Professional Documents

Culture Documents

Distributed Control Systems (DCS) - 2

Distributed Control Systems (DCS) - 2

Uploaded by

siksac123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distributed Control Systems (DCS) - 2

Distributed Control Systems (DCS) - 2

Uploaded by

siksac123Copyright:

Available Formats

Practical

DISTRIBUTED CONTROL

SYSTEMS (DCS)

WHAT YOU WILL LEARN:

A solid understanding of the architecture and operation of

Distributed Control Systems (DCSs)

Ability to design the overall DCS and process control system

Better specification of planned DCSs

Improved process performance for your plant

Understanding of the key ergonomic issues in design of operator

displays

Apply advanced control strategies to your plant control system

More effective use of your existing DCS process control

capabilities

Design and create a consistent and effective alarm philosophy for

your installation

Recognise and deal with human problems in interfacing to alarm

systems

WHO SHOULD ATTEND:

Process Control Engineers & Technicians

Automation Engineers

Operations Managers

Operators & Control Room Personnel

Metallurgists

Production Engineers

Process Engineers

Plant Engineers

IT Managers working with Networks

Electrical Engineers

Project Engineers

Electrical & Instrumentation Technicians

Maintenance Engineers & Supervisors

6.51

THE PROGRAM

THE WORKSHOP

This workshop will cover the practical

applications of the modern distributed control

system (DCS). Whilst all control systems are

distributed to a certain extent today and there is

a definite merging of the concepts of DCS,

Programmable Logic Controller (PLC) and

SCADA and despite the rapid growth in the use

of PLCs and SCADA systems, some of the

advantages of a DCS can still be said to be:

Integrity: The expected process down-time

caused by a conventional DCS is significantly

less than with using a SCADA/PLC. One

incident in a refinery can cost more than the

difference in price between a DCS and

SCADA/PLC. Reasons for this would include

redundancy, fault tolerance, diagnostic alarming

on I/O errors, system design, and others.

Engineering time: A small SCADA/PLC system

is easy to design and configure. As the system

grows bigger, the effort involved to properly

design and configure the system grows

exponentially, and also the risks that things can

go wrong. To design and implement a single loop

PID controller in a SCADA/PLC system is easy

and quick. To design and implement the base

layer control on a refinery using a SCADA/PLC

system can be an absolute nightmare.

Abnormal Situation Management and

Intelligent Alarm Management is a very

important DCS issue that provides significant

advantages over PLC and SCADA systems.

Few DCSs do justice to the process; in terms of

controlling for superior performance - most of

them merely do the basics and leave the rest to

the operators. Operators tend to operate within

their comfort zone; they don't drive the process

"like Schumacher drives his Ferrari". If more

than one adverse condition developed at the same

time and the system is too basic to act

protectively, the operator would probably not be

able to react adequately and risk a major

deviation. Not only is the process control

functionality normally underdeveloped but online process and control system performance

evaluation is rarely seen and alarm management

is often badly done. Operators consequently have

little feedback on their own performance and

exceptional adverse conditions are often not

handled as well as they should be. This workshop

gives suggestions on dealing with these issues.

Why are DCSs generally so under utilised? Often

because the vendor minimises the applications

software development costs to be sure of winning

the job, or because he does not know enough

about the process or if it is a green-field situation,

enough could not be known at commissioning

time but no allowance was made to add the

missing functionality during the ramp-up phase.

Often the client does not have the technical skills

in-house to realise the desired functionality is

missing or to adequately specify the desired

functionality.

This workshop examines all these issues and

gives suggestions in dealing with them and whilst

by no means exhaustive, provides an excellent

starting point for you in working with DCSs.

DAY ONE

DAY TWO

INTRODUCTION

ALARM SYSTEM MANAGEMENT FOR

DCSS

SUMMARY OF TYPICAL DISTRIBUTED

CONTROL SYSTEMS

Philosophies of Alarm Management

Human and Ergonomic Factors

DCS VERSUS SCADA VERSUS PLCS

Structure of good Alarm System

Comparison

Safety Integrity Level (SIL)

The Smart Instrument As A The Key

Component In A DCS System

Design of Alarm System

DCS SYSTEM ELEMENTS

Main differences between a distributed

control system and PLC/SCADA systems.

