Professional Documents

Culture Documents

BCA 2012 Building Code Stairs and Identification of Stair Flights

BCA 2012 Building Code Stairs and Identification of Stair Flights

Uploaded by

Alexander Aditya WibowoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCA 2012 Building Code Stairs and Identification of Stair Flights

BCA 2012 Building Code Stairs and Identification of Stair Flights

Uploaded by

Alexander Aditya WibowoCopyright:

Available Formats

Extract from BCA 2012 Building Code of Australia

PART 3.9.1 STAIR CONSTRUCTION

Appropriate Performance Requirements:

Where an alternative stair system is proposed as an Alternative Solution to that described in Part 3.9.1, that

proposal must comply with

(a) Performance Requirement P2.5.1; and

(b) The relevant Performance Requirements determined in accordance with 1.0.10.

DEFINITIONS

3.9.1

The following definitions are used in this Part:

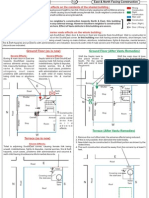

Flight means that part of a stair that has a continuous series of risers, including risers of winders, not interrupted by

a landing or floor (see Figure 3.9.1.1).

Explanatory Information:

A flight is the area of a stair that has a continuous slope created by the nosing line of treads. The length of a flight

is limited to restrict the distance a person could fall down a stair. Quarter landings, as shown in Figure 3.9.1.1, are

considered sufficient to halt a persons fall and therefore are considered for the purposes of this document not to be

part of the flight.

Figure 3.9.1.1 IDENTIFICATION OF STAIR FLIGHTS Plain View

Going means the horizontal dimension from the front to the back of a tread less any overhang from the next tread

above (see Figure 3.9.1.2)

Landing means an area at the top or bottom of a flight or between two flights.

Riser means the height between consecutive treads.

Spiral stair means a stair with a circular plan, winding around a central post with steps that radiate from a common

centre or several radii (see Figure 3.9.1.4).

Tapered tread means a stair tread with a walking area that grows smaller towards one end.

Winders means treads within a straight flight that are used to change direction of the stair (see Figure 3.9.1.1)

ACCEPTABLE CONSTRUCTION PRACTICE

3.9.1.1 Application

Compliance with this acceptable construction practice satisfies Performance Requirement P2.5.1, provided the stair

complies with the appropriate structural requirements of the Housing Provisions.

3.9.1.2 General Requirements

(a) Stairs serving habitable rooms, including external stairs must comply with 3.9.1.3 and 3.9.1.4.

(b) Stairs serving only non-habitable rooms, such as attics, storerooms and the like that are not used on a regular

or daily basis, must be constructed in accordance with(i) The provisions of this Part; or

(ii) AS1657.

Page 1 of 9

Extract from BCA 2012 Building Code of Australia

3.9.1.3 Stair Construction

Stairs must be constructed in accordance with the following:

(a) Each flight must have not more than 18 nor less than 2 risers.

(b) The nominal dimension of goings and risers of a stair must be constant throughout each stair flight except that

the going of winders in lieu of a quarter or half landing may vary from the going of the straight treads within the

same flight provided that the going of all such winders is constant.

(c) Treads must be of solid construction (not mesh or other perforated material) if the stairway is more than 10m

high or connects more than 3 storeys.

(d) A flight of stairs must not have more than 3 winders in lieu of each quarter landing or 6 winders in lieu of each

half landing.

(e) The riser opening must not allow a 125mm sphere to pass through between the treads.

(f) Treads must have a slip-resistant finish or a suitable non-skid strip near the edge of the nosings.

(g) Landings must(i) Be not less than 750mm long and where this involves a change in direction, the length is measured

500mm from the inside edge of the landing (see Figure 3.9.1.5, Diagram a); and

(ii) Have a gradient not steeper than 1:50; and

(iii) Be provided where the sill of a threshold of a doorway opens on to a stair that provides a change in floor

level or floor to ground level greater than 3 risers or 570mm (see Figure 3.9.1.5, Diagram b).

Explanatory Information:

3.8.2.2 contains the required height for a ceiling in a stairway, measured vertically from the nosing line.

3.9.1.4 Riser and Going Dimensions

The riser and going dimensions for each flight, except for the going of winders in lieu of a quarter or half landing,

must comply with the following:

(a) The going (G), riser (R) and slope relationship quantity (2R+G) must be in accordance with Figure 3.9.1.2.

