Professional Documents

Culture Documents

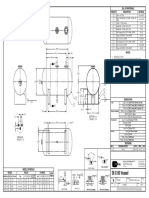

Pveng: Vessel With Large Opening Pve Sample Vessel

Uploaded by

Sivateja NallamothuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pveng: Vessel With Large Opening Pve Sample Vessel

Uploaded by

Sivateja NallamothuCopyright:

Available Formats

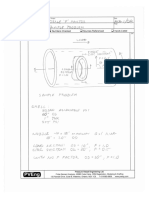

Bill of Materials

NOTES: 19.75 Item Qty Description Material

1. All welds shall be neat in appearance, free of slag and other defects.

Ø12.75 1 1 ROLLED PLATE SHELL 0.188" THICK SA-240 304

2. Vessel to be cleaned of scale, oil, weld splatter and all foreign

material prior to hydrostatic test. Ø 13.00 BCD 2 1 2" HEAVY FERRULE - 2.192" OD, 0.161" WALL SA-479 304

3. Remove all sharp edges on nozzles (1/8" minimum radius)

1.25 3 1 2" SCH40 PIPE WLD/SMLS SA-312 TP304

4. All Nozzles to support nominal loads only. Ø10.75 4 1 2" B16.5 300# RFSO FLANGE SA-182 F304

5. Vessel weight ( approx. dry ) 160 lbs 5 1 8" FERRULE (0.078 WALL) SA-312 TP304

Vessel weight ( approx. test ) 275 lbs 6 1 ROLLED PLATE CONE 0.188" THICK SA-240 304

6. Capacity 1.85 cu.ft. 7 1 10" SCH40 PIPE WLD/SMLS SA-312 TP304

7. Fluid: Water 8 2 FLANGE 14.75" OD, 10.75 ID, 1.375" THICK SA-240 304

9 6 3/4" BOLT SA-193 B7

10 6 3/4" HEX NUT SA-194 B8

11 6 3/4" PIN SA-193 B7

0.75 12 1 2" 3000# FULL COUPLING SA-182 F304

13 1 COVER 1" THICK SA-240 304

14 1 TAPERD SHELL FROM 12" SCH80 PIPE WLD/SMLS SA-312 TP304

15 12 SWING BOLT LUG 0.375"x2"x2.5" SA-240 304

TYP 1.00 16 1 PLATE 0.188" THICK SA-240 304

1/4 17 1 NAMEPLATE CS

18 1 PARKER O-RING #381 (3/16) VMQ

Ø 14.75 BCD

1.38 8X Ø0.75 Certified by

1.00 TYP

2.50 FOR 5/8 BOLTS ~

TOP VIEW (Name of Manufacturer)

Ø0.75 ITEM #8 -10" CUSTOM FLANGE

12 Ø12.75 OD 200 psi (kPa) at 350 °F (°C)

Max. allowable working pressure (MAWP)

Ø1.50 13 Ø11.38 ID 9 10 11 Ø12.750

2.00 - psi (kPa) at - °F (°C)

E F Ø12.395 Max. allowable external working pressure

DETAIL B 14 DETAIL A Ø11.855 W

-20 °F (°C) at 200 psi (kPa)

1:4 Minimum Design Metal Temperature (MDMT)

18

0.15 ~

Manufacturer's serial number

15

~

4.50

DETAIL B Ø11.50

CRN Year built

12.00 Full Pen. 12.00

3.00

17

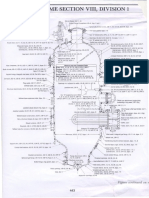

1 Design Data

16

20.00 Design Code: ASME Code Section VIII Division 1, 2007 Edition

22.50

Longitudinal weld

Design Pressure Internal: 200 psi @ 350°F

2 B C MAWP: 200 psi

Backside

Design Pressure External: N/A

8

1:3

MDMT: -20°F @ 200 psi

1.50 DETAIL A Hydro Test Pressure: 260 psi @ 55°F for 1/2 Hour

7

tap

1.50 1:2 PWHT: None

er

3.00 Radiography: None

Corrosion Allowance: 0"

