Professional Documents

Culture Documents

D3 - Buckling Analysis (Designer)

Uploaded by

Chan Keng ChunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D3 - Buckling Analysis (Designer)

Uploaded by

Chan Keng ChunCopyright:

Available Formats

Buckling Analysis

Step

00

Overview of Buckling Analysis

Buckling Analysis

Buckling analysis evaluates the instability of a structure subjected to compression loads.

The instability of the structure due to buckling is not dependent on the strengths of materials. Rather it is closely related to the

geometric shape, stiffness and boundary conditions of the structure.

When an axial compressive force is acting at the end of a long and slender structure, only the axial deformation proportional to the

magnitude of the load takes place. However, if the magnitude exceeds its critical point, the structure undergoes large deformation

without further increasing the load.

Buckling of cylinderical columns

F

A. Identical cross-section

subjected to the same

load, but with different

lengths

Deformed

B. Identical length

subjected to the same

load, but with different

cross-sections

For A, since the cross-sectional areas of the two cylindrical columns

Large

deformation

(buckling)

occurs

are the same, the stresses are the same, defined by =F/A. However, a

large deflection (buckling) may occur if the length increases.

F

For B, since the lengths are the same while their cross-sectional areas

are different, buckling will likely occur in the column of smaller

diameter, which is subjected to a larger stress. That is, a column with a

smaller cross-sectional area and longer length is more prone to

Deformed

Large

deformation

(buckling)

occurs

buckling.

Buckling Analysis

Step

00

Overview of Buckling Analysis

Loads / Boundary Conditions

Loadings are applied in the same way as linear static analysis.

Boundary conditions are defined in buckling analysis also identically to static analysis.

Buckling is significantly affected by boundary conditions, which need to reflect true constraints.

Pinned-pinned

Top free,

Bottom fixed

Fixed-fixed

Top pinned,

Bottom fixed

Buckling Analysis

Step

00

Summary

Summary

Buckling Analysis

-

Unit: N, mm

Geometric Model: Buckling.x_t

Rectangular Pipe

Loads and Boundary Conditions

-

Fixed

Force (160KN)

Results Verification

-

Displacements

Eigenvalues

Mode Shapes

Comparison with Theory

Rectangular Pipe

Step

00

Analysis Summary

Objectives of Tutorial

Understanding the basics of

linear buckling analysis and the

process of analysis

Linear Buckling Analysis Types

Linear Buckling Analysis

- A structure subjected to a large axial

pressure load

Linear Static

Analysis

- A slender column under axial loads

Geom. Stiffness

Calc.

- A thin cylindrical structure subjected to

external pressure around the edge

- A long and slender cantilever subjected to a

Eigenvalues

Analysis

K I K S 0

Buckling Load

Calc.

Pcr Pa

Eigenvalues

Calc.

Structural Stability

( Calc.)

Verification

lateral pressure load acting at the tip

Analysis Summary

Target Model

Boundary Condition (Fixed)

Load Condition

(Conc. Load)

Finite Element model (Tetra Mesher)

Apply concentrated load

at the top plane: -160 KN

Assign fixed boundary

condition at the other end

plane

Rectangular Pipe

Step

00

Analysis Summary

Calculation of the critical load

n 2 E I

Pcr

4 L2

P1

Cross Section : 150mm 150mm

Thickness (t ) : 10mm

Length ( L) : 3000mm

P3

12 70 109

1

((0.15 0.153 ) (0.13 0.133 ))

12

352.86 KN

4 32

32 70 109

1

((0.15 0.153 ) (0.13 0.133 ))

12

3175.8KN

2

43

52 70 109

1

((0.15 0.153 ) (0.13 0.133 ))

12

8821KN

4 32

P 160 KN

E 70GMa

0.33

7.850kg / m

P5

Rectangular Pipe

Step

01

Model & LBC > Geometry > Import

Procedure

1

Click [

Click [Geometry] - [Import].

Model: Select Buckling.x_t.

Click [Open].

] (New).

Note: Tutorial models are included

in the folder, Manuals / Tutorials /

Files, in the installed program

folder.

Click [New] to activate all menus.

