Professional Documents

Culture Documents

Vertical Compress Drawing

Vertical Compress Drawing

Uploaded by

NurdiansyahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vertical Compress Drawing

Vertical Compress Drawing

Uploaded by

NurdiansyahCopyright:

Available Formats

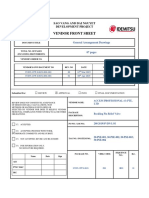

BILL OF MATERIALS

1.50

1.56

1.68

ITEM QTY

R2.50

1.50

R36.00

2.44

1.68

3.62

4.75

8X .75-10UNC

1.050 DP

6.00

7.00

2.50

1.625

1.050

3.50

.50

4.00

SECTION D-D

SCALE 1 : 16

8.00

3.75

2X

5.99

7.00

.51

1.00

5.99

60.00

20.00

11

N3

20.00

SECTION E-E

M1

19.00

SCALE 1 : 24

3

4

DESCRIPTION

MATERIAL

SA-516 70

Shell - 60.00 OD x 0.50 Thk. x 120.00 Long

Head, F&D - 60.00 OD, 1.50 SF, 60.00 ICR, 3.60

IKR, .75 Nom., .68 MAF - Note 12

Flange, RFSO - 150#, 4.00 NPS

SA-516 70

Pipe - Sch. 160, 4.00 NPS

SA-106 B

Coupling, Half - 6000#, 1.00 NPS

6

7

8

9

2

1

1

4

Flange, Pad - 150#, 2.00 NPS

Manway - 12.00 x 16.00, 3.00 x 1.00 Ring

Manway - 12.00 x 16.00, 4.00 x 1.00 Ring

Leg - W6x15 x 41.75

SA-240 316

SA-106 B/C

SA-106 B/C

SA-G40.21 44W

SA-G40.21 44W

SA-105

SA-105

10

Pad, Leg - .75 Thk. x 7.00 x 7.00

11

Lug, Lifting - .50 Thk.

SA-516 70

12

Manway Cover, .25 Thk. (See Note 11/12)

SA-516 70

NOTES:

N1 N4

1.

2.

3.

All dimensions in inches.

All welds shall be neat in appearance, free from slag and other defects.

Vessel to be cleaned of scale, oil,weld spatter and all other foreign material,

prior to hydrostatic test.

4. Remove all sharp edges on nozzles (1/8" minimum radius)

5. All nozzles to support nomial loads only.

6. Maximum misalignment of butt joints is limited to .25T (Category A, B, C, D

up to 1/2" thick)

7. All fittings conform to B16.9 standards.

8. All couplings to conform to B16.11 (2011 Add.) standards.

9. All flanges to conform to B16.5 (2009 Add.)/ B16.47 standards.

10. Flange bolt holes to straddle natural centre lines.

11. Manway Cover: Clark-Kennedy Co. CRN OH7379.5C

MAWP 150 psi, Max 650 F

12. PFHT on Heads per UCS-79(d)

120.00

114.00

162.44

1/4"

12.500

M2

10.00

DESIGN DATA

N5

6.00

Design Code:

Seismic Code:

Wind Code:

MAWP - Int / Ext:

Design Conditions

MDMT:

Corrosion Allowance:

Impact Testing:

Examination

Radiography:

PWHT:

Hydro Test:

Fluid:

Service

Capacity:

Weight - Empty:

Weight - Operating:

Code

30.000

9

N2

10

E

64.0000

NOZZLE SCHEDULE

NOZZLE

WELDS

Mark Size Qty. Service

N1

N2

N3

N4

N5

FLANGES

Type

41

42

43

UW-16.1 (c)

.375

Int Ext

Proj Proj.

Type

SB

F1

F2

BOM

ITEM #

6.00

RFSO

.375

.370

.250

3, 4

6.00

RFSO

.375

.370

.250

3, 4

UW-16.1(c)

.375

Inlet

Outlet/

Drain

Vent

UW-16.1(z-1)

.375

Process

UW-16.1(c)

.375

Process

.375

M1 12x16

Manway

.375

M2 12x16

Manway

UW-16.1 (c)

UW-16.1 (c) with

inside proj.

