Professional Documents

Culture Documents

DIN 1014 - EN 10059 Astma6: Permissible Variation Q From Straightness

DIN 1014 - EN 10059 Astma6: Permissible Variation Q From Straightness

Uploaded by

rezaeibehrouzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 1014 - EN 10059 Astma6: Permissible Variation Q From Straightness

DIN 1014 - EN 10059 Astma6: Permissible Variation Q From Straightness

Uploaded by

rezaeibehrouzCopyright:

Available Formats

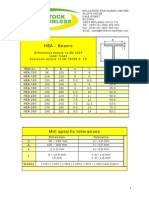

HOT ROLLED SQUARE STEEL BAR FOR GENERAL PURPOSE

PERMISSIBLE VARIATIONS

Permitted variations from

specified size

DIN 1014

6

5/16''

8

10

7/16''

12

14

15

5/8''

16

18

20

7/8''

25

1''

26

1 1/8''

30

1 1/4''

EN 10059

ASTM

0,4

DIN 1014

EN 10059

ASTM

0,005''

0,008''

0,006''

0,009''

0,4

0,6

0,5

0,007''

0,010''

0,008''

0,012''

0,5

0,75

0,6

0,6

1 3/8''

35

36

38

1 1/2''

50

2''

52

2 1/2''

80

85

3 1/2''

100

4 1/2''

"O'' ( out of round)

0,009''

0,013''

0,01''

0,015''

0,011''

0,016''

0,012''

0,9

0,018''

0,014''

0,021''

0,8

0,8

1 / 64

+ 1 / 32

- 0,00

1

1

+ 3 / 64

- 0,00

1,3

+ 1 / 16

- 0,00

1,3

1,2

0,023''

0,023''

1,5

0,035''

1,95

0,046''

1,95

" O" Out of round is the difference between the maximum and minimum diameters of the bar, measured of the same

transverse cross section.

STRAIGHTNESS

DIN 1014 - EN 10059

cross-sectional area

mm2

over

to

ASTM A 6

* Permitted

permissible variation Permitted variations

variations in

q

in Straightness for

from straightness

staraightness do not

Bars *

1000

0,004 L

1000

0,0025 L

1/4'' in any 5 ft and

1/4 and

( number of feet of

total lenght / 5 )

aplly to hot rolled

bars, if any

subsequent heating

operation has been

performed.

HOT ROLLED ANGLE STEEL BAR FOR GENERAL PURPOSE, PERMISSIBLE VARIATIONS

over and under theorical thickness for thicknesses

length of leg

nominal size

Leg

EN (mm)

out of square (k)

thickness

EN

ASTM

over

under

+1 / 32"

- 1 /32"

EN (mm)

ASTM ( inch.)

<5

5 <t 10

ASTM

10<t15

t>15

3 / 16 "

3/16"< t 3 / 8"

over 3/8"

0,008"

0,010"

---

0,010"

0,010"

0,012"

0,012"

0,015"

0,015"

---

---

---

20

25

1''

30

35

0,75

( 0,5 DIN 1028 )

40

+3 / 64"

45

-3 / 64"

0,5

50

2''

55

60

65

+1 / 16"

70

75

3"

80

-1 / 16"

3 / 128"

( 2 EN )

( 1,5 DIN

1028)

0,75

85

90

+1 / 8"

95

- 3 /32"

---

100

4"

110

120

+ 1/8"

- 1/8"

5"

DIN 1028

EN 10056

ST

RA

IG

H T

N E

SS

1,20

a ( nom.

