Professional Documents

Culture Documents

The Results of Required Steel & Strsses Are As Follow.: Minimum

Uploaded by

epcepcepcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Results of Required Steel & Strsses Are As Follow.: Minimum

Uploaded by

epcepcepcCopyright:

Available Formats

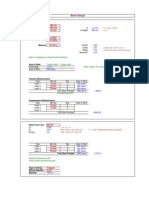

The results of required steel & strsses are as follow.

MAXIMUM

NORMAL

SEISMIC

PIER

PIER

2.000

2.000

3.142

3.142

0.073

0.073

10.000

10.000

104.41

75.09

0.02698

0.02698

DATA

D=DIA OF PIER IN M

AREA OF PILE

C=COVER FROM CL OF REINFT IN M

M=MODULAR RATIO

BD=BETA ANGLE FOR DEFINING NA IN DEG.

AS=AREA OF STEEL IN SQM

25

55 Nos

PERCENTAGE STEEL %

P=VERTICAL LOAD IN T

BM=BENDING MOMENT IN T-M

MINIMUM

NORMAL

PIER

2.000

3.142

0.073

10.000

104.74

0.02698

SEISMIC

PIER

2.000

3.142

0.073

10.000

101.62

0.02698

0.859

479.58

622.58

0.859

436.95

243.14

0.859

409.04

540.38

0.859

401.68

196.29

1.000

0.928

1.000

0.928

1.000

0.928

1.000

0.928

0.005

1.822

-0.249

1.84

0.005

1.311

0.257

1.29

0.005

1.828

-0.254

1.85

0.005

1.774

-0.201

1.79

0.909

0.845

-0.482

-0.268

-0.517

0.963

0.902

-0.863

0.497

0.277

0.533

0.961

0.905

0.857

-0.492

-0.274

-0.528

0.962

0.940

0.725

-0.395

-0.217

-0.424

0.976

NUM1=(PI-B)/8+B3/32+B1*B2/3

NUM2=2*(RO^3)/(1+B1)

NUM3((RI^3)*T/(RO+RI*A1)

NUM4=((M-1)*PI+A-A2/2

NUM=NUMERATOR=NUM2*NUM1+NUM3*NUM4

0.116

2.663

0.005

30.375

0.458

0.279

1.591

0.003

29.297

0.530

0.114

2.682

0.005

30.387

0.457

0.131

2.504

0.005

30.276

0.467

DEM1=2*(RO^2)/(1+B1)

DEM2=B2/3+(PI-B)*B1/2+B1*B4/4

DEM3=2*(RI^2)*T/(RO+RI*A1)

DEM4=(M-1)*PI*A1-A3+A*A1

DEM=DENOMINATOR=DEM1*DEM2+DEM3*DEM4

CHECK FOR ECC

CALCULATED EC=NUM/DEM

ACTUAL EC=M/P

CHECK FOR STRESSES

NAC=DEPTH OF NA BELOW CENT AXIS=RO*COS(B)

NAD=DEPTH OF NA FROM TOP=RO+NAC

DE=EFFECTIVE DEPTH=D-C

c = COMP STRESS IN CONC (t/m2) = P/DEM

2.663

0.169

0.011

-9.046

0.353

1.591

0.568

0.006

7.241

0.950

2.682

0.166

0.011

-9.224

0.346

2.504

0.195

0.010

-7.504

0.414

1.297

1.298

0.558

0.556

1.321

1.321

1.127

0.489

-0.254

0.746

1.928

1182.4

1360.0

18743

24480.0

SAFE

-0.201

0.799

1.928

969.2

2040.0

13700.8

36720.0

SAFE

RO=D/2

RI=RADIUS OF REINFT RING=RO-C

T=THK OF REINFT RING IN M

T=AS/(2PI*RI)

B=BD*PI/180

B1=COS(B)

A=ALPHA ANGLE=ACOS(RO*B1/RI)

RECOSB=RICOSA

B2=SIN(B)^3

B3=SIN(4*B)

B4=SIN(2*B)

A1=COS(A)

A2=SIN(2*A)

A3=SIN(A)

PERMISSIBLE STRESS IN CONC

t = TENSILE STRESS IN STEEL (t/m2)

PERMISSIBLE STRESS IN STEEL

-0.249

0.257

0.751

1.257

1.928

1.928

1353.0

460.0

< 1360.0 < 2040.0 <

21191.7

2452

< 24480.0 < 36720.0 <

SAFE

SAFE

Hence Provide 55 nos 25 mm dia bars

Stirrups provided 8 mm dia @ 300 mm c/c

STEEL :- FE 500 & CONCRETE GRADE :- M40

<

<

The results of required steel & strsses are as follow.

