Professional Documents

Culture Documents

Tequila PDF

Tequila PDF

Uploaded by

Eduardo GrandeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tequila PDF

Tequila PDF

Uploaded by

Eduardo GrandeCopyright:

Available Formats

Production of tequila from agave 225

Chapter 15

Production of tequila from agave: historical influences

and contemporary processes

M. Cedeo Cruz and J. Alvarez-Jacobs

Tequila Herradura, S.A. de C.V. Ex-Hda San Jose del Refugio, Amatitn, Jalisco,

Mxico

Introduction: Agave beverage alcohol

products

Tequila is classically associated with Mexico,

particularly with Jalisco, a state located in the west

of the country. This beverage is obtained by

distillation of fermented juice from only the agave

plant (Agave tequilana Weber var. Azul ) if 100%

agave tequila is required. Fermentation is carried

out by inoculated strains of Saccharomyces

cerevisiae or in some cases by a spontaneous

process. Up to 49% (w/v) sugars may come

from a source other than agave, usually sugar

cane or corn syrup, if 100% agave tequila is not

required. This tequila could not be labeled as

100% agave tequila.

Different kinds of tequila are produced in 50

registered companies in Jalisco. The tequila

products made by these companies differ mainly

in proportions of agave used, production

processes, microorganisms used in the

fermentation, distillation equipment used and the

maturation and aging times. The product known

as silver or white tequila must be distilled to a

concentration not exceeding 55% alcohol in

volume (v/v) and not less than 38% (v/v) from a

fermented wort containing not less than 51%

sugars from the agave plant. Gold tequila is the

white product to which caramel color (generally)

has been added. Rested tequila (Reposado) and

aged tequila (Aejo) are white tequila matured

in wood containers, preferably oak casks, for at

least 2 and 12 months, respectively, according

to present regulations. In practice, the aging

period is normally longer and depends on the

characteristics each company wants to give to

the final product. The products known as 100%

agave, which are becoming more popular, could

be white, rested or aged and are distilled from

fermented wort with only agave as a source of

sugars. The labels of these products must indicate

that they were obtained using only agave and

under Mexican government supervision.

Tequila is differentiated from the beverage

known as mezcal by the type of agave used in

its elaboration. Mezcal is made from Agave

potatorum, which grows in the state of Oaxaca.

Most mezcal producers use a rudimentary

fermentation and distillation process (Snchez,

1991). There is no technical reason for, or any

improvement in the organoleptic characteristics

from, the worm inside the bottles of some mezcal

brands. The worm is primarily a commercial ploy.

Worms are grown in agave plants and introduced

manually in the bottling line.

226 M. Cedeo Cruz and J. Alvarez-Jacobs

Pulque is another beverage obtained by

fermentation of the juice obtained from several

species of agave, A. atrovirens and A. salmiana

among others, by a complex succession of yeast

and bacteria that produce ethanol, a diversity of

chemical compounds, and some polymers that

give a sticky consistency to the final product

(Rzedowski, 1978; Snchez Marroquin and

Hope, 1953). Pulque is sometimes mixed with

fruits or vegetables, but has poor stability as it is

neither distilled nor pasteurized.

Agave plants still serve as food in some states

of Mxico; and other fermented regional

beverages are produced (e.g., Sotol in the state

of Chihuahua and Bacanora in the state of

Sonora), but only tequila and more recently

mezcal have reached international recognition.

Another difference between tequila and mezcal

and all other regional drinks is that both are

subject to an official standard that for tequila is

NOM006-SCFI-1993 (Secofi, 1993), and

production is supervised by the Mexican

government.

Origin and history of tequila

The word tequila is believed to originate from

the tribe of ticuilas who long ago inhabited the

hillside of a volcano bearing the same name

located near the city of Tequila. Another possible

origin is the Nahuatl word tequitl, which means

work or employment, and the word tlan, which

means place. Therefore tequila would mean

place in which labor or work is done.

The most ancient information revealing the

existence of agave and its different uses is from

the era before the Spaniards in several codices

preserved to the present time (a codex, from

the Latin codex meaning board or writing tablet,

is a manuscript volume, especially of a classic

work or scripture). The most important is the

Tonalmatlnahuatl codex, which notes that certain

tribes had learned to cook agave plants and used

them as food and to compensate for the lack of

water in desert lands. Also, these tribes

discovered that cooked agave when soaked in

water would ferment, producing a very

appreciated beverage. In fact, this primitive and

rudimentary method was used for centuries to

produce beverages from agave, considered a

sacred plant possessing divine properties. In

other codices, such as Nutall, Laud, Borgia and

Florentine, there are many references to uses

of the agave plant for soap manufacture, a

source of fiber, footwear, medicine and sewing

needles as well as thread, paper and rope. In

fact, Indians could distinguish the different species

of agave by color, size, stem, leaf width and the

different uses given each plant (Muria, 1990).

The great religious importance of agave was

apparent in those codices, as only warriors and

priests used fermented drinks in ritual ceremonies.

In prehispanic Mxico the general name for

all species of agave (or mezcal as it is also known)

was Metl, which is a representation of the

goddess Mayahuel. The alcoholic drink produced

was called Iztac octli (white wine). The first

Spaniards to arrive in Mxico referred to the

plant as maguey, a name used for an identical

plant they had seen in the Caribbean Islands,

where they first encountered new world plants

and animal life (Bottorff, 1971). It was not until

arrival of the Spaniards, who brought knowledge

of distillation techniques, that tequila took its

present form (Goncalves, 1956).

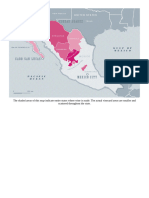

There are only two main regions for tequila

production in Mxico. The oldest, the TequilaAmatitn region that comprises the Amatitn

village, developed at the end of the seventeenth

century. The second region, the Jalisco Highlands, appeared in the last decade of the 19th

century (Luna, 1991). The first tequila production

process with a commercial purpose was

established in the city of Tequila around the end

of the 18th century. The main consumers were

in the mining zones located in the state of Jalisco.

The Spaniards tried to suppress consump-tion

of tequila in order to reduce competition for

brandy and other wines imported from Spain

with a decree signed by Carlos III forbidding its

sale and production under the pretext that its

consumption was the cause of several illnesses.

Production of tequila from agave 227

The results were negative. The governor of the

region later issued a decree imposing a tax on

tequila in order to enrich the royal coffers, thus

permitting its sale in all of New Spain. By the end

of the 19th century, expansion of the tequila

industry, helped by the railway, was evident.

However it was not until the first casks were

exported to the US that tequila was known

beyond Mxicos borders.

The Agave plant

According to Granados (1985), the genus Agave,

which means noble in Greek, was defined by

Linneaus in 1753 when he described the plant

A. americana as the first agave species known

to science. Agave plants, which are often

confused with cacti, belong to the family

Agavaceae and are succulent plants with spirallyarranged leaves forming a rosette. Some have

definite trunks, but more often they are nearly

stemless. The leaves are bluish green in color,

over 1 m long in mature plants, and end in a

sharpened brown thorn. As Backman (1944)

pointed out, the widespread distribution of some

300 species, combined with the fact that the

plants require approximately 8-12 years to mature

and hybridize very easily, make the taxonomic

and phylogenetic study of the genus Agave

extremely complicated and very difficult. The

family Agavaceae includes 20 genera and nearly

300 species. Of these, around 200 are found in

Mxico.

Several agave species are important from an

economic point of view. Fiber derived from A.

foucroydes, grown in the state of Yucatn, is

known worldwide for its use in producing ropes

and carpet. More recently, the pulp remaining

after removal of the fiber has found use in animal

feed. A. salmiana and A. atrovirens are valued

for pulque production and A. potatorum for

mezcal production. Finally, A. tequilana Weber

var. Azul, named around 1900 by the German

botanist Weber (Diguet, 1902), is used to

produce tequila.

Cultivation and harvest

The blue agave, as it is known, is the only species

out of hundreds of Agavaceae with the

appropriate characteristics for tequila production.

