Professional Documents

Culture Documents

Example Control Plan

Uploaded by

Rohmat SesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Control Plan

Uploaded by

Rohmat SesCopyright:

Available Formats

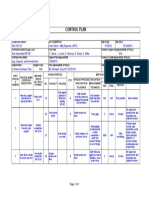

CONTROL PLAN

Control Plan Number

Key Contact/Phone

ABC101-23

John Stone - Mfg Engineer, x5412

Date (Orig.)

Part Number/Latest Change Level

Core Team

Sub-Assembly 987-00

C. Stone, J. Leard, D. Moores, G. Boyd, S. Miller

Part Name/Description

Supplier/Plant Approval/Date

12/9/2014

Other Approval/Date (If Req'd.)

N/A

PART/

PROCESS NAME/

PROCES

OPERATION

S

DESCRIPTION

NUMBER

MACHINE,

DEVICE

JIG, TOOLS

FOR MFG.

Place leg, support,

and armrest in

assembly fixture

Fixture 98701F1

CHARACTERISTICS

NO.

PRODUCT

Drive three screws

to secure arm rest

1D

Final screw

depth

Electric

screwdriver

987-01A1

Pneumatic

screwdriver

987-01A2

2D

PROCESS

Parts placed

properly in

fixture per

drawing

987-00

Screws

seated subflush

Drive torque

on screw

N/A

METHODS

CTQ?

2P

N/A

Other Approval/Date (If Req'd.)

Ed Stumpek, Eng VP (12/10/14)

2D

Drive two screws

to secure side

support

N/A

Customer Quality Approval/Date (If Req'd.)

Supplier/Plant

In-House (Kansas City)

12/10/2014

Customer Engineering Approval/Date (If Req'd.)

Leg, Support, and Armrest Asm

Supplier Code

Date (Rev.)

1/1/2012

PRODUCT/PROCESS EVALUATION/

SPECIFICATION/ MEASUREMENT

TOLERANCE

TECHNIQUE

Parts oriented

correctly (reference

drawing 987-00 with

any questions)

Screw heads subflush

Torque between 10

in-lb and 13 in-lb

Screw heads subflush

Page 1 of 1

Error proofed parts cannot be

mis-oriented

Flush gage

SAMPLE

SIZE

FREQ.

CONTROL

METHOD

N/A

N/A

Error proofed

Hourly

REACTION

PLAN

None required

P-Chart

Re-inspect all

product since last

inspection and

rework if needed

Automatically

monitored with

electric

screwdriver alarm will

sound if torque

is out of range

100%

N/A

100%

monitoring

If torque alarm

sounds, stop

production, verify

proper screws,

check pilot hole

diameter. If

correct, contact

maintenance and

engineering.

Slide flushness

gage over screw

locations - must

move freely

Hourly

P-Chart

Re-inspect all

product since last

inspection and

rework if needed

You might also like

- Control PlanDocument1 pageControl Plan786tip786No ratings yet

- Control PlanDocument1 pageControl PlanAmit PatelNo ratings yet

- Certificate of Compliance FM Approval Certificate of Compliance For Series 2000 Valve Actuators Mpa MCP m2cp Bettis en 86548Document3 pagesCertificate of Compliance FM Approval Certificate of Compliance For Series 2000 Valve Actuators Mpa MCP m2cp Bettis en 86548Ariaswanto AdiNo ratings yet

- Summary Report For Foundation Design: Calculation Sheet of FoundationDocument1 pageSummary Report For Foundation Design: Calculation Sheet of FoundationUlfa HafizdyaNo ratings yet

- Uncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial SystemsDocument4 pagesUncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial Systemsnetelsrt1298No ratings yet

- DC - Traction Motor 752RS1A-Final Test ReportDocument5 pagesDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNo ratings yet

- MONTHLY REPORT - Docx.odtDocument11 pagesMONTHLY REPORT - Docx.odtGeoffrey AyudNo ratings yet

- DN02 S09011 e XK 3176 01Document2 pagesDN02 S09011 e XK 3176 01ayemyothantNo ratings yet

- Stack WeldingDocument76 pagesStack WeldingKatie Ramirez100% (1)

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- Ppap For Neel MetalDocument40 pagesPpap For Neel MetalshuklahouseNo ratings yet

- SB-103 (Transmitter Receiver Computer)Document1 pageSB-103 (Transmitter Receiver Computer)Gerhard MNo ratings yet

- MD1 0 V 121 01 00001Document2 pagesMD1 0 V 121 01 00001tvpham123100% (1)

- Tugas Pemrogaman NC Job 7 ErvianDocument3 pagesTugas Pemrogaman NC Job 7 Erviananjay0336No ratings yet

- FIT UP of Taper Cone1, 2 & 3 With Flange 2Document1 pageFIT UP of Taper Cone1, 2 & 3 With Flange 2alokbdas100% (1)

- FF Pmi 031 2Document1 pageFF Pmi 031 2Sajan ThomasNo ratings yet

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- CMM 25-60-54 R12 3.jun.2011 Air Cruisers SlideDocument280 pagesCMM 25-60-54 R12 3.jun.2011 Air Cruisers SlideBenson GathiakaNo ratings yet

- Yz15177 2826KRB PDFDocument7 pagesYz15177 2826KRB PDFeduardo yauriNo ratings yet

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- PW1100 FWD Mount Shackle Assembly Removal - Installation Schedule Issue-01, Rev 00Document15 pagesPW1100 FWD Mount Shackle Assembly Removal - Installation Schedule Issue-01, Rev 00Pradeep K s100% (1)

- Post Tension Design of SlabDocument39 pagesPost Tension Design of SlabVikram Jain100% (1)