(b) The point for measurement of the going (G) in the slope relationship quantity as described in Figure 3.9.1.3

must be(i) For tapered treads (other than treads in a spiral stair)(A) Not more than 1m wide, the middle of the unobstructed width of the stair (see Figure 3.9.1.3,

Diagram b); and

(B) More than 1m in width, 400mm from the unobstructed width of each side of the stair (see Figure

3.9.1.3, Diagram c); and

(ii) For treads in spiral stairs, the point seven tenths of the unobstructed distance from the face of the centre

pole or support towards the handrail side (see Figure 3.9.1.4).

Figure 3.9.1.2 STAIR RISER AND GOING DIMENSIONS (mm)

Riser (R)

GOING (G)

(see Figure below

(see Figure below)

STAIR TYPE

Max

Min

Max

Min

Stairs (other than spiral)

190

115

355

240

Spiral

220

140

370

210

SLOPE RELATIONSHIP

(2R+G)

Max

Min

700

550

680

590

Page 2 of 9

Extract from BCA 2012 Building Code of Australia

Figure 3.9.1.3

MEASUREMENT OF SLOPE RELATIONSHIP Plain view

Diagram a Stair with 2 flights

Diagram b Tapered treads not more than 1m wide

Diagram c Tapered treads more than 1m in width

Figure 3.9.1.4

SPIRAL STAIRS

Diagram a Measurement for slope relationship

Page 3 of 9

Extract from BCA 2012 Building Code of Australia

Diagram b Measurement for openings in stairs

Figure 3.9.1.5

LANDINGS

Diagram a Stairway landing

Diagram b Threshold landing

3.9.1.5 Thresholds

Where a threshold is more than 190mm above the adjoining surface it must incorporate steps having riser and

going dimensions in accordance with 3.9.1.4.

Page 4 of 9

Extract from BCA 2012 Building Code of Australia

PART 3.9.2 BALUSTRADES

Appropriate Performance Requirements:

Where an alternative balustrade or other barrier is proposed as an Alternative Solution to that described in Part

3.9.2, that proposal must comply with

(a) Performance Requirement P2.1; and

(b) Performance Requirement P2.5.2; and

(c) The relevant Performance Requirements determined in accordance with 1.0.10.

ACCEPTABLE CONSTRUCTION PRACTICE

3.9.2.1 Application

Compliance with this acceptable construction practice satisfies Performance Requirement P2.5.2 for balustrades or

other barriers.

3.9.2.2 When balustrades or other barriers are required.

(a) A continuous balustrade or other barrier must be provided along the side of any roof to which public access is

provided, any stairway or ramp, any floor, corridor, hallway, balcony, deck, verandah, mezzanine, access

bridge or the like and along the side of any path of access to a building, if

(i) it is not bounded by a wall; and

(ii) its level above the surface beneath, is more than:

(A) 4m where it is possible for a person to fall through an openable window; or

(B) 1m in any other case (see Figure 3.9.2.3).

(b) The requirements of (a) do not apply to:

(i) Areas referred to in 3.9.1.2(b); or

(ii) A retaining wall unless the retaining wall forms part of; or is directly associated with a delineated path of

access to a building from the road, or a delineated path of access between buildings.

Explanatory Information

It is deemed possible for a person to fall through an openable window when a 125mm sphere is able to pass

through the window opening

3.9.2.3 Balustrades or other barrier construction

(a) The height of a balustrade or other barrier must be in accordance with the following:

(i) The height must not be less than 865mm above the nosings of the stair treads or the floor of a ramp.

(ii) The height must not be less than

(A) 1m above the floor of any access path, balcony, landing or the like (see Figure 3.9.2.1); or

(B) 865mm above the floor of a landing to a stair or ramp where the balustrade or other barrier is

provided along the inside edge of the landing and is not more than 500mm long; or

(C) 865mm above the floor beneath an openable window.

(b) A transition zone may be incorporated where the balustrade or other barrier height changes from 865mm on

the stair flight or ramp to 1m at the landing (see Figure 3.9.2.2).

(c) Openings in balustrades (including decorative balustrades) or other barriers must be constructed so that any

opening does not permit a 125mm sphere to pass through it and for stairs; the opening is tested above the

nosing line of the stair treads.

(d) A balustrade or other barrier, except a window serving as a barrier must be designed to take loading forces in

accordance with AS/NZS1170.1.

