Professional Documents

Culture Documents

Moment Connections To Column Webs

Uploaded by

Kilaru HareeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moment Connections To Column Webs

Uploaded by

Kilaru HareeshCopyright:

Available Formats

MOMENT CONNECTIONS

TO COLUMN WEBS

By M. Thomas Ferrell

This article will present

details that will accommodate

mill and shop tolerances of structural members, as well as providing for material ductility. It will

also present limit state strength

considerations for both moment

connections with field welded

beam flanges and field bolted

flange plates.

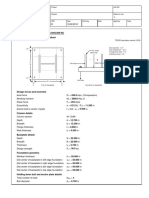

MOMENT CONNECTION

WITH FIELD WELDED

BEAM FLANGES

(FIGURE 1)

1. The connection plates must be

the same grade of material as

the weak axis moment beam.

2. The connection plate has been

extended minimum beyond

the column flange to provide better toughness and ductility.

AISCs Manual of Steel

Construction (LRFD) Volume

IIConnections, pages 10-60

through 10-65, has summarized

results of nine simulated weak

axis FR moment connection tests

performed by Driscoll, et. al., to

aid in selection of details to

ensure ductility.

3. The top connection plate

thickness is equal to tf plus .

This additional thickness is necessary to accommodate tolerances for fabrication and beam

flange tilt. Note that the bottom

of this connection plate is

aligned with the bottom of the

beam top flange.

4. The bottom connection plate

thickness is equal to tf plus 3/8.

This is necessary to accommodate tolerances for fabrication

and beam flange tilt plus possi-

ble overrun/under-run in the

beam depth. Note that the centerline of this connection plate is

aligned with the centerline of the

bottom flange of the beam.

Modern Steel Construction / March 1998

nection plates must be designed

for shear stresses due to the

eccentricity from the neutral

axis of the bolt group to the edge

of the column flange. If a column

web doubler is required due to a

strong axis moment beam, then

the additional stresses from the

shear plate must be considered

in determining the thickness of

the web doubler plate.

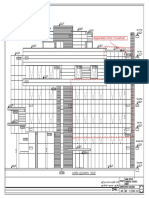

MOMENT CONNECTIONS

WITH BEAM FLANGE

PLATES (FIGURE 2)

1. It is not necessary for the

flange plates to be the same

grade of material of the weak

axis moment beam.

2. Oversized holes should be

used in the flange plates to allow

for mill tolerances in the column

beam. These connections with

oversized holes must be designed

as slip critical. If tension control

bolts are used, if possible use a

bolt gage that will allow bolts at

the bottom flange to be tightened

from inside of the beam flange.

In many cases, this is not possible due to beam flange widths

and beam depths.

5. The welds for connection

plates to the column flanges

must be designed for shear

forces. These welds may also be

subjected to tensile/compression

and shear forces when these

plates serve as stiffener plates

for a strong axis moment beam.

Use fillet welds where possible.

It is good practice to deduct

twice the weld size from the

length of plate available for

welding so that the welds do not

terminate at the edges of the

plate or column flange. If calculated stresses are transferred

through the welds at the column

web, then back-up stiffener

plates must be provided.

Modern Steel Construction / March 1998

6. Bolts for the shear plate to

beam web are normally located

outside of the column flanges.

This practice simplifies beam

erection and allows access to

tighten the bolts with use of an

impact wrench. Short slots

should be used in the plate and

standard holes in the beam web.

Flange welds should be completed before the bolts are tightened.

The short slots will hold top of

beam elevation and allow for

weld shrinkage to occur at the

flange welds. The bolts are

designed for shear forces only

(no eccentricity). The welds for

the shear plate-to-column web

are designed for shear only. The

welds for the shear plate-to-con-

3. Shims must be provided at the

top or bottom flanges to accommodate fabrication and mill tolerances for flange tilt plus possible overrun/under-run in beam

depths. Fabricators normally

prefer the shims to be at the bottom flange due to restrictions on

programming of shop equipment.

If shims are provided at the top

flange, the detail can be provided

to serve as a deck support (figure

3).

4. The flange plates must be

designed for tension yielding,

tension rupture, and compression strength.

5. The flange bolts must be

designed for shear strength.

6. The beam design flexural

strength with regard to net section must be determined to

assure that the net beam section

is adequate without reinforcing.

7. The welds for the flange plates

to the column flanges/webs are

designed using the same criteria

used for the connection plates for

the field welded flange moment

beams in figure 1.

8. The web shear plate design is

the same as for the field welded

flange moment beams.