- Codeware, Inc.: Houston, TX, USADocument34 pagesCodeware, Inc.: Houston, TX, USAtuky10No ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- RECN 2081 Zed 1002 and Zed 10FX Manufacturing ChangesDocument2 pagesRECN 2081 Zed 1002 and Zed 10FX Manufacturing ChangesLalo JonerNo ratings yet

- Approved: Soumen Mitra Senior Mec Engineer 30-May-12Document2 pagesApproved: Soumen Mitra Senior Mec Engineer 30-May-12tvpham123No ratings yet

- Manifold CoplanarDocument5 pagesManifold CoplanarClaudio Salvador Vera AranedaNo ratings yet

- Motor Grader EtrDocument15 pagesMotor Grader EtrMuhammad IchwanNo ratings yet

- MD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationDocument9 pagesMD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationTran Khuynh100% (1)

- Welder Qualification TemplateDocument1 pageWelder Qualification TemplatewentropremNo ratings yet

- SJ-QE-02 Receiving Inspection ReportDocument2 pagesSJ-QE-02 Receiving Inspection ReportRajeshSekarNo ratings yet

- Ivar Aasen Field Development Project - PDQDocument3 pagesIvar Aasen Field Development Project - PDQayemyothantNo ratings yet

- S0123 - Revision M (May)Document36 pagesS0123 - Revision M (May)vinh nguyenNo ratings yet

- Assembly Report: 320 D 948 948 CV - Merdeka MandiriDocument13 pagesAssembly Report: 320 D 948 948 CV - Merdeka MandiriedykuswariNo ratings yet

- Solar Turbine Operation Manual 3Document16 pagesSolar Turbine Operation Manual 3Pong KrubNo ratings yet

- 3BHS814079E01 Wiring Diagram R4Document52 pages3BHS814079E01 Wiring Diagram R4Roy ChaiNo ratings yet

- Assembly Report: 320 D 948 948 CV - Merdeka MandiriDocument13 pagesAssembly Report: 320 D 948 948 CV - Merdeka MandiriedykuswariNo ratings yet

- E-6012 - DC Ad Adasd Ad Adqwe Adas DaDocument159 pagesE-6012 - DC Ad Adasd Ad Adqwe Adas DaPeja JusohNo ratings yet

- Mwo 9-2320-307-23-6-9Document20 pagesMwo 9-2320-307-23-6-9And GalvanNo ratings yet

- RSST 20Document10 pagesRSST 20Giuliano DeiasNo ratings yet

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- Conocophillips: Lnterdiscipline Check FormDocument3 pagesConocophillips: Lnterdiscipline Check FormJeffry KarundengNo ratings yet

- Planned Early Submitted: E1 MATERIAL LOG @14 Sep 14 / Div. 01 16Document4 pagesPlanned Early Submitted: E1 MATERIAL LOG @14 Sep 14 / Div. 01 16stefenjohnNo ratings yet

- J U N 1 6 1998 Engineering Data Transmittal 6 2 5 0 1 2: 5. Proj./Prog./Dept./Div.Document56 pagesJ U N 1 6 1998 Engineering Data Transmittal 6 2 5 0 1 2: 5. Proj./Prog./Dept./Div.winneriNo ratings yet

- PileDocument23 pagesPileSothea BornNo ratings yet

- Ge Proprietary InformationDocument3 pagesGe Proprietary Informationdavi de laraNo ratings yet

- 06 Me30 3075 00043Document78 pages06 Me30 3075 00043Santiago SalasNo ratings yet

- Technical Information Release Dnm-Tir 005 ACDocument1 pageTechnical Information Release Dnm-Tir 005 ACTeymur AliyevNo ratings yet

- Advice 250413Document1 pageAdvice 250413Amber JonesNo ratings yet

- Mustang: Wood GroupDocument2 pagesMustang: Wood GroupayemyothantNo ratings yet

- 7.5kw Airgap 36Document1 page7.5kw Airgap 36Kiran ChollangiNo ratings yet

- Air Reciever 538017Document20 pagesAir Reciever 538017ismailinesNo ratings yet

- Desain Pondasi Tanki 550 m3 Tahan GempaDocument37 pagesDesain Pondasi Tanki 550 m3 Tahan GempaYayan LesmanaNo ratings yet

- Prodelin 1132 Manual DatasheetDocument15 pagesProdelin 1132 Manual DatasheetJaime Araya ArosNo ratings yet

- Hamilton Sundstrand APU T-62T-40C14 ManualDocument548 pagesHamilton Sundstrand APU T-62T-40C14 ManualChris Choi57% (7)

- Create Klik Button - Macros1Document2 pagesCreate Klik Button - Macros1Rohmat SesNo ratings yet

- Pareto Chart Data - Third Level - Reasons For "Did Not Order"Document3 pagesPareto Chart Data - Third Level - Reasons For "Did Not Order"Rohmat SesNo ratings yet

- Gantt 1Document3 pagesGantt 1Rohmat SesNo ratings yet

- Example Control PlanDocument1 pageExample Control PlanRohmat SesNo ratings yet

- GRR Training SlidesDocument30 pagesGRR Training SlidesRohmat SesNo ratings yet

- Dpmo CalculatorDocument9 pagesDpmo Calculatorramani_balakrishNo ratings yet

- Material GradeDocument8 pagesMaterial GradeRohmat SesNo ratings yet

- If Your Eyes Follow The Movement of The Rotating Pink Dot, The Dots Will Remain Only One Color, PinkDocument1 pageIf Your Eyes Follow The Movement of The Rotating Pink Dot, The Dots Will Remain Only One Color, PinkRohmat SesNo ratings yet

- 10 Things Science Says Will Make You HappyDocument14 pages10 Things Science Says Will Make You HappyRohmat SesNo ratings yet

- V68 DataumumDocument2 pagesV68 DataumumRohmat SesNo ratings yet