Explanatory Information

A window forming part of a barrier is not required to comply with AS/NZS1170.1 as it is exempted by 3.9.2.3(d).

However, a window serving as a barrier must comply with the glazing assembly provisions of AS2047 or AS1288.

These provisions consider the wind loading on the glass and human impact requirements

(e) For floors more than 4m above the surface beneath, any horizontal elements within the balustrade or other

barrier between 150mm and 760mm above the floor must not facilitate climbing.

Explanatory Information

For a window forming part of a barrier, a window sill between 150mm and 760mm above the floor is deemed to

facilitate climbing

Page 5 of 9

Extract from BCA 2012 Building Code of Australia

(f)

A wire balustrade must be constructed in accordance with the following and is deemed to meet the

requirements of (c):

(i) For horizontal wire systems

(A) when measured with a strain indicator, it must be in accordance with the tension values in Table

3.9.2.1; or

(B) must not exceed the maximum deflections in Table 3.9.2.1.

(ii) For non-continuous vertical wire systems, when measured with a strain indicator, must be in accordance

with the tension values in Table 3.9.2.1 (see note 4).

(iii) For continuous vertical or continuous near vertical sloped wire systems

(A) must have wires of no more than 2.5mm diameter with a lay of 77 or 719 construction; and

(B) changes in direction at support rails must pass around a pulley block without causing permanent

deformation to the wire; and

(C) must have supporting rails, constructed with a spacing of not more than 900mm, of a material that

does not allow deflection that would decrease the tension of the wire under load; and

(D) when the wire tension is measured with a strain indicator, it must be in accordance with the tension

values in Table 3.9.2.2 and measured in the furthermost span from the tensioning device.

Explanatory Information

1. For the purpose of this clause, a wire balustrade consist of a series of tensioned wire rope connected to either

vertical or horizontal supports serving as a guard to minimise the risk of a person falling from a roof, stairway,

raised floor level or the like.

2. A wire balustrade excludes wire mesh fences and the like.

3. To assist in the application of 3.9.2.3(f), the following terms have been defined:

(a) Continuous where the wire spans three or more supports

(b) Non-continuous where the wire only spans between two supports

(c) Pully block a device consisting of a wheel in which a wire runs around to change its direction

(d) Permissible deflection is the allowable bending of the wire

(e) Support rails are horizontal components of the balustrade system that span across the top and bottom

to provide structural support

4. Tables 3.9.2.1 and 3.9.2.2 contains tension requirements for wires in vertical wire balustrade systems with

varying post spacings, wire spacings and wire type. The figures contained in the table were derived from

testing the spacing combinations in order to prevent the passage of a 125mm diameter solid cone penetrating

between the wires at a predetermined force.

5. Care needs to be taken to ensure that wire tension will be maintained during the life of the balustrade. In

some situations, it may be necessary to incorporate lock-off devices to prevent loosening of the wires.

6. Likewise, if a threaded anchor bears against a soft wood post or rail, the anchor may indent the post or rail,

thus loosening the wire.

7. Temperature effects on the tension of the wire may be significant but there is little that can be done to allow for

temperature variation in service. The shorter the wire span, the lesser the effect will be.

8. Stainless steel wire with a lay of 1x19 has the greatest elastic modulus and will take up the same load with

less extension than equivalent wires with other lays

9. Sharp ends of wires at terminations and swages need to be removed for the safety of children and other

people. No wire end should protrude more than half the diameter of the wire from the swage or termination

fitting.

Page 6 of 9

Extract from BCA 2012 Building Code of Australia

Table 3.9.2.1 Wire Balustrade Construction - Required Tension for Stainless Steel Horizontal Wires

600

Wire dia.

(mm)

Lay

2.5

7X7

2.5

1X19

3.0

7X7

3.0

1x19

4.0

7x7

4.0

1x19

4.0

7x19

Wire Spacing

Clear Distance Between Posts (mm)

900

1000 1200 1500 1800 2000

2500

Minimum required tension in Newtons (N)

(mm)