These include a high inulin concentration, low

fiber content and the chemical compounds

present in the plant that contribute to the final

taste and flavor of tequila to give the beverage

its particular character. Some have attempted to

produce tequila in other states with other agave

species, but without success. The blue agave is

cultivated in the state of Jalisco in the two regions

with the right climate and soil composition for

its growth, namely the Highlands and the TequilaAmatitn region. The temperature conditions for

good agave yields are a minimum of 30C, an

optimum of 260C and maximum of 47C. Soil

should be fertile but not very deep, 30 to 40 cm.

Good drainage is required to avoid effects of

flooding, which are very harmful for

development of the agave. The plants must be

planted at 800 to 1700 m above sea level where

the annual rainfall is about 800 to 900 mm. The

correct planting time is immediately before the

rainy season, from June to September, so that

the plants do not suffer from water stress during

the first year of growth.

Propagation is accomplished by the

vegetative route in agave. Sexual reproduction

via seeds is not usual. Asexual bulbils develop in

the inflorescence at the base of the flowers,

producing small plants that after some time

detach themselves from the floral peduncle and

fall to the soil where they root. Another mode

of asexual propagation is by suckers, which are

a characteristic type of lateral bud or branch

developing at the base of the main stem. Plants

developing near each mother plant are

separated at the age of 3-4 years. These baby

plants are called first-class seed because they

are better and healthier (Snchez, 1991). In

practice, people use the word seed to refer to

such young plants, but from a botanical point of

view these are rhizome shoots or suckers

(Valenzuela, 1992). Plant cell culture is used

228 M. Cedeo Cruz and J. Alvarez-Jacobs

experimentally by some agave producers, but is

not being used commercially due to unavailability

of trained technicians and laboratory facilities to

small agave producers. Some developments are

being carried out to improve agave plants, or to

obtain plants resistant to pests; and these new

plants will be ready in the next two years (CIATE,

1993).

Land for agave cultivation must be cleared

and deep-ploughed, sometimes twice. Agave is

planted approximately 2-4 m apart in straight lines

called ruts. Sowing is done by hand in holes 15

cm in depth. Plant density is around 2000-4000

plants per hectare, depending on the plantation

system used; and yields can be between 30,000

and 200,000 kg/ha, assuming that the weight of

a harvested plant varies from 15 to 50 kg. This

variation is caused by differences in soil

conditions, quality of plants sown, rainfall, pests

and fertilization. Sometimes agave is sown

intercalated with nitrogen-fixing crops such as

peanuts, beans, chickpeas or soybeans. After the

agave has been in the soil for a year, visual

inspection is carried out to replace sick or dead

plants with new ones. This operation is called reseeding. The percentage of dead plants depends

on soil and plant characteristics, but is generally

from 8 to 15% (Prez, 1990).

Agaves regularly host borer insects that live

in the stems, leaves and fruits during the larval

stage. These include butterflies of the family

Megathymidae and moths of the family Prodoxidae. Also, the fungi Diplodia theo-bromae and

Colletotrichum agavae may cause serious

damage to agave leaves (Halffter, 1975; Agricultural Research Service, 1972).

Ehrler (1967) discovered that unlike stomata

in most plants, agave stomata close during the

day and open by night. This prevents loss of

water through transpiration during hot daylight

hours, although it results in a hotter leaf surface

than most plants could tolerate. The thick cuticle

overlying the epidermis, which is quite evident

in tequila agave, apparently prevents damage to

the leaf from high temperature. This waxy cuticle

produces turbidity in tequila because it dissolves

in the distillation step and produces a haze in

the final product when it is diluted or cooled.

One way to avoid this is to treat tequila with

activated charcoal and to filter it through pure

cellulose filter pads. This, unfortunately, results

in the loss of some aromas.

Agave fertilization is based on soil

composition, plant age, and the type of chemical

compound used. The normal procedure is to use

urea as a nitrogen source in amounts of 30-70 g

per plant added directly into the soil. In some

areas, phosphorus and potassium fertilization is

also required. As some agave regions are also

involved in cattle, swine, and chicken breeding,

manure is sometimes employed for fertilization

(GEA, 1992).

The average maturity time for agave is 10

years. Every year following planting, fields are

cultivated to loosen the soil and weed and pest

control is carried out. Each plant matures

individually. Harvest begins at eight years. The

leaves are cut from the base and left in the field

to recycle nutrients. The harvested plants free

of leaves look like large pineapples and weigh

from 20 to 90 kg. They are transported to the

distillery. Only the better plants, meaning those

of good size and high inulin content (measured

as reducing sugars) are harvested; but on the

12th year, all plants remaining (the weakest

plants) are cut. These are called drag and are

generally discarded. Agave composition varies

seasonally, but an average would be (wet basis)

27% (w/w) reducing sugars, a juice content of

0.572 ml/g and a pH of 5.2.

Tequila production

Tequilas differ greatly depending on agave quality

and origin (Highlands or Tequila-Amatitn

regions). The production process also strongly

influences quality of the final product. Some

distilleries still employ rudimentary production

methods, just as they did several decades ago

(Pla and Tapia, 1990). Most companies, however,

employ technological advances that improve

process efficiency and consistency; and some

have implemented a ISO-9000 standard. What-

Production of tequila from agave 229

ever processes are used, tequila manufacture

comprises four main steps: cooking, milling,

fermentation and distillation.

Processing harvesting agave

Agave is transported from the fields to the

factories as soon as possible to avoid weight

losses, because today most distilleries pay by

weight and not by inulin content. The heads are

unloaded from the truck in the receiving area of

the factory and must be protected from the sun

and rain in order to avoid withering and fungal

growth. Although the agave has already been

inspected during growth and at harvest, it is

examined again to reject visually unacceptable

plants or those damaged by pests. At this point,

a representative sample of agave is taken for

laboratory analysis. Modified AOAC (1990)

procedures are used to determine reducing

sugar content (after acid hydrolysis of inulin)

along with pH, moisture, dry weight, juice and

ash content.

Agave heads usually weigh between 20 and

60 kg, although some can reach 100 kg. They

are cut to sizes that facilitate uniform cooking

and handling. Different agave cutting systems

exist, but the use of axes and a specialized tool

called coa are the most popular. The heads are

cut in halves or quarters, depending on the

weight, and the pieces are arranged manually in

an oven or autoclave. Band saws can also be

used to cut the agave heads. Band saws are faster

and less labor-intensive than the manual

procedure, but the belts break frequently because

of the resinous consistency of agave. Some

factories tear uncooked agave first with a knife

and place the resulting pieces mixed with water

into autoclaves to be cooked.

Other raw materials for tequila production

When producing 100% agave tequila, the only

source of carbohydrate is the inulin hydrolyzed

from agave in the cooking step. For other kinds

of tequila the law permits the use of other sugars

in amounts of up to 49% by weight in wort

formulation. There are no legal specifications

regarding the type of adjunct sugar sources to

be used in tequila manufacture; and theoretically

any kind of fermentable sugar can be used for

the formulation of wort. In practice and from an

economical point of view, only cane sugar,

Piloncillo, cane molasses and acid- or enzymehydrolyzed corn syrup are employed. Cane

sugar is received in 50 kg bags and stored in a

dry, cool place for subsequent utilization.

Piloncillo consists of brown cones of crystallized

complete cane juice, sometimes individually

wrapped in corn or cane leaves and packed in

sacks. Cane molasses is also used but it is difficult

to handle and there is risk of spoilage over a

long storage period. Acid- or enzymehydrolyzed corn syrup may be used to formulate

the wort. All sugars used in wort formulation are

routinely analyzed by measuring solids content

and reducing and fermentable sugar content.

The cooking step: hydrolysis of inulin

Cooking the agave serves three purposes. First,

the low pH (4.5) together with the high

temperature hydrolyze inulin and other components of the plant. The correct composition of

these compounds is still unknown. In addition,

cooked agave has a soft consistency that

facilitates the milling operation.

