Professional Documents

Culture Documents

Cycle Time

Uploaded by

WeimingTanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cycle Time

Uploaded by

WeimingTanCopyright:

Available Formats

Cycle Time: Cycle time is the total time taken from a lot start of blank silicon wafers

into the fabrication process until the fabrication of the devices on the wafers is

complete. Cycle time is especially important in the semiconductor industry is

because prices of products are the highest in the early part of their lifecycle,

therefore earning the most revenue. Cycle time also affects other aspects such as

yield and qualification of products and tools. To improve yield, more knowledge

concerning the process has to be attained, of which the analysis can only be done

only after a lot has went through the full process. Therefore, cycle time directly

affects the learning speed of the process. Products and tools also have to be

qualified before entering the market and being released for production respectively.

Hence, the speed of qualification heavily depends on cycle time which affects how

fast the production or test lots are able to undergo analysis.

Misprocess: Misprocesses are deviations during wafer fabrication mainly arising due

to human processing errors. This often results in downgrading, reworking or wafer

loss (scrap). If a misprocessed wafer is allowed to continue down the production

process, many redundant and costly processing might be needed. As a result, wafer

misprocessing can have significant economic impact for the company. Therefore,

certain methodologies and steps are taken to reduce or eliminate the risk of wafer

misprocess.

You might also like

- Chapter 5Document23 pagesChapter 5gideykibrom80No ratings yet

- Industrial Training Project ProposalDocument14 pagesIndustrial Training Project ProposalHafizWahidNo ratings yet

- Six Sigma Lean Principles 152Document13 pagesSix Sigma Lean Principles 152starsankarNo ratings yet

- Chapter No Chapter Name 1 2 Company Profile 3 An Over View of Company Department 4 Production ProcessDocument28 pagesChapter No Chapter Name 1 2 Company Profile 3 An Over View of Company Department 4 Production ProcessNithin Raj AnchanNo ratings yet

- Review On Cycle Time Reduction in Manufacturing Industries: Hiten Patel, Sanjay C. ShahDocument3 pagesReview On Cycle Time Reduction in Manufacturing Industries: Hiten Patel, Sanjay C. ShahNeev AgravalNo ratings yet

- Scientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelDocument4 pagesScientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelSofiaProtopsaltiNo ratings yet

- FCC Unit TURNAROUNDDocument6 pagesFCC Unit TURNAROUNDGroover ContrerasNo ratings yet

- Overview of Semiconductor ManufacturingDocument6 pagesOverview of Semiconductor ManufacturingCarlos A. GaviriaNo ratings yet

- Intro To SMS PDFDocument6 pagesIntro To SMS PDFjoseNo ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Production Control N Capacity CalDocument23 pagesProduction Control N Capacity CalSHIKHA SINGHNo ratings yet

- Batch Vs ContinousDocument5 pagesBatch Vs ContinousYosephine Intan AyuningtyasNo ratings yet

- Minor ProjectDocument11 pagesMinor ProjectRajan RajNo ratings yet

- Case Study 3 Aylesbury Pressings, Roddy McGuinn and Martin Toher.Document6 pagesCase Study 3 Aylesbury Pressings, Roddy McGuinn and Martin Toher.Joe Potter100% (1)

- Different Types of Time in ManufacturingDocument15 pagesDifferent Types of Time in ManufacturingkazuNo ratings yet

- Lec 1 Production SystemsDocument39 pagesLec 1 Production SystemslympazzkarimiNo ratings yet

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Dies and MouldsDocument19 pagesDies and MouldsTomas Trojci TrojcakNo ratings yet

- Chapter 1 - Introduction To Production TechnologyDocument29 pagesChapter 1 - Introduction To Production TechnologyAmeer Bakry ZulkiffliNo ratings yet

- Subject - Lean ManagementDocument12 pagesSubject - Lean ManagementJyoti RawalNo ratings yet

- 4-6 7001A 2-16 A 7 Constraints Time Traps UoC7001A - 91558NSW CLR PDFDocument15 pages4-6 7001A 2-16 A 7 Constraints Time Traps UoC7001A - 91558NSW CLR PDFraiyanduNo ratings yet