Check File type and Length Unit

Rectangular Pipe

Step

02

Model & LBC > Geometry > Material

Procedure

1

Click [Geometry] - [Material].

ID: 2 , Name: Enter User Define.

Elastic Modulus: Enter 70000.

2

1

Poissons Ratio: Enter 0.33.

Mass Density: Enter7.85e-9.

4

Click [OK].

Rectangular Pipe

Step

03

Model & LBC > Geometry > Material

(Material assignment-User Define)

Procedure

1

After selection of the model in the

work window, right-click

Geometry.

Select [Material] > [User Define].

Right-click each part under Geometry

to assign them various materials.

To assign the same material on all the

parts, simply right-click Geometry and

select the material.

Rectangular Pipe

Step

04

Model & LBC > Boundary > Support

Procedure

1

Click [Boundary] - [Support].

Name: Enter Fix.

Target: Select 1 Plane (Refer to

Picture).

4

Condition: Enter Fixed.

Click [OK].

2

Rectangular Pipe

10

Step

05

Model & LBC > Static Load > Force

Procedure

1

Click [Static Load] [Force].

Select Isometric2.

Name: Enter Force.

Target: Select 1 Plane. (Refer to

Picture)

2

5

Load Type: Select Total Force.

Y Direction Load: Enter -160000.

Click [OK].

Rectangular Pipe

11

Step

06

Model & LBC > Mesh > Auto

Mesh

Procedure

1

Click [Mesh] - [Auto Mesh].

Select all the models as target.

Select High Speed Tetra Mesher.

Click [Option <<] button.

Verify that High-Order Element is

checked.

6

Click [OK].

Click [

] (Select All) Icon to select

the total model displayed on the work

window.

Rectangular Pipe

12

Step

07

Analysis & Results > Analysis Case > General

Procedure

1

Click [Analysis Case] - [General].

Name: Enter Buckling.

Analysis Type: Select [Buckling].

3

Click [OK].

Rectangular Pipe

13

Step

08

Analysis & Results > Analysis > Perform

Procedure

1

Click [Analysis] - [Perform].

Click [OK].

Save As: Enter Buckling.

Click [Save(S)].

Once midas NFX is executed, the

solver becomes engaged. Click Stop

Execution! to interrupt the calculation.

3

4

Rectangular Pipe

14

Step

09

Analysis & Results Works Tree > Buckling > Mode Analysis > MODE

Procedure

1

Click [

] (Top) Icon.

Select Deform>Deformed +

Undeformed (Transparent).

3

Select Auto Scale (*2).

In the Analysis & Results Works

Tree, Double-click MODE 1,

TOTAL DISPLACEMENT (V).

None (O)

Rectangular Pipe

15

Step

10

Analysis & Results Works Tree > Buckling > Mode Analysis > MODE

Procedure

1

Click [

] (Top) Icon.

Select Deform>Deformed +

Undeformed (Transparent).

3

Select Auto Scale (*2).

In the Analysis & Results Works

Tree, Double-click MODE 3,

TOTAL DISPLACEMENT (V).

None (O)

Rectangular Pipe

16

Step

11

Analysis & Results Works Tree > Buckling > Mode Analysis > MODE

Procedure

1

Click [

] (Top) Icon.

Select Deform>Deformed +

Undeformed (Transparent).

3

Select Auto Scale (*2).

In the Analysis & Results Works

Tree, Double-click MODE 5,

TOTAL DISPLACEMENT (V).

None (O)

Rectangular Pipe

17

Step

00

12

Analysis Summary

Comparison with Theory

n 2 E I

Pcr

4 L2

P1

12 70 109

1

((0.15 0.153 ) (0.13 0.133 ))

MODE 1

12

352.86 KN

4 32

n 1

MODE 1

160 KN 2.2055 352.875 KN

P3

P5

32 70 109

52 70 109

1

MODE 3

((0.15 0.153 ) (0.13 0.133 ))

12

3175.8KN

2

43

1

((0.15 0.153 ) (0.13 0.133 )) MODE 5

12

8821KN

4 32

n3

MODE 3

160 KN 19.221 3075.36 KN

n5

MODE 5

160 KN 50.0744 8011.904 KN

Rectangular Pipe

18

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- EC1 WindDocument10 pagesEC1 Windandre_vicenteNo ratings yet