In the pre-Hispanic era, agave cooking was

carried out in holes filled with stones heated

using wood for fuel. The stones retained the heat

for the time needed to cook the agave.

Nowadays some distillers have replaced the

stuffed stone holes with brick ovens and heating

is conducted by steam injection after the cut,

raw agave has been introduced into the oven.

Oven cooking is slow, and steam injection lasts

around 36-48 hrs to obtain temperatures of 100

0

C. After that period, the steam is shut off and

the agave is left in the oven for a further two

days to complete the cooking process. During

this step, a sweet liquid called cooking honey

230 M. Cedeo Cruz and J. Alvarez-Jacobs

is collected and used later as a source of free

sugars, mainly fructose. Also during this step

some of the sugars are caramelized; and some

of the compounds that contribute significantly

to the aroma and flavor in wort formulation are

due to its high content of fermentable sugars

(>10% w/v). Finally, the oven door is opened to

allow the cooked agave to cool. The agave is

then ready for milling.

In most distilleries brick ovens have been

replaced by steel autoclaves. Autoclaves have

superior efficiency and allow good pressure and

temperature control, enabling a homogeneous

and economic cooking. In a typical autoclave

cooking operation, steam is injected for 1 hr so

that the condensed steam washes the agave. This

condensed liquid is called bitter honey and is

discarded because it contains waxes from the

agave cuticle and has a low sugar content (<1 %

w/w). Steam is injected for an additional 6 hrs to

obtain a pressure of 1.2 kg/cm2 and a temperature of 121 C. At the end of that time the

agave remains in the autoclave for another 6 hrs

without additional steam, cooking slowly in the

remaining heat. This step produces a syrup with

a high sugar concentration (>10% by weight)

that is later used to formulate the initial wort. To

calculate the yield and efficiency of this step, the

amount of cooking honey and its reducing sugar

content as well as the cooked agave are

measured.

The main difference between autoclaved and

oven-baked agave is that careful control of

cooking time, temperature and steam pressure

must be maintained in autoclaves to prevent

overcooking or burning the agave. Overcooking

gives a smoky taste to the tequila, increases the

concentration of furfural in the final product and

reduces ethanol yield due to the caramelization

of some of the fermentable agave sugars. This is

why some factories with both cooking systems

reserve the ovens for their better-quality

products. Although it is easier to obtain wellcooked agave in an oven than in an autoclave,

there is no difference in terms of flavor and

fermentability between agave cooked in

autoclaves or in ovens if both are correctly

controlled.

Extraction of agave juice: milling

Milling has gone through three historical stages.

In ancient days cooked agave was crushed with

wood or steel mallets to extract the juice. Later,

a rudimentary mill consisting of a large circular

stone 1.3 m in diameter and 50 cm thick was

used. Driven by animals, the stone turned in a

circular pit containing cooked agave and

extracted the juice. The resulting juice was

collected by hand in wood basins and carried to

fermentation tanks. By the 1950s modern

systems were implemented in which cooked

agave was passed through a cutter to be

shredded (except in factories that did this

operation before cooking); and with a combination of milling and water extraction, sugars

were extracted. The mills used for agave are

similar to those used in the sugarcane industry

but are smaller in size (normally 50 cm wide).

This system is still employed in most distilleries.

Juice obtained in milling is mixed with the

syrup obtained in the cooking step and with a

solution of sugars, normally from sugarcane (if

the tequila to be produced is not 100% agave),

and finally pumped into a fermenter. Although

the amount of sugar employed as an adjunct is

regulated by law and must be less than 49% by

weight at the beginning of the fermentation, each

factory has its own formulation.

The milling step generates a by-product called

bagasse, which represents about 40% of the total

weight of the milled agave on a wet weight basis.

Bagasse composition (dry weight basis) is 43%

cellulose, 19% hemicellulose, 15% lignin, 3%

total nitrogen, 1% pectin, 10% residual sugars

and 9% other compounds. The bagasse, mixed

with clay, is used to make bricks; but it is also the

subject of research to find alternative uses.

Examples are use of bagasse as an animal feed

or as a substrate on which to grow edible fungi.

Attempts are also underway to recover its

components (cellulose, hemicellulose and

pectin) using high-efficiency thermochemical

reactors (Alonso et al., 1993), to obtain furfurals,

make particle board, or enzymes (cellulase and

pectinase). Many of these projects are at the

Production of tequila from agave 231

laboratory stage, and there is not enough

information to evaluate feasibility.

In milling, as in all steps of the tequila process,

a sugar balance is computed to determine the

yield. If the yield decreases, the extraction

pressure in the mill and the water/agave ratio

are increased to improve efficiency.

Fermentation

Wort formulation

To produce 100% agave tequila, only agave may

be used and the initial sugar concentration ranges

from 4 to 10% w/v, depending on the amount

of water added in milling. When other sugars

are employed, they are previously dissolved and

mixed with agave juice to obtain an initial sugar

concentration of 8-16%, depending on sugar

tolerance of the yeast strain. Wort formulation

in most of the distilleries is based solely on

previous experience. A few distilleries base wort

formulation on composition of raw materials and

nutritional requirements for yeast growth and

fermentation. In these distilleries response

surface methodology is the preferred method

to optimize nutrient concentrations, using fermentation efficiencies and the taste of the resulting

tequila as responses (Montgomery, 1984). To

complement nutritional deficiencies of agave

juice and sugars employed in the growth and

fermentation steps, urea, ammonium sulfate,

ammonium phosphate or magnesium sulfate

could be added. Because the pH of the agave

juice is around 4.5, there is no need for

adjustment and the same wort composition is

used for both inoculum growth and fermentation.

Yeasts

Some companies do not inoculate a specific

strain of S. cerevisiae and instead allow natural

fermentation to proceed. Others inoculate the

wort with fresh packages of bakers yeast or a

commercial dried yeast to obtain initial

populations of 20-50 x 106 cells/ml. The dried

yeasts were originally prepared for wine, beer,

whisky or bread production; and sometimes the

quality of the tequila obtained using these yeasts

is not satisfactory, with large variations in flavor

and aroma. To achieve high yields and maintain

a constant quality in their tequila, some

companies have been using yeast strains isolated

from a natural fermentation of cooked agave

juice. Nutrients are added; along with special

conditions such as a high sugar concentration

or temperature. These isolated and selected

yeast strains have been deposited in national

microbial culture collections, the most important

being the Biotechnology and Bioengineering

Department Culture Collection of CINVESTAVIPN, located In Mxico City.

Inoculum growth

When an inoculum is used, it is grown in the

laboratory from a pure culture of a strain of S.

cerevisiae maintained on agar slants in lyophilized

form or frozen in liquid nitrogen. All laboratory

propagation is carried out under aseptic

conditions using a culture medium with the same

ingredients used in the normal process but

enriched to promote cellular growth. The

inoculum is scaled-up with continuous aeration

to produce enough volume to inoculate

fermentation tanks at 10% of the final volume.

Populations of 200-300 x 106 cells/ml are normally achieved. Strict cleanliness is maintained in

this step as bacterial contamination is highly

undesirable. When contamination is detected,

antibiotics or ammonium bifluoride are used as

antimicrobial agents. Once an inoculum is grown,

it is maintained by mixing 10% of the volume of

an active culture with fresh agave juice and

nutrients. Although inoculation with commercial

yeast greatly improves yield and turnover time,

some companies prefer a more complex (in

terms of the microbial diversity) fermentation.

While yields might be lower and turnover time

higher, the range of microorganism produces

more compounds contributing to a more

232 M. Cedeo Cruz and J. Alvarez-Jacobs

flavored tequila. It is also important to recognize

that a change in taste and flavor could negatively

affect the market for a particular brand of tequila.

Fermentation of agave wort

Once a wort is formulated with the required

nutrients and temperature is around 30 oC, it may

be inoculated with 5 to 10% (volume) of a

previously grown S. cerevisiae culture with a

population of 100-200 million cells/ml.

