Professional Documents

Culture Documents

A Simple Self-Acting Spark Erosion Machine

Uploaded by

Julio Alvarez SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Simple Self-Acting Spark Erosion Machine

Uploaded by

Julio Alvarez SCopyright:

Available Formats

A Simple Self-Acting Spark Erosion Machine

Introduction

This machine has been designed with the requirements of the Model Engineer in mind, requiring

minimum financial outlay, straightforward construction and little electrical knowledge.

Its main use is envisaged to be the removal of broken drills or taps, but it can also be used to create

holes of any shape in any conductive material, including hardened steels.

Its mode of operation differs from typical industrial machines and many previous designs based on

similar principles which have been published in model engineering magazines. As is normal in

industrial use, the work is submerged in a bath of paraffin so that the sparking between tool and work

takes place without the presence of air, so avoiding oxidation (burning). The paraffin also aids

dispersal of erosion debris. Fire risk appears to be minimal, but precautions should be taken such as

having a fire extinguisher available.

In operation the tool is connected to a capacitor charged to about 60 volts so that an arc discharge

occurs when it contacts the workpiece. The discharge and recharge currents pass through a solenoid

coil, which applies a lift force to the tool raising it from the workpiece and extinguishing the arc.

Whilst the current continues, recharging the capacitor, the lift force holds the tool plunger against an

upper stop until the current ceases when the discharge capacitor is fully recharged. The tool plunger

then falls under gravity until the tool contacts the workpiece again, and the cycle repeats.

Construction

Drawings of the prototype are attached. Most dimensions are not critical and can be changed to suit

materials and thread sizes that happen to be available. It is important to ensure that the tool plunger

slides freely in the bearing block, and that the armature does not contact the bore of the solenoid,

causing friction. The solenoid and tool assembly must be mounted so that it can be held at an

adjustable height above the work, whilst being electrically isolated from the work. The drawings

show this being achieved by interposing sheet plastic material between the tool/solenoid assembly

and its stand, and sleeving the securing screws with insulating material.

The drawings show an anti-rotation stop fitted to prevent rotation of the tool as it oscillates vertically.

This is unnecessary if it is only intended to make circular holes or remove taps, etc.

The electrical components are available from suppliers such as RS Components, and should not cost

more than about 25 total. The 7 ohm resistors should be capable of dissipating 10 watts, so are

likely to be wirewound types. Note that the discharge current from the discharge capacitor through

the tool/workpiece is quite large, so wire cross-section should be at least 4 sq. mm.in this part of the

circuit and terminals should be adequately sized. The cable to the tool must, of course, be flexible.

Operation

Tools are normally made from copper, but brass is also suitable. Hollow (tubular) tools are ideal as

they minimise the amount of metal to be removed. Set the height of the solenoid/tool assembly

initially so that the tool rests on the work with about 3 mm lift available before hitting the upper stop,

then switch on. Repetition rate should be about 20 per second. If deep drilling is needed it will be

necessary to lower the solenoid/tool periodically to maintain the lift height which affects the

repetition rate.

Derek Lynas 2008

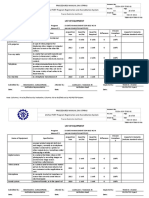

Spark Eroder Main Electrical Components

Item

1.

2.

3.

4.

5.

6.

7.

Description

Transformer, 50V, 50VA

Bridge rectifier, 200V, 1.7A

Reservoir capacitor, 2200 mfd

Discharge capacitor, 250 mfd

Series resistor, 6R8, 15W

Suppression diode, 100V, 1A

Switches and connectors

Quantity

1

1

1

1

1

1

RS Part No.

504-329

261-491

180-2122

839-044

160-433

348-5397

Approx. total cost

Price,

9.60

1.05

5.41

2.92

1.94

0.06

3.00

20.98

You might also like

- Welding-ARC WELDINGDocument6 pagesWelding-ARC WELDINGraghbirNo ratings yet

- TIG Welding in The Product Realization LabDocument12 pagesTIG Welding in The Product Realization LabFahmi HarisNo ratings yet

- Quasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General DescriptionDocument6 pagesQuasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General Descriptionapi-3864578No ratings yet

- Pinnacle - Welder - Super160manualDocument13 pagesPinnacle - Welder - Super160manualhdquanNo ratings yet

- Instruction Manual of EDM MachineDocument18 pagesInstruction Manual of EDM MachineJanak ValakiNo ratings yet

- Ispravljac Sa Regulacijom Napona-StrujeDocument9 pagesIspravljac Sa Regulacijom Napona-Strujezoran_stevNo ratings yet

- Job Knowledge 17Document4 pagesJob Knowledge 17Mehmet SoysalNo ratings yet

- Electrode Maintenance For Resistance Spot WeldingDocument3 pagesElectrode Maintenance For Resistance Spot Weldingottou812No ratings yet

- SmawDocument15 pagesSmawchella_pandianNo ratings yet

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCNo ratings yet

- The multilayer piezo actuators can reach full performance at very low operating voltage. The plate actuator NAC2023 is 15x15 mm and provides a free stroke of 3.1 μm and a blocking force of 9450 NDocument7 pagesThe multilayer piezo actuators can reach full performance at very low operating voltage. The plate actuator NAC2023 is 15x15 mm and provides a free stroke of 3.1 μm and a blocking force of 9450 NJisu RyuNo ratings yet

- Switches &MODsDocument14 pagesSwitches &MODsZack GroothouseNo ratings yet

- New Open Document TextDocument12 pagesNew Open Document TextOpris CosminNo ratings yet

- Mags Welding TheoryDocument56 pagesMags Welding Theoryscott2355No ratings yet

- DC Motor Hard Copy ReportDocument13 pagesDC Motor Hard Copy ReportShang Divina Ebrada100% (1)

- General DescriptionDocument8 pagesGeneral DescriptionRoberto ZenebreNo ratings yet

- Manual em Ingles e Bem Explicado Tig 200 AcdcDocument16 pagesManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliNo ratings yet

- How To Make A Simple Sinker EDM For Under $100Document9 pagesHow To Make A Simple Sinker EDM For Under $100ryanrenzeNo ratings yet

- Procedure For Making ProjectDocument24 pagesProcedure For Making ProjectAnkit BishtNo ratings yet

- Electro-Discharge Machining (EDM) - Industrial EngineeringDocument24 pagesElectro-Discharge Machining (EDM) - Industrial EngineeringshahadNo ratings yet

- Industrial Training: AcknowledgementDocument21 pagesIndustrial Training: AcknowledgementBharat Bhushan TiwariNo ratings yet

- Welding DictionaryDocument19 pagesWelding DictionarydrexNo ratings yet

- Light Switch: General DescriptionDocument4 pagesLight Switch: General DescriptionPranusha AdiviNo ratings yet

- Tcp50s60 Panasonic ServiceDocument55 pagesTcp50s60 Panasonic ServiceJim EzellNo ratings yet

- Panasonic BT-LH1710-1760 (E-MC) PDFDocument116 pagesPanasonic BT-LH1710-1760 (E-MC) PDFboroda2410100% (1)

- Miller Submerged Arc HandbookDocument32 pagesMiller Submerged Arc Handbookbjrhunter0% (1)

- Research Paper On Lightning ArresterDocument7 pagesResearch Paper On Lightning Arresterafmchxxyo100% (1)

- PTA WeldingDocument11 pagesPTA Weldingpavi32No ratings yet

- Mags Welding TheoryDocument57 pagesMags Welding TheoryScott TrainorNo ratings yet

- Arc Tig 135 Welder Rev 2Document28 pagesArc Tig 135 Welder Rev 2mike jonesNo ratings yet

- Smaw Module LHT-8 and 9Document7 pagesSmaw Module LHT-8 and 9Felix MilanNo ratings yet

- 3343 FT0 Arc Starter Original Complete W-Rev2 in PDFDocument3 pages3343 FT0 Arc Starter Original Complete W-Rev2 in PDFNacer MezghicheNo ratings yet

- Ac DC 206i ManualDocument4 pagesAc DC 206i Manualstef1463No ratings yet

- Zenith 32-37-42lc2da Chassis La63e SMDocument113 pagesZenith 32-37-42lc2da Chassis La63e SMraver1213No ratings yet

- Under Water WeldingDocument7 pagesUnder Water WeldingMishal SalemNo ratings yet

- InverterDocument13 pagesInverterBrinzeiMarianNo ratings yet

- Disconnectors DesignDocument14 pagesDisconnectors DesignTravis WoodNo ratings yet

- Intro TIG WeldingDocument8 pagesIntro TIG WeldingnikhilconNo ratings yet

- User'S Manual: MODEL: MMA160/200Document9 pagesUser'S Manual: MODEL: MMA160/200Vlaovic GoranNo ratings yet

- Technical Update Methods For Removal of Welds and Opening of Cracks PDFDocument12 pagesTechnical Update Methods For Removal of Welds and Opening of Cracks PDFBogdan PopescuNo ratings yet

- Panasonic Tc-p55vt50 Chassis Gpf15duDocument108 pagesPanasonic Tc-p55vt50 Chassis Gpf15duOK100% (1)

- Job Knowledge 16Document4 pagesJob Knowledge 16Mehmet SoysalNo ratings yet

- DMC-LS80P Dmc-Ls80Pc Dmc-Ls80Pl DMC-LS80E Dmc-Ls80Eb Dmc-Ls80Ee Dmc-Ls80Ef Dmc-Ls80Eg Dmc-Ls80Gc Dmc-Ls80Gk Dmc-Ls80GnDocument41 pagesDMC-LS80P Dmc-Ls80Pc Dmc-Ls80Pl DMC-LS80E Dmc-Ls80Eb Dmc-Ls80Ee Dmc-Ls80Ef Dmc-Ls80Eg Dmc-Ls80Gc Dmc-Ls80Gk Dmc-Ls80GnRonal Gutierrez100% (1)

- Eml 30Document13 pagesEml 30deborah8888100% (1)

- 100W Audio Amplifier: General DescriptionDocument6 pages100W Audio Amplifier: General DescriptionJhody FajriNo ratings yet

- Presentation On Wire EdmDocument33 pagesPresentation On Wire EdmArpit HalaniNo ratings yet

- Welder ArcDocument6 pagesWelder ArcIgnatious ChinjodziNo ratings yet

- SSG Chapter OneDocument7 pagesSSG Chapter Onekalu chimdiNo ratings yet

- Safety and Accident Prevention: Electrical HazardsDocument17 pagesSafety and Accident Prevention: Electrical HazardsMohd Idris MohiuddinNo ratings yet

- 100W Audio AmplifierDocument8 pages100W Audio Amplifierernesto ruben pazNo ratings yet

- Die Sinking ReportDocument11 pagesDie Sinking Report15 thnNo ratings yet

- Introducton 1.1 Overview:: Power Transformer Protection Using Microcontroller-Based RelayDocument51 pagesIntroducton 1.1 Overview:: Power Transformer Protection Using Microcontroller-Based RelayManoj NagarajanNo ratings yet

- Quasar Kit No. 1138 0-30 VDC Stabilized Power Supply With Current CONTROL 0.002-3 ADocument7 pagesQuasar Kit No. 1138 0-30 VDC Stabilized Power Supply With Current CONTROL 0.002-3 AIordan Dan FfnNo ratings yet

- Camera Ready Manuscript1Document11 pagesCamera Ready Manuscript1satelite54No ratings yet

- LG 32lg3000 Chassis Ld84a LCD TV SMDocument26 pagesLG 32lg3000 Chassis Ld84a LCD TV SMEmma FrostNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Quickdev16 & Super Nintendo: David Voswinkel Matthias Nagler Matt@dforce3000.deDocument181 pagesQuickdev16 & Super Nintendo: David Voswinkel Matthias Nagler Matt@dforce3000.deoptixxNo ratings yet

