide higher protection. Where an EPL is specified on a hazardous document it takes

precedence over the Zone classification.

Group Classification and Zone Data Table

Group I

Group II

Zone 0 EPL Ma

Zone 0 EPL Ga

Zone 1 EPL Ma and Mb Zone 1 EPL Ga, Gb

Zone 2 EPL Ga, Gb and Gc

Group III

Zone 20 EPL Da

Zone 21 EPL Da, Db

Zone 22 EPL Da, Db and Dc

HAZARDOUS AREA EQUIPMENT

Zone Protection Techniques

Definition

The protection technique is a specific process with negates one of the three components of

combustion.

The Australian standards are based on the International Electrotechnical Commission IEC

standards and with the CENELEC standards beings similar and now being harmonised with IEC,

in respect of Zone classification, Gas groups temperature ratings and testing methods.

Types of Application and Protection Techniques Data Table

Zone

Techniques Data

Table

Protection

HAZARDOUS AREAS AND HAZARDOUS AREA EQUIPMENT

Explosion Protection Techniques

Types of Protection Techniques Data Table

Method

Symb

Type of Protection

ol

Exclusion

Ex tD Dust-excluding ignition proof

Ex m Encapsulation

Explosion

containment

Ex n

Non-sparking (hermetically sealed devices, sealed devices

and restricted breathing)

Ex p

Pressurized enclosure/Rooms

Ex q

Sand-filled (powder filling)

Ex d

Flameproof enclosure

Energy Limitation Ex i

Intrinsic safety

Dilution

Ex v

Ventilation

Avoidance of

ignition

Ex e

Increased safety

Ex n

Non-sparking (inherently non-sparking)

Types of Application and Protection Techniques Data Table

You might also like

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- RefStd 1110 002 H v090201 Fluid-List-For-PC-NGDocument5 pagesRefStd 1110 002 H v090201 Fluid-List-For-PC-NGlucianduNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area GuidekarthipetroNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area Guidescribd8421100% (1)

- Hazardous Areas Are Defined by Three Main CriteriaDocument10 pagesHazardous Areas Are Defined by Three Main CriteriaviddyadrianNo ratings yet

- Hazardous Area Classification QuestionsDocument9 pagesHazardous Area Classification QuestionsVraja KisoriNo ratings yet

- Hazardous Areas: Gases and VapoursDocument10 pagesHazardous Areas: Gases and VapoursShah JayNo ratings yet

- Hazardous Area CllassificationDocument8 pagesHazardous Area CllassificationUlhas VajreNo ratings yet

- Hazardous Area Classifications and ProtectionsDocument8 pagesHazardous Area Classifications and ProtectionsUday GokhaleNo ratings yet

- Flametec Data SheetDocument1 pageFlametec Data SheetDang Ngoc PhuNo ratings yet

- ATEX-affisch MaluxDocument1 pageATEX-affisch MaluxHomer SilvaNo ratings yet

- Understanding Hazardous Area Classification PDFDocument7 pagesUnderstanding Hazardous Area Classification PDFNaveed IrshadNo ratings yet

- Hazardous Area BasicsDocument10 pagesHazardous Area BasicsDig ChauhanNo ratings yet

- Hazardous Area Classification and DivisionDocument51 pagesHazardous Area Classification and DivisionK LandryNo ratings yet

- ATEXDocument12 pagesATEXJacqueline AdamsNo ratings yet

- Poster Areas ClassificadasDocument1 pagePoster Areas ClassificadasYuri WentzcovitchNo ratings yet

- Hazardous Areas Are Defined by Three Main CriteriaDocument5 pagesHazardous Areas Are Defined by Three Main Criteriaswarm62No ratings yet

- AtexDocument2 pagesAtexmousypusaNo ratings yet

- Basics of Explosion Protection - IecDocument4 pagesBasics of Explosion Protection - IecbenounaomarNo ratings yet

- Chemical Engineering - Hazardous Area ClassificationDocument1 pageChemical Engineering - Hazardous Area Classificationsl1828No ratings yet

- Understanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety ExpertsDocument19 pagesUnderstanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety Experts04422236558No ratings yet

- Hazardous AREA ClassificationDocument10 pagesHazardous AREA Classificationfarzam100% (1)

- Apparatus ClassificationDocument1 pageApparatus Classificationmohamed abd el razekNo ratings yet

- Hazardous Area InformationDocument49 pagesHazardous Area Informationafic219473No ratings yet

- Atex GuideDocument6 pagesAtex GuideValiNo ratings yet

- Fundamentos ATEXDocument20 pagesFundamentos ATEXNelson_1492No ratings yet

- Hazardous Area Classification & Intrinsic SafetyDocument35 pagesHazardous Area Classification & Intrinsic SafetyMukesh C ChavanNo ratings yet