Otherwise, microorganisms present in the wort

carry out the fermentation. If an inoculum is not

added, the fermentation could last as long as

seven days. With an inoculum the fermentation

time ranges from 20 hrs in the faster process to

three days in the slower one.

Production of ethyl alcohol by yeast is

associated with formation of many fermentation

compounds that contribute to the final flavor of

the tequila. These are organoleptic compounds

or their precursors produced either in

subsequent maturation of the wort before it goes

to the distillation step, in the distillation process,

or in the barrels if tequila is aged. The factors

influencing formation of the organoleptic

compounds in alcoholic beverages have been

reviewed by many authors (Engan, 1981; Berry,

1984; McDonald et al., 1984; Ramsay and Berry,

1984; Geiger and Piendl, 1976). Experience in

the tequila industry is that the amount of

organoleptic compounds produced is lower in

fast fermentations than in slow fermentations. As

a consequence, the flavor and general quality of

tequila obtained from worts fermented slowly is

best. The rate of fermentation depends mainly

on the yeast strain used, medium composition

and operating conditions. The wort sugar content

decreases from an initial value of 4-11% to 0.4%

(w/v) reducing sugars if an efficient yeast strain

is employed. Otherwise, the residual sugar

content could be higher, increasing the production costs.

Fermentation vessels vary considerably in

volume, depending on the distillery. Their

capacity ranges from 12,000 liters for small tanks

to 150,000 liters for the largest ones; and they

are constructed of stainless steel in order to resist

the acidity of the wort. Ethanol production can

be detected almost from the onset; and a pH

drop from 4.5 to 3.9 is characteristic of the

fermentation. The alcohol content at the end of

fermentation lies between 4 and 9% v/v,

depending on the initial sugar concentration.

Alcohol losses may be significant because many

fermentation tanks are open, allowing

evaporation of alcohol with carbon dioxide.

Some of the largest distilleries have a cooling

system that keeps fermentation temperature

within a tolerable range for yeast, but small

producers do not have these systems. The

fermentation temperature can exceed 40 oC,

causing the fermentation to stop with an

accompanying loss of ethanol and flavors that

consequently decreases yields and affects the

quality of the tequila. Fermentations carried out

with pure agave juice tend to foam, sometimes

requiring the addition of silicones. In worts with

added sugars, foaming is usually not a problem.

Non-aseptic conditions are employed in

fermentation, and in consequence bacterial

activity may increase. The size of the bacterial

flora depends on a number of factors including

the extent to which bacteria grow during yeast

propagation (if used), the abundance of bacteria

on the raw materials and hygiene standards in

the distillery. There is no doubt that the activity

of these bacteria contributes to the organoleptic

characteristics of the final product. Occasionally,

the size of the bacterial population in fermenting

wort may become too large (>20 x 106 cells/

ml), in which case the bacteria use the sugars,

decreasing ethanol yields and sometimes

excreting undesirable compounds. The same

compounds used in the propagation step may

be used here to decrease common bacterial

contaminants found in tequila worts. Lactobacillus,

Streptococcus, Leuconostoc, and Pediococcus

are the most common contaminants, but Acetobacter may be found in fermented worts that are

left inactive for a long time prior to distillation.

In contrast to other distilled beverages, the

organoleptic characteristics of tequila come from

Production of tequila from agave 233

the raw material (cooked agave) as well as from

the fermentation process. In most of the

processes used in the tequila industry,

fermentation is spontaneous with the participation of microorganisms from the environment,

mostly yeasts and a few bacteria. This peculiarity

brings about a wide variety of compositions and

organoleptic properties. However, the special

characteristics of the wort make it a selective

medium for the growth of certain kind of yeasts

such as Saccharomyces and to a lesser extent,

acetic and lactic bacteria. In experiments isolating

microbial flora from musts of various origins,

different microorganisms were isolated. In most

cases, this difference in flora is responsible for

the wide variety of organoleptic characteristics

of tequila brands (Pinal, 1999). Where a single

purified strain is used, the final flavor and aroma

are more neutral since the bouquet created by

the contribution of several stains is richer than

that obtained from only one type of yeast.

Moreover, when yeast produced for bakery

applications is used, the final product is also more

neutral. It is also recognized that when non-100%

agave tequila is made, a poorer bouquet is

obtained because since a more defined medium

yields a more defined product.

Organoleptic compounds generated during

fermentation

Fusel oil

As in many other alcoholic fermentation processes, higher alcohols are the most abundant

compounds produced along with ethanol. We

have found (in decreasing order of abundance)

isoamyl alcohol, isobutanol, active isoamyl

alcohol and phenylethanol. It has been

established that production of isoamyl and

isobutyl alcohols begins after the sugar level is

lowered substantially and continues for several

hours after the alcoholic fermentation ends. In

contrast, ethanol production begins in the first

hours of the fermentation and ends with

logarithmic yeast growth (Pinal et al., 1997).

The most important factor influencing the

amount of isoamyl alcohol and isobutanol is the

yeast strain. It was found that a native strain

isolated from tequila must produces a higher

amount of such compounds when compared

with a strain usually employed in bakeries. These

results agree with those reported for Scotch

whisky (Ramsay and Berry, 1984) and beer

(Garca et al., 1994).

The carbon:nitrogen ratio also has a significant

influence on higher alcohol production. In

tequila musts, which contain mainly fructose

(.95%) as a carbon source and an inorganic

nitrogen source (ammonium sulfate), it was

found for both native and bakery yeast strains

that low carbon:nitrogen ratios result in low

amounts of isoamyl alcohol: 19 mg/L in bakery

strains and 30 mg/L for native strains vs 27 and

64 mg/L, respectively, for high carbon:nitrogen

ratios. A similar relationship exists for isobutyl

alcohol production (Figures 1 and 2).

Temperature is a third factor affecting isobutyl

and isoamyl alcohol production with higher

temperatures (e.g. 38 vs 32C) yielding higher

concentrations of those alcohols. On statistical

analysis it was found that in addition to the direct

effects of yeast strain, carbon:nitrogen ratio and

temperature, the interaction of these three

factors also had an impact on higher alcohol

concentration in tequila (Pinal et al., 1997). These

results are consistent with the fact that with high

carbon:nitrogen ratios there is a tendency to use

amino acids as a nitrogen source, which implies

the production of fusel oil as a by-product (by

the Erlich pathway). On the other hand, variables

such as the type of nitrogen source (urea or

ammonium sulfate) or the amount of inoculum

used for fermentation had little or no effect on

the production of higher alcohols. Pareto

diagrams involving all the variables tested are

depicted in Figures 3 and 4.

Methanol

Another characteristic compound present in

tequila is methanol. It is the general idea that

234 M. Cedeo Cruz and J. Alvarez-Jacobs

Figure 1. Higher alcohol production in tequila wort by a bakers yeast strain.

Figure 2. Higher alcohol production in tequila wort by a native yeast strain.

Production of tequila from agave 235

Figure 3. Pareto diagrams for isoamyl alcohol production in tequila.

Figure 4. Pareto diagrams for isobutyl alcohol production in tequila.

methanol is generated through hydrolysis of

methylated pectins present in the agave plant.

Nevertheless, it is also believed that some yeast

strains, natural or inoculated, have pectin methyl

esterases. Some authors describe various

amounts of methanol in musts with the same

composition but fermented with different strains

(Tllez, 1999).

Aldehydes

Along with the production of ethyl acetate, the

oxidation of ethanol also generates acetaldehyde, an intermediate in the production of

acetic acid. It is well known in commercial practice that an oxidation process instead of

fermentation begins after the sugar concen-

236 M. Cedeo Cruz and J. Alvarez-Jacobs

tration declines, thus provoking the increase in

the acetaldehyde level. However, there is no

formal report of such phenomena in tequila, as

it is described in beer (Hammond, 1991).

ethyl acetate, the presence of several other esters

has been described including ethyl and isoamyl

esters. Some of the most important esters found

in silver tequila are listed in Table 1.