- J4 Diagrama ElectricoDocument148 pagesJ4 Diagrama ElectricoJuan Rafael Vilchez SanchezNo ratings yet

- Sony SLV Se100 Se200 Se250 Se300 SexxxDocument81 pagesSony SLV Se100 Se200 Se250 Se300 Sexxxvideoson100% (2)

- Bus Fms Document Ver 00 02 20101110Document36 pagesBus Fms Document Ver 00 02 20101110aNo ratings yet

- 144 Layout 430-450W 20.4%: Monocrystalline ModuleDocument2 pages144 Layout 430-450W 20.4%: Monocrystalline ModuleluverygNo ratings yet

- Canon MP 160Document13 pagesCanon MP 160Derla Corina0% (1)

- NUVE EN 032-055-120 Incubators BrochureDocument2 pagesNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongNo ratings yet

- DPC18 Display ManualDocument12 pagesDPC18 Display ManualscribdribNo ratings yet

- Chronos Richardson Paletiser MaintenaceDocument47 pagesChronos Richardson Paletiser Maintenacenmarkov80No ratings yet

- TORO Reelmaster 3100-DDocument306 pagesTORO Reelmaster 3100-Ddalidelia100% (1)

- Tucson 2022 CatalogDocument8 pagesTucson 2022 CatalogHyundai CambodiaNo ratings yet

- Abbreviationsusedin AMMDocument36 pagesAbbreviationsusedin AMMShailesh KadamNo ratings yet

- RFQ For Maxon Oven Pak ItemsDocument2 pagesRFQ For Maxon Oven Pak ItemsvadivelankgNo ratings yet

- CDA3000Document2 pagesCDA3000Edilson AmilNo ratings yet

- Current-Source DC-DC ConverterDocument53 pagesCurrent-Source DC-DC ConverterpepenitoNo ratings yet

- List of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemDocument3 pagesList of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemRichardNo ratings yet

- Catalogue of Insulator and Surge Arrester - Orient ChinaDocument66 pagesCatalogue of Insulator and Surge Arrester - Orient Chinapham thang0% (1)

- A Project Report SSP 1Document22 pagesA Project Report SSP 120-301 AKSHAYNo ratings yet

- DH61CR ProductGuide03 EnglishDocument78 pagesDH61CR ProductGuide03 EnglishCarlos Miguel RamirezNo ratings yet

- ZXM8 TPLDD120 600Document2 pagesZXM8 TPLDD120 600SOLUCIONES ENERGETICAS Y PROCESOS INNOVADORESNo ratings yet

- Yamaha dgx-620 Ypg-625Document62 pagesYamaha dgx-620 Ypg-625counterexample100% (1)

- Stepper MotorDocument16 pagesStepper MotoranaNo ratings yet

- Datasheet Cable Plug Play AutomotiveDocument19 pagesDatasheet Cable Plug Play AutomotiveFatin Saffanah DidinNo ratings yet

- Servo Info and CenteringDocument5 pagesServo Info and Centeringspy004No ratings yet

- Fma2700 2800 3700 3800Document2 pagesFma2700 2800 3700 3800Yuda SatriaNo ratings yet

- Ship Particular TB STA 1 - 3000 HPDocument1 pageShip Particular TB STA 1 - 3000 HPMichael GunawanNo ratings yet

- Datasheet tl494Document6 pagesDatasheet tl494london335No ratings yet

- KCCEC List of EquipmentDocument45 pagesKCCEC List of Equipmentahmedsaber2007No ratings yet

- Smart TextilesDocument2 pagesSmart TextilesheroNo ratings yet

- Short Form Catalogue 2007: Deki Electronics LTDDocument8 pagesShort Form Catalogue 2007: Deki Electronics LTDoscar100% (1)