- Hemming ProcessDocument4 pagesHemming Processtoyota952No ratings yet

- The Nature of Production: InputDocument9 pagesThe Nature of Production: InputDacia HigginsNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- The Fabrication & Baking Industries LTD (The FBI)Document6 pagesThe Fabrication & Baking Industries LTD (The FBI)pksnithNo ratings yet

- Machining Operations-: Cycle TimeDocument25 pagesMachining Operations-: Cycle Timenurul_mohamed_10No ratings yet

- English Type 2020 EditbbbDocument15 pagesEnglish Type 2020 EditbbbChanuka PereraNo ratings yet

- Assignment 9 TQM POLIDARIO PDFDocument9 pagesAssignment 9 TQM POLIDARIO PDFALIAHDAYNE POLIDARIONo ratings yet

- HSE Management in Life Cycle of Construction ProjectDocument110 pagesHSE Management in Life Cycle of Construction Projectdeven singhNo ratings yet

- Corus 13 FullDocument4 pagesCorus 13 FullVarun PrasherNo ratings yet

- Wellbore CleanDocument84 pagesWellbore Cleanveljkosx100% (1)

- Lead TimeDocument2 pagesLead TimelawbondNo ratings yet

- Different Assembly Processes in Electronic ManufacturingDocument4 pagesDifferent Assembly Processes in Electronic ManufacturingMORRIS ANUNDANo ratings yet

- Case StudyDocument10 pagesCase Studyhasan_waqar2004No ratings yet

- Variuos Issues in Production PlanningDocument8 pagesVariuos Issues in Production PlanningJyoti RawalNo ratings yet

- Soft Vs Hard ToolingDocument17 pagesSoft Vs Hard ToolingSurya Raghavendar100% (1)

- Factors Affecting Production Process 23Document1 pageFactors Affecting Production Process 23Cinan SatharNo ratings yet

- Vasudhri Tooling LTD SectionE Group10Document6 pagesVasudhri Tooling LTD SectionE Group10Sasikumar Parupalli100% (2)

- Soft ToolingDocument5 pagesSoft ToolingArun PrasadNo ratings yet

- Lean Manufacturing DefinitionDocument5 pagesLean Manufacturing DefinitionLoymeNo ratings yet

- Factory Project PDFDocument16 pagesFactory Project PDFNikunj JadawalaNo ratings yet

- SMED in The Process Industries PDFDocument7 pagesSMED in The Process Industries PDFEduardo LópezNo ratings yet

- Blitz Case Write-UpDocument2 pagesBlitz Case Write-Upvivek100% (2)

- Set-Up Time Losses in Style VariationDocument28 pagesSet-Up Time Losses in Style VariationVachan Abhilekh ThakurNo ratings yet

- Methods of ProductionDocument5 pagesMethods of ProductionOshane BaileyNo ratings yet

- Preparing For Successful Design TransferDocument7 pagesPreparing For Successful Design TransferRahul Dhingra100% (1)

- Cellular ManufacturingDocument61 pagesCellular Manufacturingapi-3852736100% (1)

- Case Study 3 Final. Aylesbury Pressings, Roddy McGuinn and Martin Toher.Document8 pagesCase Study 3 Final. Aylesbury Pressings, Roddy McGuinn and Martin Toher.Felicia Brown0% (1)

- Operations Compedium IIFTDocument41 pagesOperations Compedium IIFTSOUVIK ROY MBA 2021-23 (Delhi)No ratings yet

- Technology Life Cycle: Upasna Sharma 45 Sakshi Uppal 44 Kritika Dua 59 Samahita Ghosh 57Document22 pagesTechnology Life Cycle: Upasna Sharma 45 Sakshi Uppal 44 Kritika Dua 59 Samahita Ghosh 57Vasundhara PahujaNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- MEE 207 Lecture 1Document11 pagesMEE 207 Lecture 1OLUWASEYI OJUOLANo ratings yet