Organic acids

Table 1. Most abundant esters found in silver

tequila.1

Small organic acids (up to six carbons) and larger

molecules (fatty acids) are produced during

fermentation. The smaller molecules can be

products of intermediate metabolism of the

normal microbial flora; and their production

depends on the presence of oxygen. The larger

fatty acids are synthesized for membrane

structures during cell growth and can also appear

at the end of the fermentation when lysis takes

place. The presence of octanoic and decanoic

acids in the final product has been described

particularly for tequila.

Ester

Esters

Distilling

Esters are very important compounds in their

particular contribution to flavor and aroma, since

they have the lowest organoleptic threshold

values (Ramsay and Berry, 1984). In particular,

ethyl acetate is the most abundant and important

compound of this family. Ethyl acetate has been

reported to be the second most abundant

compound in tequila after isoamyl alcohol. The

quantity of this compound present in the final

product can vary widely, since it is synthesized

from acetic acid (in form of acetyl-CoA) and

ethanol. Acetic acid can also be produced by

the oxidation of ethanol when the fermentation

has ceased and an oxidative process starts on

the surface of the fermentation tank by

Saccharomyces and many other yeasts such as

Brettanomyces. Therefore, long fermentation

periods (a current practice in the tequila industry)

yield high ethanol oxidation. In addition, in open

fermentation tanks with worts at low pH

containing alcohol, ethanol is also transformed

to acetic acid (itself a precursor of ethyl acetate)

by bacteria of the genera Acetobacter. Besides

Ethyl acetate

Ethyl decanoate

Ethyl lactate

Ethyl octanoate

Ethyl dodecanoate

Ethyl butanoate

Isoamyl acetate

Ethyl propanoate

Ethyl hexanoate

Ethyl hexadecanoate

%

17.77

2.78

2.74

1.92

0.95

0.63

0.58

0.57

0.48

0.48

Estarrn et al., 1999.

Distillation involves the separation and concentration of the alcohol from the fermented wort.

In addition to ethanol and other desirable

secondary products, wort contains solid agave

particles consisting mainly of cellulose and pectin,

and yeast cells in addition to proteins, mineral

salts and some organic acids. Although a great

number of types and degrees of distillation are

possible, the most common systems used in the

tequila industry are pot stills and rectification

columns. The pot still is considered the earliest

form of distilling equipment. It is of the simplest

design, consisting of a kettle to hold the

fermented wort, a steam coil, and a condenser

or a plate heat exchanger. Pot stills are often

made of copper, which fixes, according to

Thorne et al. (1971), malodorous volatile sulfur

compounds produced during fermentation.

Batch distillation using pot stills is carried out in

two steps. First the fermented wort is distilled to

increase the alcohol concentration to 20-30%

by volume, separating out the first fraction called

heads, and the last fraction, called tails.

Production of tequila from agave 237

Composition of these fractions varies depending

on many factors including the yeast strain

employed, wort nutrient composition,

fermentation time and distillation technique; but

in general, heads are rich in low boiling point

compounds such as acetaldehyde, ethyl acetate,

methanol, 1-propanol, 2-propanol, 1-butanol, and

2-methyl propanol, which give a very pleasant

flavor and taste to tequila. Heads are normally

mixed with the wort being distilled. The tails

contain high boiling point components such as

isoamyl alcohol, amyl alcohol, 2-furaldehyde,

acetic acid and ethylactate, giving a strong taste

and flavor to the tequila; and when the

concentration is above 0.5 mg/ml, the final

product becomes unpleasant. This fraction is not

used.

In the second step, the liquid obtained from

the first stage is re-distilled in a similar pot still in

order to obtain a final product that is 110 proof

if it is sold in bulk (reducing transport costs) or

80 proof if it is to be bottled. Some companies

obtain high proof tequila and dilute it with

demineralized water or water purified by reverse

osmosis.

In continuous distillation systems, the

fermented wort enters the feed plate of the

column and flows downward, crossing a series

of trays. Steam is injected from the bottom in a

coil and strips the wort of its volatile components.

Vapors condense higher in the column,

depending on component volatility, allowing

liquids to be drawn off or recycled at the various

plates as appropriate. Sometimes tequila

obtained in this way is mixed with tequila from

pot stills to balance the amount of organoleptic

compounds because in general, tequila obtained

through continuous columns has less aroma and

taste than tequila obtained from pot stills.

The presence of methanol in tequila is still a

subject of discussion because whether methanol

is produced only by a chemical reaction or in

combination with a microbial hydrolysis has not

been satisfactorily demonstrated. The chemical

reaction is demethylation of agave pectin by the

high pH during cooking and the first distillation

steps. The microbial reaction could be the

hydrolysis of agave pectin by the enzyme pectin

methyl esterase produced by some

microorganisms during the fermentation step, but

this has not yet been demonstrated. Preliminary

results favor the first theory, but some research

is still needed on this matter because it is

important to maintain the methanol concentration within the limits established by the official

standard, which is 300 mg methanol per 100 ml

of anhydrous ethyl alcohol.

Effluent disposal

The discharge from pot stills or distillation

columns is known as stillage, slops or vinasse;

and in a typical tequila distillery 7 to 10 liters of

effluent are produced per liter of tequila at 100

proof. Tequila stillage has a biological oxygen

demand (BOD) of 25 to 60 g/L. In addition to

the dissolved salts (mainly potassium, calcium,

and sulfate ions) and the low pH (<3.9) of the

stillage, there are significant disposal or treatment

problems. A general solution to the disposal

problem does not exist because every factory

has its own production process and is located

either in a city or near agave fields. As a result of

the difficulties of treating vinasses and due to their

high concentrations of dissolved matter, a host

of utilization schemes have been proposed.

Some of the methods indicated below are under

investigation and others are in use.

Recycling reduces the volume of waste to be

treated. Stillage can be recirculated, mixing 5 to

10% of the total volume of the waste obtained

with clean water to substitute for the dilution

water used to prepare the initial wort. This can

be carried out for a number of cycles, usually no

more than five, because the concentration of

dissolved salts increases and could affect the

fermentation process. Also, great care must be

taken with the final taste and flavor of the tequila

because some components present in stillage

could affect the organoleptic characteristics of

the final product. Currently, only one tequila

company uses this system.

Direct land application as irrigation water and

fertilizer in agave fields is under careful evaluation

238 M. Cedeo Cruz and J. Alvarez-Jacobs

to determine the optimum loading rates and the

effects on the agave over the long time it takes

to reach maturity. Evaporation or combustion of

stilllage could provide fertilizer or potash, but the

high cost of such a process is a serious limitation

(Sheenan and Greenfield, 1980). The production

of biomass and biochemicals including fodder

yeast is a possibility, but the remaining liquor still

has a high BOD (Quinn and Marchant, 1980).

Stillage may be used as a food supplement for

cattle, but it has an undesirable laxative effect on

animals. Biological, aerobic, or anaerobic

treatment offers a real means of disposal, but

the cost is likely to be as high as the fermentation

costs themselves (Speece, 1983; Maiorella,

1983). Ultimately, tequila vinasses should be

viewed as a raw material rather than a waste,

and a strategy should be devised that maximizes

economic and social benefits and reduces

recovery costs.

providing color and the particular taste. Reactions

among certain tequila compounds yield new

components; and oxidation reactions change

some of the original components in tequila and

those extracted from the wood. As a result of all

of these changes, the concentration of acids,

esters and aldehydes is increased, while the

concentration of fusel oils decreases as tequila

reposes in barrels.

After aging and dilution with demineralized

water (if necessary) the color of the tequila may

be adjusted to the desired value by the addition

of caramel. Alternatively, some companies

blend different batches of tequila to obtain a

standardized final product.

Government inspectors supervise the entire

aging process. Prior to bottling, tequila is filtered

through cellulose filter pads or polypropylene

cartridges. Sometimes afterwards a pretreatment

with charcoal is used to eliminate turbidity.

Maturation

Future developments

Distillation is the final stage of tequila production

if silver or white tequila is the desired product.