MAXIMUM

NORMAL

SEISMIC

PIER

PIER

2.000

2.000

3.142

3.142

0.073

0.073

10.000

10.000

103.42

75.09

0.02551

0.02551

DATA

D=DIA OF PIER IN M

AREA OF PILE

C=COVER FROM CL OF REINFT IN M

M=MODULAR RATIO

BD=BETA ANGLE FOR DEFINING NA IN DEG.

AS=AREA OF STEEL IN SQM

25

52 Nos

PERCENTAGE STEEL %

P=VERTICAL LOAD IN T

BM=BENDING MOMENT IN T-M

MINIMUM

NORMAL

PIER

2.000

1.131

0.073

10.000

103.54

0.02551

SEISMIC

PIER

2.000

1.131

0.073

10.000

101.62

0.02551

0.812

515.59

615.65

0.812

472.96

262.72

0.812

445.05

534.44

0.812

437.69

480.63

1.000

0.928

1.000

0.928

1.000

0.928

1.000

0.928

0.004

1.805

-0.232

1.82

0.004

1.311

0.257

1.29

0.004

1.807

-0.234

1.83

0.004

1.774

-0.201

1.79

0.920

0.806

-0.452

-0.250

-0.485

0.968

0.902

-0.863

0.497

0.277

0.533

0.961

0.919

0.811

-0.455

-0.252

-0.488

0.968

0.940

0.725

-0.395

-0.217

-0.424

0.976

NUM1=(PI-B)/8+B3/32+B1*B2/3

NUM2=2*(RO^3)/(1+B1)

NUM3((RI^3)*T/(RO+RI*A1)

NUM4=((M-1)*PI+A-A2/2

NUM=NUMERATOR=NUM2*NUM1+NUM3*NUM4

0.121

2.604

0.005

30.340

0.453

0.279

1.591

0.003

29.297

0.526

0.120

2.611

0.005

30.345

0.453

0.131

2.504

0.004

30.276

0.459

DEM1=2*(RO^2)/(1+B1)

DEM2=B2/3+(PI-B)*B1/2+B1*B4/4

DEM3=2*(RI^2)*T/(RO+RI*A1)

DEM4=(M-1)*PI*A1-A3+A*A1

DEM=DENOMINATOR=DEM1*DEM2+DEM3*DEM4

CHECK FOR ECC

CALCULATED EC=NUM/DEM

ACTUAL EC=M/P

CHECK FOR STRESSES

NAC=DEPTH OF NA BELOW CENT AXIS=RO*COS(B)

NAD=DEPTH OF NA FROM TOP=RO+NAC

DE=EFFECTIVE DEPTH=D-C

c = COMP STRESS IN CONC (t/m2) = P/DEM

2.604

0.178

0.010

-8.500

0.380

1.591

0.568

0.006

7.241

0.947

2.611

0.177

0.010

-8.566

0.377

2.504

0.195

0.009

-7.504

0.419

1.193

1.194

0.555

0.555

1.200

1.201

1.098

1.098

-0.234

0.766

1.928

1179.6

1360.0

17891

24480.0

SAFE

-0.201

0.799

1.928

1045.8

2040.0

14783.6

36720.0

SAFE

RO=D/2

RI=RADIUS OF REINFT RING=RO-C

T=THK OF REINFT RING IN M

T=AS/(2PI*RI)

B=BD*PI/180

B1=COS(B)

A=ALPHA ANGLE=ACOS(RO*B1/RI)

RECOSB=RICOSA

B2=SIN(B)^3

B3=SIN(4*B)

B4=SIN(2*B)

A1=COS(A)

A2=SIN(2*A)

A3=SIN(A)

PERMISSIBLE STRESS IN CONC

t = TENSILE STRESS IN STEEL (t/m2)

PERMISSIBLE STRESS IN STEEL

-0.232

0.257

0.768

1.257

1.928

1.928

1352.3

499.2

< 1360.0 < 2040.0 <

20421.2

2661

< 24480.0 < 36720.0 <

SAFE

SAFE

Hence Provide 52 nos 25 mm dia bars

Stirrups provided 8 mm dia @ 300 mm c/c

STEEL :- FE 500 & CONCRETE GRADE :- M40

<

<

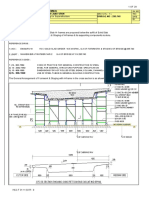

The results of required steel & strsses are as follow.