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

800

55

382

869

35

420

1140

15

250

865

25

325

1090

5

196

835

5

30

853

155

394

1038

190

630

1218

218

630

1565

178

413

1278

183

555

1500

73

422

1182

5

192

1308

290

654

1412

263

730

1368

310

735

X

270

500

1390

261

670

1705

97

480

1360

10

300

1487

358

785

1598

415

824

X

402

840

X

314

741

1639

340

785

1910

122

524

1528

15

415

1610

425

915

1785

478

1025

X

585

1050

X

506

818

X

520

1015

X

235

760

1837

20

593

2048

599

1143

2165

823

1288

X

810

1400

X

660

1083

X

790

1330

X

440

1100

2381

147

1105

2608

860

1485

2735

1080

X

X

1125

1750

X

965

1370

X

1025

1725

X

664

1358

2811

593

1303

3094

1080

1860

X

1139

X

X

1325

X

X

1168

1565

X

1180

1980

X

813

1530

3098

890

1435

3418

1285

2105

X

X

X

X

X

X

X

1491

X

X

X

X

X

1178

2130

X

1280

1844

3849

1540

2615

X

Notes:

1. Lay = number of strands by the number of individual wires in each strand. For example 7 x 19 consists of 7 strands with 19

individual wires in each strand

2. Where a change of direction is made in the run of a wire, the tensioning device is to be placed at the end of the longest span.

3. If a 3.2mm wire is used the tension figures for 3.0mm wire are applied

4. This table may also be used for a set of non-continuous (single) vertical wires forming a balustrade using the appropriate clear

distance between posts as the vertical clear distance between the rails.

5. X = Not allowed because the required tension would exceed the safe load of the wire.

6. Tension measured with a strain indicator

Table 3.9.2.2 Continuous Vertical Wire Balustrade Construction Required Wire Tension

Maximum Clear Spacing between Rails (mm)

900

Wire dia.

(mm)

Lay

2.5

7x19

2.5

7x7

Wire Spacing

(mm)

80

100

110

80

100

110

Required Tension in Newtons

145

310

610

130

280

500

Notes:

1. Lay = number of strands by the number of individual wires in each strand. For example 7 x 19 consists of 7 strands with 19

individual wires in each strand

2. Vertical wires require two pulley blocks to each 180o change of direction in the wire.

3. Near vertical wires may only require one pulley block for each change of direction.

4. Tension measured with a strain indicator

5. The table only includes 7x7 and 7x19 wires due to other wires not having sufficient flexibility to make the necessary turns.

Page 7 of 9

Extract from BCA 2012 Building Code of Australia

Table 3.9.2.3 Wire Balustrade Construction Maximum Permissible Deflection for Stainless Steel Wires

Wire dia. (mm)

2.5

3.0

4.0

Wire Spacing

(mm)

60

80

60

80

60

80

Clear Distance Between Posts (mm)

600

900

1200

1500

1800

2000

Maximum permissible deflection of each wire in mm when a

2kg mass is suspended at mid span

17

11

9

8

8

8

7

5

5

5

X

X

19

13

8

7

7

7

8

6

6

5

5

5

18

12

8

8

7

7

8

6

4

4

4

4

Notes:

1. Where a change of direction is made in the run of a wire the 2kg mass must be placed at the middle of the longest span.

2. If a 3.2mm wire is used the tension figures for 3.0mm wire are applied

3. This table may also be used for a set of non-continuous (single) vertical wires forming a balustrade using the appropriate clear

distance between posts as the vertical clear distance between the rails. The deflection (offset) is measured by hooking a

standard spring scale to the mid span of each wire and pulling it horizontally until a force of 19.6 N is applied.

4. X = Not allowed because the required tension would exceed the safe load of the wire.

5. This table has been limited to 60mm and 80mm spaces for 2.5mm, 3mm and 4mm diameter wires because the required wire

tensions at greater spacings would require the tension to be beyond the wire safe load limit, or the allowed deflection would be

impractical to measure.

(g)

A glass balustrade must comply with AS1288.

Figure 3.9.2.1 BALUSTRADE OR OTHER BARRIER CONSTRUCTION

Note: For the purposed of this Figure, a 125mm sphere must not pass between rails or through the gap when

tested above the nosing line

Figure 3.9.2.2 TRANSITION NOTES

Page 8 of 9

Extract from BCA 2012 Building Code of Australia

Figure 3.9.2.3 BALUSTRADES OR OTHER BARRIERS WHEN REQUIRED

3.9.2.4 Handrails

(a) Handrails to a stairway or ramp must

(i) be located along at least one side of the flight or ramp; and

(ii) Be located along the full length of the flight or ramp, except in the cast where a handrail is associated with a

balustrade the handrail may terminated where the balustrade terminates; and

(iii) Have the top surface of the handrail not less than 865mm vertically above the nosings of the stair treads or the

floor surface of the ramp; and

(iv) have no obstruction on or above them that will tend to break a handhold, except for newel posts, ball type

stanchions, or the like.