For rested or aged tequila, maturation is carried

out in 200 liter white oak casks or in larger wood

tanks. The time legally required is two months

for rested tequila and 12 months for aged tequila.

Tequila is generally matured for longer periods,

depending on the characteristics each company

desires for its particular brand.

As tequila ages in barrels, it is subject to

changes that will determine its final quality.

Thickness and quality of the stave, depth of the

char, temperature and humidity in the barrelling

area, entry proof (40-110 proof), length of

storage and number of cycles for the barrel (in

Mxico barrels may be re-used several times) all

affect the final taste and aroma of the tequila.

Fusel oil content decreases during maturation

owing to the adsorbant nature of the char,

smoothing the final product. Complex wood

constituents are extracted by the tequila,

Research and future developments in the

production of tequila and agave cultivation can

take many directions, but the implementation of

any change must allow quality of the final product

to be maintained and provide substantial

improvement in the process. There are several

key areas where important developments could

take place. Development of new varieties of

agave endowed with resistance to pests or

extremely dry environments, higher inulin

content, low wax content in the leaf cuticle and

superior growth rates would be of benefit.

Mechanization would improve aspects of

cultivation and harvest of agave. In addtition,

optimization of the cooking and fermentation

steps would improve yields and reduce the

amount of waste, while yeast strain selection

could improve ability to ferment musts with high

concentrations of sugars. Finally, low cost

alternatives for waste (bagasse and stillage)

treatment are needed.

Production of tequila from agave 239

Summary

Tequila is a beverage obtained from the

distillation of fermented juice from the agave

plant (Agave tequilana. Weber var. Azul). The

use of agave to produce drinks in Mxico dates

from long ago when certain tribes used it for

religious ceremonies. It was not until the arrival

of the Spaniards, who brought distillation

technique knowledge, that tequila acquired its

present form. The agave plant, which is generally

confused with cacti, is propagated through

traditional methods or by means of plant cell

culture. It is grown for 8 to 10 years before it

can be harvested and sent to the distillery.

The tequila production process comprises

four stages. In the first step, agave is cooked to

hydrolyze the polymers present in the plant,

mainly inulin, into fermentable sugars. In some

factories this step is accomplished using stone

ovens and in others it is carried out in autoclaves.

The second stage is sugar extraction from

cooked agave through milling; and the agave

juice obtained through this step can be mixed

with sugars from other sources, normally sugar

cane, if 100% agave tequila is not desired. The

third and most important stage is fermentation

in which sugars are transformed into ethanol and

other compounds such as esters and organic

acids. These, along with other substances derived

from the cooked agave, give the characteristic

flavor and taste to tequila. It is of great importance

to have a good yeast strain and nutritionally

balanced wort for tequila production, as losses

could be as high as 35% of the total production

if inefficient yeast is used or nutrients do not

appear in the right proportions. In the last stage,

fermented wort is distilled, normally using pot

stills or in some cases rectification columns, to

obtain the final product. At the end of the

distillation process white tequila is obtained.

Maturation in white oak barrels is required for

rested or aged tequila. The minimum maturation

times are 2 and 12 months, respectively, for

rested and aged tequila as required by

government regulations. At every step of the

production process, most companies employ

several quality control analyses in order to

ensure the quality of the product and the

efficiency of the process. Some major producers

of tequila are certified through an ISO-9000

standard. Tequila production is governed by the

official norm NOM-006-SCFI-1993, which must

be followed by all tequila producers to guarantee

a good quality final product.

Acknowledgement

The authors would like to express their gratitude

to Tequila Herradura, S.A. de C.V., for its support

in writing this chapter.

References

Agricultural Research Service. 1972. The Agave

family in Sonora. Agriculture Handbook

No.399, US Department of Agriculture, p.

195.

Alonso, G.S., L. Rigal and A. Gaset. 1993.

Valoracin qumica de bagazo de agave de

la industria tequilera. Rev. Soc. Quim. Mex.

3(6):19.

AOAC 1990. Distilled liquors. Official Methods

of Analysis of the Association of Official

Analytical Chemists (H. Kenneth, ed) Association of Official Analytical Chemists, Arlington, Virginia, p. 690.

Backman, G.E. 1944. A karyosystematic study of

the genus Agave. Am. J. Bot. 35:283.

Berry, D.R. 1984. Physiology and microbiology

of the malt whisky fermentation. In: Progress

in Industrial Microbiology. (M.E. Bushell, ed.)

Elsevier, Amsterdam, p. 189.

Bottorff de B., V. 1971. A guide to tequila, mezcal

and pulque. Minutae Mexicana, Mexico, D.F.

CIATE, 1993. Informe de actividades al consejo,

Agosto, Guadalajara, Jal, Mxico.

Diguet. L. 1902. Estudio sobre el maguey de tequila. Generalidades e historia. El Prog. Mex.

9:424.

Ehrler, W.H. 1967. Agave plant, efficient water

user. USDA Agr. Res. 16(4):11.

240 M. Cedeo Cruz and J. Alvarez-Jacobs

Engan, S. 1981. Beer composition: volatile substances. In: Brewing Sciences, Vol. 2 (J.R.A.

Pollock, ed.) Academic Press, London, p. 98.

Estarrn, M., T. Martn del Campo and R. Coso.

1999. Identificacin de los componentes

voltiles que caracterizan la huella

cromatogrfica distintiva de tequilas. Technical Report for Tequila Herradura S.A.

Garca, A.I., L.A. Garca and M. Daz. 1994. Fusel

alcohol production in beer fermentation processes. Process Biochem. 29:303-309.

GEA. 1992. La fertilizacin, La Jima. Boletin

Informativo, Gerencia de extensin agrcola.

Tequila Sauza, 7(50).

Geiger, E. and A. Piendl. 1976. Technological

factors in the formation of acetaldehyde

during fermentation, MBAA Tech. Q. 13:51.

Goncalves de L. O. 1956. El Maguey y el Pulque,

Fondo dc Cultura Econmica, Mxico.

Grandos, S.D. 1985. Etnobotanica de los agaves

dc las zonas ridas y semiridas. In: Biologa

y Aprovechamiento Integral del Henequn

y Otros Agaves, CICY, A.C., Mxico, p. 127.

Halffter, G. 1975. Plagas que afectan a las distintas

especies de agave cultivado en Mxico.

Secretara de Agricultura y Ganadera,

Mxico, D.F.

Hammond, J.R.M. 1981. Brewers Yeast. In: The

Yeasts, Vol. 5. Yeast Technology (A.H. Rose

and J.S. Harrison, eds.) 2nd. ed. Academic

Press, Redding, U.K.

Luna, Z.R. 1991. La historia del tequila, de sus

regiones y de sus hombres. Consejo Nacional para la Cultura y las Artes, Mxico, D.F.

MacDonald, J., P.T,V. Reeve, J.D. Ruddlesden and

F.H. White. 1984. Current approaches to

brewery fermentations. In: Progress in Industrial Microbiology. Vol. 19, Modern Applications of Traditional Biotechnologies, (M.E.

Bushell, ed.) Elsevier, Amsterdam.

Maiorella. B.L., H.W. Blanch and C.R. Wilke.

1983. Distillery effluent treatment and byproduct recovery. Proc. Biochem. 8(4):5.

Martinez, M. 1979. Catalogo de nombres vulgares y cientficos de plantas Mexicanas.

Fondo de Cultura Econmica. Mxico. p.

543.

Montgomery, D.C. 1984. Design and Analysis

of Experiments, 2nd Ed., John Wiley & Sons,

New York. p. 445.

Muria, J.M. 1990. El tequila. Boceto histrico de

una industria. Cuad. Difus. Cient. 18:13.

Prez, L. 1990. Estudio sobre el maguey llamado

Mezcal en el estado de Jalisco. Programa

de Estudios Jalisciences, Instituto del Tequila,

A.C., Mxico.

Pinal, Z.L.M. 1999. Tesis de Maestra en Procesos

Biotecnolgicos.

