Professional Documents

Culture Documents

Escaña DO

Escaña DO

Uploaded by

Viviana LópezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Escaña DO

Escaña DO

Uploaded by

Viviana LópezCopyright:

Available Formats

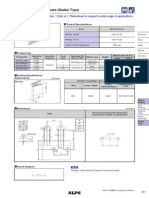

SPECIFICATION

MAX CAPACITY

mm

230 { 911 )

90

l. 75x400

mm

230 ( 9."

45

,--,l0x230(

( 71'x 16tl-..)

6"x9")

-- r

CUTTING

SPEED

RANGE

m/min.

MOTOR OUTPUT

BLADE SIZE

60Hz

- 29

46

50Hz

24

38

98

53 . 81

SAW BLADE

1. 125

COOLANT

o. 1

3353x25x0.9

inm

65

( 11 "x l "xO. 03511)

,

.

HEIGBT OF WORK BED mm

650

(25.5")

kg

450

(995LBS)

WEIGHT

1600 ( 63")

LENGHT

FLOOR SPACE

mm

710 (28")

WIDTH

1080 (42.5-")

HEIGHT

STANDARD

PIECE ACCESSORIES

HEXAGON WRENCH

ONE SET (1.5mm-10mrn)

BLADE

ONE PIECE

BRUSH

ONE PIECE

MATERIAI,, STOP

ONE

ELECTRIC SYSTEM

ONE UNIT

COMPLETE COOLANT SYSTEM

ONE UNIT

OpERATION MANUAL AND

PARTS LIST

ONE COPY

..

CHECK TO MAKE PRIOR ~O OPERATION

1) Make sure the teetb are poin~ing in the right direction.

2) Band should be properly seated on the whe~ls after correct

tension is a.pp L e d .:

.

3) Set blade holder g u des f or approximately 00311 to 005" clear- anee b e t ween -che gu:hles

a n d blade.

4) Ch~ck for slight clearance between back up .roller~ and back

of blade.

5) Have guides as close twork as possible.

6) Select proper speed and feed ..

7) Material should be. securely held in vise.

8) Collant, if required,.should

be turned on.

9) If pbs~ible,:do

not start cut on ~ sharp edge.

10) Kee~ machine lubricated.

OPERATING INSTRUC.TIONS

lWARNINGi

DO NOT .CONNECT POWER CORO TO POWER SOURCE UNTIL

THE FOLLOWING INSTRUCTIONS ARE CLEARLY UNDERSTOOD, AND

FOLLOWED.

SPEED SELECTION:

.

.Blade speed selectibn should be made ~~cording to the.material

being cut.

The following chart is for general reference only.

SPEED SELECTION

SDeed

Material Hd.gh

ap eed

a.Ll oy,

stainiess and heavy

cross sectibJ;t material

Tool, .s t a .n Le s s ahd

alloy s t e el

bearing bronzes

Cast iron, mild steel

hard brass

and bronze

Plastic, copper,

soft brass,

aluminum, other

L.ah t materials

Pullv Groove us.ed.

.s aw ..

motor

olley

pulley

50Hz

60Hz

62

73

smallest

121

small

102

157

190

medium

256

305

lar ge

lar ge

medium

small

smallest

Sorne mateials dueto ~anufa6turing processes sucb as certain type~

of cast iroh pipe or materals containing certain types of weids,

cannot be cut on t~is machine.

A GENERAL RULE TO FOLLQW IS, "IF THE MATERIAL CAN BE.CUT

A FI.LE, IT CAN BE CUT ON THIS SAW."

WITH

You might also like

- Sears Catalog 1966Document16 pagesSears Catalog 1966Kevin Haworth100% (3)

- SL-1210MK2 Service ManualDocument39 pagesSL-1210MK2 Service ManualgiosiolasNo ratings yet

- Harrison M350 Machine ManualDocument78 pagesHarrison M350 Machine ManualF1lopat100% (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- NVX5000Document16 pagesNVX5000Solomon NicuNo ratings yet

- ChaindriveDocument40 pagesChaindriverana__singhNo ratings yet

- Termpaper-Strength Analysis of Screw Jack-Mechanics of SolidsDocument21 pagesTermpaper-Strength Analysis of Screw Jack-Mechanics of SolidsOmkar Kumar JhaNo ratings yet

- TTM Post TensioningDocument103 pagesTTM Post Tensioninghorea67100% (2)

- 8.12.01.03 - Technical Data CH890Document8 pages8.12.01.03 - Technical Data CH890gytoman100% (1)

- Emco Unimat 1977 Brochure EnglishDocument8 pagesEmco Unimat 1977 Brochure Englishkriskee13100% (1)