Impact Test: Exempt Per UHA-51(d)

e

ksid

4.00

Bac eld

3 4 A 5.00

w

6

1 Update code of construction and drawing views 11/20/2008 BV

1.125 (Ref) 0 Initial Release 5/25/2005 LB

1.10 D REV DESCRIPTION DATE INITIALS

5

8.03 w REVISION HISTORY

SB w

Pressure Vessel Engineering

SIDE ELEVATION

SLIP ON FLANGE PVEng 120 Randall Drive, Suite B, Waterloo, Ontario, N2V 1C6

P: 519.880.9808

http://www.pveng.com

F: 519.880.9810

info@pveng.com

nt Full TYP. TITLE

Nozzle Schedule

Vessel with Large Opening

Wall Pen. 45°

Flange Flange

Full Outside F1

Nozzle Welds Coupling t Pen.

Nozzle

Leg Leg Leg Weld Leg41

Mark Size Qty Service Type SB F1

A

B

2"

4"

1

1

INLET

INSPECTION

I

I

3

41

16"

3 "

42

-

-

43

-

-

1

4"

-

(w)

.154"

-

-

-

Outside

Hole Inside Vessel

Wall

SIZE

PVE Sample Vessel

JOB ID DRAWING NO REV

16 Inside

1 " 1 "

C 10" 1 INLET I 4 - - 2 .365" - Inside t

B Sample 5 Sample 5 1

D 8" 1 OUTLET - - - - - - - UW-16.1 Z-1 Coupling (modified)

VENT 5 UW-16.1 (c) SCALE SHEET

E 2" 1 II - - - - - 16"

F 12" 1 ACCESS - - - - - - - TYPE I TYPE II TYP. CIRC. SEAM 1:8 1 of 1

You might also like

- Bill of Materials and Engineering DrawingsDocument1 pageBill of Materials and Engineering DrawingsFaull JackmanNo ratings yet

- TSG R0004 2009Document76 pagesTSG R0004 2009bikobelloNo ratings yet

- Credit For Internal Cladding-RevDocument3 pagesCredit For Internal Cladding-RevAhmedNo ratings yet

- Sa515 GR 70 and Sa516 GR 70 t2776 PDFDocument3 pagesSa515 GR 70 and Sa516 GR 70 t2776 PDFvtbkNo ratings yet

- BreechLock HEDocument1 pageBreechLock HEibrahim1961No ratings yet

- Studded Outlet HSB News Letter PDFDocument4 pagesStudded Outlet HSB News Letter PDFG.SWAMINo ratings yet

- Tubesheet: Design of Collar BoltDocument1 pageTubesheet: Design of Collar Boltpippo2378793No ratings yet

- Applied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarDocument7 pagesApplied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarememNo ratings yet

- QR2 - Mechanical Maintenance Question RecordDocument2 pagesQR2 - Mechanical Maintenance Question RecordMicky PlumbNo ratings yet

- ASME UM Audit Preparation ListDocument2 pagesASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- Class 1 Vs Class 2 Pressure Vessels - Hedderman ConsultingDocument3 pagesClass 1 Vs Class 2 Pressure Vessels - Hedderman ConsultinglorenzoNo ratings yet

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDocument5 pagesInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANo ratings yet

- Mechanical Engineer-Syed Zain AliDocument5 pagesMechanical Engineer-Syed Zain AliSyedZainAliNo ratings yet

- FEA Basic Safety Guidelines Manufacturing 3rd EditionDocument42 pagesFEA Basic Safety Guidelines Manufacturing 3rd EditionSaertu LogarNo ratings yet

- Ceng Ebook PDFDocument14 pagesCeng Ebook PDFMahnooranjumNo ratings yet

- Post Weld Heat Treatment ProcedureDocument18 pagesPost Weld Heat Treatment Proceduremohd as shahiddin jafriNo ratings yet

- Tube Expander-Tools PDFDocument120 pagesTube Expander-Tools PDFmarceilinus devaluantoNo ratings yet

- Material P NumberDocument11 pagesMaterial P NumberChaitanya Sai TNo ratings yet

- Specification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsDocument19 pagesSpecification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsT arekiNo ratings yet

- Installation Guidelines for Integrally Reinforced Branch FittingsDocument7 pagesInstallation Guidelines for Integrally Reinforced Branch FittingsrodofgodNo ratings yet

- Stiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselDocument4 pagesStiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselEstuardo Javier Gan RodríguezNo ratings yet

- Bleed Rings RTJDocument1 pageBleed Rings RTJAlessandro1975No ratings yet

- B16 Case 12Document2 pagesB16 Case 12InaamNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Expansion Bellow Tech ComparisonDocument10 pagesExpansion Bellow Tech ComparisonSabariMechyNo ratings yet

- Use of Alloy 718 and 725 in Oil and Gas IndustryDocument9 pagesUse of Alloy 718 and 725 in Oil and Gas IndustryEddyWangNo ratings yet

- Pressure Vessel Manual-M.asgaRZADEGANDocument79 pagesPressure Vessel Manual-M.asgaRZADEGANH BNo ratings yet

- Floor Type Oven Rental and Sales by Weldmaster IndustriesDocument1 pageFloor Type Oven Rental and Sales by Weldmaster Industriestekstep7No ratings yet

- En 13121-3:2008+a1:2010 (E)Document1 pageEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITENo ratings yet

- Elwood Parts and Service ManualDocument75 pagesElwood Parts and Service Manualdindin6666No ratings yet

- Petroleum Refining Fouling Mitigation TrainingDocument27 pagesPetroleum Refining Fouling Mitigation TrainingAtifNo ratings yet

- Welding and Characterization of 5083 Aluminium Alloy PDFDocument6 pagesWelding and Characterization of 5083 Aluminium Alloy PDFPatricio G. ArrienNo ratings yet

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- CCUG P91 Fabrication Guidelines Dave Buzza-1Document22 pagesCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarNo ratings yet

- B.16.5 Interpretation PDFDocument68 pagesB.16.5 Interpretation PDFmohdluthfiNo ratings yet

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerDocument1 pageBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123No ratings yet

- Types of Tube-To-TubesheetDocument1 pageTypes of Tube-To-TubesheetAnonymous AlhzFE9EVNNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On Lugsandry4jc100% (1)

- Welding Electrodes and Rods for Cast Iron TitleDocument5 pagesWelding Electrodes and Rods for Cast Iron TitleAnghelo AlcaldeNo ratings yet

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- VP 3209 e 031a 02 0013 Rev.dDocument254 pagesVP 3209 e 031a 02 0013 Rev.dSuryaprakashNo ratings yet

- Welding Journal - March 2012Document2 pagesWelding Journal - March 2012pkn_pnt9950No ratings yet

- Design and Finite Element Assessment of Mounded Bullet PDFDocument14 pagesDesign and Finite Element Assessment of Mounded Bullet PDFc0g100% (1)

- 006 Interpretations Volume 39Document24 pages006 Interpretations Volume 39Erick Carrasco LobosNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- 8-12 X 3000 M Spherical LPG Storage TankDocument1 page8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- A. Determine A Radius of Riser: To Calculate Welding Length On TKY Joint Please Follow Below InstructionDocument3 pagesA. Determine A Radius of Riser: To Calculate Welding Length On TKY Joint Please Follow Below InstructionBHARANINo ratings yet

- Pressure Points: Governing Code Section VIII Division 1 - 2017 EditionDocument5 pagesPressure Points: Governing Code Section VIII Division 1 - 2017 EditionzaheerNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Asme Guide For Sec Viii Div 1Document1 pageAsme Guide For Sec Viii Div 1siddharth pawarNo ratings yet

- 11110d-2 Obround Nozzle Revised DesignDocument1 page11110d-2 Obround Nozzle Revised DesignSivateja NallamothuNo ratings yet

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- Design Data: Saudi Arabian Oil CompanyDocument15 pagesDesign Data: Saudi Arabian Oil Companysuria qaqcNo ratings yet

- PV Newsletter April2021Document32 pagesPV Newsletter April2021Tushar MangratiNo ratings yet

- Sample3 DrawingDocument2 pagesSample3 DrawingMayra Denise SandriniNo ratings yet

- Rev 2 Suitcase - Piping (6 Pack)Document2 pagesRev 2 Suitcase - Piping (6 Pack)Oscar CarrascoNo ratings yet