- Hazardous Area ClassificationDocument4 pagesHazardous Area ClassificationPawan PatilNo ratings yet

- Explosion Protection and Intrinsic Safety 1012Document25 pagesExplosion Protection and Intrinsic Safety 1012ArdvarkNo ratings yet

- Harmony Product Application Guide For Harmony Rack Block I O Used in Class I Division 2 HazardousDocument17 pagesHarmony Product Application Guide For Harmony Rack Block I O Used in Class I Division 2 HazardousYhony Gamarra VargasNo ratings yet

- Ringkasan Chapter 7 Explosion KIDocument4 pagesRingkasan Chapter 7 Explosion KIRama SlaluhappyNo ratings yet

- Hazardous Area ClassificationDocument2 pagesHazardous Area ClassificationRatnakar Pai100% (1)

- XP Rating ExplanationDocument5 pagesXP Rating ExplanationTom SwiatekNo ratings yet

- Electrical Equipment in Hazardous Areas - WikiDocument6 pagesElectrical Equipment in Hazardous Areas - Wikis kNo ratings yet

- Hazardous Area ClassificationDocument36 pagesHazardous Area Classificationvenkeeku100% (1)

- Hazardous Area Classification - JacobsDocument53 pagesHazardous Area Classification - JacobsPedro Luis Choque Mamani100% (1)

- CA-4079 - Hand Book - 02062018Document49 pagesCA-4079 - Hand Book - 02062018Mohamed RizwanNo ratings yet

- Norma AtexDocument4 pagesNorma AtexV_VicNo ratings yet

- Hazardous Area Classification - JacobsDocument53 pagesHazardous Area Classification - Jacobskarthikraja21No ratings yet

- General Principles For Hazrdous Area ClassificationDocument13 pagesGeneral Principles For Hazrdous Area ClassificationwaheedNo ratings yet

- MAXON PresentationDocument27 pagesMAXON PresentationJaroslav KurucNo ratings yet

- Hazardous Areas MaterialsDocument100 pagesHazardous Areas MaterialsAnonymous 75gQGb1kQ3100% (1)

- At Ex Explosion GuidelinesDocument16 pagesAt Ex Explosion GuidelinesjovanivanNo ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- Petrel Guide To Hazardous Areas: Atex DirectiveDocument4 pagesPetrel Guide To Hazardous Areas: Atex DirectivePrabhu SingapuraNo ratings yet

- Oil&Gas Hazard ZonesDocument31 pagesOil&Gas Hazard ZonesrakicbgNo ratings yet

- ATEX and IECEX Markings ExplainedDocument4 pagesATEX and IECEX Markings ExplainedarmandogavinoNo ratings yet

- Appendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsDocument12 pagesAppendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsNaveedNo ratings yet

- Hazardous Area TerminologyDocument7 pagesHazardous Area TerminologyDayo IdowuNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Handbook of Air Pollution Prevention and ControlFrom EverandHandbook of Air Pollution Prevention and ControlRating: 5 out of 5 stars5/5 (2)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- CISA Exam - Testing Concept-Fire Suppression Systems (Domain-5)From EverandCISA Exam - Testing Concept-Fire Suppression Systems (Domain-5)Rating: 5 out of 5 stars5/5 (1)

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Internet Banking PDFDocument2 pagesInternet Banking PDFjay shahNo ratings yet

- APPLICATION FORM For Delivery Channel Services: Date of Birth: (DD-MM-YY)Document2 pagesAPPLICATION FORM For Delivery Channel Services: Date of Birth: (DD-MM-YY)jay shahNo ratings yet

- Single Phase T'MerDocument4 pagesSingle Phase T'Merjay shahNo ratings yet

- APPLICATION FORM For Delivery Channel Services: Date of Birth: (DD-MM-YY)Document2 pagesAPPLICATION FORM For Delivery Channel Services: Date of Birth: (DD-MM-YY)jay shahNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument2 pagesCurriculum Vitae: Career Objectivejay shahNo ratings yet

- Electrical MCC Room Panel Cutout & FixingDocument1 pageElectrical MCC Room Panel Cutout & Fixingjay shahNo ratings yet

- Electrical MCC Room Panel Cutout & FixingDocument1 pageElectrical MCC Room Panel Cutout & Fixingjay shahNo ratings yet

- T'Mer Basic &bushingDocument3 pagesT'Mer Basic &bushingjay shahNo ratings yet

- A. DC Resistance Test: PracticalDocument3 pagesA. DC Resistance Test: Practicaljay shahNo ratings yet

- Cable Rating FactorDocument2 pagesCable Rating Factorjay shahNo ratings yet

- Cross BusbarDocument1 pageCross Busbarjay shahNo ratings yet

- Difference Between SINGLE-PHASE VERSES THREE-PhaseDocument1 pageDifference Between SINGLE-PHASE VERSES THREE-Phasejay shahNo ratings yet