Size leg )

q ( mm )

a 150

0,004 L

a>

0,0025 L

ASTM A 6

Permitted variations in

Straightness for Bars *

* Permitted variations in

staraightness do not aplly to

hot rolled bars, if any

1/4'' in any 5 ft and 1/4 and

subsequent

heating operation

( number of feet of total

has

been

performed

lenght / 5 )

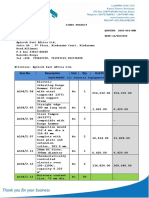

HOT ROLLED FLAT STEEL BAR FOR GENERAL PURPOSE, PERMISSIBLE VARIATIONS

thickness

3

5 1/4'' 7

10 12 1/2'' 13

width

14 15 16 18 20 22 25 1'' 30 40 50 2''

permissible variation

0,5

0,5

DIN 1017

EN 10058

1

1

60

1,5

1,5

ASTM A 6

permissible variations

10

15

0,007''

0,008''

0,01''

1/32''

0,007''

0,012''

0,015''

1 / 32 ''

+1/16 ''

- 1/32 ''

0,008''

0,015''

0,020 ''

1 / 32 ''

3 / 64''

+ 3/32 ''

- 1/16 ''

0,009''

0,015''

0,020''

1 / 32''

3 / 64 ''

+1/8''

- 3/32''

0,015''

0,016''

0,025''

1 / 32''

3 / 64''

1/64''

20

0,75

25

1''

30

0,75

35

40

45

50

2''

60

75

80

permissible variations

70

90

1,5

1,5

95

100

4''

105

110

115

2

2

120

130

140

145

2,5

2,5

150

6''

ST

RA

IG

H T

N E

SS

DIN 1017 - EN 10058

cross-sectional area

mm2

over

1000

to

1000

-

ASTM A 6

permissible

variation

q

from straightness

Permitted variations in

Straightness for Bars *

0,004 L

0,0025 L

1/4'' in any 5 ft and 1/4 and

( number of feet of total lenght / 5 )

* Permitted variations in

staraightness do not

aplly to hot rolled bars, if

any subsequent heating

operation has been

performed

HOT ROLLED ROUND STEEL BAR FOR GENERAL PURPOSE

PERMISSIBLE VARIATIONS

Permitted variations from

specified size

DIN 1013

6

5/16''

8

10

7/16''

12

15

5/8''

16

18

20

7/8''

25

1''

26

1 1/8''

30

1 1/4''

1 3/8''

35

36

1 1/2''

50

2''

52

2 1/2''

80

85

3 1/2''

100

4 1/2''

EN 10060

"O'' ( out of round)

ASTM

DIN 1013

EN 10060

0,005''

0,4

0,006''

0,4

0,008''

0,009''

0,6

0,007''

0,010''

0,008''

0,5

0,6

0,8

1,3

0,5

ASTM

0,012''

0,75

0,009''

0,013''

0,01''

0,015''

0,011''

0,6

0,016''

0,9

0,8

0,012''

0,018''

0,014''

0,021''

1 / 64"

+ 1 / 32"

- 0,00

+ 3 / 64"

- 0,00

1,3

+ 1 / 16 "

- 0,00

1,2

0,023''

0,023''

1,5

0,035''

1,95

0,046''

1,95

" O" Out of round is the difference between the maximum and minimum diameters of the bar, measured of the same

transverse cross section.

STRAIGHTNESS

DIN 1013 - EN 10060

cross-sectional area

mm2

ASTM A 6

over

to

permissible variation

q

from straightness

1000

0,004 L

1000

0,0025 L

Permitted

variations in

Straightness for

Bars *

* Permitted

variations in

staraightness do

not aplly to hot

1/4'' in any 5 ft and rolled bars, if any

subsequent heating

1/4 and

( number of feet of operation has been

performed.

total lenght / 5 )

You might also like

- G-Core G-View QuickGuide enDocument56 pagesG-Core G-View QuickGuide enManuel de Soria100% (1)

- MachiningDocument12 pagesMachiningwardendavid5591100% (1)

- Source Code Example Root Finding Visual StudioDocument5 pagesSource Code Example Root Finding Visual StudioAnonymous ep7LE5ZdP5No ratings yet

- Attachment 5 Transmission Line Design Criteria - AshxDocument33 pagesAttachment 5 Transmission Line Design Criteria - AshxAnonymous ep7LE5ZdP5No ratings yet

- Dungeon - 185Document76 pagesDungeon - 185swhitman69100% (3)

- Robot Guitar ManualDocument63 pagesRobot Guitar ManualNicolas Fernando100% (1)

- Comic by Art AdamsDocument4 pagesComic by Art AdamsCarlson E. AberinNo ratings yet

- Verneers PDFDocument82 pagesVerneers PDFericf5No ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- 05 MachiningDocument12 pages05 MachiningVisvas RajyaguruNo ratings yet

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- Cosmos Alminium-Technical SpecificationsDocument2 pagesCosmos Alminium-Technical SpecificationsmindsopenNo ratings yet

- Jord Y-Type Strainer DatasheetDocument1 pageJord Y-Type Strainer DatasheetSpoonful BurnsideNo ratings yet

- Din 6799 - Freios CavaleirosDocument3 pagesDin 6799 - Freios CavaleirostimanelNo ratings yet

- IPS S.S. - Grooved Couplings (17.03)Document4 pagesIPS S.S. - Grooved Couplings (17.03)SureshNo ratings yet

- En 8Document10 pagesEn 8KarthikRajuNo ratings yet

- Nippon Steels ShapesDocument6 pagesNippon Steels ShapesP.S.J.SarmaNo ratings yet

- Haupa: Standard ProgramDocument12 pagesHaupa: Standard ProgramAgustine SetiawanNo ratings yet

- Informations Techniques: Caractéristiques DimensionnellesDocument8 pagesInformations Techniques: Caractéristiques Dimensionnellesanto90kNo ratings yet

- 013 Seamless Pipe SizesDocument1 page013 Seamless Pipe SizesRajshekar NagarajNo ratings yet

- Steel and Stainless Steel: Thrust WashersDocument2 pagesSteel and Stainless Steel: Thrust WashersashkansoheylNo ratings yet

- Catalog For Bare Conductor PDFDocument35 pagesCatalog For Bare Conductor PDFSatay Chilly0% (1)

- Specification For Standard Sizes From Astm A53 GR B Schedule 80Document5 pagesSpecification For Standard Sizes From Astm A53 GR B Schedule 80JIMMY YOVANNY CASTRO ORTIZNo ratings yet

- Amal Cast Arrester CatalogueDocument8 pagesAmal Cast Arrester CatalogueTifano KhristiyantoNo ratings yet

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Atusa Ds Cf-fc01-Pn6-10 en EsDocument2 pagesAtusa Ds Cf-fc01-Pn6-10 en EsmadalenaNo ratings yet

- Mechanical PropertiesDocument4 pagesMechanical PropertiesSh KittanehNo ratings yet

- Rohm - Spindles and ChucksDocument12 pagesRohm - Spindles and ChucksGatyo GatevNo ratings yet

- 45 TubosgeralDocument1 page45 TubosgeralDavidson Soares da CostaNo ratings yet

- Cjenik Borera KAILDocument15 pagesCjenik Borera KAILamojodiNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Sail Catalogue 2010Document64 pagesSail Catalogue 2010chandan139No ratings yet

- Atlas Steels Product Manual Section 6Document10 pagesAtlas Steels Product Manual Section 6KaterynaNo ratings yet

- Smooth Flow: Tubing & Fittings SpecificationsDocument28 pagesSmooth Flow: Tubing & Fittings SpecificationsedgardomichligNo ratings yet

- Socitec Wirerope Iso Load Deflection PDFDocument0 pagesSocitec Wirerope Iso Load Deflection PDFraju3685No ratings yet

- Sight Glass - Sight Flow Indicator and Sight Windows Global IndustriesDocument5 pagesSight Glass - Sight Flow Indicator and Sight Windows Global IndustriesBhavin PatelNo ratings yet

- Beam Dimensions HEADocument2 pagesBeam Dimensions HEAAtif AslamNo ratings yet

- Fitting Acero Carbono A SoldarDocument21 pagesFitting Acero Carbono A Soldarcaod1712No ratings yet

- ANSI Fittings WeightsDocument42 pagesANSI Fittings Weightsmatthewwalls4386No ratings yet

- E Catalogue of KCM Special Steel Co.,ltdDocument9 pagesE Catalogue of KCM Special Steel Co.,ltdKCM Special SteelNo ratings yet

- NSF61Document12 pagesNSF61Congson Jeff100% (1)

- SA RawlboltDocument2 pagesSA Rawlboltpower_generator133850% (2)

- ASTM A108 TolerancesDocument9 pagesASTM A108 TolerancesJosh ByronNo ratings yet

- Rawlbolt: Shield Anchor Loose BoltDocument2 pagesRawlbolt: Shield Anchor Loose BoltBappy IslamNo ratings yet

- Style 77 Standard Flexible Coupling: Product DescriptionDocument0 pagesStyle 77 Standard Flexible Coupling: Product DescriptionAnibal MoralesNo ratings yet

- Din 2986Document8 pagesDin 2986Ilka RaffaelliNo ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- Quote-2020-064-NNB - AEAL PDFDocument10 pagesQuote-2020-064-NNB - AEAL PDFAdnan AdamNo ratings yet

- Catalog LDT GeneralDocument60 pagesCatalog LDT GeneralLaurentiu DumitruNo ratings yet

- Anchors 1Document46 pagesAnchors 1John EvansNo ratings yet

- Pipe Schedule and Thickness RevisedDocument4 pagesPipe Schedule and Thickness Revisedrajaram100% (1)

- Torches NM Series Combination Torch: Part Number....... 0700017241Document1 pageTorches NM Series Combination Torch: Part Number....... 0700017241Dries VandezandeNo ratings yet

- Dowel PinsDocument12 pagesDowel PinssugirinNo ratings yet

- Buffer TanksDocument3 pagesBuffer TanksManagerMechanical SSTNo ratings yet

- Machine Screw ThreadsDocument2 pagesMachine Screw ThreadsMoaed KanbarNo ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Process Vessels and Storage Vessels: Drawing N°Document7 pagesProcess Vessels and Storage Vessels: Drawing N°Rodrigo BeldaNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Stainless Steel BarDocument11 pagesStainless Steel BardhaktodesatyajitNo ratings yet

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosNo ratings yet

- OkretaljkeDocument6 pagesOkretaljkefiftyone01No ratings yet

- 1.3343 HS6-5-2CDocument3 pages1.3343 HS6-5-2CmustafabodurNo ratings yet

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderFrom EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Dr. Turer Ce5802-2018Document13 pagesDr. Turer Ce5802-2018Anonymous ep7LE5ZdP5No ratings yet

- Burj Khalifa ImportantDocument42 pagesBurj Khalifa ImportantAnonymous ep7LE5ZdP5No ratings yet

- Technical Specification: IEC/TS 60815-1Document7 pagesTechnical Specification: IEC/TS 60815-1Anonymous ep7LE5ZdP5No ratings yet

- Encryption Source CodeDocument5 pagesEncryption Source CodeAnonymous ep7LE5ZdP5No ratings yet

- Metu Thesis TemplateDocument16 pagesMetu Thesis TemplateAnonymous ep7LE5ZdP5No ratings yet

- Sdcard 30c3 PubDocument61 pagesSdcard 30c3 PubAnonymous ep7LE5ZdP5No ratings yet

- CE 7014 Chap2 Part 2Document51 pagesCE 7014 Chap2 Part 2Anonymous ep7LE5ZdP5No ratings yet

- CE 7014 Chap2 Part 5Document23 pagesCE 7014 Chap2 Part 5Anonymous ep7LE5ZdP5100% (1)

- Deep Excavation A Practical ManualDocument457 pagesDeep Excavation A Practical ManualMarianPanait100% (1)

- CE 7014 Chap2 Part 2Document51 pagesCE 7014 Chap2 Part 2Anonymous ep7LE5ZdP5No ratings yet

- ML2 MohrCircleDocument5 pagesML2 MohrCircleAnonymous ep7LE5ZdP5No ratings yet

- Instrumentation-Keystone of Dam MonitoringDocument30 pagesInstrumentation-Keystone of Dam MonitoringAnonymous ep7LE5ZdP5No ratings yet

- Ce569 ch6 7 8Document57 pagesCe569 ch6 7 8Anonymous ep7LE5ZdP5No ratings yet

- Sampled Data To Post J. M. Cimbala 500 HZ Signal, F (T)Document12 pagesSampled Data To Post J. M. Cimbala 500 HZ Signal, F (T)Anonymous ep7LE5ZdP5No ratings yet

- Modernist Novel WoolfDocument14 pagesModernist Novel WoolfSopco Stefana Madalina100% (1)

- France - July 2015 UK VK Com EnglishmagazinesDocument108 pagesFrance - July 2015 UK VK Com EnglishmagazinesUroš KroflNo ratings yet

- Part 3Document25 pagesPart 3Hoang HungNo ratings yet

- Module in Survey of Philippine Literature in EnglishDocument115 pagesModule in Survey of Philippine Literature in EnglishMariter PidoNo ratings yet

- 1 4934105030039962181Document9 pages1 4934105030039962181Maria Yolid Echeverry Cardona100% (2)

- The Cursed Cavalcade BetaDocument12 pagesThe Cursed Cavalcade BetaAndrew AkinshinNo ratings yet

- The BBW and The Beast A Shifter - Sylvia FrostDocument86 pagesThe BBW and The Beast A Shifter - Sylvia FrostMatache Adeline ValentinaNo ratings yet

- Arts ReviewerDocument3 pagesArts ReviewerZENN MARIELLE TABAQUENo ratings yet

- H150 420Document2 pagesH150 420ariesaalailisuwarnoNo ratings yet

- Swiggy Order 39097893765Document2 pagesSwiggy Order 39097893765Chintu BhardwajNo ratings yet

- Quiz-Game Written in CDocument12 pagesQuiz-Game Written in CSatwik ShridharNo ratings yet

- Administer Network HardwareDocument62 pagesAdminister Network HardwareMintesnot AdeNo ratings yet

- World of Warcraft: Herbalist HandbookDocument22 pagesWorld of Warcraft: Herbalist Handbookusmcmcarthur0% (1)

- Conversation: My School DayDocument9 pagesConversation: My School DayrossinaNo ratings yet

- B1-1 (Nivel Cuatro)Document29 pagesB1-1 (Nivel Cuatro)Jorge A. BuitragoNo ratings yet

- Activity 5: Cardboard, White Chart Paper, Ruler, Coloured Pens, Adhesive, Pencil, Eraser, Cutter, Nails and Thin WiresDocument3 pagesActivity 5: Cardboard, White Chart Paper, Ruler, Coloured Pens, Adhesive, Pencil, Eraser, Cutter, Nails and Thin WiresSudhanshu singh XIl-ANo ratings yet

- Three WishesDocument3 pagesThree WishesDOMITILA L. MAPANo ratings yet

- Extra Vegetables DIRECTV Driver 5.0.0Document11 pagesExtra Vegetables DIRECTV Driver 5.0.0Mike Jed JarboeNo ratings yet

- GIMP Made Easy GuideDocument18 pagesGIMP Made Easy Guidewj0qic800No ratings yet

- Olympus Imt ManualDocument22 pagesOlympus Imt Manualanhntran4850No ratings yet

- ChikankariDocument3 pagesChikankariagga1111No ratings yet

- (Gui To Learn and Use Calculix) : Table 1 Main Calculix CGX CardsDocument3 pages(Gui To Learn and Use Calculix) : Table 1 Main Calculix CGX CardsXavier SandovalNo ratings yet

- 14 Aconquija: Agustin Barrios Mangore (1885-1944)Document4 pages14 Aconquija: Agustin Barrios Mangore (1885-1944)chenchenNo ratings yet

- 1.2.0 Harvest PDF ManualDocument32 pages1.2.0 Harvest PDF ManualSamuel SacherNo ratings yet

- Test 1 Listening: 1. Where Will David Put His Sister's Mobile Phone?Document5 pagesTest 1 Listening: 1. Where Will David Put His Sister's Mobile Phone?Dong Phan Thi AnhNo ratings yet