MINIMUM

NORMAL

PIER

2.000

3.142

0.095

10.000

40.00

0.00942

MAXIMUM

SEISMIC

PIER

2.000

3.142

0.095

10.000

54.69

0.00942

WIND

PIER

2.000

3.142

0.095

10.000

45.81

0.00942

NORMAL

PIER

2.000

3.142

0.095

10.000

50.00

0.00942

SEISMIC

PIER

2.000

3.142

0.095

10.000

62.92

0.00942

WIND

PIER

2.000

3.142

0.095

10.000

38.26

0.00942

0.300

895.20

163.86

0.300

817.60

315.24

0.300

895.20

307.75

0.300

743.73

137.32

0.300

738.36

318.65

0.300

750.86

236.99

RO=D/2

RI=RADIUS OF REINFT RING=RO-C

T=THK OF REINFT RING IN M

T=AS/(2PI*RI)

B=BD*PI/180

B1=COS(B)

A=ALPHA ANGLE=ACOS(RO*B1/RI)

RECOSB=RICOSA

B2=SIN(B)^3

B3=SIN(4*B)

B4=SIN(2*B)

A1=COS(A)

A2=SIN(2*A)

A3=SIN(A)

1.000

0.905

1.000

0.905

1.000

0.905

1.000

0.905

1.000

0.905

1.000

0.905

0.002

0.698

0.766

0.56

0.002

0.954

0.578

0.88

0.002

0.800

0.697

0.69

0.002

0.873

0.643

0.78

0.002

1.098

0.455

1.04

0.002

0.668

0.785

0.52

0.266

0.342

0.985

0.846

0.901

0.532

0.543

-0.626

0.943

0.639

0.983

0.769

0.369

-0.057

1.000

0.770

0.982

0.638

0.450

-0.342

0.985

0.710

1.000

0.704

0.706

-0.949

0.811

0.503

0.869

0.864

0.237

0.453

0.972

0.868

0.863

0.497

NUM1=(PI-B)/8+B3/32+B1*B2/3

NUM2=2*(RO^3)/(1+B1)

NUM3((RI^3)*T/(RO+RI*A1)

NUM4=((M-1)*PI+A-A2/2

NUM=NUMERATOR=NUM2*NUM1+NUM3*NUM4

0.384

1.132

0.001

28.385

0.455

0.359

1.267

0.001

28.661

0.477

0.377

1.179

0.001

28.475

0.464

0.369

1.217

0.001

28.555

0.471

0.333

1.374

0.001

28.883

0.482

0.386

1.120

0.001

28.363

0.451

DEM1=2*(RO^2)/(1+B1)

DEM2=B2/3+(PI-B)*B1/2+B1*B4/4

DEM3=2*(RI^2)*T/(RO+RI*A1)

DEM4=(M-1)*PI*A1-A3+A*A1

DEM=DENOMINATOR=DEM1*DEM2+DEM3*DEM4

CHECK FOR ECC

CALCULATED EC=NUM/DEM

ACTUAL EC=M/P

CHECK FOR STRESSES

NAC=DEPTH OF NA BELOW CENT AXIS=RO*COS(B)

NAD=DEPTH OF NA FROM TOP=RO+NAC

DE=EFFECTIVE DEPTH=D-C

c = COMP STRESS IN CONC (t/m2) = P/DEM

1.132

1.213

0.002

23.876

1.410

1.267

0.950

0.002

17.852

1.234

1.179

1.113

0.002

21.672

1.347

1.217

1.037

0.002

19.933

1.296

1.374

0.793

0.002

13.882

1.115

1.120

1.241

0.002

24.485

1.428

0.322

0.183

0.386

0.386

0.345

0.344

0.363

0.185

0.432

0.432

0.316

0.316

0.643

1.643

1.905

574.0

1000.0

916

24480.0

SAFE

0.455

1.455

1.905

662.1

1500.0

2046.4

36720.0

SAFE

DATA

D=DIA OF PIER IN M

AREA OF PIER

C=COVER FROM CL OF REINFT IN M

M=MODULAR RATIO

BD=BETA ANGLE FOR DEFINING NA IN DEG.

