Professional Documents

Culture Documents

Convertidor D8L PDF

Uploaded by

David FierroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Convertidor D8L PDF

Uploaded by

David FierroCopyright:

Available Formats

Copyright 1991, 2011 Caterpillar Inc. All Rights Reserved.

Page 1 of 5

53Y D8L TRACK-TYPE TRACTOR Operacin de Sistemas

Nmero de publicacin SENR2336-00 Fecha de publicacin 1981/09/01 Fecha de actualizacin 1997/10/23

Torque Divider

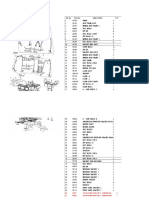

TORQUE DIVIDER

1. Flywheel.

2. Ring gear.

3. Housing.

4. Impeller.

5. Inlet passage.

6. Carrier.

7. Yoke.

8. Sun gear.

9. Planet gears.

10. Planet carrier.

11. Turbine.

file://C:\SIS\TMP\sis521prt.html

17/08/2011

Copyright 1991, 2011 Caterpillar Inc. All Rights Reserved.

Page 2 of 5

12. Stator.

13. Outlet passage.

14. Output shaft.

The torque divider connects the engine to the planetary transmission. This connection is both a

hydraulic connection and a mechanical connection. The hydraulic connection is through a torque

converter. The mechanical connection is through a planetary gear set.

The torque converter uses oil from the transmission charging pump to multiply the torque to the

transmission. When the machine works against a low load, the torque multiplication is low. When

the machine works against a high load, the torque multiplication is higher. A higher torque can then

be sent to the transmission during high load conditions. The planetary gear set also multiplies the

torque from the engine by making an increase in the mechanical advantage through its gears. This

torque multiplication also makes an increase as the load on the machine becomes higher. During no

load conditions, neither the torque converter or the planetary gear set can multiply the torque from

the engine.

The torque divider is installed into the engine flywheel (1). The torque divider housing is installed on

the engine flywheel housing. Output shaft (14) is connected to yoke (7). Yoke (7) is connected to the

planetary transmission through a drive shaft.

The components of the planetary gear set are: sun gear (8), planet carrier (10), planet gears (9) and

ring gear (2). Sun gear (8) is connected to the flywheel by splines. Planet carrier (10) is connected to

output shaft (14) by splines. Planet gears (9) are held by planet carrier (10) and are engaged with the

sun gear (8) and ring gear (2).

The components of the torque converter are: housing (3), impeller (4), turbine (11) and stator (12).

Housing (3) is connected to flywheel (1) by splines. Impeller (4) is connected to housing (3). Turbine

(11) is connectd to ring gear (2) by splines. Stator (12) is connected to carrier (6) and can not turn.

TORQUE CONVERTER

file://C:\SIS\TMP\sis521prt.html

17/08/2011

Copyright 1991, 2011 Caterpillar Inc. All Rights Reserved.

Page 3 of 5

1. Flywheel.

2. Ring gear.

3. Housing.

4. Impeller.

5. Inlet passage.

6. Carrier.

7. Yoke.

8. Sun gear.

9. Planet gears.

10. Planet carrier.

11. Turbine.

12. Stator.

13. Outlet passage.

14. Output shaft.

Torque Converter Operation

Oil for the operation of the torque converter goes through inlet passage (5) in carrier (6) to impeller

(4). The rotation of the impeller gives force to the oil. The impeller sends the oil toward the outside

of the impeller, around the inside of housing (3) to turbine (11). The force of the oil hitting the

blades of the turbine causes the turbine to turn. Since the turbine is connected to ring gear (2), torque

is sent to planet gears (9). At this point in time, the torque given to the turbine by the force of the oil

from the impeller can not be more than the torque output of the engine to the impeller.

As the oil goes from the turbine, it moves in a direction opposite to the direction of impeller (4)

rotation. Stator (12) causes the oil to change direction. Since the stator is connected to carrier (6) and

can not turn, most of the oil is sent back to impeller (4). The remainder of the oil goes from the stator

through outlet passage (13) to the oil cooler.

The force of the oil from the stator can now add to the torque output from the engine to the impeller.

This extra force can give an increase to the torque output of the engine to the turbine. The larger the

difference between the speeds of the impeller and the turbine, the larger the amount of force of the

oil from the stator. Since it is the load on the machine that changes the speed of the turbine, the

higher the load, the larger the difference in the speeds of the impeller and the turbine. It is the

different loads on the machine that control the amount of torque multiplication that the force of the

oil from the stator can add.

Torque Divider Operation

The torque converter is driven by the engine through housing (3). The planetary gear set is driven by

the engine through sun gear (8). These connections let the torque output of the engine go in two

file://C:\SIS\TMP\sis521prt.html

17/08/2011

Copyright 1991, 2011 Caterpillar Inc. All Rights Reserved.

Page 4 of 5

separate directions. Because of the larger radius of ring gear (2), most of this torque is sent by the

torque converter through the ring gear to planet gears (9). The remainder of the torque is sent by sun

gear (8) to planet gears (9). If planet carrier (10) has no resistance to rotation (no load), sun gear (8),

planet gears (9), planet carrier (10) and ring gear (2) will turn atthe same speed. The torque from the

converter and from the planetary gear set is now through the planet carrier to output shaft (14) and

the planetary transmission. Neither the torque converter or the planetary gear set can multiply the

torque from the engine when they turn at the same speed.

When the machine has a load, planet carrier (10) has a resistance to rotation. Since sun gear (8) is

turning at the rpm of the engine, this resistance to rotation causes planet gears (9) to turn on their

shafts. Their rotation is opposite the rotation of ring gear (2). This causes a decrease in the speed of

the ring gear. Since turbine (11) is connected to the ring gear, a decrease in speed will cause the

torque converter to multiply the torque of the engine from housing (3). The torque multiplication is

sent to planet carrier (10) and the output shaft through the ring gear.

With the decrease in the speed of the ring gear, the torque of the engine through sun gear (8) and the

planetary gear set also multiplies. This torque multiplication is also sent to planet carrier (10) and the

output shaft.

If the resistance to rotation of planet carrier (10) becomes higher (more load on the machine), the

speed of the ring gear will decrease more. The slower speed will let the torque multiplication through

both the torque converter and the sun gear become higher. If the resistance to rotation of the planet

carrier becomes high enough, the ring gear will stop. During some very high load conditions, the

rotation of the planet carrier and the output shaft will also stop. This will cause the ring gear to turn

slowly in the opposite direction. At this time the torque multiplication of the torque converter and the

sun gear is at its maximum.

Torque Divider Lubrication

Oil for the lubrication of the torque divider bearings and the planetary gear set comes from the

supply used for the operation of the torque converter. The bearings constantly run in oil. Bearings

and gears in planetary gear set and the pilot bearing get lubrication through passages in the output

shaft.

Outlet Relief Valve For The Torque Converter

The outlet relief valve for the torque converter is fastened to the right hand side of the torque

converter case.

LOCATION OF OUTLET RELIEF VALVE

file://C:\SIS\TMP\sis521prt.html

17/08/2011

Copyright 1991, 2011 Caterpillar Inc. All Rights Reserved.

Page 5 of 5

COMPONENTS OF THE RELIEF VALVE

1.Body. 2. Inlet passage. 3. Outlet passage. 4. Poppet valve. 5. Valve spool. 6. Shims. 7.Spring.

The outlet relief valve controls the maximum pressure in the torque converter. The setting of the

outlet relief valve is about 550 kPa (80 psi). From the outlet relief valve, the oil goes through outlet

passage (3) to the power train oil cooler.

Oil goes into body (1) through inlet passage (2). The oil goes through a hole in valve spool (5) into

the chamber between poppet valve (4) and valve spool (5). The oil moves valve spool (5) against the

force of spring (7) when the pressure of the oil becomes greater than the force of the spring. The

movement of valve spool (5) permits the oil to flow through outlet passage (3).

Copyright 1991, 2011 Caterpillar Inc.

