Professional Documents

Culture Documents

Daewoo Matiz 2000-2013 Sohc Engine Mechanical

Daewoo Matiz 2000-2013 Sohc Engine Mechanical

Uploaded by

DANNYCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daewoo Matiz 2000-2013 Sohc Engine Mechanical

Daewoo Matiz 2000-2013 Sohc Engine Mechanical

Uploaded by

DANNYCopyright:

Available Formats

SECTION 1B

SOHC ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in B unless otherwise

noted.

TABLE OF CONTENTS

Description and Operation . . . . . . . . . . . . . . . . . .

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Valve Train . . . . . . . . . . . . . .

1B-2

1B-2

1B-2

1B-2

Engine Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Rod . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Piston Pin . . . . . . . . . . .

1B-3

1B-3

1B-3

1B-3

Timing Belt and Pulley . . . . . . . . . . . . . . . . . . . . . 1B-4

Engine Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-4

Component Locator . . . . . . . . . . . . . . . . . . . . . . . . 1B-5

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manifold & Air Flow System . . . . . . . . . . . . . . . . .

Timing Belt & Engine Mount . . . . . . . . . . . . . . . .

1B-5

1B-6

1B-7

1B-8

Diagnostic Information and Procedure . . . . . . . 1B-9

Compression Pressure Check . . . . . . . . . . . . . . . 1B-9

Oil Pressure Check . . . . . . . . . . . . . . . . . . . . . . . . 1B-9

Adjustment of Valve Clearance . . . . . . . . . . . . . 1B-10

Ignition Timing Check and Adjustment

(Typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Timing Check and Adjustment . . . . . . . .

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . .

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . . .

DAEWOO M-150 BL2

1B-11

1B-12

1B-14

1B-14

Air Filter Assembly . . . . . . . . . . . . . . . . . . . . . . .

Air Filter Element . . . . . . . . . . . . . . . . . . . . . . . . .

Positive Crankcase Ventilation (PCV) Hose

and Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . .

1B-14

1B-15

Exhaust Manifold (Typical) . . . . . . . . . . . . . . . . .

Exhaust Manifold (Euro III) . . . . . . . . . . . . . . . .

Timing Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1B-18

1B-20

1B-21

1B-23

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Distributor Case . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket . . . . . . . . . . . . . . . . .

Engine Mount Damping Block . . . . . . . . . . . . . .

1B-24

1B-26

1B-28

1B-32

Engine Mount Front Damping Bush . . . . . . . . .

Engine Assembly . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Valve Train

Components . . . . . . . . . . . . . . . . . . . . . . . . . . .

1B-34

1B-35

1B-47

Engine Block Components . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Specifications . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications . . . . . . . . . .

1B-59

1B-71

1B-71

1B-73

1B-15

1B-16

1B-47

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-75

Special Tools Table . . . . . . . . . . . . . . . . . . . . . . . 1B-75

1B 2 SOHC ENGINE MECANICAL

DESCRIPTION AND OPERATION

ENGINE TYPE

The engine is 4-cycle, water-cooled, in-line 3 cylinders

with displacement of 796cc (68.572.0mm) (2.70

2.83 in.).

Engine model

(Specifications)

F8C Type SOHC /

2 Valve (MPI)

Maximum power (kw/rpm)

37.5 / 6,000

Maximum torque (NSm/rpm)

68.6 / 4,600

Compression ratio

9.3 : 1

D102B002

CYLINDER HEAD AND VALVE TRAIN

The cylinder head is made of cast aluminum alloy for

better strength in hardness with lightweight, and camshaft (k) and rocker arm shaft (h) arranged in-line support.

D102B001

ENGINE LUBRICATION

The engine lubrication is of the wetsump method to draw

up the oil forced by the oil pump. The oil pump is of a

trochoid type, and mounted on crankshaft at crankshaft

pulley side (a). Oil is drawn up through oil pump pickup

tube (b) and passed through pump (c) to oil filter (d). The

filtered oil flows into two paths in engine block. In one

path (e), oil reaches crankshaft journal bearings. Oil

from crankshaft journal bearings is supplied to connecting rod bearings by means of intersecting passages

drilled in crankshaft, and then injected from a small hole

provided on big end of connecting rod to lubricate piston

(f), rings, and cylinder wall. In another path (g), oil goes

up to cylinder head and lubricates rocker arm (i), valve

(j), camshaft (k), etc. through the oil hole provided on the

rocker arm shaft (h).

D102B003

The combustion chambers are formed into the manifold

combustion chambers with increased squish parts for

better combustion efficiency and its intake and exhaust

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 3

parts are installed in the cross flow arrangement. The

rocker arm (i) operates in seesaw motion to close and

open the intake and exhaust valves (j) with camshaft by

turning the rocker arm shaft of each intake and exhaust

part.

crankshaft (m) and its small end to piston pin to transmit

the power.

The big end is detachable, and its upper and lower parts

are fastened by bolting after the metal bearings (q) are

inserted.

ENGINE BLOCK

As the largest part of the engine components. the block

(l) has all the necessary parts attached to outer surface

of it.

On the inside surface of block, there are bore surfaces

by horning, which are cylinders, and on the periphery of

the cylinders, there are the passages to prevent the

over-heated and to lubricate the engine block.

CRANKSHAFT

The crankshaft (m) is to convert the rectilinear motion

into the rotation motion through the connecting rod (n)

which transmits the power generated by combustion.

On the one side of it, oil pump, crankshaft pulley and

timing belt pulley are attached, and oil seal housing and

flywheel are on the other side.

A special steel of high grade cast iron is used for the material to stand the bending load and distortion. The material of the main bearing (o) is aluminum alloy. The split

thrust bearings (p) are inserted in the journal bearing

part (No.3).

PISTON, PISTON RING AND PISTON

PIN

Piston

The piston (r) is of the open skirt type and its crown is

exposed in the combustion chamber to generate power.

Its land and skirt parts are made of coat aluminum alloy

which is light and has excellent heat conductivity in order

to meet its continuous and high speed reciprocation

movement.

Piston Ring

It is composed of two compression rings (s) and one oil

ring (t) and installed between the grooves of the piston

to make the high speed reciprocating movement maintaining a remarkable air tightness as well as cylinders. It

is a critical parts to affect the compression pressure, oil

consumption, compression, blow by pressure and engine performance.

Piston Pin

The pin (u) is not fixed to the piston or connecting rod

and its both ends are assembled by the circlip (v) in the

full floating type. The pin is used to transmit the power

from the crown part of piston to connecting rod.

D102B004

CONNECTING ROD

The connecting rods (n) are made of forged steel, and

its section is typed I with its big end connected to

DAEWOO M-150 BL2

D102B005

1B 4 SOHC ENGINE MECANICAL

TIMING BELT AND PULLEY

ENGINE MOUNT

The timing belt connects the camshaft timing pulley (w)

and the crankshaft timing pulley (x). The timing belt

coordinates the crankshaft and the camshaft and keeps

them synchronized. The timing belt also turns the coolant pump (y). The timing belt and the pulleys are toothed

so that there is no slippage between them. There is a

tension pulley (z) that maintains the correct timing belt

tension. The timing belt is made of a tough reinforced

rubber similar to that used on the serpentine drive belt.

The timing belt requires no lubrication.

This is to absorb or reduce the engine vibration and impact from the wheeled road. Engine mount is attached to

the enginefront side, the engine-right side and the engine-rear side and one transaxle mount is attached to

the transaxle side.

D102B007

D102B006

D102B008

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 5

COMPONENT LOCATOR

CYLINDER HEAD

D12B4011

1

2

3

4

5

6

Oil Filler Cap

Cylinder Head Cover

Cylinder Head Cover (Euro III)

Distributor Case

Camshaft

Exhaust Rocker Arm

DAEWOO M-150 BL2

7

8

9

10

11

Cylinder Head Gasket

Cylinder Head

Intake Rocker Arm

Exhaust Valve

Intake Valve

1B 6 SOHC ENGINE MECANICAL

ENGINE BLOCK

D21B0011

1

2

3

4

5

Oil Level Gauge Stick

Piston

Connecting Rod

Engine Block

Oil Filter

6

7

8

9

10

Flywheel

Crankshaft

Oil Pan

Oil Pump Strainer

Oil Pump Assembly

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 7

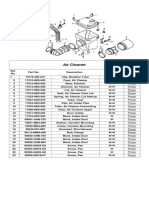

MANIFOLD & AIR FLOW SYSTEM

D21B0021

1 Intake Manifold

2 Exhaust Gas Recirculation (EGR) Pipe

3 Exhaust Gas Recirculation (EGR) Valve and

Solenoid

4 Throttle Body Assembly

5 Air Filter Assembly

6 Resonator

DAEWOO M-150 BL2

7

8

9

10

11

12

Snorkel

Oxygen Sensor

Exhaust Manifold

Exhaust Manifold Heat Shield

Exhaust Manifold Heat Shield (Euro III)

Exhaust Manifold (Euro III)

1B 8 SOHC ENGINE MECANICAL

TIMING BELT & ENGINE MOUNT

D12B4041

1

2

3

4

5

6

7

8

Engine Mount Damping Block

Engine Mount Intermediate Bracket

Engine Mount Brace Bracket

Transaxle Mount Bracket

Transaxle Mount Damping Block

Engine Mount Front Bracket

Engine Mount Front Damping Bush

Timing Belt

9

10

11

12

13

14

15

Timing Belt Tensioner

Crankshaft Gear

Timing Belt Upper Front Cover

Timing Belt Lower Front Cover

Crankshaft Pulley

Engine Mount Lower Bracket

Engine Mount Upper Bracket

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 9

DIAGNOSTIC INFORMATION AND PROCEDURE

COMPRESSION PRESSURE CHECK

OIL PRESSURE CHECK

Tools Required

Tools Required

0991564510 Compression Pressure Gauge

Check the compression pressure in the following procedures:

1. Warm up the engine to the normal operating temperature (Cooling temperature : 8090_C (176194_F)).

2. Stop the engine and then remove the high tension

cable and the spark plug.

0991577310 Oil Pressure Gauge

Prior to check oil pressure, check the followings:

3. Disconnect the distributor optical sensor connector.

4. Install the compression pressure gauge 0991564510

(a) in the hole of spark plug.

D Check oil level and add if required.

D Replace the discolored, deteriorated or diluted oil.

D Check any oil leakage and repair the defective parts.

Check the compression pressure in the following procedures:

1. Remove the oil pressure switch (b) from the cylinder

block.

2. Install the oil pressure gauge 0991577310 (c) to the

mounting place of the oil pressure switch.

D12B301A

D12B302A

5. Disengage the clutch in Neutral (to lighten starting

load on engine upon cranking), and depress the accelerator all the way to make the throttle fully open.

6. Crank the engine with the starting motor, and read the

highest pressure on the compression pressure gauge.

D The difference of measured value between cylinders

is 98.06kPa (14.22 psi) and less.

D On checking, make the connection perfectly airtight

between the hole of spark plug and compression pressure gauge.

Compression

Pressure

400 rpm

Unit

Standard

Limit

kPa(psi)

1,225.75

(177.73)

1,176.72

1,274.78

(170.62

184.84)

7. After checking, remove the gauge and install the removed parts.

DAEWOO M-150 BL2

3. Start the engine and warm up to the normal operating

temperature.

4. Raise the engine speed up to 2,000rpm and then

read oil pressure.

Item

Unit

Standard

Oil Pressure 2000rpm

kPa

(psi)

245.15294.18

(35.5542.66)

5. After checking, wrap the threads of oil pressure

switch with a seal tape and tighten it to the specified

torque 1216 NSm (106144 lb-in).

6. Start the engine and check oil pressure switch for oil

leakage.

1B 10 SOHC ENGINE MECANICAL

ADJUSTMENT OF VALVE

CLEARANCE

Adjust the valve clearance in the following procedures:

1. Remove the air filter/resonator assembly and the

relevant parts installed on the cylinder head cover.

2. Remove the cylinder head cover hexagon bolts and

remove the cover.

3. Turn over the crankshaft to make No.1 cylinder

matched with the compression top dead center.