- CableDocument2 pagesCablejay shahNo ratings yet

- Insulation LevelsDocument3 pagesInsulation Levelsjay shahNo ratings yet

- Vector GroupDocument2 pagesVector Groupjay shahNo ratings yet

- PTC1Document5 pagesPTC1jay shahNo ratings yet

- SWG To Square MM Conversion (Cable)Document3 pagesSWG To Square MM Conversion (Cable)jay shahNo ratings yet

- Pickup Point (CT & PT)Document3 pagesPickup Point (CT & PT)jay shahNo ratings yet

- 배관 두께 계산 ASEM A53 부터 ASTM A312 재질의 두께 계산을 테이블화 하여 참조할 수 있는 자료Document14 pages배관 두께 계산 ASEM A53 부터 ASTM A312 재질의 두께 계산을 테이블화 하여 참조할 수 있는 자료Kim JungdaeNo ratings yet

- 603HBS 14-KD-0001 r0 General SLDDocument4 pages603HBS 14-KD-0001 r0 General SLDrahul SinghNo ratings yet

- All India Senior School Certifcate Examination: Divine Child School MehsanaDocument19 pagesAll India Senior School Certifcate Examination: Divine Child School MehsanaAshishNo ratings yet

- Linde - LBPP HistoryDocument9 pagesLinde - LBPP Historynacho_16727No ratings yet

- Bacharach Stinger 2000 2000Document2 pagesBacharach Stinger 2000 2000Chethaka Lankara SilvaNo ratings yet

- Fuels and CombustionDocument47 pagesFuels and CombustionMelai Pinlac-AdanteNo ratings yet

- Fire Extinguisher Classes - CanadaDocument2 pagesFire Extinguisher Classes - CanadamuruganandamdesinghNo ratings yet

- Worksheet Class 11 25-9-23-29-9-23 - 23092023 - 111356Document4 pagesWorksheet Class 11 25-9-23-29-9-23 - 23092023 - 111356Adithya PramodNo ratings yet

- 8ed1 AirPollutionDocument1 page8ed1 AirPollutionLamis AhmedNo ratings yet

- Fuels & Combustion Technology (Major Elective Û I) (Chemical Group)Document2 pagesFuels & Combustion Technology (Major Elective Û I) (Chemical Group)raumil123759033% (3)

- 1998-Plasma Reforming of MethaneDocument8 pages1998-Plasma Reforming of MethaneakkusawNo ratings yet

- CCUS G20 Report 1702179946Document224 pagesCCUS G20 Report 1702179946MT HazrieNo ratings yet

- Landfill and Digester Gas SpecificationsDocument6 pagesLandfill and Digester Gas Specificationssiyavash seifNo ratings yet

- Laboratory Leaching CementationDocument6 pagesLaboratory Leaching CementationRonNo ratings yet

- Hgu: Process Flow Diangram: CN BLDocument1 pageHgu: Process Flow Diangram: CN BLAakashNo ratings yet

- Gbhe-Peg-015 Practical Guide On The Reduction of DiscDocument87 pagesGbhe-Peg-015 Practical Guide On The Reduction of DiscjrfmlNo ratings yet

- 2012 Internation Pet Refining Journal India Lube Paper-TECHNOLOGY UOP Oct12Document10 pages2012 Internation Pet Refining Journal India Lube Paper-TECHNOLOGY UOP Oct12Chatt JrNo ratings yet

- PMS Self StudyDocument16 pagesPMS Self StudyAbhishek KabburNo ratings yet

- EvaporationDocument49 pagesEvaporationYOSEF BUDIMANNo ratings yet

- Hydrogen 14 Session 19 - MNMDocument95 pagesHydrogen 14 Session 19 - MNMChakravarthy BharathNo ratings yet

- IKO Linear Interchange ChartDocument1 pageIKO Linear Interchange ChartleviettienCTMNo ratings yet

- Catalytic CrackingDocument43 pagesCatalytic Crackingjeygar12100% (2)

- Bureau of Fire Protection Tarlac City Fire StationDocument86 pagesBureau of Fire Protection Tarlac City Fire Stationgelo twofiveNo ratings yet

- Laboratory ExperimentsDocument9 pagesLaboratory ExperimentsSandra MacatangayNo ratings yet

- Energy BalancesDocument3 pagesEnergy BalancesDaniel DubeNo ratings yet

- Lecture Note 1 (Introduction)Document29 pagesLecture Note 1 (Introduction)hkaqlqNo ratings yet

- Le ChatelierDocument11 pagesLe ChatelierWendy TangNo ratings yet

- Gea Membrane Filtration Brochure For Dairy IndustryDocument24 pagesGea Membrane Filtration Brochure For Dairy Industryjoaquincasaklen50% (2)

- 10 Juha AnttilaDocument14 pages10 Juha AnttilaRAJNISH KUMARNo ratings yet