Professional Documents

Culture Documents

Jis G3103 PDF

Uploaded by

Chairul AnwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jis G3103 PDF

Uploaded by

Chairul AnwarCopyright:

Available Formats

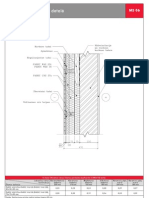

TYPE

STANDARD

GRADE

SB42

Carbon

Steel and

Molybdenu

m alloy

steel plates

for boilers

and other

pressure

vessels

SB46

JIS G

3103

(1987)

(applicabl SB49

e till the

end of

1990)

SB46M

SB49M

SB 410

Carbon

steel and

molybden

um alloy

steel

plates for

boilers

and other

pressure

vessels

SB 450

JIS G

3103

(1987)

applicable

onand after

Jan 1,

1991

SB 480

SB 450M

SB 480 M

TENSION TEST

CHEMICAL COMPOSITION ( max )

thickness : t

C

mm.

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

0.24

0.27

0.3

0.28

0.31

0.33

0.31

0.33

0.35

0.18

0.21

0.23

0.2

0.23

0.25

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

50 < t < 100

t < 25

25 < t < 50

0.24

0.27

0.3

0.28

0.31

0.33

0.31

0.33

0.35

0.18

0.21

0.23

0.2

0.23

50 < t < 100

0.25

Si

Mn

0.15-0.30

0.90

0.035

0.040

Yield Strength (min)

Cu

Mo

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.15-0.30

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.035

0.035

0.035

0.035

0.035

0.035

0.035

0.035

0.035

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.45-0.60

0.45-0.60

0.45-0.60

0.45-0.60

BEND TEST

Elongation (min)

thick : t

Kgf / mm2

thick : t

Kgf / mm2

thick : t

mm.

[N/mm2]

mm.

[N / mm2 ]

mm.

<

<

<

<

Tensile Strength

23

[226]

42-56

[412549]

25

[245]

46-60

[451588]

27

[265]

49-63

[481618]

26

[255]

46-60

[451588]

28

[275]

49-63

[481618]

23

[225]

42-56

[410550]

25

[245]

46-60

[450590]

27

[265]

49-63

[480620]

26

[255]

46-60

[450590]

28

[275]

49-63

[480620]

<

Angle

No.1A

(Degree)

21

180

No.10

No.1A

25

19

No.10

No.1A

23

17

180

180

No.10

No.1A

21

19

No.10

No.1A

23

17

No.10

21

No.1A

21

180

180

25

19

No.10

No.1A

23

17

180

180

No.10

No.1A

21

19

No.10

No.1A

23

17

180

21

1.0 t

1.0 t

1.0 t

1.25 t

0.5 t

0.75 t

Test

piece

No.1 at

right

angles to

rolling

direction

1.0 t

0.5 t

0.75 t

1.0 t

0.75 t

1.0 t

1.0 t

1.0 t

1.25 t

0.5 t

0.75 t

0.75 t

180

No.10

0.5 t

0.75 t

1.0 t

0.75 t

0.75 t

180

No.10

No.1A

Inside

radius

1.0 t

Test

piece

No.1 at

right

angles to

rolling

direction

You might also like

- Jis FlangesDocument10 pagesJis FlangesdodoconNo ratings yet

- JIS MaterialsDocument2 pagesJIS Materialszoksi100% (1)

- Jis G-4801Document3 pagesJis G-4801Phillip MillerNo ratings yet

- Jis h3300Document1 pageJis h3300Nabil ShaikhNo ratings yet

- JIS G4309-1999祥凄詩佪Document11 pagesJIS G4309-1999祥凄詩佪tsengccNo ratings yet

- Jis h3250Document1 pageJis h3250NPD Quality100% (1)

- Jis G3463 PDFDocument39 pagesJis G3463 PDFhbook100% (1)

- Jis B2316Document1 pageJis B2316OluwachidiNo ratings yet

- Gelzbet GaminiaiDocument10 pagesGelzbet GaminiaiMindaugas KinderisNo ratings yet

- GSW Jis 3537Document2 pagesGSW Jis 3537YJoe18No ratings yet

- Jis G-3101Document3 pagesJis G-3101Phillip MillerNo ratings yet

- GB Ploksciu Gamyba Ir MontavimasDocument20 pagesGB Ploksciu Gamyba Ir MontavimasMarius GrigaliunasNo ratings yet

- Smeigiamas Temperatūros Jutiklis TJ-SDocument2 pagesSmeigiamas Temperatūros Jutiklis TJ-SAdm ProninNo ratings yet

- Jis G3112-2004Document2 pagesJis G3112-2004tkm2004100% (1)

- Vigas Tech DuomenysDocument22 pagesVigas Tech DuomenysVykintas ImbrasasNo ratings yet

- BIRCOsolid - Nutekamieji LatakaiDocument25 pagesBIRCOsolid - Nutekamieji LatakaiMartynasNo ratings yet

- 01 Sienu Konstrukcijos E9343Document74 pages01 Sienu Konstrukcijos E9343inter1560No ratings yet

- 0,4 KV Oro Kabelių Kabinimo Ant Bendrų Atramų Brėžiniai Ir Oro Kabelių Bei Laidų Montavimo LentelėsDocument46 pages0,4 KV Oro Kabelių Kabinimo Ant Bendrų Atramų Brėžiniai Ir Oro Kabelių Bei Laidų Montavimo LentelėsTomasNo ratings yet