This article is adapted from a

paper by M. Thomas Ferrell,

P.E., for the 1998 National Steel

Construction Conference. Ferrell

is

President

of

Ferrell

Engineering, Inc., a specialty

structural engineering firm located in Birmingham, AL.

You might also like

- Connections: Best Tips of The 21st CenturyDocument4 pagesConnections: Best Tips of The 21st Centurysymon ellimac100% (1)

- Dropping Main Reinforcement Bas For Use As Support BarsDocument4 pagesDropping Main Reinforcement Bas For Use As Support BarsElie Farhat100% (1)

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- 30 Rules For Good Connections.5Document4 pages30 Rules For Good Connections.5chipchipperson100% (1)

- Base Plates and Anchor Rods - Steel Design AISCDocument3 pagesBase Plates and Anchor Rods - Steel Design AISCpenneng0% (2)

- Simple Steel ConnectionsDocument7 pagesSimple Steel ConnectionsShams Abbas NaqviNo ratings yet

- Connection CostsDocument3 pagesConnection CostsShajit KumarNo ratings yet

- 24 Tips For Simplifying Braced Frame ConnectionsDocument2 pages24 Tips For Simplifying Braced Frame Connectionsgpax42100% (1)

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Reinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551Document42 pagesReinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551mikollimNo ratings yet

- Specifying CamberDocument3 pagesSpecifying CamberarsiajanNo ratings yet

- AISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFDocument24 pagesAISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFhoustonhimselfNo ratings yet

- Ej 2019 q3 Issue PDFDocument58 pagesEj 2019 q3 Issue PDFRonny HurtadoNo ratings yet

- Engineering For Steel ConstructionDocument2 pagesEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- The Reinforcement of Steel ColumnsDocument7 pagesThe Reinforcement of Steel ColumnsRanga KalharaNo ratings yet

- Axial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsDocument38 pagesAxial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsAnonymous 7MdZQn1100% (1)

- Designing HSS ConnectionsDocument8 pagesDesigning HSS Connectionsjarneberg100% (1)

- Site FixesDocument4 pagesSite FixesBalaji SampathNo ratings yet

- Structural Steel Desig - Recommended PDFDocument63 pagesStructural Steel Desig - Recommended PDFNatalia Oviedo100% (1)

- Rfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure StripsDocument6 pagesRfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure Stripsvelmurug_bala100% (1)

- Detailing Corner RFIs 09-3, 09-4, and 09-5Document3 pagesDetailing Corner RFIs 09-3, 09-4, and 09-5frankytgNo ratings yet

- Base Plate DesignDocument6 pagesBase Plate DesignSana UllahNo ratings yet

- Cantilevered Hung FramesDocument43 pagesCantilevered Hung FramesG-off Robson100% (1)

- Sherman - Extended Shear TabsDocument148 pagesSherman - Extended Shear TabsRohan KarandeNo ratings yet

- Moment Connection HSS Top Plate 9-27-2014Document36 pagesMoment Connection HSS Top Plate 9-27-2014Jesus Rafael Curiel PensoNo ratings yet

- Tolerating Tolerances Article PDFDocument3 pagesTolerating Tolerances Article PDFteedNo ratings yet

- AISC - Splice ConferenceDocument4 pagesAISC - Splice ConferenceKamal HalawiNo ratings yet

- Design of Steel Strctures IIDocument3 pagesDesign of Steel Strctures IIRajiv SawaruthNo ratings yet

- 02 MF AnchorsDocument13 pages02 MF AnchorsAn SusiNo ratings yet

- Clipconn Bolt Weld 13Document42 pagesClipconn Bolt Weld 13NEONo ratings yet

- Especificaciones de MaterialesDocument6 pagesEspecificaciones de MaterialesArturo AppleyxrdNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFrohalestatNo ratings yet

- Awc Wood Connection Design Des330 1 Slide Per PageDocument112 pagesAwc Wood Connection Design Des330 1 Slide Per Pagecerratosys100% (1)

- ESQUEMAS UNIONES MetalicasDocument165 pagesESQUEMAS UNIONES MetalicasGuillermo Hortigüela Cordoba100% (6)

- 005 Connections 2Document69 pages005 Connections 2Siam100% (1)

- AISC Design Guide 09 - Torsional Analysis of Structural Steel Members - ErrataDocument5 pagesAISC Design Guide 09 - Torsional Analysis of Structural Steel Members - Errataslowrainandfastbird100% (1)