All Rights Reserved.

file://C:\SIS\TMP\sis521prt.html

17/08/2011

You might also like

- 18511006-Download 2013-2014 Suzuki Df100 Df115 Df140 Repair ManualDocument384 pages18511006-Download 2013-2014 Suzuki Df100 Df115 Df140 Repair Manualchuck88% (8)

- T-REX 1200R Parts Manual CAMPAGNA MOTORSDocument70 pagesT-REX 1200R Parts Manual CAMPAGNA MOTORScytoxxNo ratings yet

- Camshaft, ServiceDocument31 pagesCamshaft, ServiceIzz Bahar100% (7)

- Komatsu Crawler Doozer D61pxi 23 Shop Manual 25k14004Document20 pagesKomatsu Crawler Doozer D61pxi 23 Shop Manual 25k14004crystal100% (48)

- Caterpillar Service Manual CT S Eng3304dDocument10 pagesCaterpillar Service Manual CT S Eng3304dHugo VillcaNo ratings yet

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Transmision D6D PDFDocument72 pagesTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- Transmision de Tractor Oruga d4H CaterpiilarDocument174 pagesTransmision de Tractor Oruga d4H CaterpiilarSegundo Francisco Jauregui Valencia100% (9)

- Motor Basico C9Document9 pagesMotor Basico C9GerardoNo ratings yet

- 920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesDocument6 pages920 & 930 WHEEL LOADERS POWER TRAIN Pruebas y AjustesKarlOs Junco Sicha100% (1)

- Attachment 1: Nett Greentrap DPF Off-Road Certified Engine Family List (0 0.2 G/BHP-HR PM)Document24 pagesAttachment 1: Nett Greentrap DPF Off-Road Certified Engine Family List (0 0.2 G/BHP-HR PM)Goran MatovicNo ratings yet

- Case 580f Tractor Loader Backhoe Operators ManualDocument8 pagesCase 580f Tractor Loader Backhoe Operators Manualأكرم تيجي100% (1)

- Summer Training Report On Sona Koyo Steering Systems LTDDocument35 pagesSummer Training Report On Sona Koyo Steering Systems LTDRahul HansNo ratings yet

- English - System Operation - Embrague Freno y Dirección D8L TRACTOR 3408 ENGINEDocument48 pagesEnglish - System Operation - Embrague Freno y Dirección D8L TRACTOR 3408 ENGINEAron Benito Pari MachacuayNo ratings yet

- SENR3255 - D5 GB System Operation-1Document49 pagesSENR3255 - D5 GB System Operation-1frgmanNo ratings yet

- Digrama d6h FrenosDocument63 pagesDigrama d6h FrenosRODRIGO HERNANDEZNo ratings yet

- 938f TransmisiDocument23 pages938f TransmisiYudi setiawanNo ratings yet

- D 8 LDocument7 pagesD 8 LChristian RamosNo ratings yet

- Tabla de Presiones de Trans D6NDocument3 pagesTabla de Presiones de Trans D6NDavid manjarresNo ratings yet

- Caterpillar D353, 379, 398,399 Series: Clevite Heavy Duty Engine Parts Offering ForDocument4 pagesCaterpillar D353, 379, 398,399 Series: Clevite Heavy Duty Engine Parts Offering ForIgorCencičNo ratings yet

- Especificaciones Técnicas Caja D6CDocument2 pagesEspecificaciones Técnicas Caja D6CAlfredo Guzmán100% (2)

- Hydraulic Fan Speed - Test and Adjust: Shutdown SIS Previous ScreenDocument9 pagesHydraulic Fan Speed - Test and Adjust: Shutdown SIS Previous ScreenAbi JithNo ratings yet

- Tractor Fiat 480 Firing OrderDocument2 pagesTractor Fiat 480 Firing OrderRehan RashidNo ratings yet

- Piston and Rings: C4.4 Engines For Caterpillar Built MachinesDocument4 pagesPiston and Rings: C4.4 Engines For Caterpillar Built MachinesDiego Alejandro QuinteroNo ratings yet

- Spécifications Et Réglages TransmissionDocument8 pagesSpécifications Et Réglages TransmissionKJDNKJZEFNo ratings yet

- Transmission Oil Pump (3S2616) : EspecificaçõesDocument2 pagesTransmission Oil Pump (3S2616) : EspecificaçõesRaphael Bueno0% (1)

- CAT D7G-Sprocket AssembliesDocument20 pagesCAT D7G-Sprocket Assembliesyoga_jpbmbm100% (1)

- D8R Transmission PumpDocument3 pagesD8R Transmission PumpLenin GullapalliNo ratings yet

- Engine Cat 3116: Head InstallationDocument8 pagesEngine Cat 3116: Head InstallationYeremiaNo ratings yet

