Professional Documents

Culture Documents

Contoh Formu1

Uploaded by

Robiansah Tri AchbarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contoh Formu1

Uploaded by

Robiansah Tri AchbarCopyright:

Available Formats

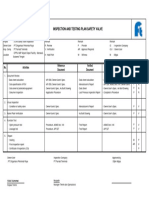

FORM U-1A MANUFACTURER'S DATA REPORT FOR PRESSURE VESSELS

(Alternative Form for Single Chamber, Completely Shop or Field Fabricated Vessels Only)

As Required by the Provisions of the ASME Boiler and Pressure Vessel Code Rules, Section VIII, Division 1

1. Manufactured and certified by

(Name and address of Manufacturer)

2. Manufactured for

(Name and address of Purchaser)

3. Location of installation

(Name and address)

4. Type

(Horizontal or vertical, tank)

(Manufacturers serial number)

(CRN)

(National Board number)

(Drawing number)

(Year built)

5. The chemical and physical properties of all parts meet the requirements of material specifications of the ASME BOILER AND PRESSURE VESSEL

CODE. The design, construction, and workmanship conform to ASME Rules, Section VIII, Division 1

Year

to

[Addenda, if applicable (date)]

[Special service per UG-120(d)]

(Code Case numbers)

6. Shell

(Nominal thickness)

(Material spec. number, grade)

(Corr. allow.)

[Length (overall)]

(Inner diameter)

7. Seams

[Long. (welded, dbl., sngl., lap, butt)]

(Eff., %)

[R.T. (spot or full)]

(H.T. temp.)

(Time, hr)

8. Heads: (a) Material

(Eff., %) (No. of courses)

[Girth (welded, dbl., sngl., lap, butt)]

(b) Material

(Spec. no., grade)

Location (Top,

Bottom, Ends)

Minimum

Thickness

Corrosion

Allowance

Crown

Radius

(Spec. no., grade)

Knuckle

Radius

Elliptical

Ratio

Conical

Apex Angle

Hemispherical

Radius

Flat

Diameter

Side to Pressure

(Convex or Concave)

(a)

(b)

If removable, bolts used (describe other fastenings)

(Material spec. number, grade, size, number)

9. MAWP

at max. temp.

(Internal)

(External)

at

Min. design metal temp.

Proof test

(Internal)

(External)

. Hydro., pneu., or comb. test pressure

.

.

10. Nozzles, inspection, and safety valve openings:

Purpose

(Inlet, Outlet, Drain etc.)

No.

11. Supports: Skirt

Diameter

or Size

Type

Lugs

(Yes or no)

Material

Nozzle

Flange

Legs

(Number)

Nozzle Thickness

Nom.

Corr.

Reinforcement

Material

Other

(Number)

Attachment Details

Nozzle

Flange

Location

(Insp. Open.)

Attached

(Where and how)

(Describe)

12. Remarks: Manufacturers Partial Data Reports properly identified and signed by Commissioned Inspectors have been furnished for the following

items of the report:

(Name of part, item number, Manufacturers name and identifying stamp)

CERTIFICATE OF SHOP/FIELD COMPLIANCE

We certify that the statements made in this report are correct and that all details of design, material, construction, and workmanship of this vessel

conform to the ASME BOILER AND PRESSURE VESSEL CODE, Section VIII, Division 1. U Certificate of Authorization Number

.

expires

Date

Co. name

Signed

(Manufacturer)

(Representative)

CERTIFICATE OF SHOP/FIELD INSPECTION

Vessel constructed by

at

.

I, the undersigned, holding a valid commission issued by the National Board of Boiler and Pressure Vessel Inspectors and/or the State or Province of

and employed by

have inspected the component described in this Manufacturer's Data Report on

, and state that,

to the best of my knowledge and belief, the Manufacturer has constructed this pressure vessel in accordance with ASME BOILER AND PRESSURE

VESSEL CODE, Section VIII, Division 1. By signing this certificate neither the Inspector nor his/her employer makes any warranty, expressed or

implied, concerning the pressure vessel described in this Manufacturer's Data Report. Furthermore, neither the Inspector nor his/her employer

shall be liable in any manner for any personal injury or property damage or a loss of any kind arising from or connected with this inspection.