Universidad

de

Guadalajara, Guadalajara, Mxico.

Pinal, L., M. Cedeo, H. Gutirrez and J. AlvarezJacobs. 1997. Fermentation parameters influencing higher alcohol production in the

tequila Process. Biotechnol. Lett. 19(1):4547.

Pla, R. and J. Tapia. 1990. El agave azul, de las

mieles al tequila. In: Centro de Estudios

Mexicanos y Centroamericanos, Instituto

Francs de America Latina y el Institut

Francais dc Recherche Scientifique pour le

developement en Cooperation, Mxico, p.

61.

Quinn, J.P. and R. Marchant. 1980. The treatment

of malt whisky distillery waste using the fungus Geotrichum candidum. Water Res.

14:545.

Ramsay, C.M. and D.R. Berry. 1984. The effect

of temperature and pH on the formation of

higher alcohols, fatty acids and esters in malt

whisky fermentation. Food Microbiol. 1:117.

Ramsay, C.M. and D.R. Berry. 1984. Physiological control of higher alcohol formation in

Scotch whisky fermentation. In: Current

Developments in Yeast Research (G.G.

Stewart and I. Russell, eds) Pergamon Press,

London, Canada.

Rzedowski, J. 1978. Vegetacin de Mxico, Ed.

Limusa. Mxico.

Snchez, A.F. 1991. Comparacin de

metodologas de micropropagacin de

Agave tequilana Weber. Tesis de Ing.

Agrnomo, Facultad de Agronoma,

Universidad de Guadalajara, Guadalajara,

Mxico.

Snchez-Marroqun, A. and P.H. Hope. 1953.

Fermentation and chemical composition

Production of tequila from agave 241

studies of some species. Agric. Food Chem.

246:1.

Secofi, Norma Oficial Mexicana. 1993.

NOM006-SCFI-1993, Bebidas alcohlicas,

Tequila. Especificaciones, Diario oficial del

13 de Octubre, p. 48.

Sheenan, G.J. and P.F. Greenfield. 1980. Utilization, treatment and disposal of distillery

wastewater. Water Res. 14:257.

Speece, R.E. 1983. Anaerobic biotechnology for

industrial wastewater treatment. Environ. Sci.

Technol. 17(9):416A.

Tllez, P. 1999. Tesis de Maestra en Procesos

Biotecnolgicos.

Universidad

de

Guadalajara, Guadalajara, Mxico.

Thorne, R.S.W., E. Helm and K. Svendsen. 1971.

Control of sulfur impurities in beer aroma, J.

Inst. Brew. 77(2):148.

Valenzuela, Z.A. 1992. Floracin y madurez del

agave, La Jima. Boletin Informativo, Gerencia

de extensin agrcola. Tequila Sauza 5:33.

242 M. Cedeo Cruz and J. Alvarez-Jacobs

You might also like

- The Culture History of Mexican VanillaDocument18 pagesThe Culture History of Mexican VanillaElisa RNo ratings yet

- MDVR-Ceiba Video Management Software User ManualDocument27 pagesMDVR-Ceiba Video Management Software User ManualTTB Vision0% (1)

- Cocaine Training Rev 3Document0 pagesCocaine Training Rev 3Mark ReinhardtNo ratings yet

- "Mental Fitness For Traders" by Norman HalletDocument35 pages"Mental Fitness For Traders" by Norman Halletapi-26247058100% (2)

- Cacao Specialty Crop PDFDocument23 pagesCacao Specialty Crop PDFariyadi100% (1)

- Tequila - The Spirit of MexicoDocument47 pagesTequila - The Spirit of MexicoSabuj JanaNo ratings yet

- Christmas Words and Traditions British English TeacherDocument7 pagesChristmas Words and Traditions British English TeacherJulieNo ratings yet

- Del Maguey - Brand PresentationDocument18 pagesDel Maguey - Brand PresentationJorge Luis VargasNo ratings yet

- Some Medicinal Plants of JharkhandDocument2 pagesSome Medicinal Plants of Jharkhandniharikas1987No ratings yet

- Cocoa Bean (Also Cacao BeanDocument9 pagesCocoa Bean (Also Cacao BeanVillaci5No ratings yet

- Post Harvest Compendium - VanillaDocument51 pagesPost Harvest Compendium - VanillaKapithas KNo ratings yet

- History of ChocolateDocument8 pagesHistory of ChocolateAndrei ŞteopanNo ratings yet

- Module 3 Reflective Essay GuidanceDocument10 pagesModule 3 Reflective Essay GuidanceKainatNo ratings yet

- Grape Vines - With Chapters on Pot Culture, Propagation and VarietiesFrom EverandGrape Vines - With Chapters on Pot Culture, Propagation and VarietiesNo ratings yet

- Tequila ProjectDocument82 pagesTequila ProjectDeepak JettaNo ratings yet

- Collecting and Exhibiting Tree LeavesDocument4 pagesCollecting and Exhibiting Tree LeavesChuck AchbergerNo ratings yet

- Agave Mezcal Pulque: Master Mezcalier Yesenia PimentelDocument7 pagesAgave Mezcal Pulque: Master Mezcalier Yesenia PimentelYesenia PimentelNo ratings yet

- The Cocoanut With reference to its products and cultivation in the PhilippinesFrom EverandThe Cocoanut With reference to its products and cultivation in the PhilippinesNo ratings yet

- Action Plan - SDRRM SY 2019-2020Document5 pagesAction Plan - SDRRM SY 2019-2020Gem Rafer100% (1)

- Tequila and Mezcal CopenhagenDocument52 pagesTequila and Mezcal Copenhagenelayne9324No ratings yet

- Teaching Argument WritingDocument8 pagesTeaching Argument WritingAmanda Garcia0% (1)

- Tequila and Other Agave Spirits From West-Central Mexico: Current Germplasm Diversity, Conservation and OriginDocument15 pagesTequila and Other Agave Spirits From West-Central Mexico: Current Germplasm Diversity, Conservation and OriginWDIV NewsOpsNo ratings yet

- The History of TequilaDocument6 pagesThe History of TequilaAmanda RossNo ratings yet

- Tequilas: Charm Analysis of Blanco, Reposado, and Anejo TequilasDocument11 pagesTequilas: Charm Analysis of Blanco, Reposado, and Anejo TequilasMaribel Romero PontifesNo ratings yet

- The Physics Behind The Fizz in Champagne and Sparkling WinesDocument88 pagesThe Physics Behind The Fizz in Champagne and Sparkling WinesCromironNo ratings yet

- MezcalDocument11 pagesMezcalSoporte Web SucasaNo ratings yet

- Tequila Made Me Do It: 60 Tantalizing Tequila and Mezcal CocktailsFrom EverandTequila Made Me Do It: 60 Tantalizing Tequila and Mezcal CocktailsNo ratings yet

- MezcalDocument4 pagesMezcalandrija rokiNo ratings yet

- Cocoaroma Ponto ComDocument8 pagesCocoaroma Ponto ComValéria BritoNo ratings yet

- How Is Tequila MadeDocument4 pagesHow Is Tequila MadeI Made PuputNo ratings yet

- The Essential Tequila & Mezcal Companion: How to Select, Collect & Savor Agave SpiritsFrom EverandThe Essential Tequila & Mezcal Companion: How to Select, Collect & Savor Agave SpiritsNo ratings yet

- PICADocument16 pagesPICAKrasnici AlijaNo ratings yet

- Blue Agave: How Tequila Is MadeDocument1 pageBlue Agave: How Tequila Is Madesachin ranaNo ratings yet

- GomezArriola The Agave Landscape and The Ancient Tequila Industrial InstallationsDocument8 pagesGomezArriola The Agave Landscape and The Ancient Tequila Industrial InstallationsUnited States National Committee of the International Council on Monuments and SitesNo ratings yet

- An Unusual Spice From Oaxaca The Flowers of Quararibea FunebrisDocument35 pagesAn Unusual Spice From Oaxaca The Flowers of Quararibea FunebrisChuck AchbergerNo ratings yet