- Column To Steel Plate CalculationDocument1 pageColumn To Steel Plate CalculationChan Keng ChunNo ratings yet

- BZ Ehm 5Document33 pagesBZ Ehm 5Chan Keng ChunNo ratings yet

- D3 - Buckling Analysis (Designer)Document18 pagesD3 - Buckling Analysis (Designer)Chan Keng ChunNo ratings yet

- Plastic AnalysisDocument37 pagesPlastic AnalysisChan Keng ChunNo ratings yet

- Tutorial 4 - Flexural Members - Bending and ShearDocument42 pagesTutorial 4 - Flexural Members - Bending and ShearChan Keng ChunNo ratings yet

- Shabu Ten DINNER: Weekday Shabu Shabu Buffet at Shabu Ten, 1 Utama For 2 PeopleDocument1 pageShabu Ten DINNER: Weekday Shabu Shabu Buffet at Shabu Ten, 1 Utama For 2 PeopleChan Keng ChunNo ratings yet

- Lecture 2 Intro Continued - 2072Document46 pagesLecture 2 Intro Continued - 2072Chan Keng ChunNo ratings yet

- Tutorial 2 - Axially Loaded Members-TensionDocument27 pagesTutorial 2 - Axially Loaded Members-TensionChan Keng ChunNo ratings yet

- LiftingLugStress Rev 1.5Document20 pagesLiftingLugStress Rev 1.5ilijarskNo ratings yet

- Tutorial 5 - Flexural Members - Lateral Torsional BucklingDocument32 pagesTutorial 5 - Flexural Members - Lateral Torsional BucklingChan Keng ChunNo ratings yet

- Lecture 1 Introduction - 2072Document48 pagesLecture 1 Introduction - 2072Chan Keng ChunNo ratings yet

- ASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedDocument68 pagesASME BTH-1-2011 Design of Below The Hook Lifting Devices ReducedAnthony Gravagne100% (5)

- Stainless Steel Grade 316 Data Sheet (Aalco)Document3 pagesStainless Steel Grade 316 Data Sheet (Aalco)Chan Keng ChunNo ratings yet

- Summary - Flexural Members - Lateral Torsional BucklingDocument5 pagesSummary - Flexural Members - Lateral Torsional BucklingChan Keng ChunNo ratings yet

- Kaolite Insulating CastablesDocument2 pagesKaolite Insulating CastablesChan Keng ChunNo ratings yet

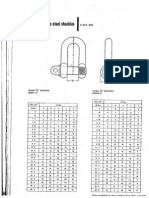

- Higher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Document2 pagesHigher Tensile Steel 'D' and 'Bow' Shackles To BS 3032Chan Keng ChunNo ratings yet

- CNPC No7 Chinese Steel Sections (2004)Document5 pagesCNPC No7 Chinese Steel Sections (2004)Chan Keng ChunNo ratings yet

- Astm A 216, Grade WCBDocument12 pagesAstm A 216, Grade WCBChan Keng ChunNo ratings yet

- AISC Steel Construction Manual, 13th Edition, Second PrintingDocument8 pagesAISC Steel Construction Manual, 13th Edition, Second PrintingLuis Gonzales Salazar67% (3)

- 304 Vs 316 PDFDocument2 pages304 Vs 316 PDFRiza KhanNo ratings yet

- Strength of Fillet and Full Penetration Butt Weld To BS 639Document1 pageStrength of Fillet and Full Penetration Butt Weld To BS 639Chan Keng ChunNo ratings yet

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Plastic AnalysisDocument37 pagesPlastic AnalysisChan Keng ChunNo ratings yet

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDocument20 pagesTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- Construction Costs GraphicalDocument0 pagesConstruction Costs GraphicalSudhakar GanjikuntaNo ratings yet

- CED 2 Final Presentation - Compile PDFDocument133 pagesCED 2 Final Presentation - Compile PDFChan Keng Chun100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Understanding IBR 1950Document7 pagesUnderstanding IBR 1950sammar_10No ratings yet