Date

Commissions

Signed

(Authorized Inspector)

[National Board (incl. endorsements), State, Province, and number]

(07/10)

SAVE

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Surface Vehicle InformationDocument13 pagesSurface Vehicle InformationanupthattaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- SQL Queries Interview Questions and Answers - Query ExamplesDocument25 pagesSQL Queries Interview Questions and Answers - Query Examplesiveraj67% (9)

- Blues CheatDocument77 pagesBlues CheatRobbie ChambersNo ratings yet

- Body Flanges On ShellsDocument2 pagesBody Flanges On ShellsPadmanabhan VenkateshNo ratings yet

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- WPS AMC-0195 Rev 01Document3 pagesWPS AMC-0195 Rev 01umer.shariff87No ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- LBC-125 SpecificationDocument1 pageLBC-125 Specificationastiadi engineeringNo ratings yet

- Nde MapDocument8 pagesNde MapjorgekarlosprNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Test Package - NEWDocument14 pagesTest Package - NEWDilshad AhemadNo ratings yet

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Document1 pageTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mNo ratings yet

- Pretest Piping Punch List (Empty)Document1 pagePretest Piping Punch List (Empty)Jorge GarciaNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Inspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di InspeksiDocument3 pagesInspection of Test Plan Pressure Vessel: LOCATION: Isi Sesuai Lokasi Peralatan Akan Di Inspeksizvlcar nainNo ratings yet

- Procedure of Hydrotest For Suction and Fine Filter.Document14 pagesProcedure of Hydrotest For Suction and Fine Filter.narendraNo ratings yet

- 0.hydro Test Package Index - 2Document13 pages0.hydro Test Package Index - 2VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- Occpl: Hydro & Pneumatic Test ProcedureDocument3 pagesOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNo ratings yet

- Water Tightness Test Report For Water Retaining StructureDocument2 pagesWater Tightness Test Report For Water Retaining StructureLakshithaGonapinuwalaWithanageNo ratings yet

- ITP - Field Application of Heat Shrink SleeveDocument6 pagesITP - Field Application of Heat Shrink SleeveVasilica BArbarasaNo ratings yet

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 pagesEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetDocument13 pagesSTOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetAHMED AMIRANo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Itp PSV, Dppu ImipDocument1 pageItp PSV, Dppu ImipHendra WidyantoroNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- WPS Asme Ix PDFDocument4 pagesWPS Asme Ix PDFSergiu LungNo ratings yet

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Document12 pagesPolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamNo ratings yet

- 32 Samss 008Document26 pages32 Samss 008naruto256100% (1)

- NDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofDocument9 pagesNDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofrony16novNo ratings yet

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul JabbarNo ratings yet

- Iqwq FT LTTDS 00 0004 - 0 PDFDocument8 pagesIqwq FT LTTDS 00 0004 - 0 PDFhapinefeNo ratings yet

- What Books Are The Best For Learning Thermodynamics?: 8 AnswersDocument4 pagesWhat Books Are The Best For Learning Thermodynamics?: 8 AnswersnitharsunNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- RT ProcedureDocument51 pagesRT ProcedureAwale UdinNo ratings yet

- 0 WD990 EM440 00101 Equipment List RevFDocument20 pages0 WD990 EM440 00101 Equipment List RevFManuel Jesus Perez MelgarNo ratings yet

- Welding Quality Control and Inspection FormDocument1 pageWelding Quality Control and Inspection FormSamer BayatiNo ratings yet

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- COPI - Welding Spec For Flowlines To API 1104-1999Document12 pagesCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- SAIC & SATR - InstrumentationDocument4 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNo ratings yet

- Itp Ralgo HssDocument5 pagesItp Ralgo Hssmark quijlvoNo ratings yet

- Form T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIDocument1 pageForm T-1B Manufacturer'S Data Report For Class 2 Transport Tanks As Required by The Provisions of The ASME Code Rules, Section XIIEmma DNo ratings yet

- BPVC Viii-1 U-1a PDFDocument2 pagesBPVC Viii-1 U-1a PDFabdesselam00No ratings yet

- Form A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Document2 pagesForm A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DNo ratings yet

- Asme Interactive Form U 1aDocument1 pageAsme Interactive Form U 1aJleemax OctaNo ratings yet

- Alloying Elements and Their EffectsDocument5 pagesAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Influence of PWHT To Steel Phase & PropertiesDocument6 pagesInfluence of PWHT To Steel Phase & PropertiesDimas AnugrahNo ratings yet

- Principles of DrawingDocument6 pagesPrinciples of DrawingSudesh Gubale BNo ratings yet

- Drain A Tank CalculationDocument743 pagesDrain A Tank CalculationDimas AnugrahNo ratings yet