- Why Does An Excavator Sometimes Have One Track Faster?Document3 pagesWhy Does An Excavator Sometimes Have One Track Faster?Manuel GagnoNo ratings yet

- WDM D9R PTDocument2 pagesWDM D9R PTRendy PratamaNo ratings yet

- 936e Wheel Loader SisDocument3 pages936e Wheel Loader SisjoelNo ratings yet

- Transmision Planetery GearDocument8 pagesTransmision Planetery GearGerald BoyNo ratings yet

- Dokumen - Tips - Caterpillar Cat 416e Backhoe Loader Prefix Lms Service Repair Manual lms00001 and Up 1586118026Document20 pagesDokumen - Tips - Caterpillar Cat 416e Backhoe Loader Prefix Lms Service Repair Manual lms00001 and Up 1586118026Victor Admin Baus Ingeniería AplicadaNo ratings yet

- Transmission Hydraulic Control ValvesDocument7 pagesTransmission Hydraulic Control ValvesDarío Ache EmeNo ratings yet

- d8k Motor D342Document4 pagesd8k Motor D342Omar Suazo100% (1)

- CAT 926 - 3204 Engine TDC PDFDocument3 pagesCAT 926 - 3204 Engine TDC PDFferdyak1100% (1)

- Calibracion de ValvulasDocument5 pagesCalibracion de ValvulasSteve da RiviaNo ratings yet

- 920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsDocument56 pages920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsTransportation MaintananceNo ratings yet

- CAT 769c Valvula de Control de Transmision 1Document28 pagesCAT 769c Valvula de Control de Transmision 1Taller Pahr100% (1)

- Medidas y Torque Cilindros y BloqueDocument4 pagesMedidas y Torque Cilindros y BloqueIvan Castellanos100% (1)

- 938FDocument21 pages938Fمحمد يونسNo ratings yet

- Automatic Timing Advance 2Document10 pagesAutomatic Timing Advance 2nuari tri sNo ratings yet

- Chequeo Tiempo Bomba de Inyeccion 3056 CATDocument10 pagesChequeo Tiempo Bomba de Inyeccion 3056 CATAlejandro ValenzuelaNo ratings yet

- Pruebas y Ajustes 416bDocument30 pagesPruebas y Ajustes 416bVictor NunezNo ratings yet

- Tractores d9r D10r-HeuiDocument49 pagesTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- Hydraulic Pump 120GDocument25 pagesHydraulic Pump 120GSteven Y.MNo ratings yet

- Grader Engine and Powertrain TestDocument2 pagesGrader Engine and Powertrain TestGeorge Jhonson0% (1)

- Torque ConverterDocument18 pagesTorque ConverterAlex CastilloNo ratings yet

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainDocument23 pages938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleNo ratings yet

- Presion de Lubricacion de La TransmisionDocument3 pagesPresion de Lubricacion de La TransmisionEdgar Martinez CarmonaNo ratings yet

- Transmission Planetary 966Document13 pagesTransmission Planetary 966Walid Houran100% (1)

- 3304B y 3306B 1NS1-UP 1PS1-UP 1RS1-UPDocument41 pages3304B y 3306B 1NS1-UP 1PS1-UP 1RS1-UPCristobal Campos100% (4)

- Short Block For CAT 320 D PDFDocument5 pagesShort Block For CAT 320 D PDFerisunarkoNo ratings yet

- Transmission Planetary 966Document13 pagesTransmission Planetary 966Ahmed Rezk100% (1)

- Motor 3306 PDFDocument221 pagesMotor 3306 PDFCicero Melo100% (2)

- Catalogo de Partes Motores CATDocument10 pagesCatalogo de Partes Motores CATpablo100% (1)

- Shutdown: No Equipment Selected No Equipment Selected No Equipment SelectedDocument2 pagesShutdown: No Equipment Selected No Equipment Selected No Equipment SelectedFrezgi Birhanu100% (1)

- 1 Systems OperationDocument34 pages1 Systems Operationashraf elsayedNo ratings yet

- Convertidor CatDocument6 pagesConvertidor Catcarlos mendoza esquivelNo ratings yet

- 10 Torque DividerDocument6 pages10 Torque DividerLuc Iano JhonNo ratings yet

- Búsqueda Del Medio - Senr3454 - d9n Tractor Power TrainDocument43 pagesBúsqueda Del Medio - Senr3454 - d9n Tractor Power TrainAntoni Jesus Gabriel Amesquita CardenasNo ratings yet