(When the camshaft sprocket notch (d) is aligned with

the timing belt rear cover triangle pointer (e) and the

crankshaft sprocket point (f) is aligned with the oil

pump housing point (g), the compression top dead

center is on the ignition sequence for No. 1 cylinder.)

D102B304

6. Check the valve clearance for the No. 1 cylinder exhaust top dead center.

Condition

Exhaust top dead

center of No.1

cylinder

Cylinder

No.

Intake

Exhaust

Q f marks indicates the place where the valve clearance can be checked and adjusted.

D Check and adjust the valve clearance (i) using thickness gauge (j).

D102B303

4. Check the valve clearance for No. 1 cylinder compression top dead center.

Condition

Compression top

dead center of

No.1 cylinder

Cylinder

No.

Intake

Exhaust

Q f marks indicates the place where the valve clearance can be checked and adjusted.

5. If the checking for the valve clearance of No.1 cylinder compression top dead center is over, position

No.1 cylinder on the exhaust top dead center as rotating the crankshaft in a 360degree arc. (When the

camshaft sprocket point (h) is aligned with the timing

belt rear cover triangle pointer (e), the exhaust top

dead center is on the ignition sequence for No. 1 cylinder.)

D102B305

D102B306

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 11

The measured value of valve clearance should meet the

specified value. If not, adjust the valve clearance.

Important: In case of hot engine, warm up the engine

until the electric cooling fan begins to work and stop the

engine to adjust the clearance with 2030 minutes there

from.

Unit : mm (in.)

Item

Specified value

Intake

0.150.02

(0.00590.0008)

Exhaust

0.320.02

(0.01260.0008)

Intake

0.250.02

(0.00980.0008)

Exhaust

0.420.02

(0.01650.0008)

Cold

Valve

Clearance

Hot

IGNITION TIMING CHECK AND

ADJUSTMENT (TYPICAL)

Note: Ignition timing could not be adjusted for Direct

Ignition System (Euro Stage III).

Check and adjust the ignition timing in the following procedures:

1. Warm up the engine to the normal operating temperature.

2. Turn off the lamp and audio system and shift the shift

gear lever in Neutral.

8. When adjusting the valve clearance, loosen the adjust nut (k) and then tighten or loosen the adjust rod (l)

properly.

D12B3081

3. Connect terminal A and terminal C of ALDL connector using the wire (m) or connect the scan tool (n) with

ALDL connector.

4. Connect the timing light (o) with No. 1 cylinder high

tension cable and check the specified value for the

ignition timing, flashing notch on the crankshaft

pulley.

D102B307

Item

Specified Value

Ignition timing 950rpm

10_ BTDC

Important: In flashing the timing light, if crankshaft

pulley notch (p) is matched with the mark (10) for timing

check, the ignition timing is 10_ BTDC.

D102B309

DAEWOO M-150 BL2

1B 12 SOHC ENGINE MECANICAL

2. Turning the crankshaft clockwise twice, align the

notch (d) on the crankshaft pulley (c) with the mark 0

(e) for the timing check on the timing belt front lower

cover.

D102B310

5. If the ignition timing exceeds the specified value,

loosen the distributor bolts and adjust it to the specified ignition timing by turning the distributor body (s).

D102B313

3. Check if the notch (f) on the camshaft sprocket is

aligned with the triangle pointer (g) on the timing belt

rear cover.

Important: Notch (f) should be aligned with pointer (g)

to set the valve timing normally.

D102B311

VALVE TIMING CHECK AND

ADJUSTMENT

Check the valve timing in the following procedures:

1. After removing the high headlamp, loosen the bolts

(a) and remove the timing belt front upper cover (b).

D102B314

D102B312

DAEWOO M-150 BL2

SOHC ENGINE MECANICAL 1B 13

Adjust the valve timing in the following procedures:

1. Loosen the bolt and remove the timing belt pulley (c).

In loosening the bolt, use the driver (h) in the picture

shown.

4. Using the bolt, turn the crankshaft clockwise to align

the mark (m) on the crankshaft sprocket with the

pointer (n) on the oil pump housing. Then, turn the

camshaft to align the notch (f) with the pointer (g).