- Pengantar NDT 2003Document27 pagesPengantar NDT 2003Dimas AnugrahNo ratings yet

- Jewelry 7000 Years An International History and Illustrated Survey From The Collections of The - Hugh Tait - May 1991 - Abradale Books - 9780810981034 - Anna's ArchiveDocument264 pagesJewelry 7000 Years An International History and Illustrated Survey From The Collections of The - Hugh Tait - May 1991 - Abradale Books - 9780810981034 - Anna's Archiveeve100% (2)

- Newyearbook PDFDocument165 pagesNewyearbook PDFAlberto CenniniNo ratings yet

- Bombardier Zefiro Technical Description enDocument15 pagesBombardier Zefiro Technical Description ennickerlesstezla100% (1)

- Accounting 2 - MCQs (Revison) - AnswerDocument8 pagesAccounting 2 - MCQs (Revison) - Answernemoyassin4No ratings yet

- Industrial RobotDocument32 pagesIndustrial RobotelkhawadNo ratings yet

- Inter-Bank Fund Transfer: Case Study 6Document5 pagesInter-Bank Fund Transfer: Case Study 6Ravi RanjanNo ratings yet

- Unit - 5 SelectionDocument7 pagesUnit - 5 SelectionEhtesam khanNo ratings yet

- Noli and El FiliDocument2 pagesNoli and El FiliGeramei Vallarta TejadaNo ratings yet

- Food Photographs Practical Guidelines II Development and Use of Photographic Atlases For Assessing Food Portion SizeDocument7 pagesFood Photographs Practical Guidelines II Development and Use of Photographic Atlases For Assessing Food Portion SizemmmdeandradeNo ratings yet

- Microprocessor AEE Part4Document144 pagesMicroprocessor AEE Part4PeterNo ratings yet

- Drug-Induced Sleep Endoscopy (DISE)Document4 pagesDrug-Induced Sleep Endoscopy (DISE)Luis De jesus SolanoNo ratings yet

- Avamar - ADS Data Erasure-YES - I Understand All Data Will Be Lost by Performing This Procedure!Document30 pagesAvamar - ADS Data Erasure-YES - I Understand All Data Will Be Lost by Performing This Procedure!dansegui.mir4No ratings yet

- Neonatal Phototherapy: Operator ManualDocument16 pagesNeonatal Phototherapy: Operator ManualAbel FencerNo ratings yet

- Rapid Prototyping and ToolingDocument2 pagesRapid Prototyping and ToolingelangandhiNo ratings yet

- Classroom EtiquetteDocument1 pageClassroom EtiquetteJerrold MangaoNo ratings yet

- De Thi Minh Hoa 9 Lên 10 - Bui Van VinhDocument18 pagesDe Thi Minh Hoa 9 Lên 10 - Bui Van VinhKim AnhNo ratings yet

- CE6306-Strength of Materials NotesDocument16 pagesCE6306-Strength of Materials NotesTrishul SampathNo ratings yet

- 24 - Mubangizi-WHOPQP GMP Inspections UpdatesDocument17 pages24 - Mubangizi-WHOPQP GMP Inspections UpdatessamxuNo ratings yet

- Pakistan: Nation-State, State-Nation or Multinational State?Document12 pagesPakistan: Nation-State, State-Nation or Multinational State?Asif KhanNo ratings yet

- Nursing Case Study - 1 - (Acs)Document32 pagesNursing Case Study - 1 - (Acs)nidhiNo ratings yet

- Sow English Year 2 2023Document12 pagesSow English Year 2 2023Noramaliza GhazaliNo ratings yet

- History of Operating SystemDocument16 pagesHistory of Operating SystemBryan John BerzabalNo ratings yet

- CAT LOGO ALPINESTARS OFF-ROAD 2021Document73 pagesCAT LOGO ALPINESTARS OFF-ROAD 2021Carla ArcosNo ratings yet

- Karta Ronjenje en 163341Document2 pagesKarta Ronjenje en 163341mulalic_dNo ratings yet

- Management of Developing DentitionDocument51 pagesManagement of Developing Dentitionahmed alshaariNo ratings yet

- UntitledDocument385 pagesUntitledDelta BravoNo ratings yet

- PHP - Google Maps - How To Get GPS Coordinates For AddressDocument4 pagesPHP - Google Maps - How To Get GPS Coordinates For AddressAureliano DuarteNo ratings yet

- 1 Man Is The Crowning Glory of God's CreationDocument12 pages1 Man Is The Crowning Glory of God's CreationCaptainBreezy YeezyNo ratings yet