- Metal Deck DesignDocument38 pagesMetal Deck DesignKenneth DavisNo ratings yet

- AISC Live Webinars: Today's Live Webinar Will Begin Shortly. Please Stand byDocument28 pagesAISC Live Webinars: Today's Live Webinar Will Begin Shortly. Please Stand byHectorNo ratings yet

- Combined Systems SEAOC Blue BookDocument3 pagesCombined Systems SEAOC Blue BookHirad GrivaniNo ratings yet

- Proprietary Connections Hamburger CordovaDocument8 pagesProprietary Connections Hamburger CordovaPauloAndresSepulvedaNo ratings yet

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocument5 pagesGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaNo ratings yet

- Connection Design GuidelinesDocument4 pagesConnection Design GuidelinesABDUL REHMANNo ratings yet

- World of PipingDocument13 pagesWorld of PipingHafiz Usama ShahzadNo ratings yet

- Bolted Beam Splice: (A) Conventional SpliceDocument11 pagesBolted Beam Splice: (A) Conventional SpliceKimberly Binay-anNo ratings yet

- 30 Good RulesDocument4 pages30 Good RulesSamet Karataş100% (1)

- Anchor Bolt and Anchor Base PlateDocument2 pagesAnchor Bolt and Anchor Base PlateHugo Mario Ariza PalacioNo ratings yet

- Glulam Construction and Connection DetailsDocument7 pagesGlulam Construction and Connection DetailsNiceman NatiqiNo ratings yet

- 5 SlimDek Connection - AW 48240Document12 pages5 SlimDek Connection - AW 48240in678No ratings yet

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Or Less: How To Determine The Best Connections For Steel Joists and Metal DeckDocument4 pagesOr Less: How To Determine The Best Connections For Steel Joists and Metal DeckMinh Tâm TrầnNo ratings yet

- Prying Forces in The Bolts Become Significant When Ninety Percent of The YieldDocument2 pagesPrying Forces in The Bolts Become Significant When Ninety Percent of The YieldRC Dela RocaNo ratings yet

- Detailing Considerations Design Guide 7 - bk745 PDFDocument5 pagesDetailing Considerations Design Guide 7 - bk745 PDFFunkNo ratings yet

- ES 49BranchConnections PDFDocument7 pagesES 49BranchConnections PDFprabuharan89No ratings yet

- FRP Flange DesignDocument29 pagesFRP Flange DesignSubhadip RoyNo ratings yet

- Design and Construction FailuresDocument23 pagesDesign and Construction Failuresgokulnath.asoorNo ratings yet

- SS051a SecureDocument16 pagesSS051a SecureilovevinaNo ratings yet

- A 503 Window Schedule1699537950122Document1 pageA 503 Window Schedule1699537950122Amro Ahmad AliNo ratings yet

- 5120544-Spo-A-5906-0 (T)Document1 page5120544-Spo-A-5906-0 (T)Amro Ahmad AliNo ratings yet

- Aed130164 00 DD SD 0602 BDocument1 pageAed130164 00 DD SD 0602 BAmro Ahmad AliNo ratings yet

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliNo ratings yet

- Ar-39 Wall SecDocument1 pageAr-39 Wall SecAmro Ahmad AliNo ratings yet

- Window Schedule 13 11 2013-ModelDocument1 pageWindow Schedule 13 11 2013-ModelAmro Ahmad AliNo ratings yet

- Partial Elevation: SCALE 1:20Document1 pagePartial Elevation: SCALE 1:20Amro Ahmad AliNo ratings yet

- KWT NG 01 03 00Document1 pageKWT NG 01 03 00Amro Ahmad AliNo ratings yet

- SHS 60x60x4 SHS 30x30x3.2Document1 pageSHS 60x60x4 SHS 30x30x3.2Amro Ahmad AliNo ratings yet

- + Steel InsertDocument1 page+ Steel InsertAmro Ahmad AliNo ratings yet

- 3A Alucobond PLUS SpecsDocument8 pages3A Alucobond PLUS SpecsyassdayshoumNo ratings yet

- InsurancesDocument1 pageInsurancesAmro Ahmad AliNo ratings yet

- Ludo (Sorry) - Game StrategyDocument8 pagesLudo (Sorry) - Game Strategysuperyoopy100% (1)

- 2020 AMC Years 7-8 JuniorDocument8 pages2020 AMC Years 7-8 JuniorTodor DobrevNo ratings yet

- Xpert R410a Onoff Ar Na 230613Document62 pagesXpert R410a Onoff Ar Na 230613Wilson Segovia CarrascoNo ratings yet