AS=AREA OF STEEL IN SQM

20

30 Nos

PERCENTAGE STEEL %

P=VERTICAL LOAD IN T

BM=BENDING MOMENT IN T-M

PERMISSIBLE STRESS IN CONC

t = TENSILE STRESS IN STEEL (t/m2)

PERMISSIBLE STRESS IN STEEL

0.766

0.578

0.697

1.766

1.578

1.697

1.905

1.905

1.905

629.7

662.5

659.7

< 1000.0 < 1500.0 < 1330.0 <

495.5

1372

808.4

< 24480.0 < 36720.0 < 32558.4 <

SAFE

SAFE

SAFE

Hence Provide 30 nos 20 mm dia bars

Stirrups provided 8 mm dia @ 150 mm c/c

STEEL :- FE 500 & CONCRETE GRADE :- M30

<

<

0.785

1.785

1.905

525.9

< 1330.0

353.0

< 32558.4

SAFE

You might also like

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonNo ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignLam TranNo ratings yet

- Continuous BeamsDocument450 pagesContinuous BeamssreenivasaeeNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara84% (25)

- RCC11 Element DesignDocument6 pagesRCC11 Element Designredz00No ratings yet

- RCC design of major bridge abutmentsDocument26 pagesRCC design of major bridge abutmentsshashibhushan singhNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Column DesignDocument68 pagesColumn DesignPiyush Tiwari100% (1)

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Cone Calculations - AD MerkblatterDocument15 pagesCone Calculations - AD MerkblatterSajal KulshresthaNo ratings yet

- Box Girder Super Structure1Document87 pagesBox Girder Super Structure1hemantkle2u75% (4)

- Gantry Girder UnprotectedDocument95 pagesGantry Girder Unprotectedjignesh14283% (12)

- Shutter DesignDocument28 pagesShutter DesignRajendra Prasad GubbalaNo ratings yet

- Geometrical Properties Material Properties: Design of Helicoidal StairDocument10 pagesGeometrical Properties Material Properties: Design of Helicoidal StairLeóstenis Gonçalves de AlmeidaNo ratings yet

- Flyover FaislabadDocument72 pagesFlyover Faislabadnespak06No ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignSovich82No ratings yet

- Stability BookletDocument38 pagesStability Bookletnawan100% (2)

- Box Girder Super Structure Design DetailsDocument98 pagesBox Girder Super Structure Design DetailsMark Christopher Del Rosario100% (1)

- Design of Grade SlabDocument7 pagesDesign of Grade SlabMUTHUKKUMARAM100% (1)

- Verifica Giunto Secondo AsmeDocument5 pagesVerifica Giunto Secondo AsmeFabio TemporiniNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearMohammed RasheeduddinNo ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element Designein_joNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignMuhammad IshaqNo ratings yet

- Industria Acero de Los Andes S.A.: Geometry and Volume of HeadsDocument4 pagesIndustria Acero de Los Andes S.A.: Geometry and Volume of HeadsJoc LuisNo ratings yet

- Culvert (Excel)Document97 pagesCulvert (Excel)Dwi Ist56% (9)

- StaircaseDocument8 pagesStaircaseVenkat BalajiNo ratings yet

- SSB L SectionDocument20 pagesSSB L SectionMuhammad Azeem KhanNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- 12 Design of Hordy Slab 23052014Document1 page12 Design of Hordy Slab 23052014Ahmad Badsha QuadriNo ratings yet

- Motherfather RoofbeamsDocument208 pagesMotherfather RoofbeamsDanely Cuales SucgangNo ratings yet

- Circular Concrete Pile DesignDocument3 pagesCircular Concrete Pile DesignPn EkanayakaNo ratings yet

- Tata Projects Limited Design of Thickener/Feedbox Tower: TPL-039-CV-CAL-6946Document67 pagesTata Projects Limited Design of Thickener/Feedbox Tower: TPL-039-CV-CAL-6946Anonymous SKbL67p9No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Album of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199From EverandAlbum of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Characteristic Modes: Theory and Applications in Antenna EngineeringFrom EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Novel Carbon Materials and Composites: Synthesis, Properties and ApplicationsFrom EverandNovel Carbon Materials and Composites: Synthesis, Properties and ApplicationsXin JiangNo ratings yet

- Album of Dated Latin Inscriptions, Part I, Plates: Rome and the Neighborhood, Augustus to NervaFrom EverandAlbum of Dated Latin Inscriptions, Part I, Plates: Rome and the Neighborhood, Augustus to NervaNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Martial Arts - Bruce Lee's Speed TrainingDocument4 pagesMartial Arts - Bruce Lee's Speed Trainingbrogan97% (33)

- STAAD - Pro: Department of Civil Engineering, Iit RoorkeeDocument21 pagesSTAAD - Pro: Department of Civil Engineering, Iit RoorkeeNayan FataniaNo ratings yet