UW-16.1 (c) with

inside proj.

.375

1.25

1.25

.75

1.25

7, 12

.50

1.50

8, 12

1.00

41

Outside

Shell

Typ. Long Seam

UW-16.1 (c)

DATE

DRW

CHK

Release

3/21/2012

TSB

LB

XYZ Vessel Corp.

123 Basic Street

Seatown, Ontario, Canada

X1Y 2Z3

XYZ

Certified by

XYZ Vessel Corp.

(Name of Manufacturer)

F (C)

150 psi (kPa) at 120

Max. allowable working pressure (MAWP)

F (C)

psi (kPa) at

Max. allowable external working pressure

150 psi (kPa)

-20 F (C) at

Min. Design Metal Temperature (MDMT)

A

S

M

E

W

Outside

Shell

F2

F1

F1

UW-16.1 (c) with

inside projection

Eng

CRN

Slip On Flange

UW-16.1 (z-1) Coupling

Manufacturer's serial number

2012

Year built

Pressure Vessel Engineering, Ltd.

120 Randall Drive, Suite B

Waterloo, Ontario, Canada

N2V 1C6

www.pveng.com

info@pveng.com

Tel. 519-880-9808

Fax 519-880-9810

Title

Compress Sample

Size

Job ID

N-0000

SB

Typ. Circ. Seam

REVISION HISTORY

4x 90.0

41

Nozzle

Outside

Nozzle

Typ.

Outside

REV.

45.0

43

Typ.

REVISIONS

56.5000

8x

ASME VIII-1 2010 ed. 2011 add.

IBC 2009, Site E, I 1, Ss .75, S1 .30, R 2

N/A

150 / 0 psi @ 120 F

-20 F @ 150 psi

0

Exempt per UG-20(f)

None

None

195 psi @ 70 F

Air / Water

213 cu. ft.

4900 lb

18000 lb

Scale

1:1

Drawing No.

PVE-6161

Material

Revision:

PVEdwg-6161-0.1 Compress Sample

See BOM

Sheet

1 OF 1

This drawing and the information herein is confidential, and must not be reproduced

or used in any way without the written permission of Pressure Vessel Engineering Ltd.

You might also like

- Drawing Heat Exchanger Assembly Rev 02 PDFDocument9 pagesDrawing Heat Exchanger Assembly Rev 02 PDFDaniel Corredor Gonzalez100% (2)

- Böhler Welding CalcDocument2 pagesBöhler Welding CalcMOHAN0% (1)

- Tanks - Addition of Shell Nozzles by Hot TappingDocument2 pagesTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzNo ratings yet

- Sample3 Drawing PDFDocument2 pagesSample3 Drawing PDFMas Arman TewoNo ratings yet

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingSourav HaitNo ratings yet

- Sample13 DrawingDocument2 pagesSample13 DrawingSourav HaitNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocument4 pagesOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNo ratings yet

- Sample (Material Purchase Specification) PDFDocument13 pagesSample (Material Purchase Specification) PDFTenottoNo ratings yet

- How To Order Alfa ValveDocument0 pagesHow To Order Alfa ValveZoebairNo ratings yet

- 3 2 Purchase Material SpecificationDocument1 page3 2 Purchase Material Specificationanon_376696588No ratings yet

- Time Schedule Shelter - PetronasDocument1 pageTime Schedule Shelter - PetronasSulist N WahyudieNo ratings yet

- MSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001Document6 pagesMSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001vladmir18No ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- SVDN CPP I 0031 D01 0001 Rev.01 General Arrangement DrawingsDocument7 pagesSVDN CPP I 0031 D01 0001 Rev.01 General Arrangement DrawingsjfdlksaNo ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- Price List - PowerMaster Tube ExpanderDocument1 pagePrice List - PowerMaster Tube ExpanderAnuj JainNo ratings yet

- As Built: Rfso, C/W Dip PipeDocument18 pagesAs Built: Rfso, C/W Dip Piperomeo112976No ratings yet