(b) The requirements of (a) do not apply to

(i) areas referred to in 3.9.1.2(b); or

(ii) a stairway or ramp providing a change in elevation of less than 1m; or

(iii) a landing; or

(iv) a winder where a newel post is installed to provide a handhold; or

(v) a stairway or ramp in a Class 10 building

Explanatory Information:

1. A balustrade top rail may be suitable as a handrail if it meets 3.9.2.4

2. A handrail is only required on one side of the flight or ramp

3. The handrail may extend the full length of the flight or ramp except where the handrail is associated with the

balustrade, in which case the handrail can terminate where the balustrade is allowed to terminate. This would

allow for designer or geometric balustrades which may finish a few treads from the bottom of the stairway.

4. An example of where a handrail is not required would be a flight consisting of 5 risers as the change in elevation

is less than 1m.

5. A handrail is not required for winders if a newel post is installed to provide a handhold.

Page 9 of 9

You might also like

- ACORN - Superglide 120 - Installation-ManualDocument32 pagesACORN - Superglide 120 - Installation-ManualAlain2983% (6)

- Complete Internal Audit Checklist (HSE)Document59 pagesComplete Internal Audit Checklist (HSE)Meer Jan89% (18)

- Fixed Access Ladders: Engineering Data Sheet 2-04 - Ministry of LabourDocument7 pagesFixed Access Ladders: Engineering Data Sheet 2-04 - Ministry of LabourEd Cortes50% (2)

- Economical Structural Steel WorkDocument83 pagesEconomical Structural Steel Workc_arkell100% (20)

- Nissan SkylineDocument39 pagesNissan SkylineNeville Dickens50% (2)

- Philippine PWD CodeDocument58 pagesPhilippine PWD CodeMk Gonzales100% (2)

- Ladders Engineering Data Sheet Ontario - 2014Document5 pagesLadders Engineering Data Sheet Ontario - 2014Eric0% (1)

- OSHA Regulations 1926 Subpart L ScaffoldsDocument34 pagesOSHA Regulations 1926 Subpart L ScaffoldsfiercecatNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Close Quarter BattleDocument37 pagesClose Quarter Battleeddie6355100% (3)

- Building SOR 2014 (Excel Sheet)Document423 pagesBuilding SOR 2014 (Excel Sheet)Amit Patel50% (2)

- TCXDVN 296-2004 FinalDocument52 pagesTCXDVN 296-2004 Finalapi-3697396100% (6)

- Fire ReportDocument39 pagesFire ReportAsif Rajian Khan AponNo ratings yet

- 3.9.1 StairDocument4 pages3.9.1 StairchadNo ratings yet

- Guard ExcerptDocument7 pagesGuard Excerptmahantesh_82No ratings yet

- Staircases: Download Civil Engineering EbookDocument38 pagesStaircases: Download Civil Engineering EbookYudirwan Tanjung100% (1)

- VBBL Stairs Sect 9.8Document7 pagesVBBL Stairs Sect 9.8BangshoongNo ratings yet

- Osha 1910.25 StaiwaysDocument10 pagesOsha 1910.25 StaiwaysDinda Adharia GhaisaniNo ratings yet

- Ontario Stairs Buildign Code Bylaw S 9.8 StairsDocument11 pagesOntario Stairs Buildign Code Bylaw S 9.8 StairsakkNo ratings yet

- Kharagpur - Staircase Design PDFDocument38 pagesKharagpur - Staircase Design PDFjmusopole50% (2)

- StanData - Stairs in Dwelling UnitsDocument9 pagesStanData - Stairs in Dwelling UnitstitantoughNo ratings yet

- 3.9.2 BalustradesDocument6 pages3.9.2 BalustradeschadNo ratings yet

- 1910.29 - Fall Protection Systems and Falling Object Protection - Criteria and Practices. - Occupational Safety and Health AdministrationDocument13 pages1910.29 - Fall Protection Systems and Falling Object Protection - Criteria and Practices. - Occupational Safety and Health AdministrationJose FloresNo ratings yet

- Osha Spiral Staircase Req.Document5 pagesOsha Spiral Staircase Req.njkasdncjkdNo ratings yet