- 3 3 3 Reverse Engineering Worksheet 1Document4 pages3 3 3 Reverse Engineering Worksheet 1api-275555576No ratings yet

- Steel Erection Code of PracticeDocument94 pagesSteel Erection Code of Practicedadz mingiNo ratings yet

- P45-69Z V3.0 Schematic DiagramDocument10 pagesP45-69Z V3.0 Schematic DiagramAhmed El SharkawyNo ratings yet

- Vsi 52 Dec 2010Document4 pagesVsi 52 Dec 20103LifelinesNo ratings yet

- Mubeen Ahmad: Mobile: +92-3085235851Document3 pagesMubeen Ahmad: Mobile: +92-3085235851engr.zubair34No ratings yet

- Rainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing EngineersDocument8 pagesRainwater and Stormwater Harvesting Systems: Continuing Education From The American Society of Plumbing Engineers185412No ratings yet

- QC of Continuous Flight Auger PilesDocument1 pageQC of Continuous Flight Auger Pilesnischal_babuNo ratings yet

- Profimat MT: United Grinding Technologies Blindtext Key DataDocument9 pagesProfimat MT: United Grinding Technologies Blindtext Key DataMiskoNo ratings yet

- Abid Ali SAP Resume (Experience)Document3 pagesAbid Ali SAP Resume (Experience)Abid AliNo ratings yet

- Manhattan Associates Technical Placement Paper Level1Document7 pagesManhattan Associates Technical Placement Paper Level1placementpapersampleNo ratings yet

- IM KR180A E 4thDocument80 pagesIM KR180A E 4thbatizap batizapNo ratings yet

- Kata Loge 128Document312 pagesKata Loge 128Anonymous O5F8rZYuboNo ratings yet

- Falcon DEMCO Fire Alarm Bell (Weatherproof Type)Document1 pageFalcon DEMCO Fire Alarm Bell (Weatherproof Type)LaMinn PaingNo ratings yet

- Building A Model Steam Engine From Scratch Chapter 1, 150 121Document19 pagesBuilding A Model Steam Engine From Scratch Chapter 1, 150 121Liam Clink100% (2)

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 pagesKSB KWP: Non-Clogging Centrifugal PumpsalfredNo ratings yet

- Butterworth Filter Design With A Low Pass ButterworthDocument8 pagesButterworth Filter Design With A Low Pass ButterworthashishkkrNo ratings yet

- Design and Development of Vibratory Cockles Grading MachineDocument23 pagesDesign and Development of Vibratory Cockles Grading MachinehalizaNo ratings yet

- LECTURE 5 Cor 1Document44 pagesLECTURE 5 Cor 1teamrelax75% (4)

- Comparative Study of The Performances of Four Photovoltaic-Thermal Solar Air CollectorsDocument21 pagesComparative Study of The Performances of Four Photovoltaic-Thermal Solar Air CollectorsMarco MGNo ratings yet

- DS Mod4Document32 pagesDS Mod4Nikhitha HBNo ratings yet

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- Analysis and Design of MOSFET Based Amplifier in Different ConfigurationsDocument8 pagesAnalysis and Design of MOSFET Based Amplifier in Different ConfigurationsPraveen KumarNo ratings yet

- Copperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDocument12 pagesCopperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDillon TrinhNo ratings yet

- Aircraft Construction, Repair & Modification Mock Board Exam 10Document5 pagesAircraft Construction, Repair & Modification Mock Board Exam 10July TadeNo ratings yet

- Method of Statement For Electrical Works-UPDATEDocument35 pagesMethod of Statement For Electrical Works-UPDATEWaleed AbdulsattarNo ratings yet

- Conveyor Belt: Heavy Duty RubberDocument5 pagesConveyor Belt: Heavy Duty RubberHeidrahNo ratings yet

- Croner PKE280 H35 Spec SheetDocument2 pagesCroner PKE280 H35 Spec Sheetvictor hugoNo ratings yet

- Dynamo - WikipediaDocument13 pagesDynamo - WikipediaIKENNANo ratings yet

- Sony FDR AX1 - E ProDocument68 pagesSony FDR AX1 - E ProTodorNo ratings yet