- Energy TransportDocument16 pagesEnergy TransportainmnrhNo ratings yet

- Surveying Lab ManualDocument76 pagesSurveying Lab ManualIan Lawrence YupanoNo ratings yet

- Lastexception 63811739610Document11 pagesLastexception 63811739610BNo ratings yet

- Eng8Quarter1Week1 2Document6 pagesEng8Quarter1Week1 2Duero-Hadjilatip KayeNo ratings yet

- GP125 - 200s Maintenance Manual-A520180913Document170 pagesGP125 - 200s Maintenance Manual-A520180913paulatclayxNo ratings yet

- Updated Eva ResumeDocument1 pageUpdated Eva Resumeapi-534826411No ratings yet

- Json Out InvoiceDocument2 pagesJson Out Invoicetkpatel529No ratings yet

- Gep Primary Water Resource Aug12 NSWDocument50 pagesGep Primary Water Resource Aug12 NSWNitin AroraNo ratings yet

- Vallorbs Guide Cut Vs Rolled ThreadsDocument3 pagesVallorbs Guide Cut Vs Rolled ThreadsOrlando AriasNo ratings yet

- Sapient Paper On 11Th April, 2008Document12 pagesSapient Paper On 11Th April, 2008rayorizNo ratings yet

- Practical Research 2 Module 1: Characteristics, Strengths, Weaknesses, and Kinds of Quantitative ResearchDocument6 pagesPractical Research 2 Module 1: Characteristics, Strengths, Weaknesses, and Kinds of Quantitative Research306947 Bancal Pugad ISNo ratings yet

- RealSens Pipetech WorkshopDocument45 pagesRealSens Pipetech Workshopalioo44No ratings yet

- SPPU Report FormatDocument50 pagesSPPU Report FormatAmit Devidas AherNo ratings yet

- Physiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsDocument12 pagesPhysiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsRafida I CNo ratings yet

- Karatina University: University Examinations 2017/2018 ACADEMIC YEARDocument4 pagesKaratina University: University Examinations 2017/2018 ACADEMIC YEARKimondo KingNo ratings yet

- 4UIE - AB - Nov 23Document2 pages4UIE - AB - Nov 23aaaNo ratings yet

- Quiz 1 Distribusi Plus JawabanDocument6 pagesQuiz 1 Distribusi Plus JawabandimasfupNo ratings yet

- PW160-7K S 0411Document890 pagesPW160-7K S 0411ado_22100% (3)

- Lecture On Dictionaries - Jupyter NotebookDocument13 pagesLecture On Dictionaries - Jupyter NotebookruchikaNo ratings yet

- DLP #7 Eng 7Document2 pagesDLP #7 Eng 7Lenn Don50% (2)

- PMRC Mar Va 115Document11 pagesPMRC Mar Va 115adamsaufimahmud1988No ratings yet

- MCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesDocument30 pagesMCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesBollu SatyanarayanaNo ratings yet

- Black Mirror Analysis: 15 Million Merits (Due 27/04/16)Document11 pagesBlack Mirror Analysis: 15 Million Merits (Due 27/04/16)Will MunnyNo ratings yet

- Kinematics of A Novel Nine Degree of Freedom Configurable Gough-Stewart PlatformDocument19 pagesKinematics of A Novel Nine Degree of Freedom Configurable Gough-Stewart PlatformNeider NadidNo ratings yet

- LTE OFDMA SimulationDocument9 pagesLTE OFDMA Simulationrajendra4343No ratings yet

- Aristotles Three Modes of PersuasionDocument3 pagesAristotles Three Modes of PersuasionJoy Grace DuremdesNo ratings yet

- Business Ethics Case StudiesDocument25 pagesBusiness Ethics Case Studiesswaggerbox100% (2)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- The Inimitable Jeeves [Classic Tales Edition]From EverandThe Inimitable Jeeves [Classic Tales Edition]Rating: 5 out of 5 stars5/5 (3)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsFrom EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo ratings yet

- 438 Days: An Extraordinary True Story of Survival at SeaFrom Everand438 Days: An Extraordinary True Story of Survival at SeaRating: 4.5 out of 5 stars4.5/5 (189)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- The Importance of Being Earnest: Classic Tales EditionFrom EverandThe Importance of Being Earnest: Classic Tales EditionRating: 4.5 out of 5 stars4.5/5 (44)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveFrom EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo ratings yet

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsFrom EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldFrom EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldRating: 4.5 out of 5 stars4.5/5 (30)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)