D102B315

D102B318

2. Remove the oil level gauge guide tube (i) and the timing belt front lower cover (j).

5. Install the timing belt (l) and the tensioner (k). (Do not

tighten the tensioner bolt completely.)

Turning the crankshaft clockwise twice, align the

mark (m) with the pointer (n) and tighten the tensioner

bolt to 1523 NSm (1117 lb-ft).

D102B316

3. Remove the timing belt tensioner (k) and the timing

belt (l).

D12B319A

6. Install all removed parts.

D102B317

DAEWOO M-150 BL2

You might also like

- Isuzu Engine 6WF1-TC Commanrail Workshop ManualDocument291 pagesIsuzu Engine 6WF1-TC Commanrail Workshop ManualYu Tuner92% (85)

- Service Manual #22 4.2 D-Tronic DieselDocument878 pagesService Manual #22 4.2 D-Tronic DieselPhil B.50% (4)

- 5-Cylinder Diesel Engine BAC BLK BPD BPE VW TouaregDocument169 pages5-Cylinder Diesel Engine BAC BLK BPD BPE VW TouaregNP100% (7)

- 2.5 TdiDocument36 pages2.5 Tdipsychoreality100% (3)

- Especificaciones Tecnicas Motor 4g54 2.6ltsDocument20 pagesEspecificaciones Tecnicas Motor 4g54 2.6ltsjr50% (2)

- AW7x Rebuild PDFDocument136 pagesAW7x Rebuild PDFmasakp100% (2)

- Manual de Partes Bobcat S-300 PDFDocument400 pagesManual de Partes Bobcat S-300 PDFRoberth Alexander Ríos Nieves100% (6)

- Manual Weichai WD 615.46 - Euro IIDocument62 pagesManual Weichai WD 615.46 - Euro IISamuelOliveira100% (15)

- Service Manual For SC11CB EngineDocument92 pagesService Manual For SC11CB Enginegustavo100% (6)

- BJB BKC Bru Bls Bxe BXF BXJ Engine EngDocument207 pagesBJB BKC Bru Bls Bxe BXF BXJ Engine EngMihai Lungu50% (2)

- Service.: AUDI A2 - Engine and GearboxDocument44 pagesService.: AUDI A2 - Engine and GearboxAlex StirbuNo ratings yet

- Subaru 4-Stroke V-Twin Engines Service ManualDocument85 pagesSubaru 4-Stroke V-Twin Engines Service ManualALFREDO TEXACANo ratings yet

- S62 EngineDocument26 pagesS62 EngineALJASMI78No ratings yet

- S 54Document28 pagesS 54Szabo ArnoldNo ratings yet

- Generator Testing Manual For Rotor & ExciterDocument20 pagesGenerator Testing Manual For Rotor & ExciterRakesh KumarNo ratings yet

- Mercruiser Stern Drive Service ManualDocument14 pagesMercruiser Stern Drive Service ManualDes Stirling0% (1)

- ALPHA ONE Gen.2Document43 pagesALPHA ONE Gen.2Andrea Nakicenovic100% (1)

- TM9-2815-200-35 AVDS-1790-2A M60 EngineDocument780 pagesTM9-2815-200-35 AVDS-1790-2A M60 EngineTom TechoueyresNo ratings yet

- (TOYOTA) Manual de Taller Toyota Hiace PDFDocument30 pages(TOYOTA) Manual de Taller Toyota Hiace PDFMarvin SNo ratings yet

- Generator Bolting and TorquesDocument2 pagesGenerator Bolting and TorquesAbisholita MecaTronics100% (1)

- TCM Crankshaft, Counterweight and Connecting Rod Repair Sb00-3aDocument35 pagesTCM Crankshaft, Counterweight and Connecting Rod Repair Sb00-3aElmer VillegasNo ratings yet

- Chevrolet Aveo 2016 EngineDocument77 pagesChevrolet Aveo 2016 EngineHugo HerreraNo ratings yet

- Service Manual Musso Engine (OM 600)Document187 pagesService Manual Musso Engine (OM 600)Dennis Cezar Mendes100% (1)

- Musso A1 B3Document186 pagesMusso A1 B3Julio ReyesNo ratings yet

- Ford 300cid 6cylinder Industrial Service ManualDocument10 pagesFord 300cid 6cylinder Industrial Service Manualvirginia100% (51)

- Chapter 2 Part A 2.6L Four-Cylinder EngineDocument20 pagesChapter 2 Part A 2.6L Four-Cylinder EngineFlorin FurculesteanuNo ratings yet

- Isuzu Engine 6wf1 TC Commanrail Workshop ManualDocument20 pagesIsuzu Engine 6wf1 TC Commanrail Workshop Manualfrank100% (54)

- 20-547792 enDocument132 pages20-547792 enRené Seyer EspatacusNo ratings yet

- 194-210 CSG649Document107 pages194-210 CSG649IV FVNo ratings yet

- Mercruiser MCM 43l AlphaDocument40 pagesMercruiser MCM 43l AlphaDarrel WhiteNo ratings yet

- Motor 4M41 MitsubishiDocument105 pagesMotor 4M41 MitsubishiMario Rogers100% (13)

- En 4J2 1C2Document75 pagesEn 4J2 1C2Trafu LarNo ratings yet

- Moyno: 2000 PumpsDocument29 pagesMoyno: 2000 PumpsSavalia HardikNo ratings yet

- 233 2.0-Litre Engine PDFDocument41 pages233 2.0-Litre Engine PDFAllan Cancino100% (1)

- FORD Puma 2Document18 pagesFORD Puma 2Uriel MF100% (1)

- Mitsubishi DelicaDocument104 pagesMitsubishi DelicaGabriel BalcazarNo ratings yet

- Cummins Engine Service Manual Cum S H NHDocument11 pagesCummins Engine Service Manual Cum S H NHWalter Lazo50% (2)

- Rukovodstvo Po Obsluzhivaniju Dvigatelej Hyundai D6a D8aDocument168 pagesRukovodstvo Po Obsluzhivaniju Dvigatelej Hyundai D6a D8ajack comboNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi SezDocument41 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi SezLuciano LiuzziNo ratings yet

- 4-Cylinder Diesel Engine (1.9 L Engine)Document207 pages4-Cylinder Diesel Engine (1.9 L Engine)PepePerez1234No ratings yet

- Mich 75a PartsDocument130 pagesMich 75a PartsOficina FernandinhoNo ratings yet

- S01AAHW8820-4 Cyl Injection Engine (4V) MechanicsDocument181 pagesS01AAHW8820-4 Cyl Injection Engine (4V) MechanicsBogdan MocanuNo ratings yet

- S80 MCCDocument236 pagesS80 MCCAnonymous 8rb48tZS100% (1)

- LANCER Workshop ManualDocument21 pagesLANCER Workshop ManualHameed0% (1)

- Engine BWA, BPY - 2.0 LTR, 4-Valve, Turbo - A005TT00520Document201 pagesEngine BWA, BPY - 2.0 LTR, 4-Valve, Turbo - A005TT00520Jonathan AmirmadhiNo ratings yet

- SSP 255Document40 pagesSSP 255get_prasadns3358100% (1)

- Section: Engine MechanicalDocument64 pagesSection: Engine Mechanicalvadim vadimNo ratings yet

- Em PDFDocument64 pagesEm PDFGael AlvarezNo ratings yet

- Sohc Engine Mecanical 1B - 13: D102B315 D102B318Document3 pagesSohc Engine Mecanical 1B - 13: D102B315 D102B318BENBRIKA MebroukNo ratings yet

- 4-Cylinder TDI Engine CBBDocument240 pages4-Cylinder TDI Engine CBBdasomasoNo ratings yet

- Engines (M52TU)Document27 pagesEngines (M52TU)Leonard 'Leo' Ng100% (1)

- SSP 260 - The 1.2ltr 3 Cylinder Petrol Engine SDocument36 pagesSSP 260 - The 1.2ltr 3 Cylinder Petrol Engine Spravinkumarkr100% (1)

- Crankcase and Cylinder HeadDocument69 pagesCrankcase and Cylinder HeadGreg HannaNo ratings yet

- Yamaha FZ6-N 2004 (Europe) Supplementary Service ManualDocument77 pagesYamaha FZ6-N 2004 (Europe) Supplementary Service Manualm.kelleci7248No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Dt15 Service Manual-1Document22 pagesDt15 Service Manual-1Marvin S0% (3)