- Evaluation of 8090 and Weldalite-049 Aluminum-Lithium AlloysDocument39 pagesEvaluation of 8090 and Weldalite-049 Aluminum-Lithium Alloysskylancer-3441No ratings yet

- Pts Industrial & Pipeline Technologies (India) Private LimitedDocument3 pagesPts Industrial & Pipeline Technologies (India) Private LimitedSomxeshNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaNo ratings yet

- Fab Shop DrawingsDocument14 pagesFab Shop DrawingszainyousafzaiNo ratings yet

- JCM Split Tee and Weld On Outlets For Industrial ServiceDocument1 pageJCM Split Tee and Weld On Outlets For Industrial ServiceochableNo ratings yet

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Document18 pagesPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNo ratings yet

- Installation of T1501 PIPE ProcedureDocument6 pagesInstallation of T1501 PIPE Procedure1339979No ratings yet

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Document57 pagesPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoNo ratings yet

- Presentation For KOM Vendor-SubcontDocument19 pagesPresentation For KOM Vendor-Subcontahmad kusumaNo ratings yet

- SC20 Sample CoolerDocument3 pagesSC20 Sample CoolerjdanastasNo ratings yet

- Corporation.: Unpriced QuotationDocument12 pagesCorporation.: Unpriced QuotationavaisharmaNo ratings yet

- Pressure Vessel Handbook 14th Edition - Megyesy 2008Document501 pagesPressure Vessel Handbook 14th Edition - Megyesy 2008y.kirthy vasanNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Page No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressDocument93 pagesPage No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressSiva baalanNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinNo ratings yet

- Copia de EPCDocument32 pagesCopia de EPCPeter RodriguezNo ratings yet

- Notes:: TAG# SV-01Document1 pageNotes:: TAG# SV-01omarNo ratings yet

- Customer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaDocument2 pagesCustomer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaomarNo ratings yet

- Dimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesDocument8 pagesDimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesSimbu ArasanNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- ANSI-ASME B16.5 Blind Flange 300lb PDFDocument1 pageANSI-ASME B16.5 Blind Flange 300lb PDFVishal MistryNo ratings yet

- LP Separator v1015 RubybDocument2 pagesLP Separator v1015 RubybBùi Văn HợpNo ratings yet

- TK 1100Document26 pagesTK 1100romeo112976No ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Pipe Dimensions Imperial/MetricDocument3 pagesPipe Dimensions Imperial/MetricmtbecerrapNo ratings yet

- Mud Agitator Drawing 15KW-Layout1Document1 pageMud Agitator Drawing 15KW-Layout1enuvos engineeringNo ratings yet

- Material Reference 1 FinalDocument8 pagesMaterial Reference 1 FinaldramiltNo ratings yet

- Flange - Weld Neck, ANSI Class 150, B16.5 (In)Document8 pagesFlange - Weld Neck, ANSI Class 150, B16.5 (In)Roni FirmansyahNo ratings yet

- C9709 Foam ChamberDocument1 pageC9709 Foam Chamberkalimutu2010No ratings yet

- Step 3 Hydrotest Diagram Stage 1Document1 pageStep 3 Hydrotest Diagram Stage 1mansih457100% (1)

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Cartridge Valves For Submarine, Aircraft Carrier Rocket LauncherDocument27 pagesCartridge Valves For Submarine, Aircraft Carrier Rocket LauncherPeter JonesNo ratings yet

- PlannerDocument36 pagesPlannerFaull JackmanNo ratings yet

- Walworth - V Iron Plug - 2012Document44 pagesWalworth - V Iron Plug - 2012Faull JackmanNo ratings yet

- FMC - Desairador VerticalDocument4 pagesFMC - Desairador VerticalFaull JackmanNo ratings yet

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 pagesModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanNo ratings yet

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 pagesModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanNo ratings yet

- Pressfit 316 Stainless Steel Pipe SystemDocument12 pagesPressfit 316 Stainless Steel Pipe SystemFaull JackmanNo ratings yet