- Canalis KT - KTC3200TC4Document2 pagesCanalis KT - KTC3200TC4Dani Good VibeNo ratings yet

- Varztines Jungtys EC 3GDocument54 pagesVarztines Jungtys EC 3GMarius PuzauskasNo ratings yet

- Grindų Ant Grunto Šiltinimas XPS PlokštėmisDocument2 pagesGrindų Ant Grunto Šiltinimas XPS PlokštėmisDavid SamveljanNo ratings yet

- Deflex 2009 Ugnies - BarjeraiDocument4 pagesDeflex 2009 Ugnies - BarjeraiScenic777No ratings yet

- Ruukki Skardu BrosiuraDocument8 pagesRuukki Skardu Brosiuratopnoch5454No ratings yet

- Plieno Cheminė SudėtisDocument13 pagesPlieno Cheminė SudėtisDovydas PačėsaNo ratings yet

- KG Katalogas LTDocument8 pagesKG Katalogas LTLucasNo ratings yet

- MS 06Document1 pageMS 06api-3742990No ratings yet

- CatalogDocument97 pagesCatalogjustinas.bandzeviciusNo ratings yet

- Oring Sizes JISB2401 PDFDocument4 pagesOring Sizes JISB2401 PDFMohamad RifkiNo ratings yet

- Oring Sizes JISB2401 PDFDocument4 pagesOring Sizes JISB2401 PDFEdgardo BadanoNo ratings yet

- Vedinimo BiudzetasDocument1 pageVedinimo BiudzetasTomas GeneviciusNo ratings yet

- Paulius Burokas THM 1 HWDocument7 pagesPaulius Burokas THM 1 HWPaulius Burokas (Asterix05)No ratings yet

- Baskutis DaivaroDocument11 pagesBaskutis DaivaroLukas SavickasNo ratings yet

- VOLTEX - Technines Charakteristikos - LT - 2020Document5 pagesVOLTEX - Technines Charakteristikos - LT - 2020Mantas RutkauskasNo ratings yet

- SienŲ Su Oro Tarpais Projektavimas Ir StatybaDocument24 pagesSienŲ Su Oro Tarpais Projektavimas Ir Statybaapi-3742990100% (1)

- VamzdziaiDocument1 pageVamzdziaiGintaras ShakaNo ratings yet

- Vitocrossal - 300 - Techninis PasasDocument6 pagesVitocrossal - 300 - Techninis PasasTomas VitulskisNo ratings yet

- PAROC SSN CAD Book 2020 LT-1Document136 pagesPAROC SSN CAD Book 2020 LT-1Hire-minibus Lithuania Buso-nuomaNo ratings yet

- Betoniniu Grindinio Trinkeliu TyrimasDocument2 pagesBetoniniu Grindinio Trinkeliu TyrimasAndrius KazlauskasNo ratings yet

- Sienos Varzos SkaiciavimasDocument2 pagesSienos Varzos SkaiciavimasPauliusVasiliauskasNo ratings yet

- Gelžbetoninės Briaunuotos Perdangos Plokštės Ir Dvišlaitės Sijos Projektavimas Su Iš Anksto Įtempta ArmatūraDocument58 pagesGelžbetoninės Briaunuotos Perdangos Plokštės Ir Dvišlaitės Sijos Projektavimas Su Iš Anksto Įtempta Armatūratopnoch5454100% (1)

- Dvigrandžių Atramų Brėžiniai Ir Laidų Montavimo LentelėsDocument83 pagesDvigrandžių Atramų Brėžiniai Ir Laidų Montavimo LentelėsTomasNo ratings yet

- Naujien - Allon - Su DetalemDocument1 pageNaujien - Allon - Su DetalemJollunas AVNo ratings yet

- Danfoss Valve 2Document4 pagesDanfoss Valve 2mavenplanningengineerNo ratings yet

- Kauno Technologijos Universitetas Mechanikos Inžinerijos Ir Dizaino Fakultetas Mechanikos Inžinerijos KatedraDocument24 pagesKauno Technologijos Universitetas Mechanikos Inžinerijos Ir Dizaino Fakultetas Mechanikos Inžinerijos Katedramedis medinisNo ratings yet

- Priedas 10543Document106 pagesPriedas 10543TomasMikoNo ratings yet

- 123Document3 pages123Raminta RamaNo ratings yet

- Jis B 1301 KeyDocument1 pageJis B 1301 Keyxuanphuong2710No ratings yet

- LT Caurtekas PDFDocument26 pagesLT Caurtekas PDFAndris RazgalisNo ratings yet

- Viadrus U22 Instrukcija 2010Document33 pagesViadrus U22 Instrukcija 2010Edvardas MaslauskasNo ratings yet

- STR 2.05.08 2005 Plieninių Konstrukcijų Projektavimas. Pagrindinės Nuostatos Ar - 2007-12-19 PDFDocument348 pagesSTR 2.05.08 2005 Plieninių Konstrukcijų Projektavimas. Pagrindinės Nuostatos Ar - 2007-12-19 PDFAurimas MiškinisNo ratings yet

- STR Plieniniu Konstrukciju ProjektavimasDocument131 pagesSTR Plieniniu Konstrukciju ProjektavimasasdaeaNo ratings yet

- Atmintine ProjektuotojuiDocument3 pagesAtmintine ProjektuotojuiJonas Nulis VienasNo ratings yet

- Katalogas 2022 KSLDocument29 pagesKatalogas 2022 KSLfusrojNo ratings yet