Requirements of the operator interface

within the DCS

Layout of a DCS system with data highway

communications paths

Redundancy in the DCS

DATA COMMUNICATIONS IN A DCS

Overview of DCS & SCADA

Communications (field/operator/long

distance)

Network topologies

Foundation Fieldbus

Measurement of Performance

DISTRIBUTED CONTROL SYSTEM

REPORTING

Alarm reporting, types of alarms generated

and acceptance of alarms

The different types of logs and reports which

can be configured on a DCS system

Data history use in logs, reports and

trend displays

DISTRIBUTED CONTROL SYSTEM

CONFIGURATION

The organisation of system data files

Data configuration procedures necessary for

setting up the DCS area database

The need for different security levels

attached to various operating parameters

Profibus

Devicenet

Industrial Ethernet

Configuration control procedures adopted to

ensure data integrity

Routers, switches, hubs

ADVANCED CONTROL STRATEGIES

TCP/IP

Industrial Network security

Links to MES and ERP

THE BASIC CONTROLLER

Identification of the PCBs, which make up

the controller

Function of the central processing unit

(CPU)

MAINTENANCE CONSIDERATIONS

Maintenance requirements of system and

system elements

The requirements for in-built diagnostics and

for maintenance diagnostic routines

The requirements for installation of

UPS system

The types of memory

Recovery of a DCS following a

power outage

Discrete and logic control

THREE TYPICAL APPLICATIONS

Sequential and batch control

BASIC DCS CONTROLLER

CONFIGURATION

Control modes available within each

controller slot

COMPARISON OF OFFERINGS FROM

DCS VENDORS

SUMMARY AND CLOSURE

Tracking and initialisation in control slots

used for cascade control

Control algorithms

The use of diagnostics

PROGRAMMING OF DCS SYSTEMS

Block Configuration

IEC 61131-3 "open" Programming

languages (structured text, function

block,ladder, sequential)

PRACTICAL SESSIONS

Tips and tricks in programming

Simulation Software - Simulation of a typical

DCS will be used.

THE OPERATOR INTERFACE

Specification of a DCS

The operators process 'window'

Configuration of a typical DCS Control Loop

using a typical plant problem

The various operator display configurations

The requirement for keyboard entry of data

Ergonomic requirements in the operator

environment

idc@idc-online.com

w w w. i d c - o n l i n e . c o m

You might also like

- Pilling Requirement To EC 2Document7 pagesPilling Requirement To EC 2raymond sabado100% (3)

- ORCAweb Administrator Guide V3.40Document113 pagesORCAweb Administrator Guide V3.40Kelipys FirminoNo ratings yet

- Intact Stability Code 2008Document97 pagesIntact Stability Code 2008anil.rai89% (9)

- Requirements BS7609Document3 pagesRequirements BS7609soryn_25No ratings yet

- DCS Presentation - Based Centum VPDocument77 pagesDCS Presentation - Based Centum VPrvicentclases100% (4)

- S-Series Hardware InstallDocument76 pagesS-Series Hardware InstallSaad BroNo ratings yet

- Foxboro Control SystemDocument6 pagesFoxboro Control Systemluriah100% (2)

- RTP 3000 DCSDocument15 pagesRTP 3000 DCSBhaskaran RamaniNo ratings yet

- Enterprise Portfolio and Project Manag. (EPPM)Document22 pagesEnterprise Portfolio and Project Manag. (EPPM)Rodrigo Prestes100% (1)

- Whitepaper Dcs Migrations IstecDocument17 pagesWhitepaper Dcs Migrations IstecRohit ShahNo ratings yet

- 5257 CS7X Control SystemDocument12 pages5257 CS7X Control SystemEslam Shibl100% (1)

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- TRICON Product Spec PDFDocument78 pagesTRICON Product Spec PDFUdaya Kumar Krishnan100% (1)

- DCS Configuration, Hardware & SofwareDocument37 pagesDCS Configuration, Hardware & SofwareEngineer Naeem AkhtarNo ratings yet

- Basic Concept of DCSDocument11 pagesBasic Concept of DCSWidodo Pudji MuljantoNo ratings yet

- DCS ArchitecturesDocument111 pagesDCS ArchitecturesSubodh Sawant100% (1)

- What Is A Distributed Control System?Document62 pagesWhat Is A Distributed Control System?Kharol A. Bautista100% (1)

- Scada System Software RequirementsDocument21 pagesScada System Software RequirementsadactivatorNo ratings yet

- Dcs SystemDocument29 pagesDcs SystemSandeep Sachan100% (3)

- Fieldbus Basics PDFDocument37 pagesFieldbus Basics PDFsalic2013No ratings yet

- HIMA HIQUAD SystemsDocument3 pagesHIMA HIQUAD Systemssina20795No ratings yet

- Distributed Control System AssignmentDocument11 pagesDistributed Control System AssignmentGhulam Mustaqeem100% (1)

- Modbus FAQDocument5 pagesModbus FAQspoof183No ratings yet

- DCS FinalDocument46 pagesDCS FinalShivesh SinghNo ratings yet

- Funds of Distributed Control SystemsDocument55 pagesFunds of Distributed Control SystemsAttreau0% (2)

- Main Report DCSDocument26 pagesMain Report DCSjoymotiNo ratings yet

- EBM White PaperDocument12 pagesEBM White PapermcaffeyNo ratings yet

- CENTUM CS 3000 R3.ppsxDocument49 pagesCENTUM CS 3000 R3.ppsxSamee UllahNo ratings yet

- Ref Batch ManagementDocument280 pagesRef Batch Managementjustine_fabian2No ratings yet

- Presentation DCSDocument89 pagesPresentation DCSMohamed BalbaaNo ratings yet

- FSC Maintenance and Support Services: Safety Management SystemsDocument2 pagesFSC Maintenance and Support Services: Safety Management Systemsmemt0% (1)

- Foundation Fieldbus Questions and AnswersDocument14 pagesFoundation Fieldbus Questions and Answerssandystays100% (1)

- ICS OverviewDocument36 pagesICS Overviewisra marabahNo ratings yet

- Orbit 60 Series System Datasheet 137M5182 PDFDocument35 pagesOrbit 60 Series System Datasheet 137M5182 PDFJuan Antonio MarinNo ratings yet

- Abb Dcs ArchitectureDocument21 pagesAbb Dcs ArchitectureAitzaz Hussain100% (1)

- Section 10 - INSTRUMENTATION, CONTROL AND AUTOMATION - Rev-01 PDFDocument132 pagesSection 10 - INSTRUMENTATION, CONTROL AND AUTOMATION - Rev-01 PDFdharman_sNo ratings yet

- Interaction of Process Design and Control: Ref: Seider, Seader and Lewin (2004), Chapter 20Document34 pagesInteraction of Process Design and Control: Ref: Seider, Seader and Lewin (2004), Chapter 20josejuanramos100% (1)

- Commissioning of A PLCDocument10 pagesCommissioning of A PLCTahir DonNo ratings yet

- Instrumentation Control Technician On The Job GuideDocument23 pagesInstrumentation Control Technician On The Job Guidefaizy24No ratings yet

- Write Protected BlockDocument1 pageWrite Protected BlockMILONo ratings yet

- Steam Turbine Control Solutions: FeaturesDocument4 pagesSteam Turbine Control Solutions: Featuresmsw123No ratings yet

- Instrumentation Automation Part25Document2 pagesInstrumentation Automation Part25ArunNo ratings yet

- His ConfigurationDocument80 pagesHis ConfigurationIndraAtmajaNo ratings yet

- Section 10 Humans in ControlDocument64 pagesSection 10 Humans in ControlAhmed FaragNo ratings yet

- Communication Protocols PDFDocument14 pagesCommunication Protocols PDFChethan SNo ratings yet

- Foxboro DCSDocument11 pagesFoxboro DCSLeni A100% (1)

- CENTUM XL Engineering Function Manual-IM33G4Q10 11E 004Document65 pagesCENTUM XL Engineering Function Manual-IM33G4Q10 11E 004Ahmad Fadhil Reviansyah100% (2)

- DCS FundamentalsDocument64 pagesDCS Fundamentalskali bangon100% (3)

- Difference Between PLC and DcsDocument2 pagesDifference Between PLC and DcsHari PrasanthNo ratings yet

- Tech DeltaVDocument8 pagesTech DeltaVFarhan SiddiquiNo ratings yet

- Centum VP AuthenticationDocument21 pagesCentum VP Authenticationabhayy05No ratings yet

- PLC To Deltav Systems MigrationDocument14 pagesPLC To Deltav Systems MigrationzacriasNo ratings yet

- CENTUM VP Documents - Yokogawa Electric CorporationDocument1 pageCENTUM VP Documents - Yokogawa Electric CorporationDhirender DagarNo ratings yet

- PRM HART MUX ConnectivityDocument12 pagesPRM HART MUX ConnectivityShiva Prasad M PattarNo ratings yet

- DeviceNet TroubleshootingDocument15 pagesDeviceNet TroubleshootingBocefaloNo ratings yet

- Webfield JX 300xp Control System PDFDocument32 pagesWebfield JX 300xp Control System PDFusman janNo ratings yet

- Proces wp001 - en P PDFDocument16 pagesProces wp001 - en P PDFReinaldo GomezNo ratings yet

- 9720081-010 Triconex SOE Recorder Users Guide 4.5.0Document130 pages9720081-010 Triconex SOE Recorder Users Guide 4.5.0jorisanNo ratings yet

- Centum VP Engineering: Course CodeDocument3 pagesCentum VP Engineering: Course CodeRabah AmidiNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Process Control and Industrial Automation Complete Self-Assessment GuideFrom EverandProcess Control and Industrial Automation Complete Self-Assessment GuideNo ratings yet

- Distributed Control System A Complete Guide - 2020 EditionFrom EverandDistributed Control System A Complete Guide - 2020 EditionNo ratings yet

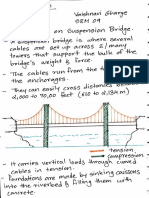

- TOS Suspension Bridge Sem 9Document3 pagesTOS Suspension Bridge Sem 9VAISHNAVI GHARGENo ratings yet

- Green Meadows - Hakimi - 3rd & 5th Floor Plan-REVISEDDocument1 pageGreen Meadows - Hakimi - 3rd & 5th Floor Plan-REVISEDPraveenNo ratings yet

- MDM Console 71Document398 pagesMDM Console 71Ravi Dutt RamanujapuNo ratings yet

- RCD GuidelinesDocument5 pagesRCD GuidelinesFlorenz Marc BermundoNo ratings yet

- AISG ES-RAB V 2.1.0Document21 pagesAISG ES-RAB V 2.1.0excaliburslvNo ratings yet

- MagLev Air Cooled Chiller CatalogDocument20 pagesMagLev Air Cooled Chiller Catalogbmw72No ratings yet

- 2 - STP - VTP PDFDocument12 pages2 - STP - VTP PDFAndreaMagiNo ratings yet

- Sheet 04 Barrel VaultDocument1 pageSheet 04 Barrel VaultSoham SatamNo ratings yet

- Contact Center Services Housekeeping ScheduleDocument2 pagesContact Center Services Housekeeping ScheduleJoy Celestial50% (2)

- AquaFlow 3.2 UserManualDocument20 pagesAquaFlow 3.2 UserManualJuan Carlos Cruz ENo ratings yet

- Abu Bakar-Electrical EngrDocument2 pagesAbu Bakar-Electrical EngrUsama FarooqiNo ratings yet

- Profile-Drawing - Philip Morris ExtensionDocument1 pageProfile-Drawing - Philip Morris ExtensionJOSEPH PARINONo ratings yet

- Brooklyn Centre Bi-Centennial Home Tour - Aug 11-12, 2012Document6 pagesBrooklyn Centre Bi-Centennial Home Tour - Aug 11-12, 2012Brian CumminsNo ratings yet

- Service Manual: Room Air ConditionerDocument68 pagesService Manual: Room Air ConditionerarteorNo ratings yet

- Design of Walls With Linear Elastic Finite Element Methods: Master Thesis ReportDocument123 pagesDesign of Walls With Linear Elastic Finite Element Methods: Master Thesis ReportOmer AnwaarNo ratings yet

- Zend Framework 1-10-x enDocument1,742 pagesZend Framework 1-10-x enJohn SnowNo ratings yet

- Daily Status Followup Sheet - HCM R2Document6 pagesDaily Status Followup Sheet - HCM R2Mikiyas YehualashetNo ratings yet

- MongoDB Data Models GuideDocument39 pagesMongoDB Data Models GuideRicardo Vercesi100% (1)

- XXVV GGFDDocument2 pagesXXVV GGFDAmet koko TaroNo ratings yet

- Diseño Interior - Junio 2017 PDFDocument147 pagesDiseño Interior - Junio 2017 PDFInter GomezNo ratings yet

- CRCDocument7 pagesCRCShreyaskar SinghNo ratings yet

- Key Fact Sheets - NBN Services - Tangerine TelecomDocument1 pageKey Fact Sheets - NBN Services - Tangerine TelecomJonnyNo ratings yet

- Muuto - Catalogue Winter2015Document60 pagesMuuto - Catalogue Winter2015Morad HaceneNo ratings yet

- Car Renting Management System Proposal PDFDocument3 pagesCar Renting Management System Proposal PDFmain channelNo ratings yet