- Torque Divider D8RDocument8 pagesTorque Divider D8RIslam ShoukryNo ratings yet

- 920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED B45Y 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsDocument17 pages920 WHEEL LOADER 62K07095-UP (MACHINE) POWERED B45Y 3304 ENGINE (SEBP1054 - 00) - Systems & ComponentsTransportation Maintanance100% (1)

- Cat 3PW Partes ConvertidorDocument3 pagesCat 3PW Partes ConvertidorguidoNo ratings yet

- Cat 3PW Partes 2 ConvertidorDocument3 pagesCat 3PW Partes 2 ConvertidorguidoNo ratings yet

- Cat 3PW Especificaciones ConvertidorDocument3 pagesCat 3PW Especificaciones ConvertidorguidoNo ratings yet

- 210 HDocument2 pages210 Hguido0% (1)

- 11 - Linhai CuvDocument108 pages11 - Linhai CuvTeofil Catalin TironNo ratings yet

- 03/27/2013 14:15:32 AP1011: Bill List by Vendor - Detail 1 Tracy DavisDocument79 pages03/27/2013 14:15:32 AP1011: Bill List by Vendor - Detail 1 Tracy DavisMahmoofNo ratings yet

- Sym VS 125 - 150 (EN)Document195 pagesSym VS 125 - 150 (EN)manualsym100% (1)

- Manual 05k en InglesDocument22 pagesManual 05k en InglesCocom Ivan100% (2)

- Mechanical DriveDocument1 pageMechanical DriveAmit PrusethNo ratings yet

- Catalogo Norco 2021 V2 Compressed-ComprimidoDocument80 pagesCatalogo Norco 2021 V2 Compressed-ComprimidonelsonNo ratings yet

- ZSK 9121 CB - 01Document23 pagesZSK 9121 CB - 01Joaquin Adolfo Chavez Quiroz100% (1)

- Manual Transmission and Differential 6-SPEED (6MT)Document128 pagesManual Transmission and Differential 6-SPEED (6MT)Truong Van HoatNo ratings yet

- Parts Catalog: 0CR10-M41000ENDocument70 pagesParts Catalog: 0CR10-M41000ENIndo BinaDiesel100% (2)

- Tomos Streetmate A55 - Information and Tuning ManualDocument29 pagesTomos Streetmate A55 - Information and Tuning ManualMieczysław MichalczewskiNo ratings yet

- Electronic Fuel Injection OverviewDocument9 pagesElectronic Fuel Injection Overviewalllhass97No ratings yet

- LG400Document72 pagesLG400Klemen SelanNo ratings yet

- VXN150 Vixion Side Cover PDFDocument2 pagesVXN150 Vixion Side Cover PDFHarris Jum'aniandaNo ratings yet

- Partes AWP-40S Molinos Santa MartaDocument134 pagesPartes AWP-40S Molinos Santa MartaMichaels SanclementeNo ratings yet

- 11C 1.8L EngineDocument32 pages11C 1.8L Enginedanieldario33No ratings yet

- Experimental-Report-4 FixDocument6 pagesExperimental-Report-4 FixNguyễn Quốc HưngNo ratings yet

- Service Manual For Chery QQ6 - QR513 Transmission Case PDFDocument121 pagesService Manual For Chery QQ6 - QR513 Transmission Case PDFPedro Emilio Miguez CastrillonNo ratings yet

- E-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsDocument4 pagesE-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsAdrian MacayaNo ratings yet

- Ignition TuningDocument7 pagesIgnition TuningГеорги ПренчевNo ratings yet

- IPL, Briggs, 14B907-0110-B1, 950 Series, EngineDocument25 pagesIPL, Briggs, 14B907-0110-B1, 950 Series, EngineGiacomo DesideriNo ratings yet

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Document7 pages0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanNo ratings yet

- Ns 150Document80 pagesNs 150Mark Lester Pilar0% (1)

- Pull Wire Switch - Safe T Pull - STP P 2&4Document13 pagesPull Wire Switch - Safe T Pull - STP P 2&4生月No ratings yet

- RVR 2011 20L PDFDocument99 pagesRVR 2011 20L PDFnicolas sanatanaNo ratings yet