- Advanced Connection SystemsDocument11 pagesAdvanced Connection SystemsAnre Thanh HungNo ratings yet

- Bruno Presezzi Casting LinesDocument23 pagesBruno Presezzi Casting LinesTKNo ratings yet

- Special Purpose Basic SwitchDocument5 pagesSpecial Purpose Basic Switchng_viet_cuong_groupNo ratings yet

- MachiningDocument12 pagesMachiningwardendavid5591100% (1)

- Datasheet Amt102 EncoderDocument8 pagesDatasheet Amt102 EncoderPablo Davila100% (1)

- Accouplement MecDocument19 pagesAccouplement MecAli Ben Belgacem MahroukNo ratings yet

- ShaftClampEls LowDocument20 pagesShaftClampEls LowBaneMarkovicNo ratings yet

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocument5 pagesEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Pipe Cutting Machines CatalogueDocument5 pagesPipe Cutting Machines Cataloguedakshraj jadejaNo ratings yet

- User ManualDocument24 pagesUser ManualMario Lucchini Dell'OroNo ratings yet

- Data 3863 CR Motores PDFDocument2 pagesData 3863 CR Motores PDFRaul CruzNo ratings yet

- APHS - 31120 Technıcal DataDocument6 pagesAPHS - 31120 Technıcal DataPraveen Kumar PedapudiNo ratings yet

- Kemet Tooling EquipmentDocument13 pagesKemet Tooling EquipmentdurgaganeshNo ratings yet

- Model 52H Hydraulic Shear: Operation, Parts & Maintenance ManualDocument10 pagesModel 52H Hydraulic Shear: Operation, Parts & Maintenance ManualOmar SalmonNo ratings yet

- Accessories Final v.1Document11 pagesAccessories Final v.1Peter TanNo ratings yet

- N-Eupex y N-Eupex Ds - CatalogoDocument25 pagesN-Eupex y N-Eupex Ds - CatalogoJohn Salazar0% (1)

- Globe Motor Spec SheetDocument4 pagesGlobe Motor Spec Sheetargh112No ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- TriumphDocument15 pagesTriumph1zmajNo ratings yet

- Tool TrolleyDocument17 pagesTool TrolleysanjeevvangeNo ratings yet

- Manganese 12 14%Document3 pagesManganese 12 14%Sreedhar Rakesh VellankiNo ratings yet

- ABRAuk Creusabro 4800Document3 pagesABRAuk Creusabro 4800Anonymous 48jYxR1CNo ratings yet

- PEM Self Locking Fasteners Nylon InsertDocument6 pagesPEM Self Locking Fasteners Nylon InsertAce Industrial SuppliesNo ratings yet

- DRC Packaged Encoders T23BA Data SheetDocument4 pagesDRC Packaged Encoders T23BA Data SheetElectromateNo ratings yet

- Acoplamientos TSK PDFDocument4 pagesAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesNo ratings yet

- Aceros PoscoDocument35 pagesAceros PoscoregistrosegNo ratings yet

- DryLin Linear Drive TechnologyDocument52 pagesDryLin Linear Drive TechnologyigusukNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHung LeNo ratings yet

- Yaesu G-450A Operating ManualDocument15 pagesYaesu G-450A Operating Manualdj03djj100% (1)

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocument4 pages18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuNo ratings yet

- Easiturn Brochure and Illustrated Parts Manual OCRDocument80 pagesEasiturn Brochure and Illustrated Parts Manual OCRgraham4877No ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Step Beam: NylonDocument2 pagesStep Beam: NylonUriel Cruz MedelNo ratings yet

- 002 Poly-Norm Revolex-Kx Poly enDocument0 pages002 Poly-Norm Revolex-Kx Poly envyvy83No ratings yet

- YCM NSV SeriesDocument26 pagesYCM NSV SeriesCNC SYSTEMSNo ratings yet

- Linear Motion Slide Toothed Belt DriveDocument20 pagesLinear Motion Slide Toothed Belt DrivePetar HosticNo ratings yet

- B GravographDocument12 pagesB GravographWahyu PcNo ratings yet

- TSKDocument4 pagesTSKar174_569868987No ratings yet

- 12mm Size Insulated Shaft TypeDocument5 pages12mm Size Insulated Shaft TypeshyhuNo ratings yet

- Brosura FrankenDocument28 pagesBrosura FrankenTraian-Vasile MaximNo ratings yet

- Knuth Milling Machine VHF 3Document5 pagesKnuth Milling Machine VHF 3martin_jaitmanNo ratings yet

- DPDT Basic Switch For Two Independent Circuit ControlDocument5 pagesDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNo ratings yet

- Sirio TornadoDocument2 pagesSirio Tornadonoorhakim100% (1)

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet