Professional Documents

Culture Documents

AW 5754 AlMg3 Aluminium Plates Data Sheet

Uploaded by

Luis QuinoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AW 5754 AlMg3 Aluminium Plates Data Sheet

Uploaded by

Luis QuinoCopyright:

Available Formats

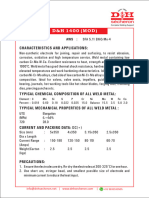

ALUMINIUM PLATES

EN AW 5754 - AlMg3

Material available

Thickness: Sheets 0,3-6 mm - Shates 3-10 mm, Plates 8-140 mm

Dimension: 1020 x 2020 mm, 1270 x 2520 mm, 1520 x 3020 mm, 2000 x 4000 mm or as requested.

Main Usage

Main Properties

Tooling

Machines and Machine parts

Pressure containers

Cans for beverages and grocery

Solid basic material

High ductility and elongation

Very good corrosion resistance

Very small tension of the basic material

Consistent stability in the core of thick

plates

Also workable if non-tension levelled

good welding propertiers

Important norms and literature:

DIN 1725 T.1:

DIN 1745 T.1:

Aluminum alloys, forgeable alloys

Coils and sheets of aluminum and forgeable alloys

>0,35mm Thickness

DIN 1745 T.1: technical specification

DIN 1783:

cold rolled dimensional specification

DIN 59600

hot rolled dimensional specification

Further Standards: ASTM; AMS; QQ-A-250

Admission

DIN 4113 / AD-Merkbl. W.6/1 / Germ. Lloyd /

Deutsche Bundesbahn (DS 952)

Further norms and admissions: On request

Chemical composition. EN573-3:2013

Si

Fe

Cu

Mn

Mg

Cr

Zn

Ti

Other. Elem

Other elements

0,40

0,40

0,10

0,50

2,6-3,6

0,30

0,20

0,15

Mn+Cr 0,1-0,6

0,05 (single)

0,15 (together)

Typical mechanical properties. EN485 - 2

Thickness

Rm

MPa

Temper

Rp0,2

MPa

A50 mm

%

Hardness

HB

Coils mm

Sheets

mm

Acron

Number

Description

0,35-3,0

0,35-6,0

W19

3.3535.10

soft

190-230

80

20

50

3,0-10

0,35-3,0

0,35-3,0

0,35-3,0

0,35-3,0

0,35-3,0

0,35-3,0

0,35-3,0

6,0-50

25-50

10-25

5,0-10

0,35-10

0,35-10

0,35-10

0,35-10

0,35-4,0

0,35-4,0

0,35-3,0

W19

F19

F20

F21

F22

G22

F24

G24

F27

G27

F29

"

3.3535.07

"

"

3.3535.24

3.3535.25

3.3535.26

3.3535.27

3.3535.28

3.3535.29

3.3535.30

"

Hot rolled

"

"

Cold rolled

Re-annealed

Cold rolled

Re-annealed

Cold rolled

Re-annealed

Cold rolled

190-230

190

200

210

220-260

220-260

240-280

240-280

265-305

265-305

290

80

80

120

140

165

130

190

160

215

190

250

18

12

10

12

9

14

5

10

4

7

3

50

50

60

60

65

65

73

73

80

80

85

Remarks

DIN

AA

.07=hot rolled

.10=soft

.24= 1/4 hard

.25= 1/4 hard

.26= 1/2 hard

.27= 1/2 hard

.28= 4/4 hard

.29= 3/4 hard

.30= full hard

=F

=O

= H12

= H22

= H14

= H24

= H16

= H26

= H18

Physical properties:

Density

g/cm

Solidification range

C

Electrical conductivity

%IACS

Thermal conductivity

W/m K

Thermal expansion

(m m-1 K-1)

E - modulus

(N / mm)

2,66

610-640

20-23

140-160

23,9

-70.000

Properties and details (Rating in decreasing tendency. 1= very good; 5= bad; na= not applicable; ns= not suitable)

Durability:

Seawater: 1-2

Weather conditions: 1

Hot forming property:

Bar extrusion: 4

Die forging: 3

Hammer forging: 2

Cold formability:

Upsetting, staking, flushing

Up to temper .24: 2

Deep drawing (Temp..10): 2

Bending: 2

Pressure forming: 3

Impact extruding: 4

weldability

Gas-fusion welding: 2

WIG-Welding: 1

MIG- Welding : 1

Temp.: SG-AlMg3; SG-AlMg5

Resistance spot welding: 3

Brazeability:

Brazing with melter: 5

Brazing without melter : 4

Soldering, abraison soldering: 3

Soldering with melter : 5

Machinability:

Temper soft-annealed: 3

Work-hardened: 2

Remarks to the machinability

Tools for the machining of Aluminium:

Usable cutting velocities high, preferably

>2000 m/min.

The usage of thread moulders is recommended when producing windings.

Surface treatment

Decorative Anodizing: 2

AQ acc. to DIN 17611: 1

Protective anodization: 1

Painting, lamination: 3

Electroplated coating: 2

Chemical nickel coating: 2

General Tips

Practically free of tension

You might also like

- Thickness: Sheets 1-6 MM, Plates 8-150 MM Dimension: 1020 X 2020 MM, 1270 X 2520 MM, 1520 X 3020 MM, or As RequestedDocument1 pageThickness: Sheets 1-6 MM, Plates 8-150 MM Dimension: 1020 X 2020 MM, 1270 X 2520 MM, 1520 X 3020 MM, or As RequestedmanulalsNo ratings yet

- D2 Tool Steel SpecificationDocument1 pageD2 Tool Steel SpecificationRamdika Nur HariantoNo ratings yet

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- 1.2379 X153Crmov12 Cppu: Chemical CompositionDocument2 pages1.2379 X153Crmov12 Cppu: Chemical CompositionAdrian Finichiu100% (1)

- PB Uddeholm Sverker 21 EnglishDocument12 pagesPB Uddeholm Sverker 21 EnglishulfwisenNo ratings yet

- GB Grade Asp 2060Document2 pagesGB Grade Asp 2060João MirandaNo ratings yet

- DIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Aisi A2: Cold Work Tool SteelDocument21 pagesAisi A2: Cold Work Tool SteelRahul NambiarNo ratings yet

- Impact: Wear Resistant SteelDocument6 pagesImpact: Wear Resistant SteelmazuckNo ratings yet

- Aisi D2: Cold Work Tool SteelDocument7 pagesAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- C45Document4 pagesC45Cristhian Solano BazalarNo ratings yet

- Material Info - HSS M-42Document4 pagesMaterial Info - HSS M-42ਗਗਨ ਜੋਤNo ratings yet

- Vac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)Document33 pagesVac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)AmitNo ratings yet

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocument39 pagesCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniNo ratings yet

- 2010 Datasheet DMV 825Document4 pages2010 Datasheet DMV 825Roman BorovkovNo ratings yet

- Datasheet Polystone P CopolymerDocument1 pageDatasheet Polystone P CopolymerKhanh PhamNo ratings yet

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- TDBL - Polystone P Grey Homopolymer - GBDocument1 pageTDBL - Polystone P Grey Homopolymer - GBreinpolyNo ratings yet

- 1.2436 X210CrW12Document2 pages1.2436 X210CrW12nguyenthihoaivietnamNo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- DS Duplex 2205Document2 pagesDS Duplex 2205Gigin BakrNo ratings yet

- Sheet Metalwork Aluminium 5251Document2 pagesSheet Metalwork Aluminium 5251Josko SpehNo ratings yet

- Top Tool Steel for Cold FormingDocument9 pagesTop Tool Steel for Cold FormingJim ToddNo ratings yet

- PB Uddeholm Sleipner EnglishDocument12 pagesPB Uddeholm Sleipner EnglishAlfya ChinikamwalaNo ratings yet

- SS 2304Document2 pagesSS 2304Madan YadavNo ratings yet

- PB Uddeholm Sverker 21 EnglishDocument12 pagesPB Uddeholm Sverker 21 EnglishKOSTASPDFNo ratings yet

- Technical Data Sheet: Polystone Pps Grey SKDocument1 pageTechnical Data Sheet: Polystone Pps Grey SKrseresfer34533373563No ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- High-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCDocument3 pagesHigh-Carbon, High Chromium Cold Work Tool Steel: GMTC GMTCpvdangNo ratings yet

- X5CrNiCuNb 16-41.4542Document2 pagesX5CrNiCuNb 16-41.4542nuesteNo ratings yet

- Calmax D20140711 PDFDocument12 pagesCalmax D20140711 PDFSinan YıldızNo ratings yet

- YSS Cold Working Die PDFDocument11 pagesYSS Cold Working Die PDFHoang Le VuNo ratings yet

- Hot RolledDocument16 pagesHot Rolledlbo33No ratings yet

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- Industeel DuplexDocument2 pagesIndusteel DuplexClaudio SampaioNo ratings yet

- Dac BDocument15 pagesDac BArief BudimanNo ratings yet

- PB Uddeholm Calmax EnglishDocument12 pagesPB Uddeholm Calmax EnglishxulubNo ratings yet

- Asaab 8407 - 2MDocument11 pagesAsaab 8407 - 2MPrabath MadusankaNo ratings yet

- Sikadur®-31 CF Slow: Product Data SheetDocument4 pagesSikadur®-31 CF Slow: Product Data SheetMichael MazoNo ratings yet

- WWW Steelss Com Carbon Steel St37 3u HTMLDocument4 pagesWWW Steelss Com Carbon Steel St37 3u HTMLdjpinguimNo ratings yet

- Die Tool GradesDocument13 pagesDie Tool Gradesdarwin_huaNo ratings yet

- 1 Cutting ToolDocument27 pages1 Cutting ToolKemalMalovcicNo ratings yet

- Ceradur GBDocument1 pageCeradur GBsakarisoNo ratings yet

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDocument4 pagesDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- Tj-Ningbo - materialDesignUddLayout (Automatisch Gespeichert)Document79 pagesTj-Ningbo - materialDesignUddLayout (Automatisch Gespeichert)Hasta MahardikaNo ratings yet

- Production Technology Ch21Document16 pagesProduction Technology Ch21Nimmagadda BharathNo ratings yet

- Powerpoint Presentation: Cutting Tool and MaterialDocument27 pagesPowerpoint Presentation: Cutting Tool and MaterialMayank RawatNo ratings yet

- Post WeldDocument4 pagesPost WelddanemsalNo ratings yet

- Corrax D20140714Document8 pagesCorrax D20140714mj_davis04No ratings yet

- ERD Tin Product BrochureDocument10 pagesERD Tin Product BrochureLaura ElgarristaNo ratings yet

- Trovidur ds2012Document2 pagesTrovidur ds2012Nick BesterNo ratings yet

- Dillidur 400 V: Water Quenched Wear Resistant SteelDocument4 pagesDillidur 400 V: Water Quenched Wear Resistant SteelCristobal A. Mir G.No ratings yet

- Cu Al 6 Ni 2Document4 pagesCu Al 6 Ni 2Lola PerezNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Testing Requirements One Eighty Presentation 2Document22 pagesTesting Requirements One Eighty Presentation 2Manohar SeetharamNo ratings yet

- D 3350Document9 pagesD 3350carlospelaezNo ratings yet

- SSW - Article Inox Martensita PDFDocument6 pagesSSW - Article Inox Martensita PDFLuis QuinoNo ratings yet

- Chapter 2Document12 pagesChapter 2CrisStructEngNo ratings yet

- Astm F2620-11Document21 pagesAstm F2620-11Gianfranco Niquín100% (3)

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- 04 Weld Micro Structure 01Document33 pages04 Weld Micro Structure 01Japneet GhaiNo ratings yet

- 04 Weld Micro Structure 01Document33 pages04 Weld Micro Structure 01Japneet GhaiNo ratings yet

- Piezoelectric PropiertiesDocument10 pagesPiezoelectric PropiertiesLuis QuinoNo ratings yet

- Deciphering Weld SymbolsDocument11 pagesDeciphering Weld SymbolsAhmad Reza AtefNo ratings yet

- Study of Inspection Methods and Quality Control For Welded Highway Structures PDFDocument16 pagesStudy of Inspection Methods and Quality Control For Welded Highway Structures PDFLuis QuinoNo ratings yet

- API Standards For Pipe Inspections PDFDocument38 pagesAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- SSW - Article Inox Martensita PDFDocument6 pagesSSW - Article Inox Martensita PDFLuis QuinoNo ratings yet

- Angle BM GeneralDocument21 pagesAngle BM GeneralLuis QuinoNo ratings yet

- 5) Oil Chalk Test PDFDocument2 pages5) Oil Chalk Test PDFkyeong cheol lee75% (16)

- Deciphering Weld SymbolsDocument11 pagesDeciphering Weld SymbolsAhmad Reza AtefNo ratings yet

- Supercito: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito: MMA Electrodes C-MN and Low-Alloy SteelsLuis QuinoNo ratings yet

- Tofd 1 PDFDocument8 pagesTofd 1 PDFLuis QuinoNo ratings yet

- Section Leadership Manual: The American Society For Nondestructive Testing, IncDocument83 pagesSection Leadership Manual: The American Society For Nondestructive Testing, IncLuis QuinoNo ratings yet

- Costo Soldadura Tubos PDFDocument2 pagesCosto Soldadura Tubos PDFLuis QuinoNo ratings yet

- 3irss Catalog 2006 PDFDocument45 pages3irss Catalog 2006 PDFLuis QuinoNo ratings yet

- Angle BM GeneralDocument21 pagesAngle BM GeneralLuis QuinoNo ratings yet

- Acicular FerriteDocument6 pagesAcicular FerriteLuis QuinoNo ratings yet

- Weld TerminologiaDocument25 pagesWeld TerminologiaLuis QuinoNo ratings yet

- Astm E1003 PDFDocument3 pagesAstm E1003 PDFJairo Wilches80% (5)