- What Is Continuous ProductionDocument7 pagesWhat Is Continuous ProductionUsh RuffNo ratings yet

- Basics of TestingDocument47 pagesBasics of TestingEE166Srushti Vibhute.No ratings yet

- What Is Lean Manufacturing?Document20 pagesWhat Is Lean Manufacturing?ramyasureshiyerNo ratings yet

- Process Design and AnalysisDocument20 pagesProcess Design and AnalysisSaroj MishraNo ratings yet

- Technology Life CycleDocument8 pagesTechnology Life Cyclesanamkothari91No ratings yet

- Variuos Issues in Production PlanningDocument10 pagesVariuos Issues in Production PlanningJyoti RawalNo ratings yet

- Internship Report - Manufacturing CompanyDocument57 pagesInternship Report - Manufacturing CompanyJennifer Douglas100% (3)

- Benefits Parallel ProcessingDocument4 pagesBenefits Parallel ProcessingAnnaKarenina56No ratings yet

- Ch1105 Materials Science For Chemical EngineersDocument2 pagesCh1105 Materials Science For Chemical EngineersWeimingTanNo ratings yet

- Welcome To Formulation: Zaher@ntu - Edu.sgDocument29 pagesWelcome To Formulation: Zaher@ntu - Edu.sgWeimingTanNo ratings yet

- Course Outline - Lecture Course Outline LectureDocument71 pagesCourse Outline - Lecture Course Outline LectureWeimingTanNo ratings yet

- Goboard LCD Manual GuideDocument6 pagesGoboard LCD Manual GuideWeimingTanNo ratings yet

- Appendix M: Methodology of Equipment Sizing: Mixer and SplitterDocument6 pagesAppendix M: Methodology of Equipment Sizing: Mixer and SplitterWeimingTanNo ratings yet

- CH4303-Bioseparation Tutorial 3Document2 pagesCH4303-Bioseparation Tutorial 3WeimingTanNo ratings yet

- Tutorial 3 AnswersDocument2 pagesTutorial 3 AnswersWeimingTanNo ratings yet

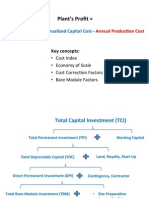

- Summary Slides For The Economics ChapterDocument3 pagesSummary Slides For The Economics ChapterWeimingTanNo ratings yet

- HxequnsDocument2 pagesHxequnsOmar MahmoudNo ratings yet

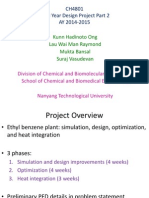

- FYDP Part 2 Course InformationDocument4 pagesFYDP Part 2 Course InformationWeimingTanNo ratings yet

- Lecture Notes Chapter1-9Document296 pagesLecture Notes Chapter1-9WeimingTanNo ratings yet

- Homework 5Document1 pageHomework 5WeimingTanNo ratings yet

- CH4303 LT1 Excercise His TagDocument2 pagesCH4303 LT1 Excercise His TagWeimingTanNo ratings yet

- Chap. 5 Questions and VocabDocument26 pagesChap. 5 Questions and VocabWeimingTanNo ratings yet

- CHE4250 CHP 1 NotesDocument60 pagesCHE4250 CHP 1 NotesWeimingTanNo ratings yet

- CH4303 LT1 Excercise His TagDocument2 pagesCH4303 LT1 Excercise His TagWeimingTanNo ratings yet

- Tut 1 - ch4250 - 2014 Sem 2 - Mfwang NtuDocument2 pagesTut 1 - ch4250 - 2014 Sem 2 - Mfwang NtuWeimingTanNo ratings yet

- Homework 4Document1 pageHomework 4WeimingTanNo ratings yet

- Summary Slides For The Economics ChapterDocument3 pagesSummary Slides For The Economics ChapterWeimingTanNo ratings yet

- FYDP Part 2 Course InformationDocument4 pagesFYDP Part 2 Course InformationWeimingTanNo ratings yet

- FYDP Part 2 BriefingDocument12 pagesFYDP Part 2 BriefingWeimingTanNo ratings yet