- Tips and Tricks For Using STAADDocument2 pagesTips and Tricks For Using STAADYusak Santoso UseNo ratings yet

- Move CalDocument2 pagesMove CalepcepcepcNo ratings yet

- Computation of Centrifugal Force For Curved DecksDocument3 pagesComputation of Centrifugal Force For Curved DecksepcepcepcNo ratings yet

- Bridge BearingDocument162 pagesBridge BearingKabbilawsh Peruvazhuthi100% (6)

- Advances in Bridge Fatigue TestingDocument11 pagesAdvances in Bridge Fatigue TestingrammirisNo ratings yet

- Bow-String Girder - Design & Construction AspectsDocument12 pagesBow-String Girder - Design & Construction Aspectsepcepcepc100% (1)

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- Covid 19 PDFDocument117 pagesCovid 19 PDFvicky anandNo ratings yet

- 3 Manacsa&Tan 2012 Strong Republic SidetrackedDocument41 pages3 Manacsa&Tan 2012 Strong Republic SidetrackedGil Osila JaradalNo ratings yet

- A Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video ApplicationsDocument8 pagesA Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video Applicationskvpk_vlsiNo ratings yet

- REMOVE CLASS 2024 SOW Peralihan MajuDocument4 pagesREMOVE CLASS 2024 SOW Peralihan MajuMohd FarezNo ratings yet

- Amazon Invoice Books 4Document1 pageAmazon Invoice Books 4raghuveer9303No ratings yet

- Technology Class ResumeDocument4 pagesTechnology Class Resumeapi-259588430No ratings yet

- Trial BalanceDocument2 pagesTrial BalanceJoseph Bayo BasanNo ratings yet

- MAT ALLEN SAMPLE PAPER-01 MENTAL ABILITY TEST QUESTIONSDocument10 pagesMAT ALLEN SAMPLE PAPER-01 MENTAL ABILITY TEST QUESTIONSSachin KumarNo ratings yet

- 2 Both Texts, and Then Answer Question 1 On The Question Paper. Text A: Esports in The Olympic Games?Document2 pages2 Both Texts, and Then Answer Question 1 On The Question Paper. Text A: Esports in The Olympic Games?...No ratings yet

- DWDM Route Planning A4 WPDocument3 pagesDWDM Route Planning A4 WPChavara MatekweNo ratings yet

- Business Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDocument1 pageBusiness Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDorothy ParkerNo ratings yet

- MCQs on PharmacologyDocument101 pagesMCQs on PharmacologyMohammad Rashid88% (8)

- 01 The-Mckinsey-Edge-Hattori-En-26154Document5 pages01 The-Mckinsey-Edge-Hattori-En-26154Waqar AhmedNo ratings yet

- AlternatorDocument3 pagesAlternatorVatsal PatelNo ratings yet

- Measurement of Mass and Weight by NPLDocument34 pagesMeasurement of Mass and Weight by NPLN.PalaniappanNo ratings yet

- Pharmacology Ain Shams 123 - Compress 1Document552 pagesPharmacology Ain Shams 123 - Compress 1ahmed hoty100% (1)

- Rustom Shams PDFDocument48 pagesRustom Shams PDFmtaha85No ratings yet

- 2023 Catalog Score SummerDocument65 pages2023 Catalog Score Summermadhudasa0% (2)

- Curriculam VitaeDocument3 pagesCurriculam Vitaeharsha ShendeNo ratings yet

- USP FriabilityDocument2 pagesUSP Friabilityshdph100% (1)

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Engr2227 Apr03Document10 pagesEngr2227 Apr03Mohamed AlqaisiNo ratings yet

- Forecast Time Series-NotesDocument138 pagesForecast Time Series-NotesflorinNo ratings yet

- Qcs 2010 Section 13 Part 3 Accessories PDFDocument3 pagesQcs 2010 Section 13 Part 3 Accessories PDFbryanpastor106No ratings yet

- Fellowship in OncotherapeutDocument3 pagesFellowship in OncotherapeutNayan ChaudhariNo ratings yet

- Classical Fields 2Document2 pagesClassical Fields 2Jonathan SanchezNo ratings yet

- Management Theory and Practice: Methods of Performance AppraisalDocument3 pagesManagement Theory and Practice: Methods of Performance AppraisalRadha maiNo ratings yet

- Public OpinionDocument7 pagesPublic OpinionSona Grewal100% (1)

- FMAI - Ch04 - Stock MarketDocument105 pagesFMAI - Ch04 - Stock Marketngoc duongNo ratings yet