- Nozzle Schedule: General NotesDocument1 pageNozzle Schedule: General NotesArielNo ratings yet

- RegO Pop-Action ValveDocument1 pageRegO Pop-Action ValveSwapnil JawaleNo ratings yet

- Ins PT005Document1 pageIns PT005faisal hajjNo ratings yet

- Thermodynamic Steam Traps DT 32Document1 pageThermodynamic Steam Traps DT 32Son Trinh PhuongNo ratings yet

- Pressure Vessel Firetube DesignDocument1 pagePressure Vessel Firetube DesignSivateja NallamothuNo ratings yet

- Pressure Vessel Firetube DesignDocument1 pagePressure Vessel Firetube DesignSivateja NallamothuNo ratings yet

- 56Document38 pages56Sivateja NallamothuNo ratings yet

- 11110d-2 Obround Nozzle Revised DesignDocument1 page11110d-2 Obround Nozzle Revised DesignSivateja NallamothuNo ratings yet

- 56Document38 pages56Sivateja NallamothuNo ratings yet

- Vessel With Large Opening: PVE SamplesDocument25 pagesVessel With Large Opening: PVE SamplesSivateja NallamothuNo ratings yet

- Nozzle F Factor CalculationsDocument5 pagesNozzle F Factor CalculationsSivateja NallamothuNo ratings yet

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGSivateja NallamothuNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Vessel Description: Pressure Vessel Engineering, LTDDocument40 pagesVessel Description: Pressure Vessel Engineering, LTDSivateja NallamothuNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Pressure Vessel Engineering, LTD.: CustomerDocument34 pagesPressure Vessel Engineering, LTD.: CustomerSivateja Nallamothu100% (1)

- Four Heads Compress Calculation SetDocument14 pagesFour Heads Compress Calculation Settvmehta01No ratings yet

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- Zick AnalysisDocument12 pagesZick AnalysisrksahayNo ratings yet

- Sample3 Drawing PDFDocument2 pagesSample3 Drawing PDFMas Arman TewoNo ratings yet

- Nozzle F Factor CalculationsDocument5 pagesNozzle F Factor CalculationsSivateja NallamothuNo ratings yet

- Generic Vessel Registration - Pressure Vessel Engineering2Document8 pagesGeneric Vessel Registration - Pressure Vessel Engineering2Sivateja NallamothuNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Comparison Between Head Types - Hemi, SE, F&D and Flat - Pressure Vessel EngineeringDocument8 pagesComparison Between Head Types - Hemi, SE, F&D and Flat - Pressure Vessel EngineeringSivateja NallamothuNo ratings yet

- Heat Exchanger Specification SheetDocument5 pagesHeat Exchanger Specification SheetNur Izzati KamrulnizamNo ratings yet

- Sample21 SpreadsheetDocument20 pagesSample21 SpreadsheetSivateja NallamothuNo ratings yet

- HeatExchanger DrawingDocument7 pagesHeatExchanger DrawingSivateja NallamothuNo ratings yet

- More FEA Samples - Pressure Vessel EngineeringDocument22 pagesMore FEA Samples - Pressure Vessel EngineeringSivateja NallamothuNo ratings yet

- PVEdwg 6847 0.0 Generic VesselDocument1 pagePVEdwg 6847 0.0 Generic VesselSivateja NallamothuNo ratings yet

- Bill of Materials for Pressure Vessel ComponentsDocument1 pageBill of Materials for Pressure Vessel ComponentsSivateja NallamothuNo ratings yet

- More FEA Samples - Pressure Vessel EngineeringDocument22 pagesMore FEA Samples - Pressure Vessel EngineeringSivateja NallamothuNo ratings yet

- Tri-Clamp Design DataDocument2 pagesTri-Clamp Design DataSivateja NallamothuNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument20 pagesPveng: Pressure Vessel Engineering LTDSivateja NallamothuNo ratings yet

- Factory Physics Foundations of Manufacturing Management PDFDocument2 pagesFactory Physics Foundations of Manufacturing Management PDFJayNo ratings yet

- CAT C32 RNY Series Maintenance Interval ScheduleDocument3 pagesCAT C32 RNY Series Maintenance Interval Scheduleharikrishnanpd3327No ratings yet