- 2012 Building CodeDocument11 pages2012 Building CodeygfrostNo ratings yet

- 2018 Building Code Changes PDFDocument74 pages2018 Building Code Changes PDFvsdfsd258No ratings yet

- Project Report - InternshipDocument60 pagesProject Report - InternshipRajashri RajkumarNo ratings yet

- Section 9.15. Footings and Foundations BC - 2018dbp9s915Document9 pagesSection 9.15. Footings and Foundations BC - 2018dbp9s915Trevor ClineNo ratings yet

- LaddersDocument11 pagesLaddersNaveen ReddyNo ratings yet

- 1910.23-OSHA Ladders StandardsDocument10 pages1910.23-OSHA Ladders Standardsr afriantoNo ratings yet

- Sway Bracing:: PW P P, P PDocument3 pagesSway Bracing:: PW P P, P PShafiullah AmanNo ratings yet

- OSHA-Scaffolding DesigDocument50 pagesOSHA-Scaffolding DesigKrm ChariNo ratings yet

- Column Design 1. Guideline For Fixing The Position and Orientation of Columns in The LayoutDocument14 pagesColumn Design 1. Guideline For Fixing The Position and Orientation of Columns in The LayoutV.m. RajanNo ratings yet

- Osha 1956.502Document10 pagesOsha 1956.502DURANLEENo ratings yet

- Robin Report1Document44 pagesRobin Report1Saurabh GargNo ratings yet

- NAT BCA 07-10 Stair Construction For Class 1 BuildingsDocument2 pagesNAT BCA 07-10 Stair Construction For Class 1 Buildingsusername_imanNo ratings yet

- Demolition E2004 Section 3Document29 pagesDemolition E2004 Section 3cclNo ratings yet

- General Design Requirements: 4.1 Access 4.1.1 This Section Aims To Ensure Proper Access For All People, With or WithoutDocument65 pagesGeneral Design Requirements: 4.1 Access 4.1.1 This Section Aims To Ensure Proper Access For All People, With or WithoutvaibhavNo ratings yet

- Advisory Circular: Federal Aviation AdministrationDocument18 pagesAdvisory Circular: Federal Aviation Administrationtally3tallyNo ratings yet

- Advisory Circular: Federal Aviation AdministrationDocument22 pagesAdvisory Circular: Federal Aviation AdministrationMohamed OsamaNo ratings yet

- 4.3 Stairs and RampsDocument11 pages4.3 Stairs and RampsthakrarhitsNo ratings yet

- Advisory Circular: Federal Aviation AdministrationDocument11 pagesAdvisory Circular: Federal Aviation Administrationvikas00707No ratings yet

- 7-2 - CFR 1910 (SubPart D - 1910.29)Document10 pages7-2 - CFR 1910 (SubPart D - 1910.29)Mohamed HelmyNo ratings yet

- Section 9.8. Stairs, Ramps, Handrails and Guards: 9.8.1. ApplicationDocument11 pagesSection 9.8. Stairs, Ramps, Handrails and Guards: 9.8.1. ApplicationJacob de WildeNo ratings yet

- AIRPORT Control Tower PrincipleDocument7 pagesAIRPORT Control Tower PrincipleJude Maala Onanad100% (1)

- Cantilever DesignDocument8 pagesCantilever DesignJun CrisostomoNo ratings yet

- OSHA 1926 Subpart R - Steel ErectionDocument30 pagesOSHA 1926 Subpart R - Steel Erectionferrero68100% (1)

- OSHA Fixed Ladders DesignDocument7 pagesOSHA Fixed Ladders Designken910076No ratings yet

- APP068Document7 pagesAPP068Savio WongNo ratings yet

- Bridge Design BasicsDocument16 pagesBridge Design BasicsTanvir Shahrier MahmudNo ratings yet

- MP 3 4 Swimming Pool BarriersDocument39 pagesMP 3 4 Swimming Pool Barrierssnorburn1No ratings yet

- New Ontario Building Code Highlights: The Corporation of The City of Sarnia Building DepartmentDocument13 pagesNew Ontario Building Code Highlights: The Corporation of The City of Sarnia Building Departmentparag7676No ratings yet

- StairsDocument21 pagesStairstomnubiNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Design of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresFrom EverandDesign of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresRating: 3.5 out of 5 stars3.5/5 (2)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Noise and Vibration Control in Automotive BodiesFrom EverandNoise and Vibration Control in Automotive BodiesRating: 4 out of 5 stars4/5 (1)

- The Access Manual: Designing, Auditing and Managing Inclusive Built EnvironmentsFrom EverandThe Access Manual: Designing, Auditing and Managing Inclusive Built EnvironmentsNo ratings yet

- Balcony Stair Balustrade ExtractDocument9 pagesBalcony Stair Balustrade ExtractNeville DickensNo ratings yet

- SB50 Anderson ConnectorsDocument6 pagesSB50 Anderson ConnectorsNeville DickensNo ratings yet

- Industrial BuildingsDocument62 pagesIndustrial BuildingsilovevinaNo ratings yet

- Check List - Off Grid Power SystemsDocument10 pagesCheck List - Off Grid Power SystemsNeville DickensNo ratings yet

- Keyboard ShortcutsDocument1 pageKeyboard ShortcutsNguyễn KhoaNo ratings yet

- Lesson11 CastUnitDrawing PDFDocument23 pagesLesson11 CastUnitDrawing PDFKadutrisampaNo ratings yet

- Sprint Car Racing: Non-Winged Sprint CarsDocument5 pagesSprint Car Racing: Non-Winged Sprint CarsNeville DickensNo ratings yet

- NiraliDocument13 pagesNiraliNIYATI PANDYANo ratings yet

- Live WorkDocument82 pagesLive Workcmpn_arqpoliNo ratings yet

- Fire Safety AssignmentDocument35 pagesFire Safety AssignmentFelix OoNo ratings yet

- BP 220 PD 957 QuestionnaireDocument5 pagesBP 220 PD 957 QuestionnaireJan WickNo ratings yet

- Note 4Document6 pagesNote 4MuskanNo ratings yet

- Stair DetailsDocument7 pagesStair DetailsDennis LugoNo ratings yet

- BQ With Priced (Water Tank)Document107 pagesBQ With Priced (Water Tank)INTAN FARHANA MOHD ROSLANNo ratings yet

- Shopping Mall: Case StudyDocument64 pagesShopping Mall: Case Studybijaya neupaneNo ratings yet

- The0Ry of Design: Module Iii - CirculationDocument45 pagesThe0Ry of Design: Module Iii - CirculationThirumeni MadavanNo ratings yet

- Smay Smoke and Heat Control SystemsDocument22 pagesSmay Smoke and Heat Control SystemsLiviu ToaderNo ratings yet

- 3 - Two Side Road - House ExamplesDocument123 pages3 - Two Side Road - House ExamplesRPh Krishna Chandra Jagrit100% (1)

- Frozen Heat Chapt SevenDocument29 pagesFrozen Heat Chapt Sevennot_a_geekNo ratings yet

- Chdeb AmbaraDocument16 pagesChdeb AmbaravsmkreddysNo ratings yet

- Stair LiftDocument8 pagesStair LiftVASNo ratings yet

- BUILDING BYE LAWS RELATED TO FIRE SAFETY PROVISIONS - IndiaDocument20 pagesBUILDING BYE LAWS RELATED TO FIRE SAFETY PROVISIONS - IndiaSONY ABRAHAMNo ratings yet

- Malaysia Boleh!: Reference Calculation Output Staircase (Supported by Beams)Document6 pagesMalaysia Boleh!: Reference Calculation Output Staircase (Supported by Beams)Chung May LynnNo ratings yet

- Guido Cimadomo (c6)Document15 pagesGuido Cimadomo (c6)Red OuanNo ratings yet

- Chapter-2 Functional Planning of BuildingsDocument17 pagesChapter-2 Functional Planning of BuildingsSileshi AzagewNo ratings yet

- The Legacy of BaelardDocument21 pagesThe Legacy of BaelardAlbertNo ratings yet

- Traditional To Modern Residential ArchitectureDocument11 pagesTraditional To Modern Residential ArchitectureRimsha AkramNo ratings yet

- Mojar Project Civil EngineerDocument25 pagesMojar Project Civil Engineerahmadnuman448No ratings yet

- Code Case Study QuestionsDocument19 pagesCode Case Study QuestionsAlexandra Román FranquiNo ratings yet

- Amendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering WorksDocument8 pagesAmendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering Worksraviteja036No ratings yet

- The Maps Below Show The Changes in The Art Gallery Ground Floor in 2015 and Present DayDocument4 pagesThe Maps Below Show The Changes in The Art Gallery Ground Floor in 2015 and Present DayThanh Hieu Nguyen ThiNo ratings yet