- (HYUNDAI) Manual de Taller Cableado Hyundai Accent 1995 2003 PDFDocument5 pages(HYUNDAI) Manual de Taller Cableado Hyundai Accent 1995 2003 PDFMarvin SNo ratings yet

- (HYUNDAI) Manual de Taller Cableado Hyundai Accent 1995 2003 PDFDocument5 pages(HYUNDAI) Manual de Taller Cableado Hyundai Accent 1995 2003 PDFMarvin SNo ratings yet

- Job Profile Chart & Competency UnitDocument13 pagesJob Profile Chart & Competency UnitMohd FadhliNo ratings yet

- Mast Lift Cylinders, Models With Single Lift Cylinder MastDocument3 pagesMast Lift Cylinders, Models With Single Lift Cylinder MastJhonny Rodriguez100% (1)

- WA380 6 S N 65001 UP Ecot3Document648 pagesWA380 6 S N 65001 UP Ecot3ELIASNo ratings yet

- Parts Catalog: 2009/5 (May.) PublishedDocument30 pagesParts Catalog: 2009/5 (May.) Publishedxuan bach vuNo ratings yet

- Malaysia: Vpbc5 Mnm3 Dnlgm1 CS6Document61 pagesMalaysia: Vpbc5 Mnm3 Dnlgm1 CS6Muhammad SafwanNo ratings yet

- 2014 Price ListDocument17 pages2014 Price ListMartin J.No ratings yet

- Metso Quote For SparesDocument8 pagesMetso Quote For Sparesmanian_arsNo ratings yet

- Harmonic Drive Ultra Flat Component SpecsheetDocument4 pagesHarmonic Drive Ultra Flat Component SpecsheetElectromateNo ratings yet

- Agrotron 120-130-150-150.7-165.7Document358 pagesAgrotron 120-130-150-150.7-165.7JhonTerry100% (1)

- Disclosure To Promote The Right To Information: IS 3823 (1988) : Rolling Bearings - Static Load Ratings (PGD 13: Bearing)Document12 pagesDisclosure To Promote The Right To Information: IS 3823 (1988) : Rolling Bearings - Static Load Ratings (PGD 13: Bearing)karthikeyanNo ratings yet

- Al125 Xeon Water PumpDocument1 pageAl125 Xeon Water PumpRizky NoerNo ratings yet

- ConectoresDocument1 pageConectoresjoaquin suarezNo ratings yet

- Catálogo de Peças 6060 Tier 3Document93 pagesCatálogo de Peças 6060 Tier 3posvendasdf5No ratings yet

- Learn To Drive Manual Cars For DummiesDocument29 pagesLearn To Drive Manual Cars For DummiesAndrut ApostolNo ratings yet

- Yanmar-6ey18al Part BookDocument5 pagesYanmar-6ey18al Part BookDong Yun KimNo ratings yet

- Et 56601016Document74 pagesEt 56601016JohnnyNo ratings yet

- 2009-07-04 170949 Mazda TimingDocument8 pages2009-07-04 170949 Mazda TimingSuksan SananmuangNo ratings yet

- Operation Manual Zoomlion QY40Document133 pagesOperation Manual Zoomlion QY40Hải Tiến100% (1)

- BARDEN Parts ListDocument20 pagesBARDEN Parts ListDwiki RamadhaniNo ratings yet

- KYOSHO SuperTen FW04Document36 pagesKYOSHO SuperTen FW04xerwaneNo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectiontipo3331No ratings yet

- fl400 Parts BookDocument46 pagesfl400 Parts BookroadiesgarageNo ratings yet

- Aficio MP 301Document74 pagesAficio MP 301Oficina ProduçãoNo ratings yet

- Manual Transmision 4WDDocument39 pagesManual Transmision 4WDmarcelo angel mena farfanNo ratings yet

- 2010 XFWorkshop 3 LDDocument3,260 pages2010 XFWorkshop 3 LDHakan ŞenNo ratings yet

- How To Use This ManualDocument6 pagesHow To Use This ManualCARLOSNo ratings yet