- Module 4 Self-Concept, Perceptions and AttributionsDocument25 pagesModule 4 Self-Concept, Perceptions and AttributionsJoebet Debuyan100% (3)

- NJM3771D2Document9 pagesNJM3771D2mahdi elmayNo ratings yet

- Shop Manual Engine 12V 140e PDFDocument601 pagesShop Manual Engine 12V 140e PDFHarry Wart Wart100% (3)

- Products Profile Unitech Ikkcomunitech Ikkcomsfspsfsp Profile 6 SFSPDocument46 pagesProducts Profile Unitech Ikkcomunitech Ikkcomsfspsfsp Profile 6 SFSPSaad AkramNo ratings yet

- OOP With C++ (Assignment - 3) CSE, 3 Semester: Prepared By: Deepak Uniyal (Assistant Professor CSE, GEU)Document2 pagesOOP With C++ (Assignment - 3) CSE, 3 Semester: Prepared By: Deepak Uniyal (Assistant Professor CSE, GEU)Govind TripathiNo ratings yet

- (Atlas Copco) - Industrial Power Tools 2012Document332 pages(Atlas Copco) - Industrial Power Tools 2012mg_catana100% (1)

- Archaeoastronomy in IndiaDocument19 pagesArchaeoastronomy in IndiaParag MahajaniNo ratings yet

- 3 Practice English May of 2006Document2 pages3 Practice English May of 2006Edison ViverosNo ratings yet

- Technical Specification Centurio L7-1M-S 1250Document3 pagesTechnical Specification Centurio L7-1M-S 1250slobamsNo ratings yet

- Tir A9 14 PDFDocument99 pagesTir A9 14 PDFGino Tironi100% (7)

- Project Time Management and Budget PlanningDocument68 pagesProject Time Management and Budget PlanningLindelani ndalaNo ratings yet

- Panasonic CX 491 P Datasheet PDFDocument24 pagesPanasonic CX 491 P Datasheet PDFGanesh MandpeNo ratings yet

- Jongka:the Traditional Korean Family: Exploring Jongka Food in The Context of Korean Food CategoriesDocument14 pagesJongka:the Traditional Korean Family: Exploring Jongka Food in The Context of Korean Food CategoriesSözen BayraktarNo ratings yet

- Math11 SP Q3 M8 PDFDocument12 pagesMath11 SP Q3 M8 PDFJessa Banawan EdulanNo ratings yet

- Controller Tuning Methods for Process ControlDocument17 pagesController Tuning Methods for Process ControltrshaaaNo ratings yet

- Perbandingan Harga LaptopDocument5 pagesPerbandingan Harga Laptopgihe purnamaNo ratings yet

- Venn DiagramDocument9 pagesVenn DiagramMyla Nazar OcfemiaNo ratings yet

- Modifier: 1. Pre-Modify The NounDocument3 pagesModifier: 1. Pre-Modify The NounShariful IslamNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- 3x Anglais Ecran-4Document4 pages3x Anglais Ecran-4EMRE KAAN USTANo ratings yet

- Conveyor Control System ProjectDocument15 pagesConveyor Control System ProjectzhackhieNo ratings yet

- Peru 120W Solar All in One V2.0Document6 pagesPeru 120W Solar All in One V2.0luciano añorgaNo ratings yet

- Identify What Is Being Described in Each NumberDocument2 pagesIdentify What Is Being Described in Each NumberAeronn Jass SongaliaNo ratings yet

- Verb Tense Grade 9Document2 pagesVerb Tense Grade 9tba.shraddhaNo ratings yet

- Modeling For Simulation and Control of Acid-Base Neutralization SystemsDocument12 pagesModeling For Simulation and Control of Acid-Base Neutralization SystemscacacocoNo ratings yet

- SAIL Catalogue: DownloadDocument16 pagesSAIL Catalogue: Downloadmishra usNo ratings yet

- Exit StrategyDocument2 pagesExit StrategyMuhammad KashifNo ratings yet

- Katalog Promo PC200-8 Okt 2020Document6 pagesKatalog Promo PC200-8 Okt 2020ariy yuli styawanNo ratings yet