- Your Guide To Mezcal-And Why Agave Type Matters +Document13 pagesYour Guide To Mezcal-And Why Agave Type Matters +SimonNo ratings yet

- The Culture History of Mex Henry BrumanDocument18 pagesThe Culture History of Mex Henry Brumanmaxws3000No ratings yet

- Organizational Chart of BeveragesDocument16 pagesOrganizational Chart of BeveragesIpyang De SilvaNo ratings yet

- MexicoDocument5 pagesMexicoBTNo ratings yet

- Stanford Avalon Community Garden: Agave Jalisco Mexico Tequila Distilled BeverageDocument2 pagesStanford Avalon Community Garden: Agave Jalisco Mexico Tequila Distilled BeverageShehryar KhanNo ratings yet

- Mezcal Menu EnglishDocument38 pagesMezcal Menu EnglishRaul SazNo ratings yet

- Presentation IshDocument7 pagesPresentation IshAnkush RaiNo ratings yet

- Cacao Review: Maldonado Ortega Ruth 3/D O.G.SDocument1 pageCacao Review: Maldonado Ortega Ruth 3/D O.G.SYaritza PilayNo ratings yet

- 9 Tequila1Document9 pages9 Tequila1Ketan ChandeNo ratings yet

- Tequila ProductionDocument2 pagesTequila ProductionEduardo Puga JimenezNo ratings yet

- International Cocktails: (Different Types of Tequila)Document6 pagesInternational Cocktails: (Different Types of Tequila)edcel boberNo ratings yet

- Industria Del Bacanora y Su Proceso de Elaboraci N Bacanora Industry and Its Process of Production PDFDocument12 pagesIndustria Del Bacanora y Su Proceso de Elaboraci N Bacanora Industry and Its Process of Production PDFIzMxel HaaRpp MoNroyNo ratings yet

- Cocoa (Theobroma Cacao L.) : Theobroma Cacao Also Cacao Tree and Cocoa Tree, Is A Small (4-8 M or 15-26 FT Tall) EvergreenDocument12 pagesCocoa (Theobroma Cacao L.) : Theobroma Cacao Also Cacao Tree and Cocoa Tree, Is A Small (4-8 M or 15-26 FT Tall) EvergreenApam BenjaminNo ratings yet

- Lecture 8 (Tequila)Document36 pagesLecture 8 (Tequila)MikeyNo ratings yet

- Jsfa.10586 para DiscutirDocument10 pagesJsfa.10586 para DiscutirMonica RiveraNo ratings yet

- Avocado Cosmetology RecipesDocument8 pagesAvocado Cosmetology RecipesMike ChemistNo ratings yet

- TequilaDocument16 pagesTequilaTokir AnwarNo ratings yet

- Chocolate Consumption and Cuisine: From Chaco To New MexicoDocument8 pagesChocolate Consumption and Cuisine: From Chaco To New Mexicosantafesteve100% (1)

- The CacaoDocument5 pagesThe CacaoSri AnggreniNo ratings yet

- Basic Mock TestDocument5 pagesBasic Mock TestSaviour MaterialNo ratings yet

- A Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical AspectsDocument18 pagesA Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical AspectsGustavo PachecoNo ratings yet

- 46.chincona Cultivation in CeylonDocument11 pages46.chincona Cultivation in CeylonchathuraNo ratings yet

- The Avocado: Excerpted (Pages 9-78) FromDocument47 pagesThe Avocado: Excerpted (Pages 9-78) FromFadhlinalias NoorNo ratings yet

- Ielts ReadingDocument12 pagesIelts ReadingScarletRoseNo ratings yet

- Etnobotany Field Trip To ChocolaDocument17 pagesEtnobotany Field Trip To ChocolaAlberto CelarieNo ratings yet

- For All Bad Mezcal, For All Good Too. in This Earthly World, Mezcal Gold Is Liquid Gold.Document6 pagesFor All Bad Mezcal, For All Good Too. in This Earthly World, Mezcal Gold Is Liquid Gold.reyna ocampoNo ratings yet

- History of Chocolate PDFDocument6 pagesHistory of Chocolate PDFIbrahim KhleifatNo ratings yet

- Beverage TechnologyDocument16 pagesBeverage TechnologyJayanthi BaskaranNo ratings yet

- Davao CacaoDocument12 pagesDavao CacaoEli Leopoldo GenestonNo ratings yet

- Zizumbo Et - Al. 2009 - Distillation in Western Mesoamerica Before European ContactDocument15 pagesZizumbo Et - Al. 2009 - Distillation in Western Mesoamerica Before European ContactHéctor Cardona MachadoNo ratings yet

- Ecuador Land of Chocolate 2019 PDFDocument19 pagesEcuador Land of Chocolate 2019 PDFFanny CondoNo ratings yet

- PapOxy 2Document396 pagesPapOxy 2PrabhasvaraNo ratings yet

- UMC100 Modbus InterfaceDocument37 pagesUMC100 Modbus InterfaceRatheesh KumarNo ratings yet

- Battery Pack Report: General InfoDocument2 pagesBattery Pack Report: General InfoAlexandr KorolchukNo ratings yet

- Planning of High Tibial Osteotomy: Rizki Rahmadian, AMT Lubis, C SinghDocument1 pagePlanning of High Tibial Osteotomy: Rizki Rahmadian, AMT Lubis, C SinghArun VNo ratings yet

- References: b3083 Introduction To MicrofinanceDocument33 pagesReferences: b3083 Introduction To MicrofinanceNitzia VazquezNo ratings yet

- Atm Network IcqDocument9 pagesAtm Network IcqPranay KoolNo ratings yet

- Viktorijanska Književnost - SkriptaDocument53 pagesViktorijanska Književnost - SkriptagigaweaponNo ratings yet

- 4as Detailed Lesson Plan in TLE 6-1Document6 pages4as Detailed Lesson Plan in TLE 6-1Asmara EbrahimNo ratings yet

- Consonant SoundsDocument20 pagesConsonant SoundsRoselyn Lictawa Dela CruzNo ratings yet

- WHO 2018 Health at A Glance Mortality Asia Pac Region OctoberDocument3 pagesWHO 2018 Health at A Glance Mortality Asia Pac Region Octoberbiko97jcjNo ratings yet

- Peptic Ulcer in Children 1995Document11 pagesPeptic Ulcer in Children 1995kadekapiklestariNo ratings yet

- Kristian Jarosz Candidate QuestionnaireDocument2 pagesKristian Jarosz Candidate QuestionnaireThe News-HeraldNo ratings yet

- Speak Now 1 Present Continuous Grammar PresentationDocument16 pagesSpeak Now 1 Present Continuous Grammar PresentationSheena SuicoNo ratings yet

- PDFDocument595 pagesPDFKharisma PratamaNo ratings yet

- Demonstration Lesson Plan Englsh 8Document4 pagesDemonstration Lesson Plan Englsh 8Sofia BernaldezNo ratings yet

- Tips On How To Write A Better Narrative EssayDocument6 pagesTips On How To Write A Better Narrative EssayAjlia AzamNo ratings yet

- Y%S, XLD M Dka %SL Iudcjd Ckrcfha .Eiü M %H: The Gazette of The Democratic Socialist Republic of Sri LankaDocument13 pagesY%S, XLD M Dka %SL Iudcjd Ckrcfha .Eiü M %H: The Gazette of The Democratic Socialist Republic of Sri LankaYoonus MaheesNo ratings yet

- A History of Islamic Societies PDFDocument47 pagesA History of Islamic Societies PDFSimone SidasowNo ratings yet

- HoyDocument6 pagesHoyPaul Arman MurilloNo ratings yet

- Joshua 1 2ndDocument5 pagesJoshua 1 2ndPatrick EdrosoloNo ratings yet

- Dattatray BhosaleDocument2 pagesDattatray Bhosalerajeshkanna1000No ratings yet

- Basic Uses of English TensesDocument5 pagesBasic Uses of English TensesAjal PNo ratings yet